Joint structure for portable work and storage container

a joint structure and portable work technology, applied in the field of portable work and storage containers, can solve the problems of affecting the overall structure affecting the stability of the frame structure, and requiring a lot of space for storage or transportation of storage containers, so as to improve the rigid structure of the portable work and facilitate the disassembly and transportation. , the effect of improving the rigidity of the portable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

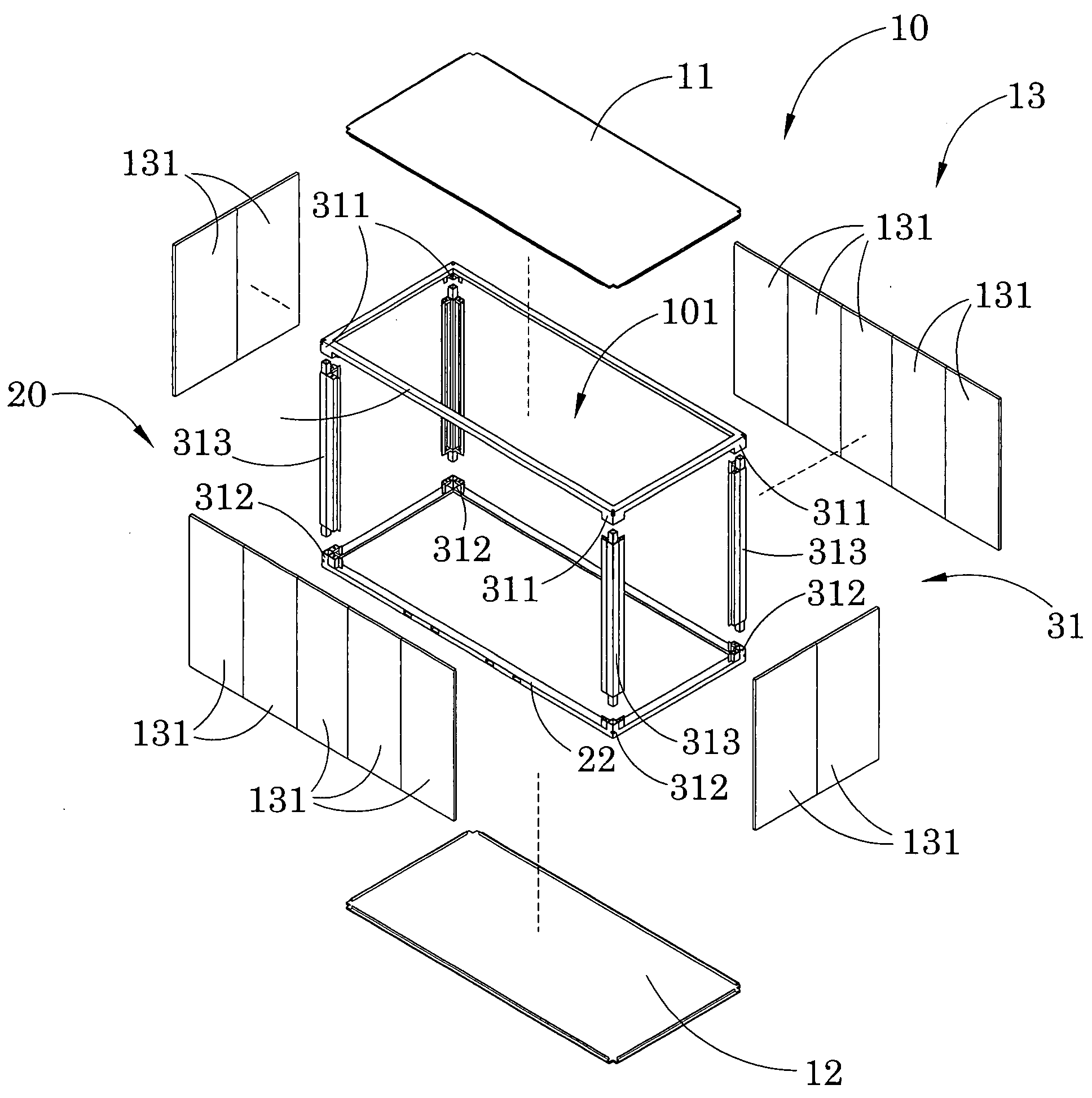

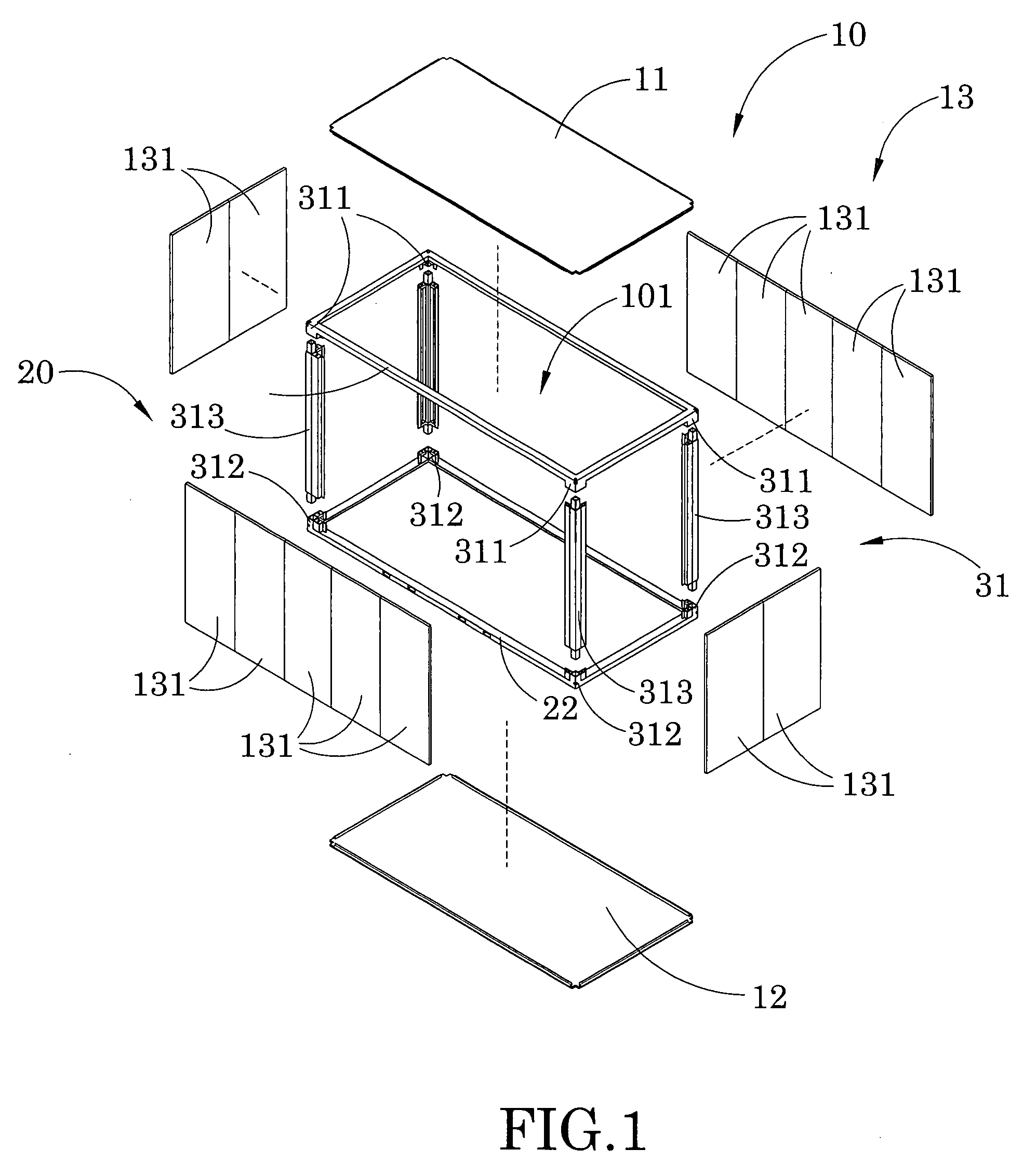

[0028]Referring to FIG. 1 of the drawings, a portable work and storage container according to a preferred embodiment of the present invention is illustrated, wherein the portable work and storage container comprises a wall frame 10, a supporting frame 20 and a joint structure 30.

[0029]The wall frame 10 comprises a top wall 11, a bottom wall 12, and a surrounding wall 13 defining a storage compartment 101 therewithin.

