Method of handling spent catalyst

A waste catalyst and treatment method technology, applied in the fields of metal alloy, high-temperature slag and sulfur, and oil recovery, can solve the problems of waste of resources, incomplete recovery, pollution of the atmospheric environment, etc., and achieve the effect of saving resources and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

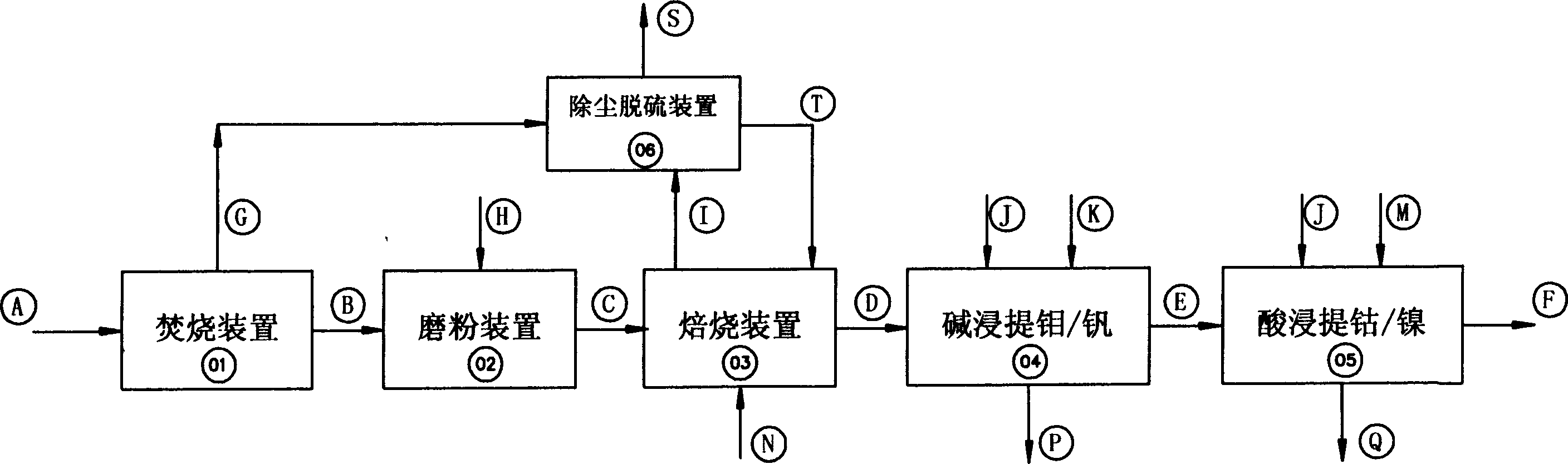

[0019] The spent catalysts in petroleum refining are treated according to the following process:

