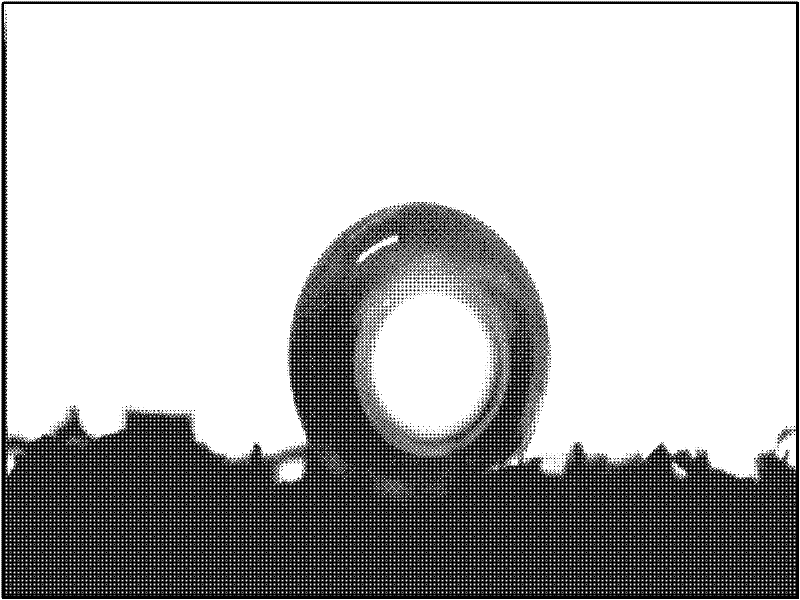

Preparation method and application of super-hydrophobic/super-lipophilic material in oil-water separation field

A super-oleophilic and super-hydrophobic technology, applied in the direction of liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of low efficiency and high cost of adsorbing organic matter, and achieve the goal of increasing energy utilization rate, small specific gravity and improving ecological environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

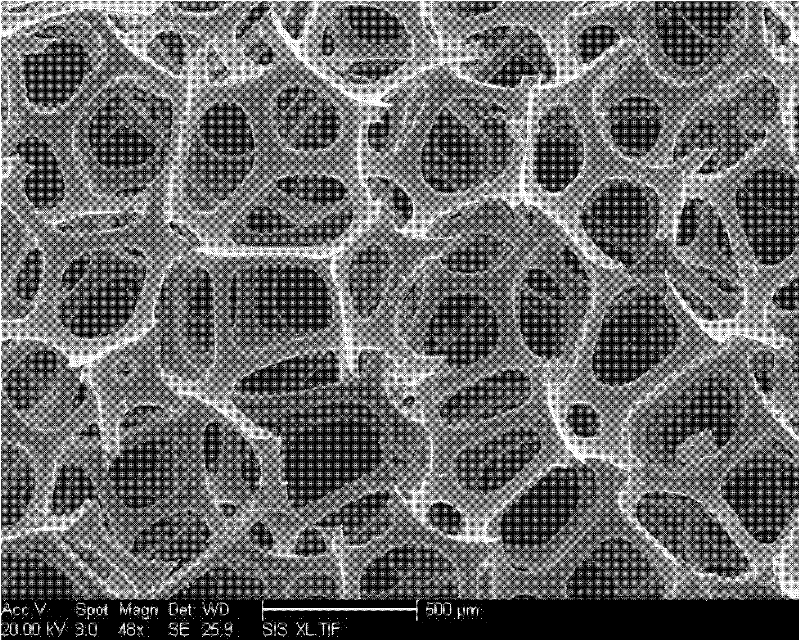

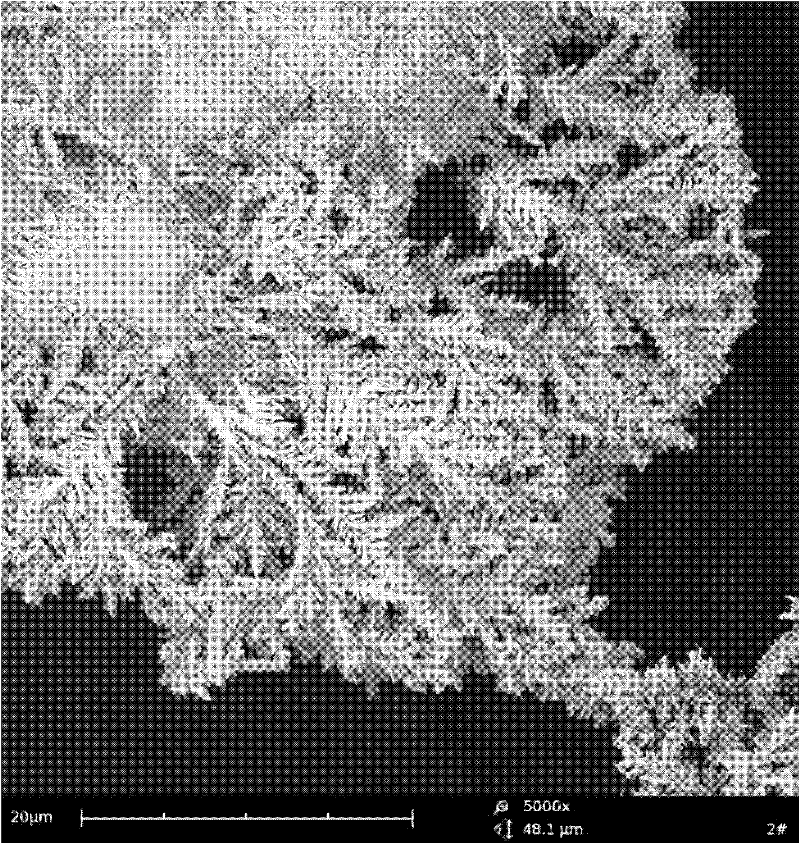

specific Embodiment approach 1

[0009] Specific embodiment one: the preparation method of a kind of superhydrophobic / super lipophilic material of the present embodiment is carried out according to the following steps: one, according to CrO 3 The concentration of sulfuric acid with a concentration of 50g / L~150g / L and a mass percent concentration of 98% is 50g / L~150g / L. Weigh CrO 3 And the sulfuric acid that mass percent concentration is 98% and joins in water, mixes evenly, obtains coarse liquid; Two, press SnCl 2 The concentration of hydrochloric acid with a concentration of 20g / L~60g / L and a mass percent concentration of 37% is 1mL / L~100mL / L. Weigh SnCl 2 And mass percent concentration is 37% hydrochloric acid and joins in water, mixes evenly, obtains sensitization liquid; Three, press AgNO 3 The concentration of ammonia water with a concentration of 5g / L~15g / L and a mass percent concentration of 25% is 5mL / L~20mL / L. Weigh the AgNO 3 Add ammonia water with a mass percentage concentration of 25% into water...

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment is different from Embodiment 1 in that: in step 4, the matrix is polyurethane sponge, silk, wood, rubber, cotton, hemp or paper fiber. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 5, the method of copper plating on the surface of the substrate is electroless copper plating or electroplating copper, and the method of galvanizing the surface of the substrate is electrogalvanization. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com