Coarsened-sidewall AlGaInP-base LED and manufacture method thereof

A roughening, n-type technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low light-emitting efficiency of AlGaInP-based LEDs, and achieve the effect of improving electro-optical conversion efficiency, reducing heat generation, and facilitating production and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

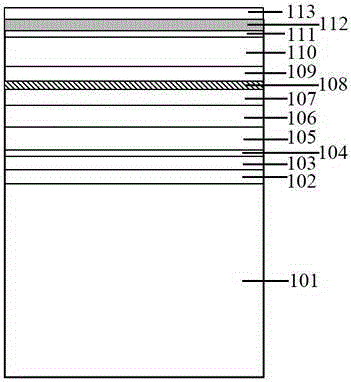

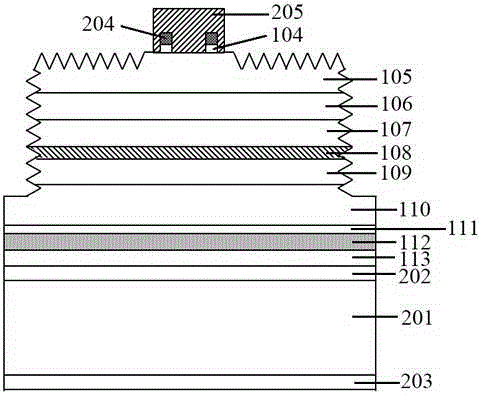

[0033] One, such as figure 1 and 2 Shown is the structural representation of the preferred example of the present invention in the manufacturing process, and the manufacturing steps are as follows:

[0034] 1. If figure 1 As shown, an epitaxial layer is grown on a GaAs temporary substrate 101 by MOCVD equipment, and the epitaxial layer includes a buffer layer 102, a GaInP cut-off layer 103, an n-GaAs ohmic contact layer 104, an n-AlGaInP roughening layer 105, and an n-AlGaInP current spreading layer. layer 106 , n-AlGaInP confinement layer 107 , MQW multiple quantum well active layer 108 , p-AlGaInP confinement layer 109 , p-GaP window layer 110 .

[0035] Wherein the n-GaAs ohmic contact layer 104 preferably has a thickness of 20nm to 100nm, and a doping concentration of 1×10 19 cm -3 Above, the doping element is Si, so as to form a good ohmic contact with the n-type extended electrode 204 . The preferred thickness of the p-GaP window layer 110 is 600nm to 8000nm, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com