Method of preparing polymeric adhesive compositions utilizing the mechanism of interaction between the polymer components

a polymer and composition technology, applied in the field of polymer compositions, can solve the problems of limited absorption of these materials, wound injury upon removal, and use of adhesives, and achieve the effects of minimizing damage to gums or mucous membranes in the mouth, minimizing leakage of active agents, and facilitating handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation and Properties of Adhesive Compositions Based on the Combination of the Ladder-Like and Carcass-Like Types of Crosslinking of the Film-Forming Polymer

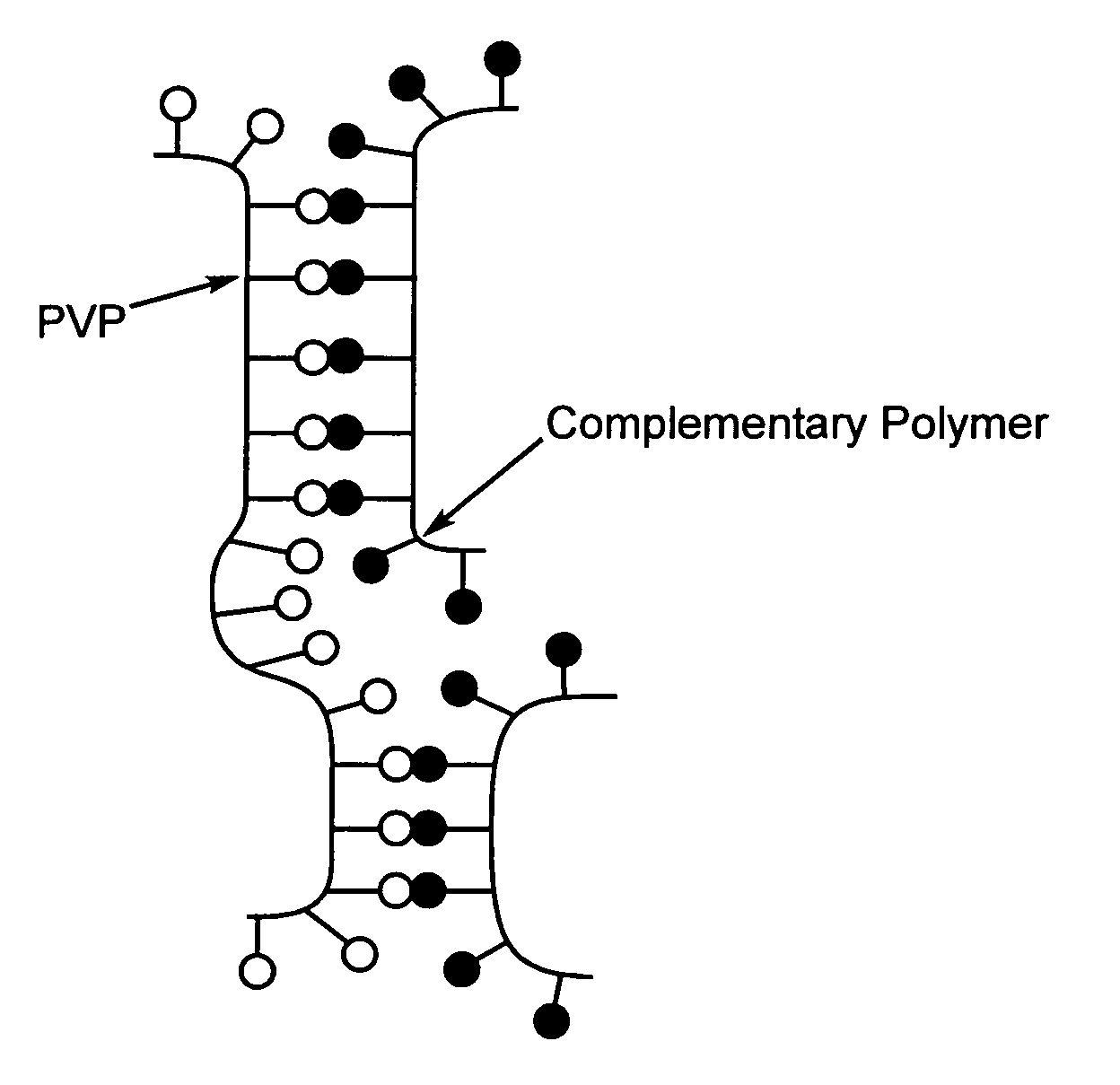

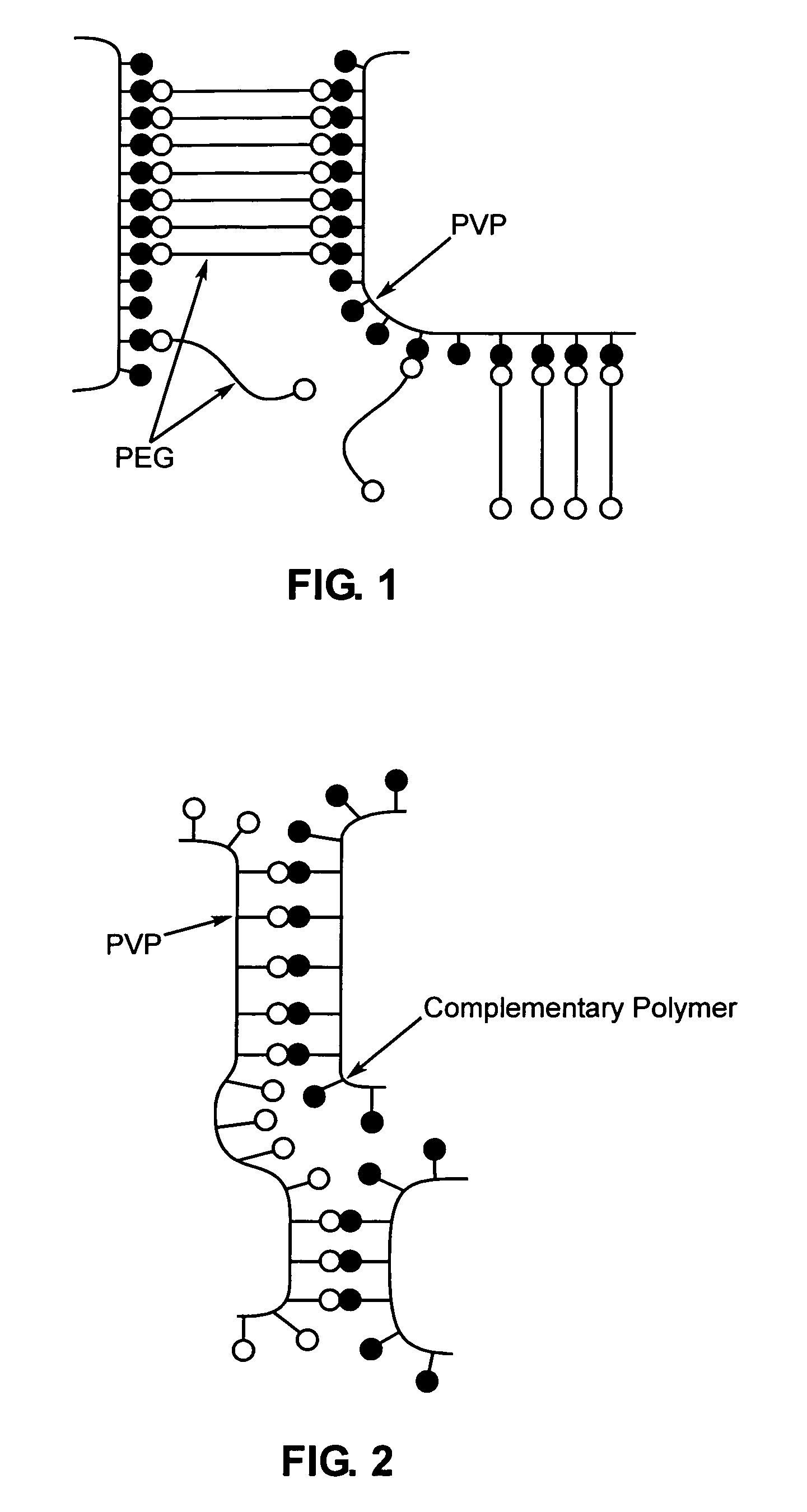

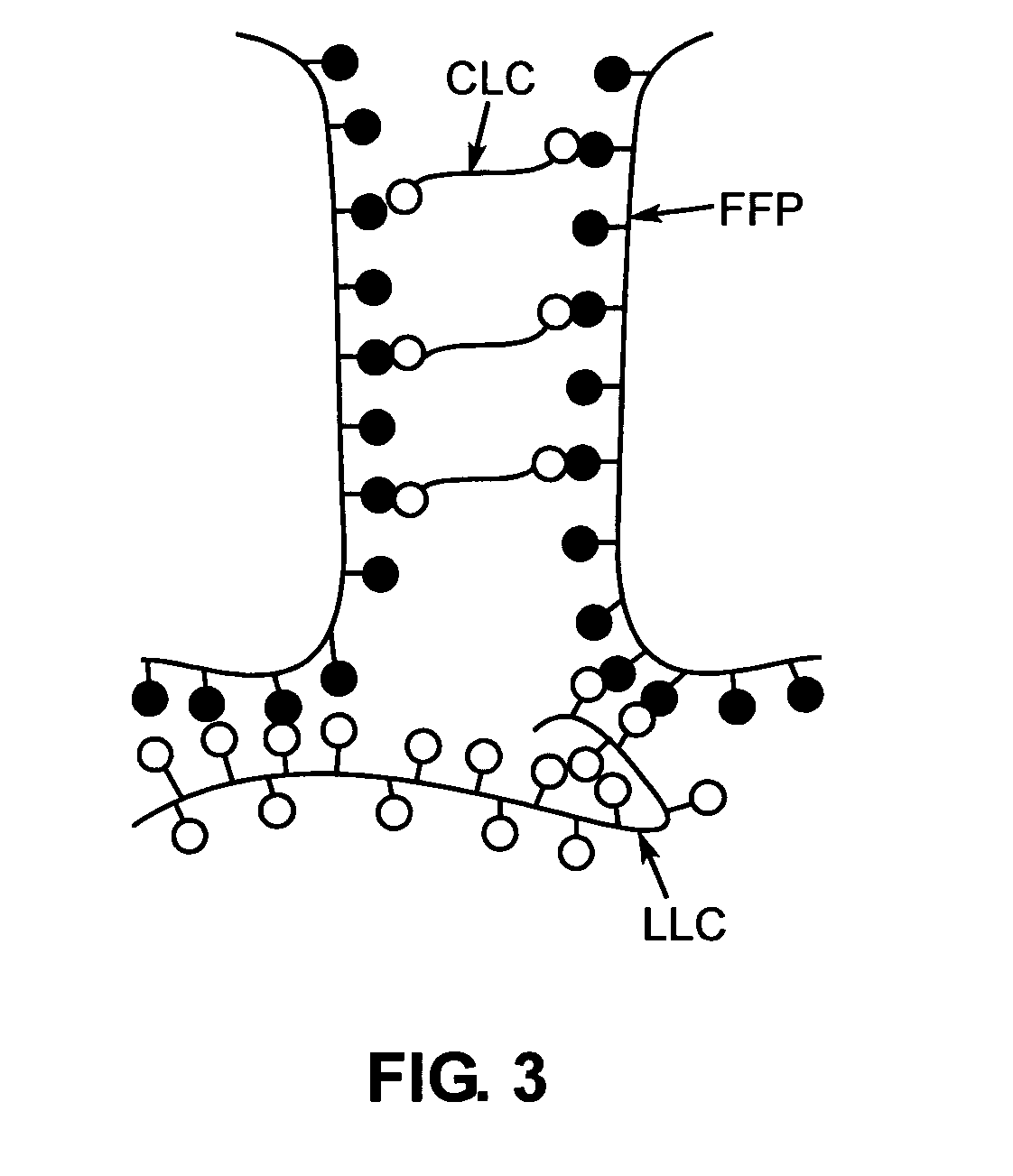

[0175] First, PVP 90 is selected as the film-forming polymer. In this case, examples of complementary polymers that are able to crosslink the PVP non-covalently by the formation of a water-insoluble ladder-like interpolymeric complex with PVP are: homopolymers or copolymers of polyacrylic acid (PAA), polymethacrylic acid (PMA), homopolymers or copolymers of maleic acid, homopolymers or copolymers of polyvinyl alcohol (PVA), homopolymers