Dental colored zirconia ceramic material and its preparation method

A technology for zirconia ceramics and dentistry, which is applied in the field of colored zirconia ceramics for dentistry and its preparation, and can solve problems such as many influencing factors, different dyeing results, and uneven dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, a preparation method of colored zirconia ceramics for dental use

[0032] (1) Zirconia raw material is 3Y-TZP, Pr 6 o 11 、Er 2 o 3 It is a coloring agent, and its specific components are shown in Table 1;

[0033] (2) Put all the raw materials into the ball milling tank, and perform ball milling with the ratio of raw materials: absolute ethanol: zirconia ball milling beads = 1:1:1, the ball milling speed is 300r / min, and the ball milling time is 12-24h; after ball milling Dry the powder in a constant temperature drying oven at 50-70°C for 12-24 hours; add 3wt% PVA to the dried powder for grinding, and the amount of polyvinyl alcohol added is 0.4-1ml / g powder Then pass through a 50-mesh sieve for granulation; dry-press the granulated powder at a pressure of 4 MPa and hold the pressure for 2 minutes; then perform cold isostatic pressing and hold the pressure at 200 MPa for 3 minutes;

[0034] (3) Heat the molded ceramic block at a heating rate of 50°C / h...

Embodiment 2

[0036] Embodiment 2, a preparation method of colored zirconia ceramics for dental use

[0037] (1) Zirconia raw material is 3Y-TZP, Pr 6 o 11 、Er 2 o 3 It is a coloring agent, and its specific components are shown in Table 1;

[0038] (2) Same as step (2) of Example 1;

[0039] (3) Same as step (3) of Example 1 to obtain colored zirconia ceramics.