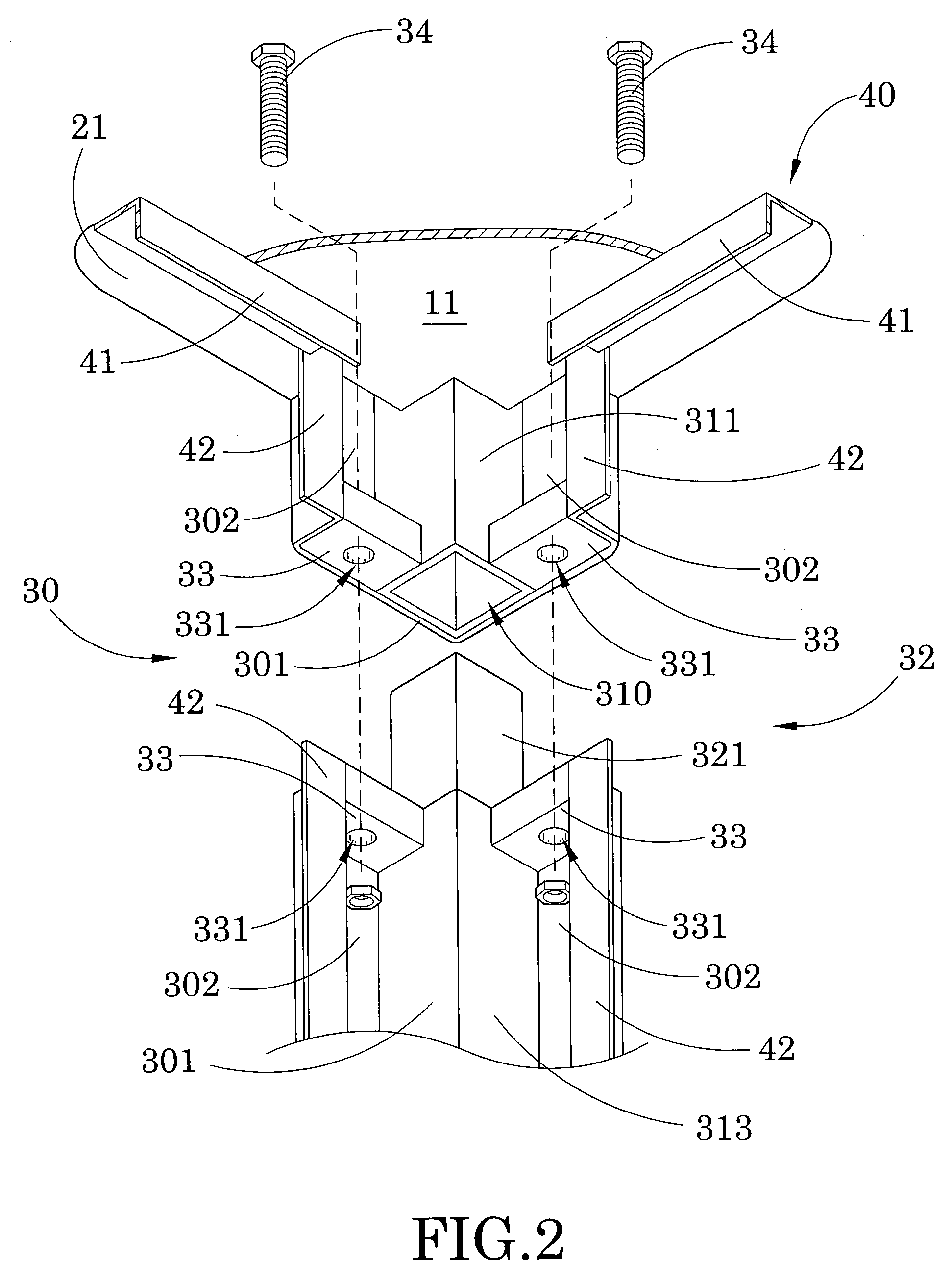

[0030]The supporting frame 20 comprises a top retention frame 21 encirclingly mounting to the top wall 11 and a bottom retention frame 22 encirclingly mounting to the bottom wall 12, wherein the surrounding wall 13 is mounted between the top and bottom retention frames 21, 22.

[0031]As shown in FIGS. 1 to 4, the joint structure 30 couples the top retention frame 21 with the bottom retention frame 22, wherein the joint structure 30 comprises a plurality of joint members 31 spacedly extended between the top and bottom retention frames 21, 22, and a plurality of reinforcing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com