Colored filter board

A color filter and filter technology, applied in optics, optical components, nonlinear optics, etc., can solve problems such as environmental pollution, high cost of chrome-plated metal film layers, and prolonged production cycle, and achieve the goal of reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

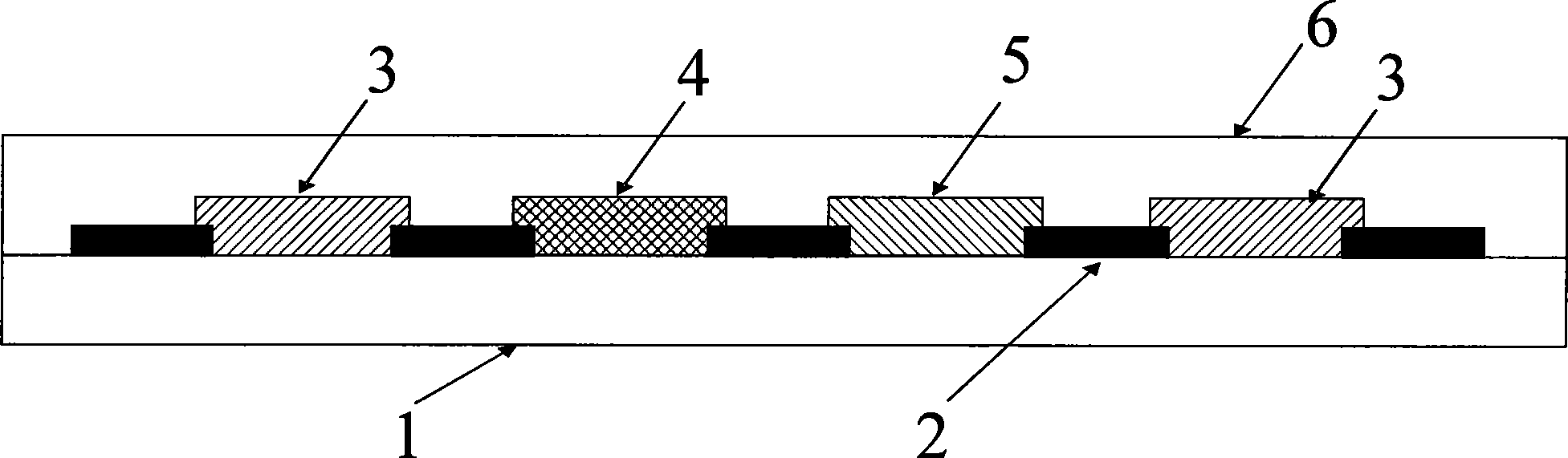

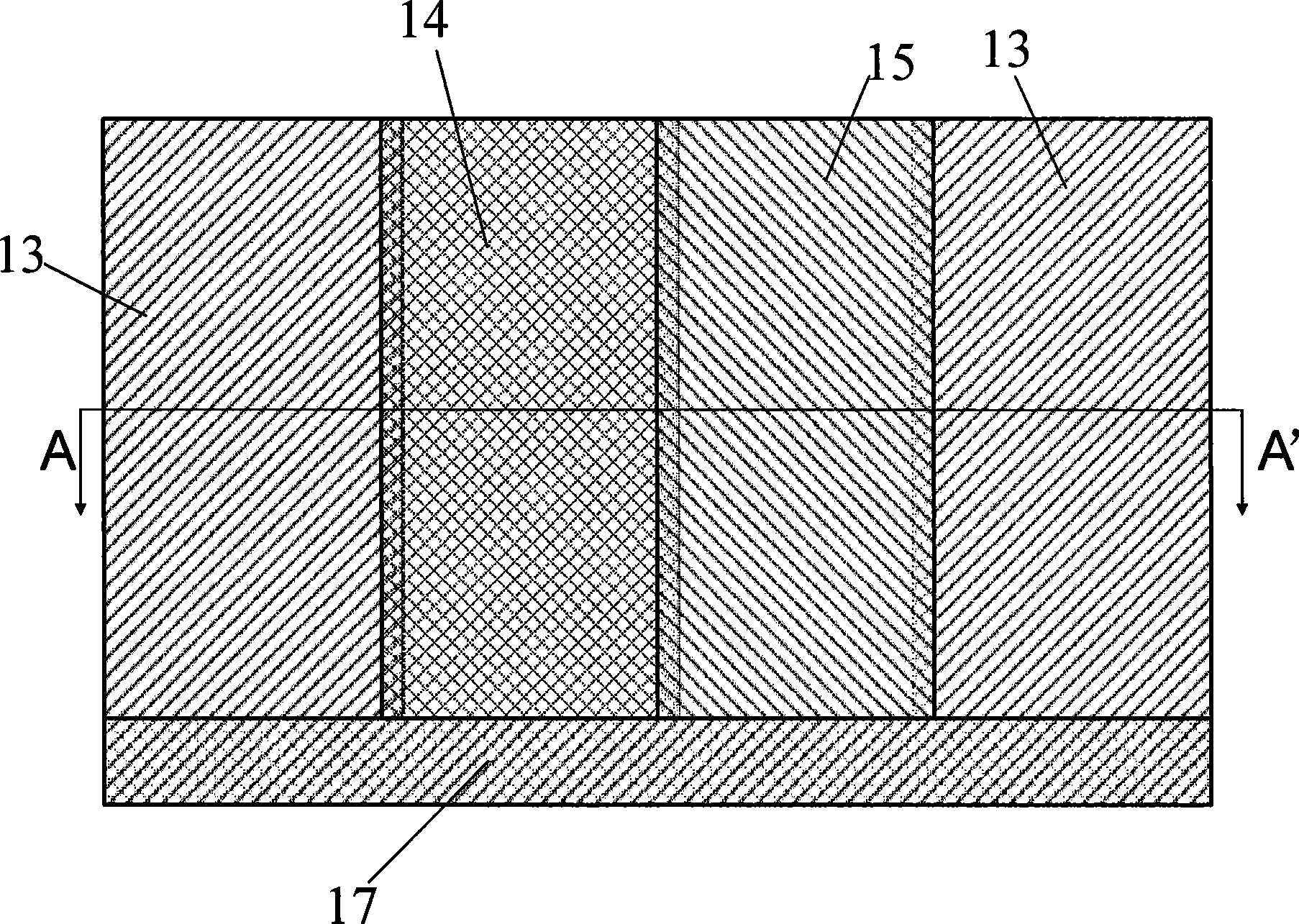

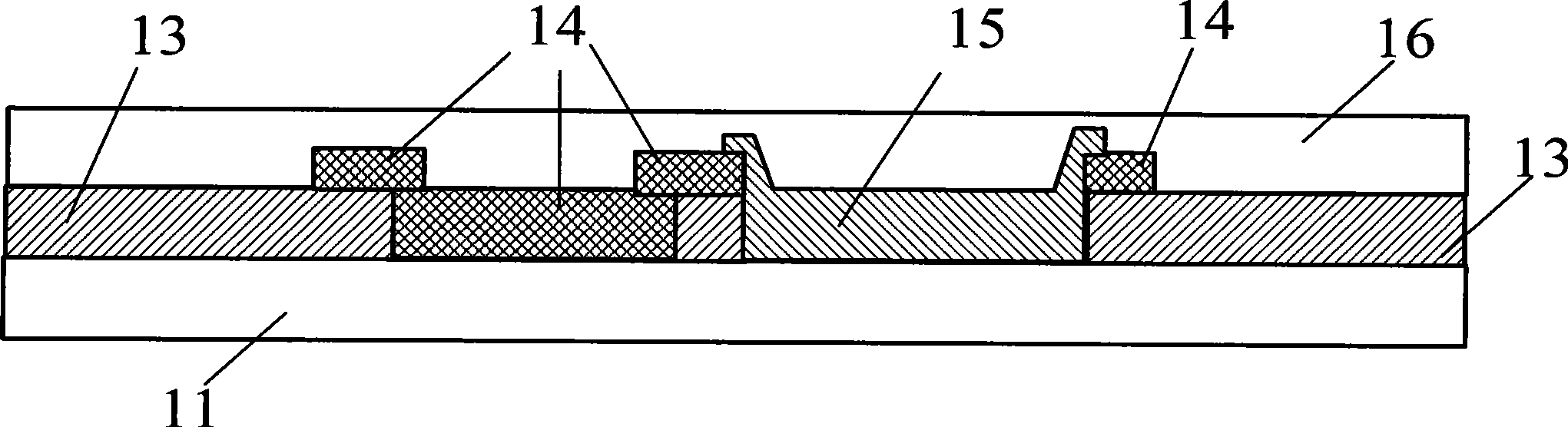

[0018] The color filter plate of the present invention will be further described in detail with reference to the accompanying drawings.

[0019] figure 2 It is a structural schematic diagram of the color filter plate of the first embodiment of the present invention, image 3 for along figure 2 A-A'direction sectional view. like figure 2 , image 3 As shown, the color filter plate of the first embodiment of the present invention includes: a glass substrate 11; a blue color filter 13, formed on the glass substrate 11; a red color filter 14, when necessary The shading area overlaps with the blue filter 13; a green filter 15 is formed between the blue filter 13 and the red filter 14; a cover layer 16 is used to carry out the above-mentioned each filter flattening treatment. Because in the area where the red filter 14 overlaps with the blue filter 13, the total film thickness is larger than the film thickness of the non-overlapping area, in order to ensure that the steps o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com