A kind of multi-junction tandem solar cell and its manufacturing method

A solar cell and manufacturing method technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low quality of battery materials, affect efficiency, lattice mismatch, etc., to solve lattice mismatch and improve utilization efficiency. , the effect of improving battery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The manufacturing method of the multi-junction laminated solar cell provided in this embodiment includes the following steps:

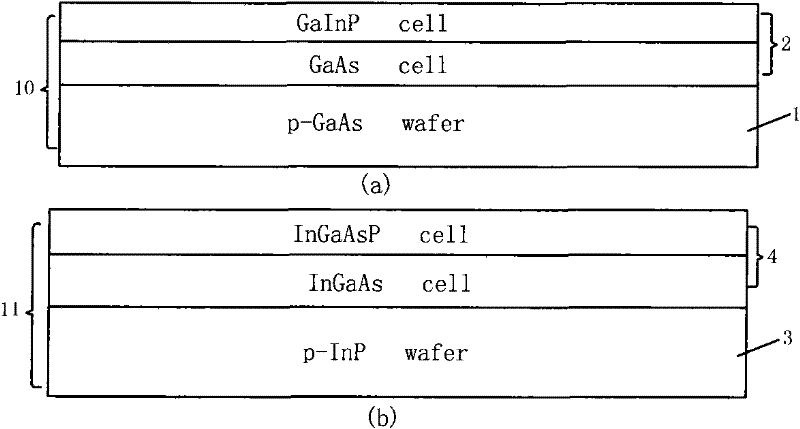

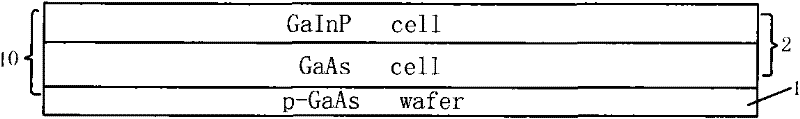

[0046] 1. Use molecular beam epitaxy (MBE) or metal organic chemical vapor deposition (MOCVD) methods to sequentially grow GaAs and GaInP epitaxial layers 2 on p-GaAs substrate 1 to obtain upper battery cell 10, see figure 1 (a); InGaAs, InGaAsP epitaxial layer 4 is grown sequentially on p-InP substrate 3 to obtain bottom battery cell 11, see figure 1 (b). The above two battery cells are double junction battery cells, and the lattice of each battery cell is completely matched.

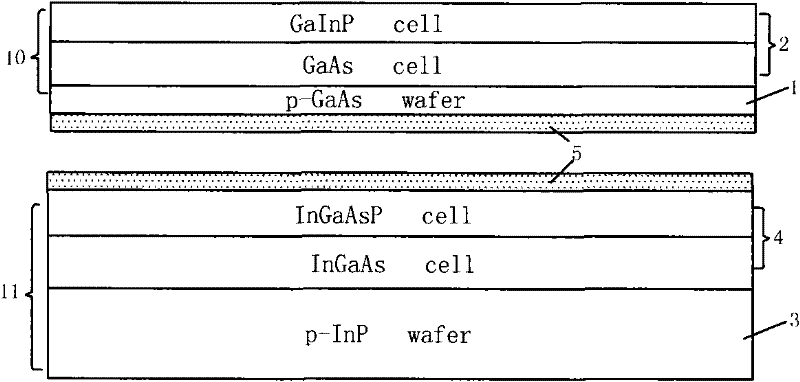

[0047] 2. Use chemical mechanical polishing (CMP) method to thin and polish the substrate 1 in the upper battery cell 10 to below 150μm, see figure 2 , In order to reduce the part of incident light that is absorbed in the transmission process.

[0048] 3. A metal thin film layer 5 is vapor-deposited on the back of the substrate 1 of the upper battery cell 10 and on the top of...

Embodiment 2

[0053] The manufacturing method of the multi-junction laminated solar cell provided in this embodiment includes the following steps:

[0054] 1. Use molecular beam epitaxy (MBE) or metal organic chemical vapor deposition (MOCVD) method to grow GaAs, GaInP epitaxial layer 2 on p-GaAs substrate 1 in order to obtain upper battery cell 10, see figure 1 (a); InGaAs, InGaAsP epitaxial layer 4 is sequentially grown on p-InP substrate 2 to obtain bottom battery cell 11, see figure 1 (b). The above two battery cells are both double-junction battery cells, and the lattice of each battery cell is completely matched.

[0055] 2. Use chemical mechanical polishing (CMP) method to thin and polish the substrate 1 in the upper battery cell 10 to below 150μm, see figure 2 In order to reduce the part of the incident light that is absorbed in the transmission process.

[0056] 3. A layer of antireflection and antireflection film 6 is vapor-deposited on the back of the substrate 1 of the upper battery c...

Embodiment 3

[0061] The manufacturing method of the multi-junction laminated solar cell provided in this embodiment includes the following steps:

[0062] 1. Use molecular beam epitaxy (MBE) or metal organic chemical vapor deposition (MOCVD) methods to sequentially grow InGaAs and InGaAsP epitaxial layers 4 on p-InP substrate 3 to obtain bottom cell 11, see Picture 9 (b).

[0063] On the p-GaAs substrate 1, molecular beam epitaxy (MBE) or metal organic chemical vapor deposition (MOCVD) is used to grow a layer of corrosion barrier layer 9 with a thickness of 50-1000 nm. The material of the corrosion barrier layer 9 is AlGaAs, and then using the same method to grow GaInP and GaAs materials on the corrosion barrier layer 9 to form the epitaxial layer 2 to obtain the upper battery cell 10, see Picture 9 (a). It is worth noting that the material layers of this upper battery cell 10 from bottom to top are p-GaAs, AlGaAs, GaInP, and GaAs respectively. Compared with the epitaxial layer 2 of the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com