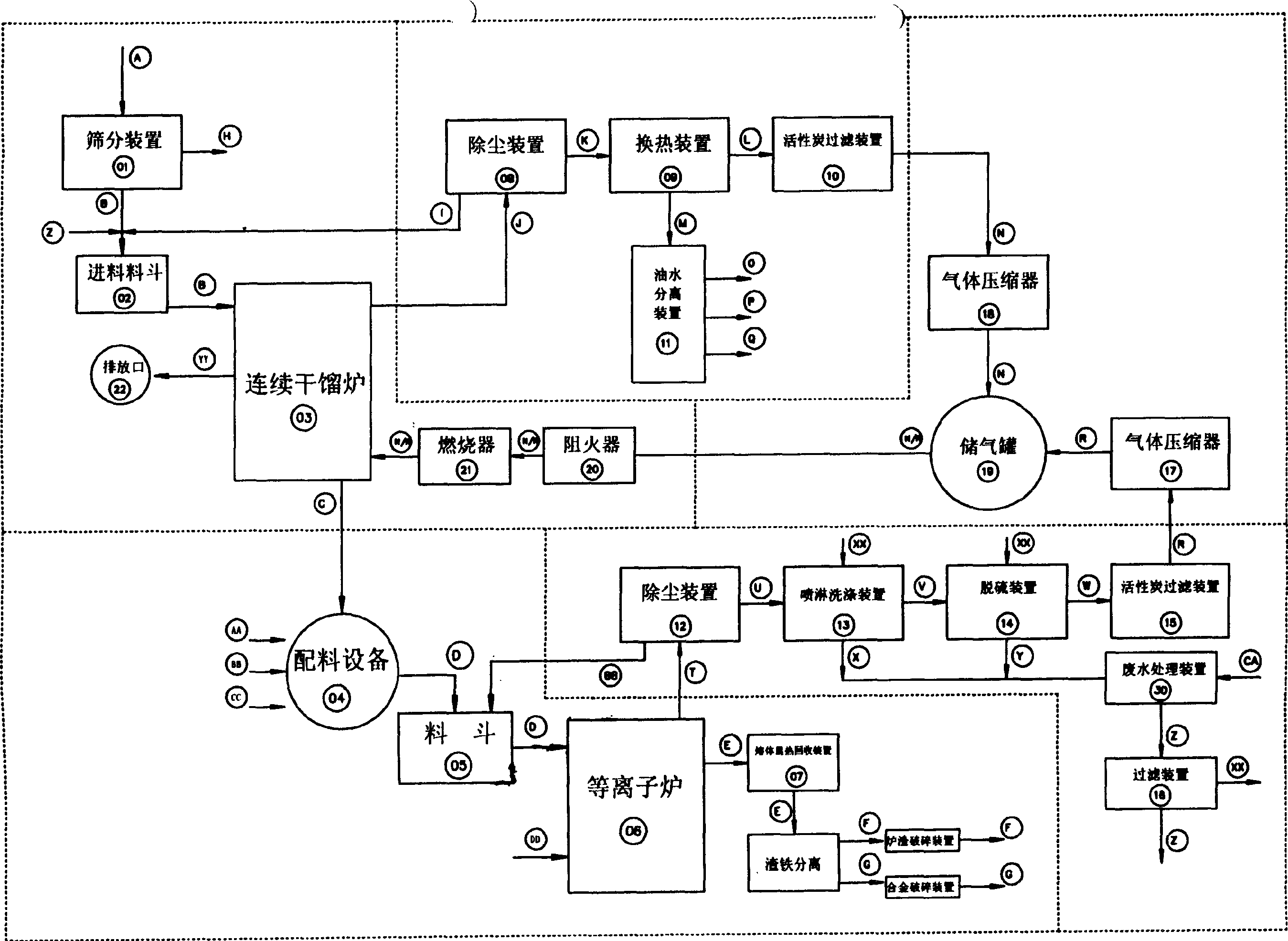

[0020] 1. Pretreatment: Send the spent catalyst A to the sieving machine 01 for screening, and sieve out the inert ceramic balls H mixed in the spent catalyst to obtain the spent catalyst B with particles smaller than 20×20mm.

[0021] 2. Dry distillation: Send the spent catalyst B to the lifting hopper, lift it through the lifting hopper, send the spent catalyst B to the dry distillation equipment feed hopper 02, and then supply it to the dry distillation device 03, and keep the temperature in the dry distillation device 03 at 500-600 ℃, the spent catalyst B is continuously retorted for 2 hours, and converted into spent catalyst C after dehydration, deoiling and desulfurization, transported to the discharge hopper of the retort equipment, and the spent catalyst C is taken out through the discharge device; the retort gas J generated by continuous retort, Enter the dedusting devic...

Embodiment 2

[0025] According to the method described in embodiment 1, the discarded catalyst of petroleum industry hydrorefining is processed:

[0026] 1. Pretreatment: Sieve out the inert ceramic balls mixed in the spent catalyst to obtain spent catalyst B smaller than 20×20mm.

[0027] 2. Dry distillation: send spent catalyst B to dry distillation equipment, and conduct continuous dry distillation at 550°C for 1.5 hours to obtain spent catalyst C with a weight loss of less than 2% at 500°C after dehydration, deoiling and desulfurization; The entrained waste catalyst powder is recovered and returned to the dry distillation equipment for further processing. The dry distillation gas after dust removal is cooled and recovered by heat exchange of high boiling point oil, water vapor and sulfur mixture, and the mixture is separated from oil and water to obtain crude oil, sulfur and oily wastewater; heat exchange After the dry distillation gas is filtered, it becomes a clean flammable low-boili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com