Unlimited-layer electrically controlled fracturing sliding sleeve

A technology of fracturing sliding sleeves and electric control, which is applied in wellbore/well components, construction, production fluids, etc. It can solve the problems of complex devices, low operating efficiency, and limited number of fracturing stages, and achieves simple structure and convenient use , Improve the effect of fracturing and operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

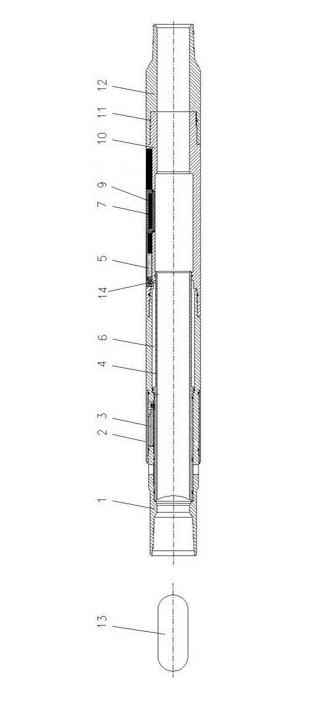

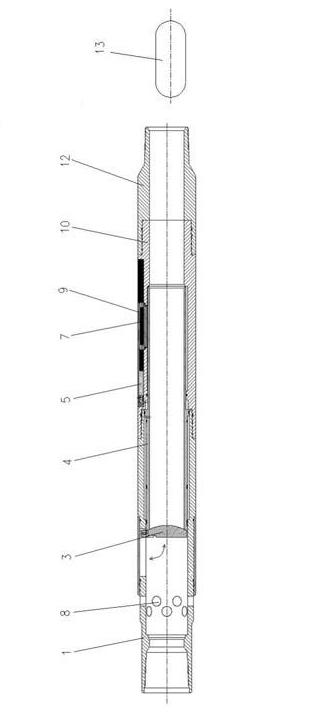

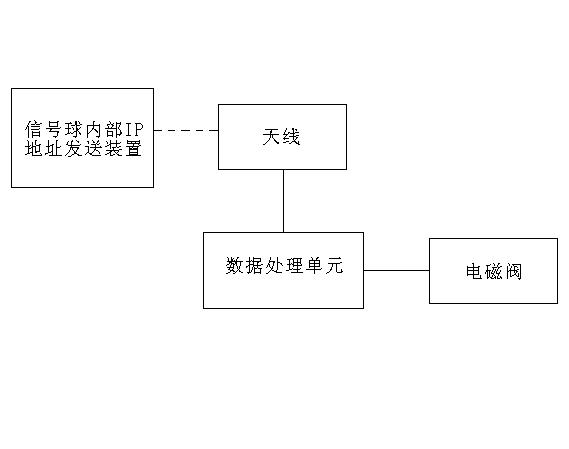

[0015] Such as figure 1 , 2 , 3, this embodiment provides an unlimited-layer electronically controlled fracturing sleeve, including an outer cylinder sleeve, an inner sleeve 4 and a signal ball 13, and the outer cylinder sleeve is composed of an upper joint 1, a middle joint 10, a lower The three parts of the joint 12 are sequentially socketed. The upper joint 10 is provided with a flow channel hole 8 for fracturing. The signal ball 13 is provided with a signal sending device for sending a specific IP address. The upper joint 10 There is a sealing chamber 6 between the inner sliding sleeve 4, and the chamber is pre-installed with hydraulic oil. The sealing chamber 6 is provided with a pressure relief hole 14, and the middle joint 10 is provided with a valve for controlling the opening of the pressure relief hole 14. The closed solenoid valve 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com