Preparation method of tooth color imitating dental tetragonal polycrystalline zirconia ceramics

A zirconia ceramic, tetragonal technology, used in dental preparations, dentistry, dental prostheses, etc., can solve problems such as coloring, achieve excellent mechanical properties, good color stability, and expand the scope of indications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

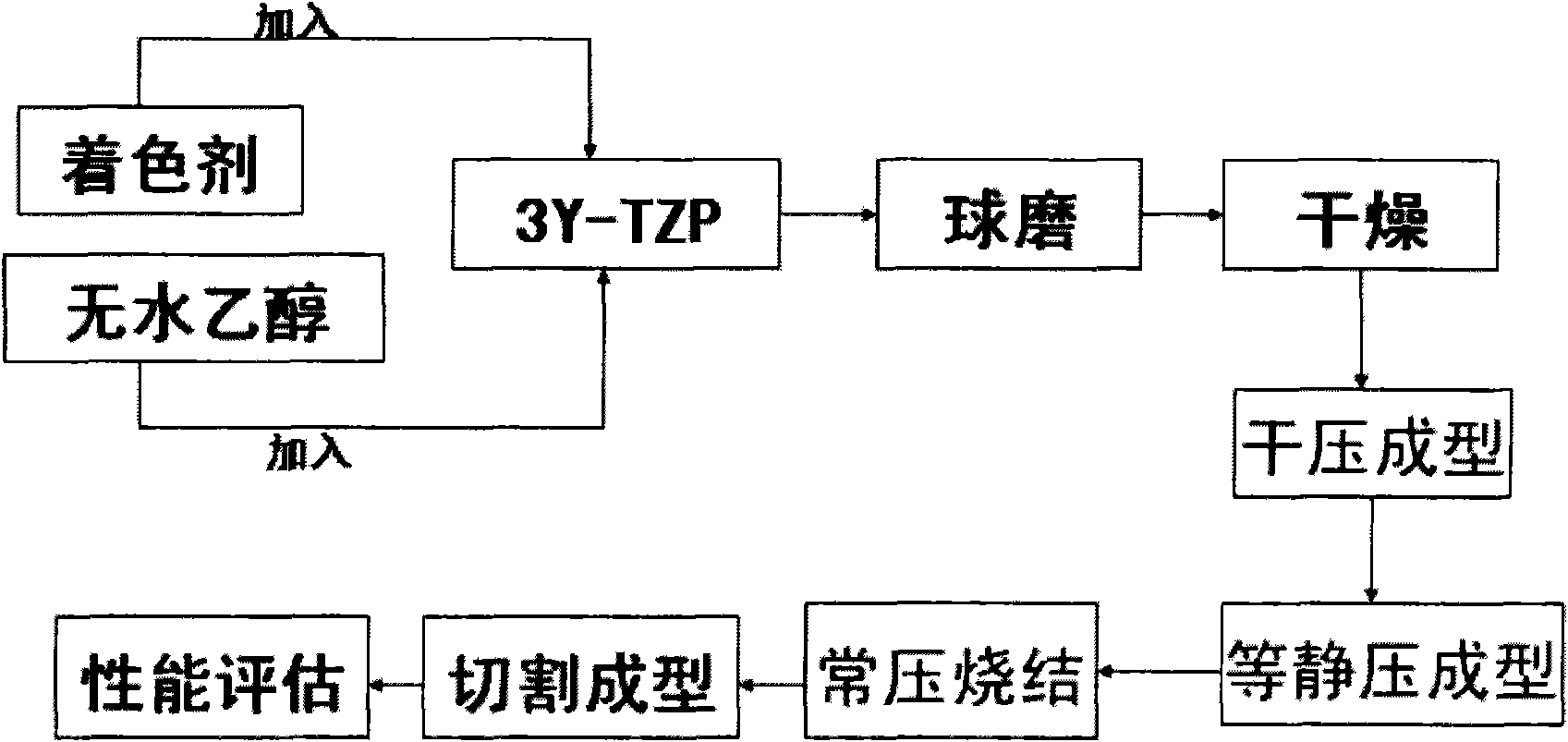

[0025] A method for preparing tooth-colored dental tetragonal polycrystalline zirconia ceramics, the specific steps are:

