Multiple-oxide-doped gradient-color zirconia dental prosthesis and preparation method thereof

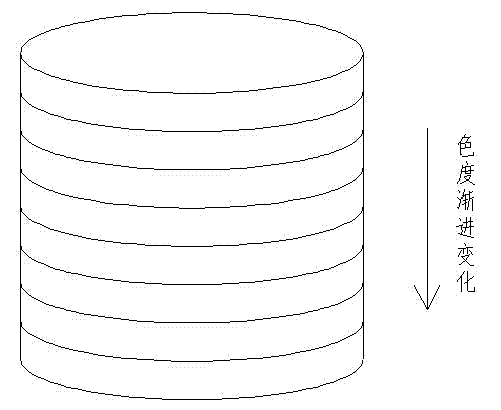

A zirconia and gradient color technology, applied in the field of gradient zirconia dental restorations and its preparation, to achieve stable effects, easy operation, and rich color control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The powders A, B, C, and D are proportioned by mass fraction: 10%: 10%: 10%: 70%; 13%: 13%: 13%: 61%; 16%: 16%: 16%: 52 %; 19%: 19%: 19%: 43%; 22%: 22%: 22%: 34% mixed evenly to obtain 5 different colored powder porcelain layers, wherein the adjacent porcelain layers contain A, B, The total mass fraction difference of C is 9%, and the stacking thickness of each layer is 15mm.

[0038] According to the above sequence, five kinds of powders were successively added into the forming mold for layering and stacking, the pre-drying pressure was 0.5Mpa, the dry-pressing pressure was 5MPa, and the holding time was 5s. Then carry out cold isostatic pressing forming, the cold isostatic pressing pressure is 200MPa, and the holding time is 60s. The prepared green body was put into a sintering furnace for pre-sintering, the sintering temperature was 850°C, and the holding time was 90 minutes. Then the plain embryo is engraved to ensure that the surface finish and size of the plain ...

Embodiment 2

[0041] The powders A, C, and D are proportioned by mass fraction: 12%: 10%: 78%; 14%: 12%: 74%; 16%: 14%: 70%; 18%: 16%: 66%; 20%: 18%: 62%; 22%: 20%: 58%; 24%: 22%: 54% Mix evenly to get 7 kinds of powder porcelain layers of different colors, in which the adjacent porcelain layers contain A and C The total mass fraction difference is 4%, and the stacking thickness of each layer is 20mm.

[0042] According to the above sequence, 7 kinds of powders were successively added into the forming mold for layering and stacking, the pre-drying pressure was 5Mpa, the dry-pressing pressure was 20MPa, and the holding time was 30s. Then carry out cold isostatic pressing forming, the cold isostatic pressing pressure is 120MPa, and the holding time is 90s. The prepared green body was put into a sintering furnace for pre-sintering, the sintering temperature was 750°C, and the holding time was 100min. Then the plain embryo is engraved to ensure that the surface finish and size of the plain em...

Embodiment 3

[0044] The powders B, C, and D are proportioned by mass fraction: 17%: 9%: 74%; 18%: 11%: 71%; 19%: 13%: 68%; 20%: 15%: 65%; 21%: 17%: 62%; 22%: 19%: 59%; 23%: 21%: 56%; 24%: 23%: 53%; 25%: 25%: 50% Mix well and get 9 kinds For powder porcelain layers of different colors, the difference between the total mass fractions of B and C in adjacent porcelain layers is 3%, and the stacked thickness of each layer is 13mm.

[0045] According to the above sequence, 9 kinds of powders were successively added into the forming mold for layering and stacking, the pre-drying pressure was 1Mpa, the dry-pressing pressure was 10MPa, and the pressure holding time was 18s. Then carry out cold isostatic pressing forming, the pressure of cold isostatic pressing is 80MPa, and the holding time is 120s. The prepared green body was put into a sintering furnace for pre-sintering, the sintering temperature was 550°C, and the holding time was 120 minutes. Then the plain embryo is engraved to ensure that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com