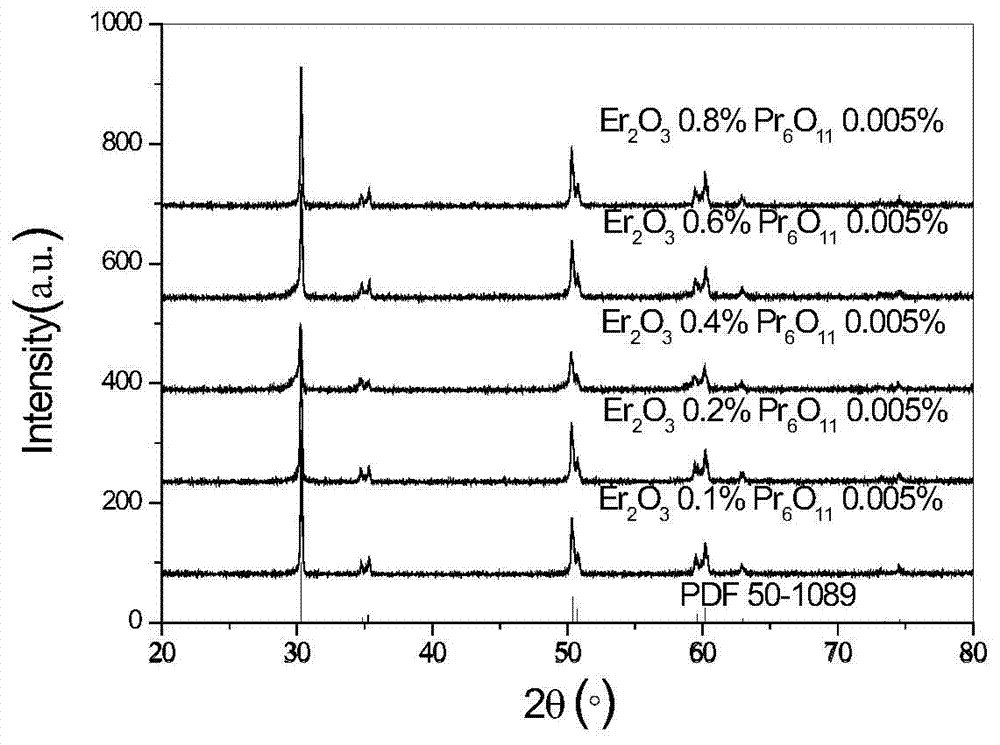

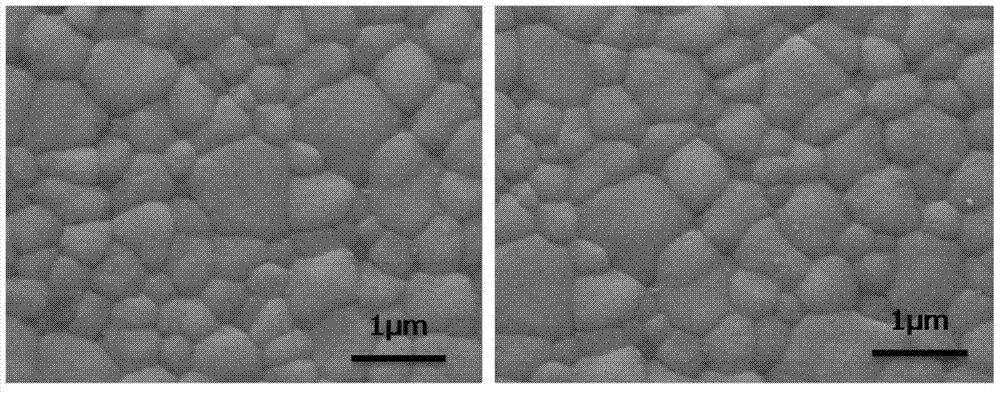

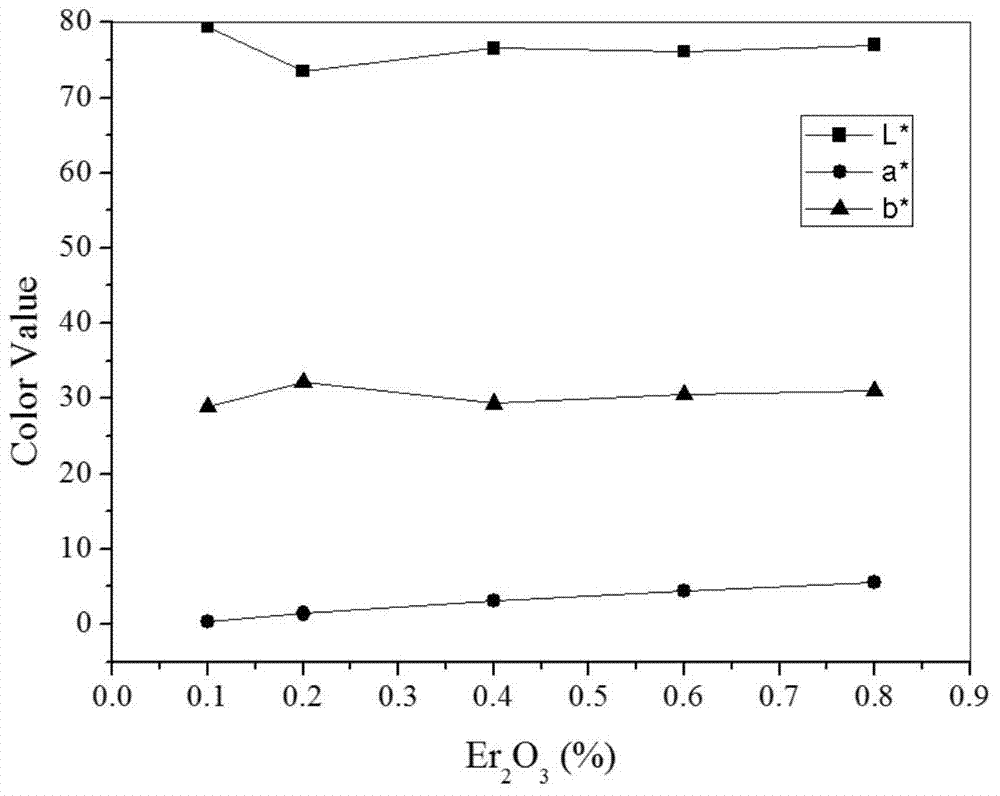

[0040] The XRD spectrum, SEM figure and chromaticity value of the colored zirconia ceramics are as follows figure 1 , 2 , 3 shown.

Embodiment 3

[0041] Embodiment 3, a preparation method of colored zirconia ceramics for dental use

[0042] (1) Zirconia raw material is 3Y-TZP, Pr 6 o 11 、Er 2 o 3 It is a coloring agent, and its specific components are shown in Table 1;

[0043] (2) Same as step (2) of Example 1;

[0044] (3) Same as step (3) of Example 1 to obtain colored zirconia ceramics.

[0045] The XRD spectrum and chromaticity values of the colored zirconia ceramics are as follows: figure 1 and image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com