or copolymers of polyvinyl phenol, alginic acid and hydroxypropyl cellulose (HPC). One such non-covalent crosslinker of PVP is a copolymer of methacrylic acid and ethyl acrylate (1:1), commercially available from Röhm Pharma Polymers as Eudragit L 100-55. Blending the Eudragit L 100-55 with an adhesive PVP 90-PEG 400 mixture, results in the formation of an insoluble, homogeneous single-phas...

example 2

Adhesive Properties of Hydrogels in Swollen State

[0181] This example demonstrates the adhesive properties of the PVP-PEG-Eudragit L 100-55 blend as function of hydration degree. Preparation of films: 30 g of PEG 400 was dissolved in 280 g of ethanol. Under vigorous stirring, 12 g of Eudragit L 100-55 powder was added. Under vigorous stirring, 58 g of PVP 90 powder was added. The mixture was stirred over 2 hours to obtain a homogeneous solution. The solution was stored over 5 hours to let air bubbles dissipate. Polymer films were prepared by solution casting onto a PET backing, followed by drying at ambient temperature over 1 day. The films then were dried in an oven at 110° C. overnight. Films of a size of 0.20±0.04 mm were obtained. The PVP-PEG-Eudragit L 100-55 films of different hydration degree were prepared by spraying controlled amounts of distilled water over film surfaces. The films then were covered with a PET release liner, sealed in aluminum pouches and stored over 7 day...

example 3

Effect of Composition of Methacrylic Acid Copolymers on Performance Properties of their Blends with a PVP-PEG Adhesive

[0183] In the following example PVP 90 was chosen as the film-forming polymer, whereas copolymers of methylmethacrylate and methacrylic acid (Eudragit L 100 and Eudragit S 100) served as the ladder-like crosslinkers. PEG 400 was used as the carcass-like crosslinker. Films were prepared and tested.

[0184] Eudragit L 100 differs from Eudragit L 100-55 by the composition of hydrophobic monomer, while the content of monomer units of methacrylic acid is the same (50%). In Eudragit L 100-55 the hydrophobic monomer units are represented by ethyl acrylate, while Eudragit L 100 is a copolymer of methacrylic acid with methyl methacrylate. In turn, Eudragit S 100 is distinguished from Eudragit L 100 by the decreased content of the units of methacrylic acid (33% instead of 50%), whereas methyl methacrylate is hydrophobic monomer in both copolymers.

[0185] Preparation of films: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com