Microfluid heat radiation channel, heat radiation method and preparation method thereof

A technology of heat dissipation channels and microfluidics, which is applied in the fields of electric solid state devices, semiconductor devices, semiconductor/solid state device components, etc. low difficulty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

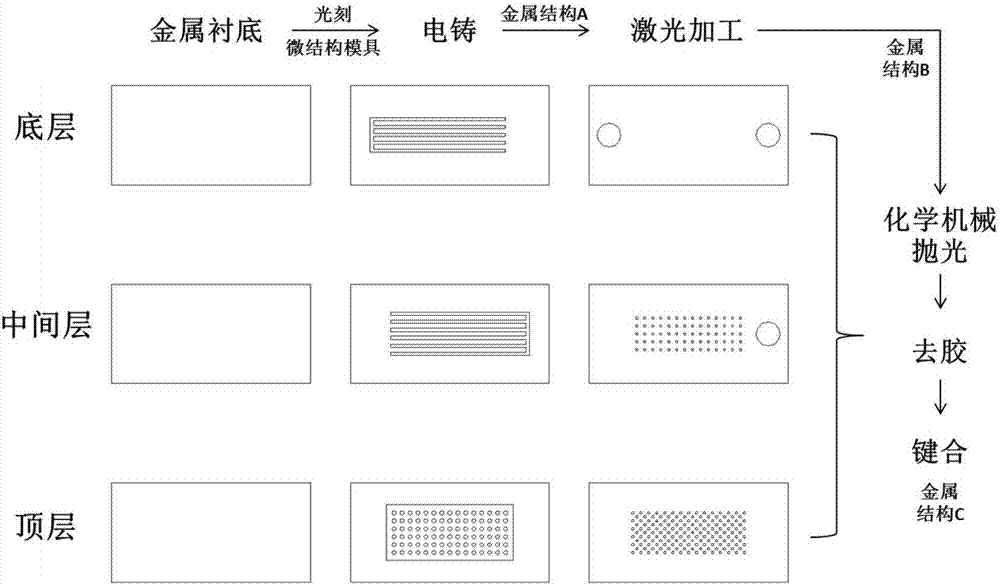

[0050] Step 1: Provide a metal substrate with a surface roughness RMS less than 10 nm.

[0051] Preferably, the metal is copper.

[0052] Preferably, the number of the metal substrates is three, namely the top metal substrate, the middle metal substrate and the bottom metal substrate.

[0053] Step 2: using photoresist or photosensitive dry film on the surface of the three-layer metal substrate to prepare a microstructure mold.

[0054] Step 3: Transfer the structure into a metal structure A (as shown in FIG. 4( a )) through an electroforming process.

[0055] Preferably, the electroforming process is a copper electroforming process.

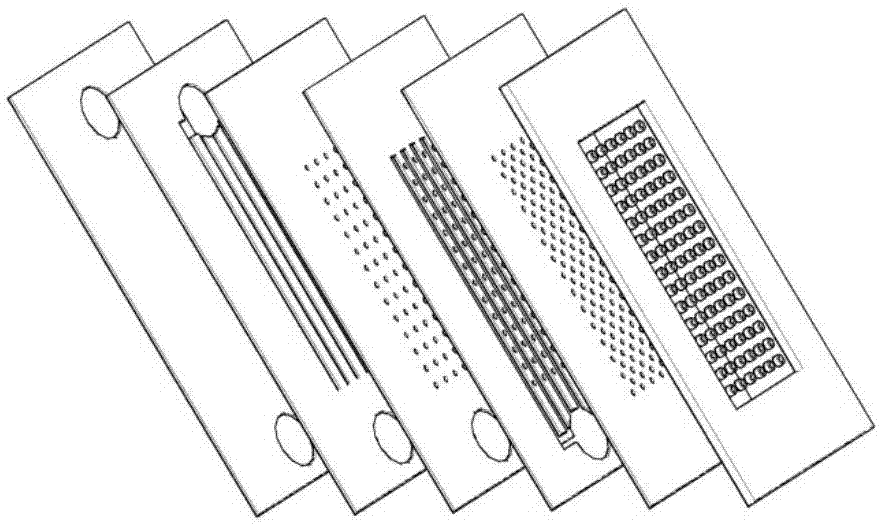

[0056] Preferably, the metal structure A is a three-layer structure, which are:

[0057] (a) a straight-through reflow channel on the surface of the underlying substrate;

[0058] (b) a straight-through liquid inlet channel on the surface of the intermediate layer substrate;

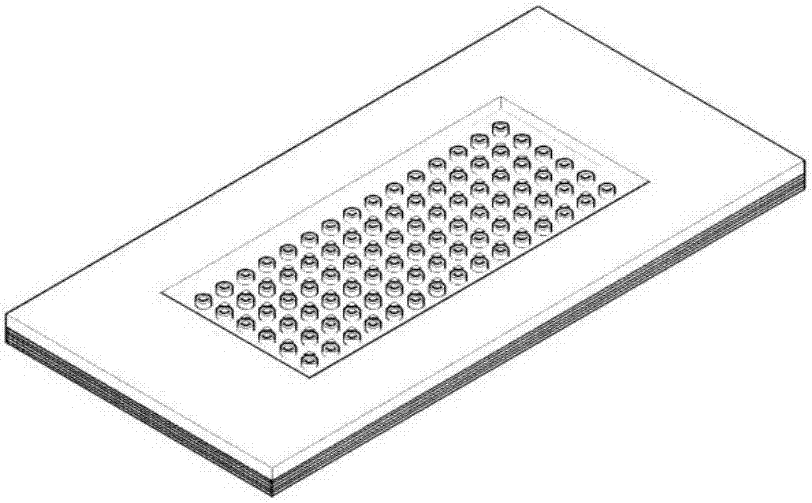

[0059] (c) Cylindrical bosses on the top substrate surface.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com