Golf club head with a carbon fiber block

a golf club head and carbon fiber technology, applied in the field of golf club heads, can solve the problem of limited face area (42) of the golf club head (40)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

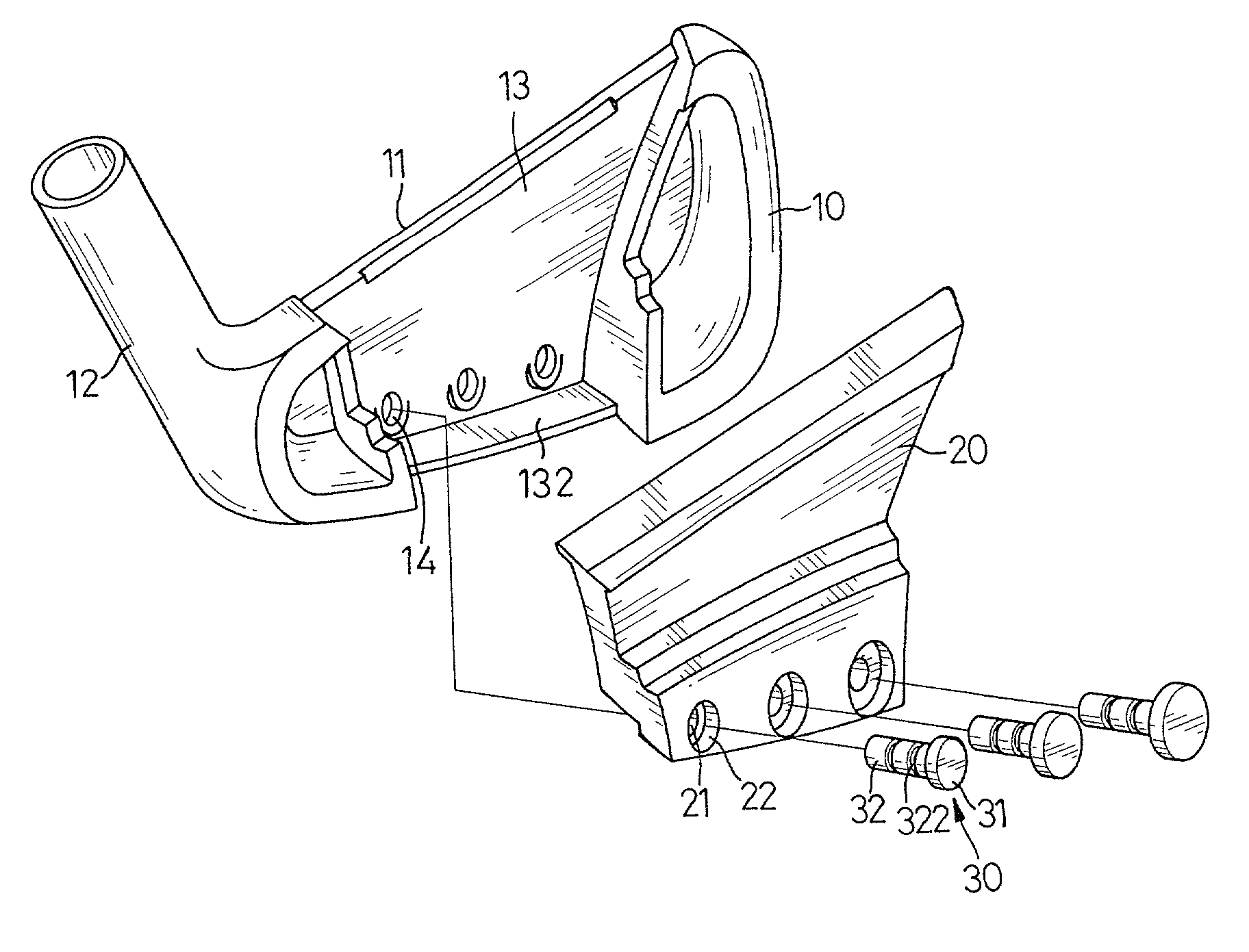

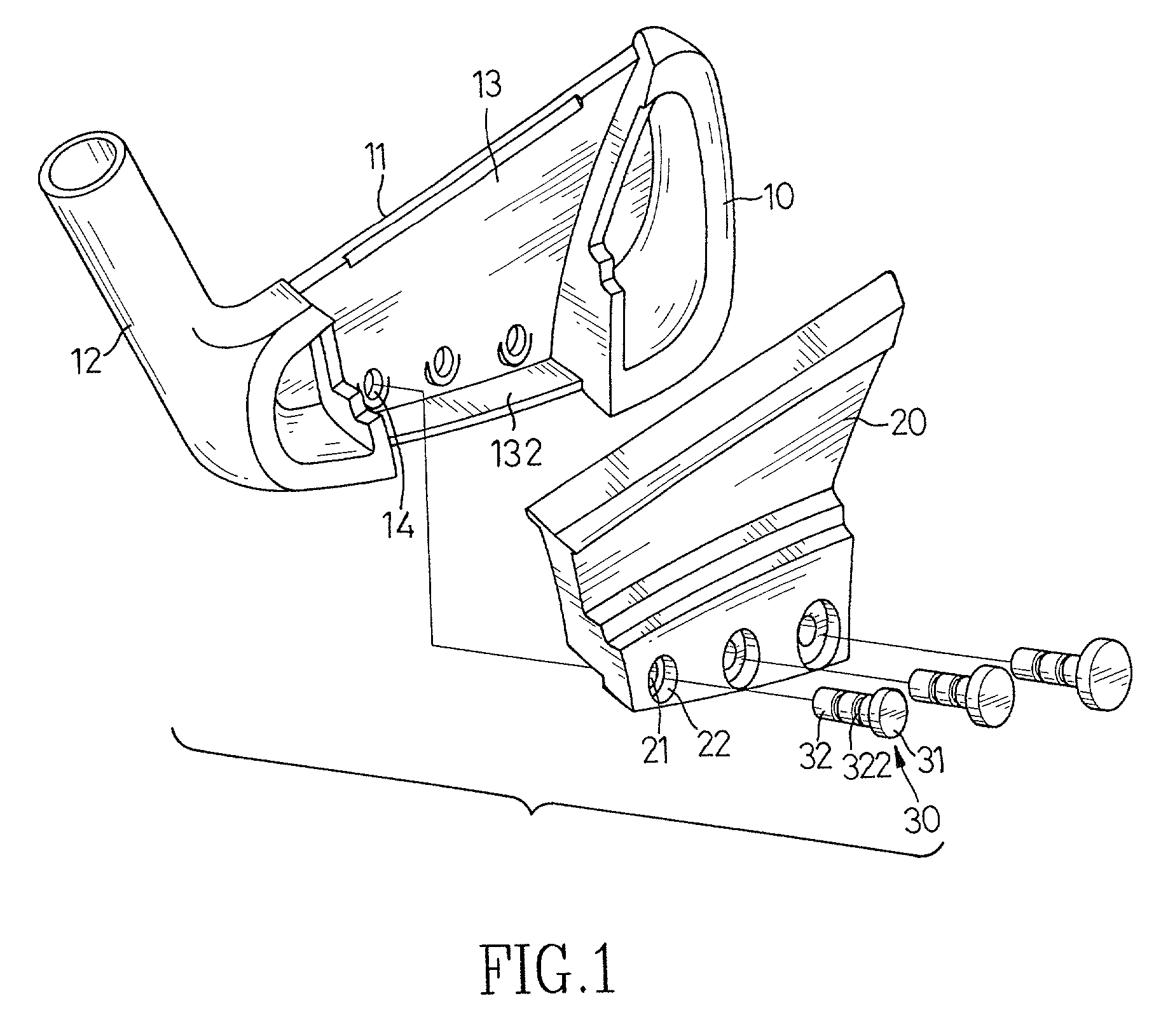

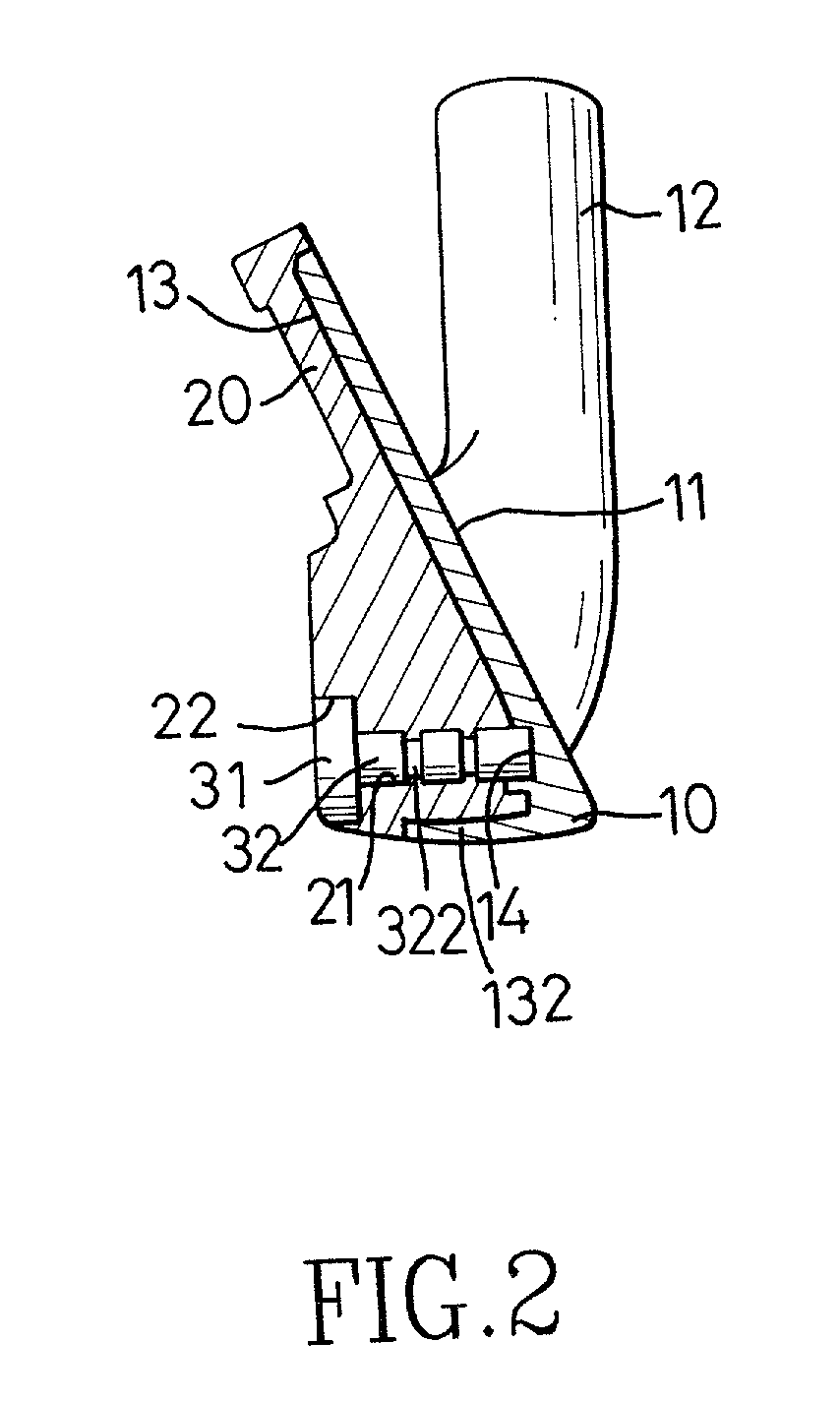

[0012] With reference to FIG. 1, a golf club head in accordance with the present invention comprises a body (10) and a carbon fiber block (20). The body (10) has a face (11) defined on one side of the body (10) for hitting the golf ball. A tubular neck (12) is integrally formed on one end of the body (10) to connect with a shaft of an iron. A cavity (13) is defined in the body (10) opposite to the face (11).

[0013] The carbon fiber block (20) is securely mounted in the cavity (13). A lip (132) laterally extends from the face defining the cavity (13) of the body (10) to engage the block (20), such that the attachment between the body (10) and the block (20) is enhanced.

[0014] At least one countersunk through hole (21) is defined in the block (20). A weighted plug (30) is-inlaid in each-countersunk through hole (21) in the block (20). Each weighted plug (30) has a head (31) and a shaft (32). The plug (30) shaft (32) integrally extends from the head (31). The head (31) has a diameter la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com