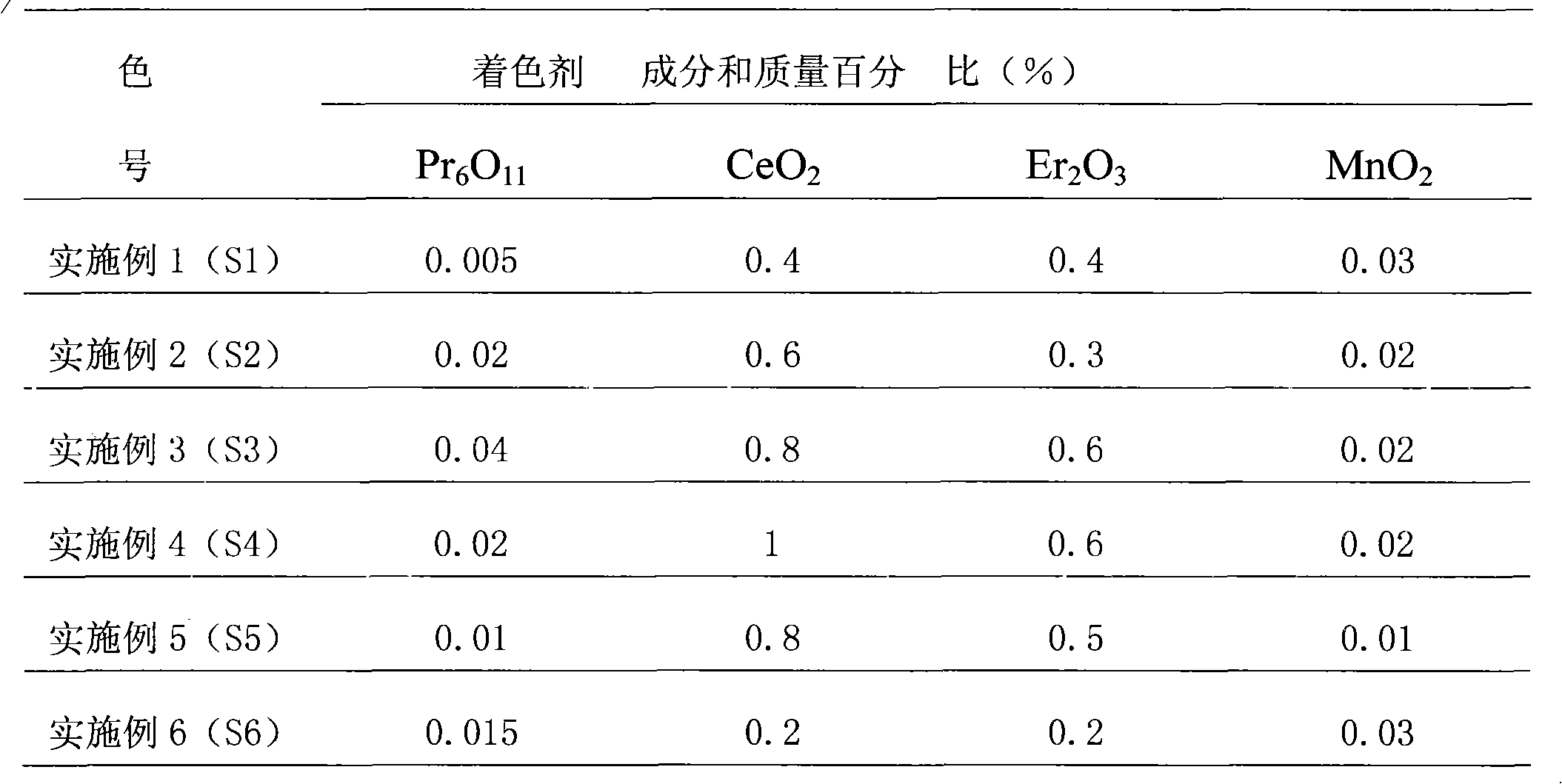

[0026] (1) The raw material is 3Y-TZP ceramic blank, with rare earth oxide as Pr 6 o 11 , CeO 2 , Er 2 o 3 and transition element oxide MnO 2 It is a coloring agent, and the specific components are shown in Table 1;

[0027] The full name of the 3Y-TZP is tetragonal polycrystalline zirconia ceramics;

[0028] (2) Coloring agent and dehydrated alcohol are added in 3Y-TZP, and ball milling is carried out, and powder: dehydrated alcohol: agate ball milling beads are added in the agate ball milling tank with a mass ratio of 1:1:1 to Wet ball milling at 200 rpm for 24 hours to mix evenly, then dry, put in a constant temperature drying oven, dehydrate and dry at 100°C for 12 hours, pass through a 180-mesh sieve for use, dry press after drying, and then carry out isostatic pressing Molding, molding under the molding pressure of 300MPa and keeping the press...

Embodiment 2

[0032] A method for preparing tooth-colored dental tetragonal polycrystalline zirconia ceramics, the specific steps are:

[0033] (1) The raw material is 3Y-TZP ceramic blank, with rare earth oxide as Pr 6 o 11 , CeO 2 , Er 2 o 3 and transition element oxide MnO 2 It is a coloring agent, and the specific components are shown in Table 1;

[0034] The full name of the 3Y-TZP is tetragonal polycrystalline zirconia ceramics;

[0035] (2) with the step (2) of embodiment 1;

[0036] (3) With the step (3) of embodiment 1.

Embodiment 3

[0038] A method for preparing tooth-colored dental tetragonal polycrystalline zirconia ceramics, the specific steps are:

[0039] (1) The raw material is 3Y-TZP ceramic blank, with rare earth oxide as Pr 6 o 11 , CeO 2 , Er 2 o 3 and transition element oxide MnO 2 It is a coloring agent, and the specific components are shown in Table 1;

[0040] The full name of the 3Y-TZP is tetragonal polycrystalline zirconia ceramics;

[0041] (2) with the step (2) of embodiment 1;

[0042] (3) With the step (3) of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com