Colored figured sea-island composite ultrafine short fiber and preparation method thereof

A technology of fine short fibers and islands in the sea, applied in the field of polyester chemical industry, can solve the problems of increased dyeing process, poor color fastness of colored fibers, and increased production costs, so as to achieve lower production costs, high color fastness, and better dyeing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

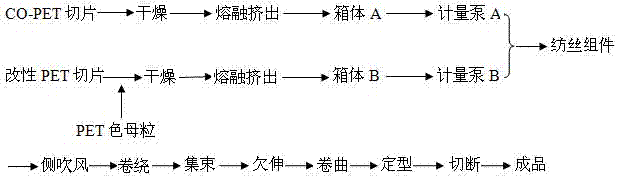

Method used

Image

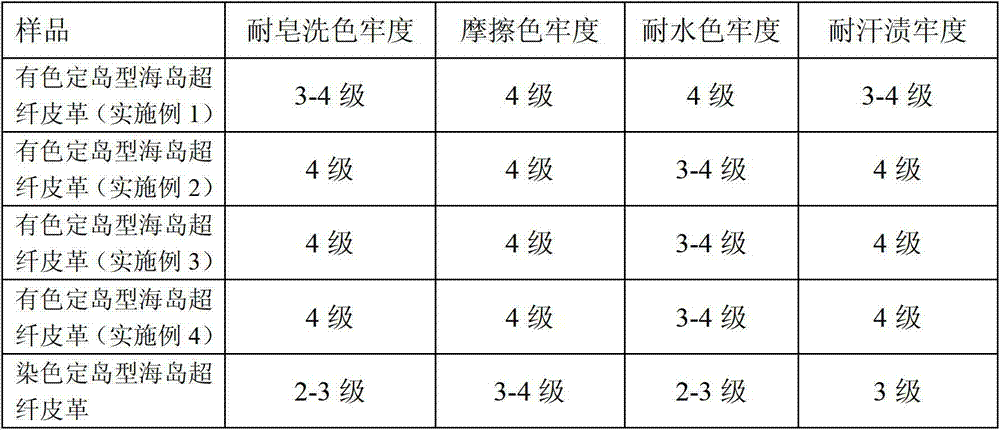

Examples

Embodiment 1

[0020] (1) Preparation of modified PET

[0021] The purified terephthalic acid and ethylene glycol are mixed and beaten in a molar ratio of 1.2:1, and antimony trioxide, tripotassium phosphate and cobalt acetate are added to the slurry, and then enter the esterification kettle for esterification reaction. The inner temperature of the esterification reaction temperature is controlled at 253±2°C, the end point of the reaction is determined according to the water output of the esterification, and the esterified product is sent to the polycondensation kettle. The PEG with a molecular weight of 7000 is melted into a solution with saturated steam at 180°C, and then added to a polycondensation kettle in a proportion of 0.5% of the weight of the esterified product to carry out the polycondensation reaction. The polycondensation reaction is in the low vacuum stage, and the temperature is controlled at 250 ± 2 °C, and the high vacuum stage , the temperature is controlled at 276±2℃. Aft...

Embodiment 2

[0025] (1) Preparation of modified PET

[0026] The molar ratio of purified terephthalic acid and ethylene glycol in Example 1 was changed to 1.3:1, the molecular weight of PEG was changed to 6000, and the amount of PEG added was changed to 0.6%. same.

[0027] (2) Preparation of colored island-type sea-island composite ultrafine short fibers

[0028]The pigmented PET masterbatch with a pigment content of 1.5% and the modified PET chips obtained above were mixed uniformly in a mass ratio of 9:91. As the island component, the island component and the sea component were pre-crystallized, dried (pre-crystallized The temperature is 67°C, the time is 2h, the drying temperature is 145°C, the time is 18h, and the water content of the two components after drying is less than 30ppm), then melted, extruded, and fed into two components by a twin-screw extruder. a box. The temperature of the four temperature control zones of the screw extruder of the sea component and the temperature o...

Embodiment 3

[0030] (1) Preparation of modified PET

[0031] The molar ratio of purified terephthalic acid and ethylene glycol in Example 1 was changed to 1.4:1, the molecular weight of PEG was changed to 5000, and the amount of PEG added was changed to 0.7%. same.

[0032] (2) Preparation of colored island-type sea-island composite ultrafine short fibers

[0033] The pigmented PET masterbatch with a pigment content of 1.5% and the modified PET chips prepared above were mixed uniformly in a mass ratio of 11:89. As the island component, the island component and the sea component were pre-crystallized and dried (pre-crystallized). The temperature is 67°C, the time is 2h, the drying temperature is 145°C, the time is 18h, and the water content of the two components after drying is less than 30ppm), then melted, extruded, and fed into two components by a twin-screw extruder. a box. The temperature of the four temperature control zones of the screw extruder of the sea component and the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com