Manufacturing method of single intermetallic compound micro-interconnecting structure of flip chip

A flip-chip, interconnect structure technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as failure, electronic products can not work, fracture, etc., to achieve improved creep resistance, excellent stability, The effect of improving reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific Embodiment 1: The method for preparing a flip-chip single intermetallic compound micro-interconnection structure in this embodiment is realized by the following steps:

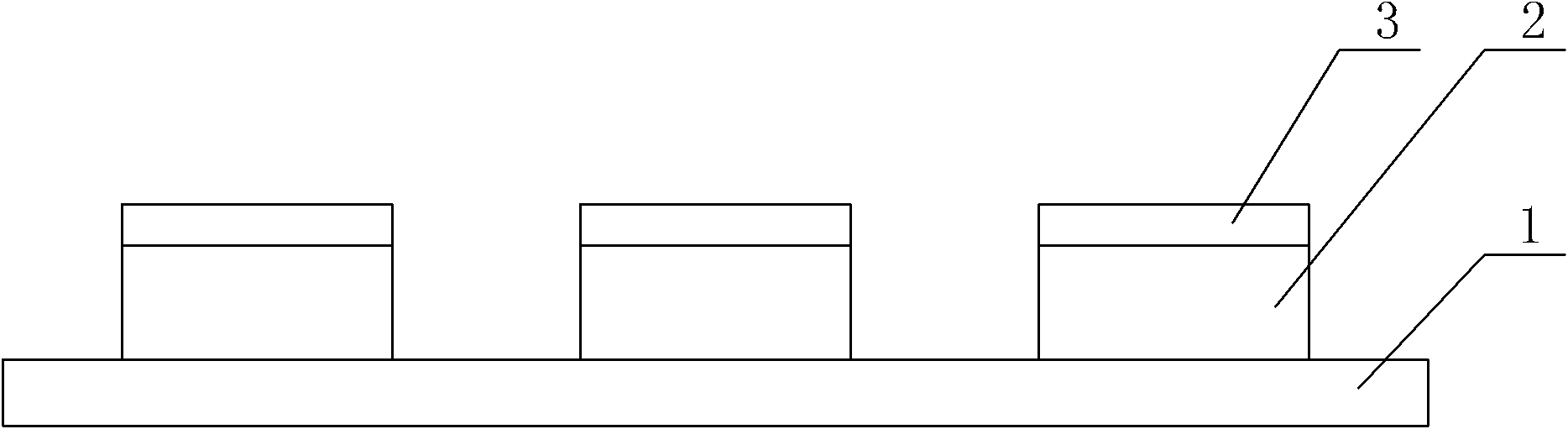

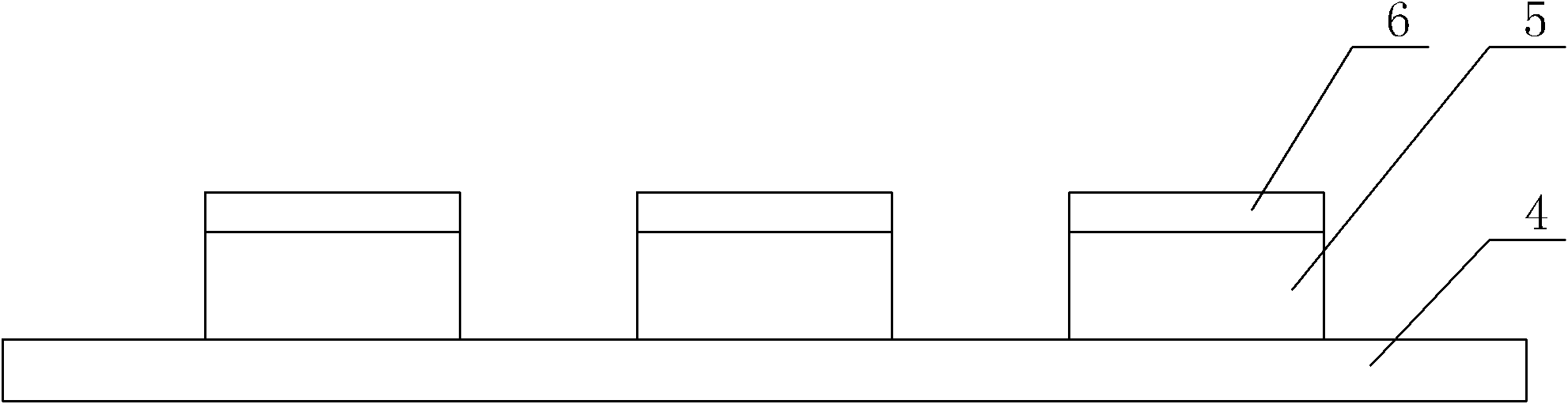

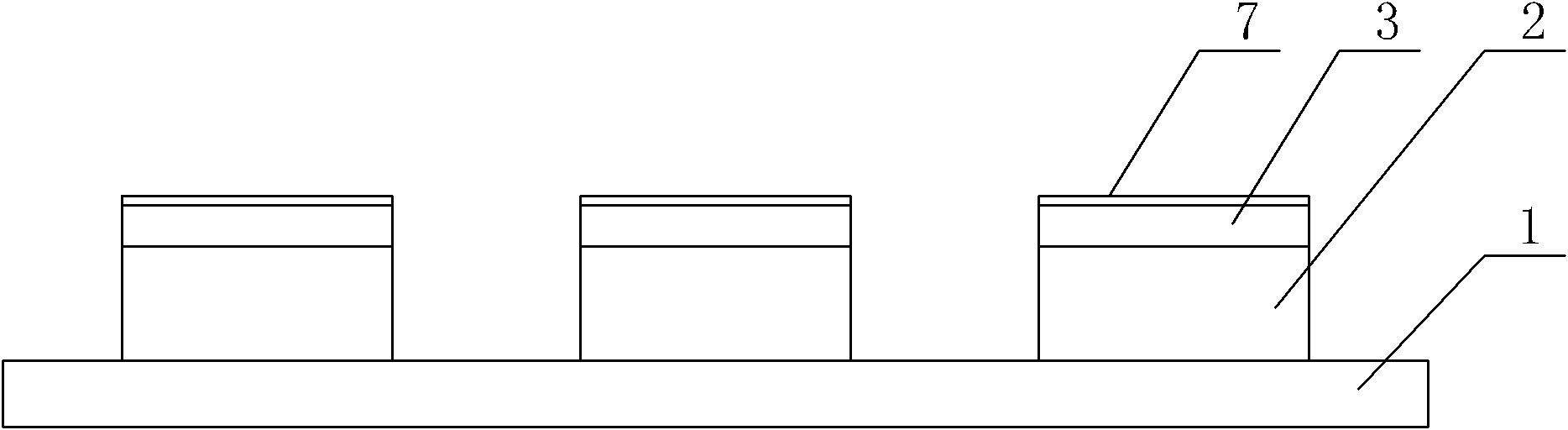

[0020] Step 1: prepare a chip metal base layer 2 on each metal surface on the chip 1, prepare a chip metal surface layer 3 on the horizontal plane of the chip metal base layer 2, and the chip metal base layer 2 is defined as a chip metal pad (see Figure 1a ); prepare substrate metal base layer 5 on each metal surface on substrate 4, prepare substrate metal surface layer 6 on the horizontal plane of described substrate metal base layer 5, and described substrate metal base layer 5 is defined as substrate metal pad (referring to Figure 1b ); the material of the chip metal pad and the material of the substrate metal pad are Cu, Au, Pd, Ag, Ni or Pt, and the material of the chip metal pad is the same as that of the substrate metal pad, and the chip The metal surface layer 3 and the substrate metal...

specific Embodiment approach 2

[0025] Embodiment 2: In step 1 of this embodiment, the metal pads of the chip and the metal pads of the substrate are in the shape of a cylinder or a cube, and the diameter of the metal pad of the chip in the shape of the cylinder is the same as the metal pad of the substrate in the shape of the cylinder. The diameters of the bonding pads are both 20-1000 μm; the side lengths of the cube-shaped chip metal pads and the side lengths of the cube-shaped chip metal pads are both 20-1000 μm. It can meet the requirements of different solder joint sizes in electronic packaging. Other method steps are the same as those in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: In step 1 of this embodiment, the ratio of the thickness of the metal pad of the substrate to the thickness of the metal surface layer of the substrate ranges from 5:1 to 10:1. In order to generate single intermetallic compound solder joints. Other method steps are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com