Process for producing colored shaped article from curable resin, colored shaped article produced from curable resin, and shaping apparatus

A technology of curable resin and manufacturing method, which is applied in the field of manufacture of colored moldings composed of curable resins, colored moldings composed of curable resins and molding devices, and can solve problems such as inability to obtain reliable coloring effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Best way to implement the invention

[0030] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

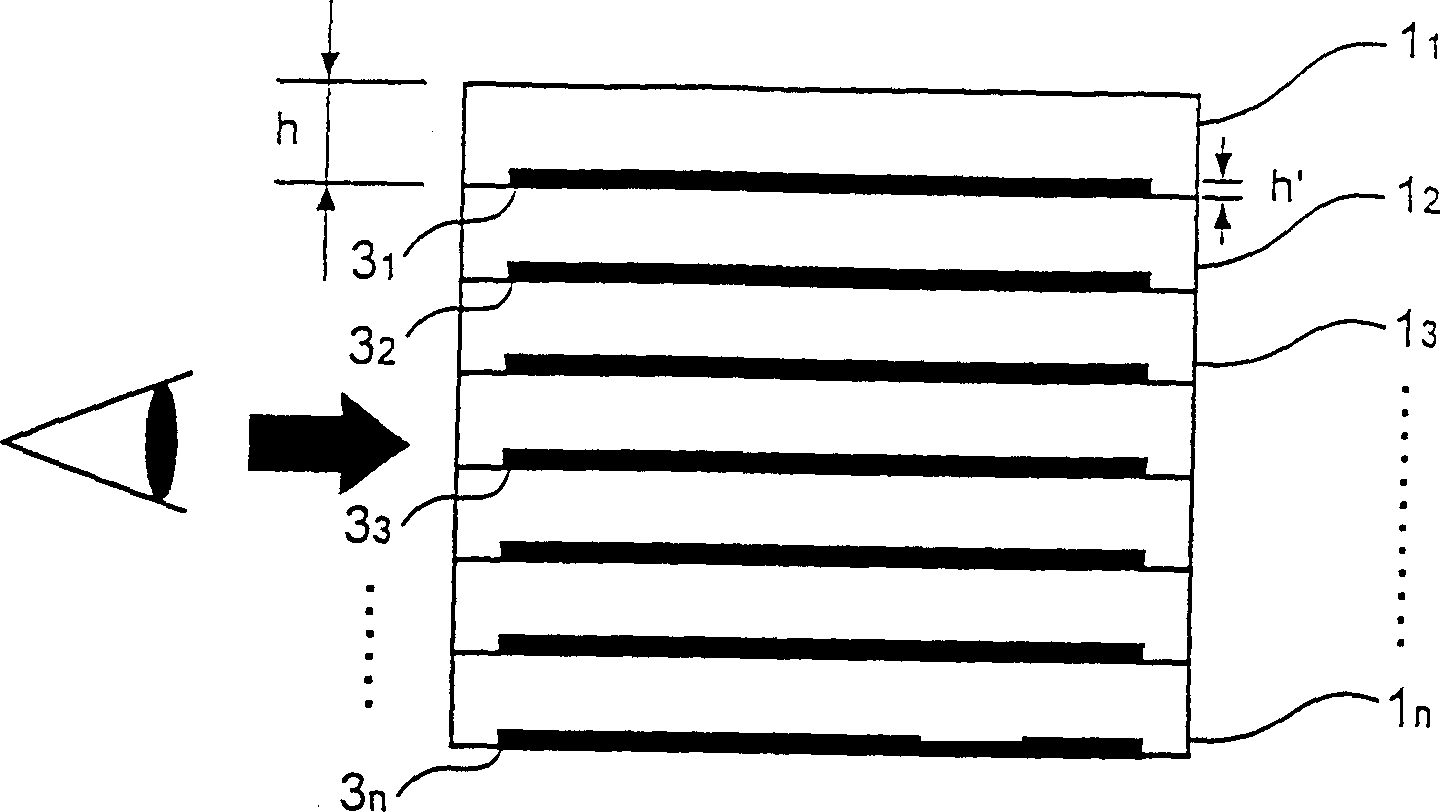

[0031] figure 2 It is a cross-sectional view showing an example of a colored molded product composed of a photocurable resin according to an embodiment of the present invention.

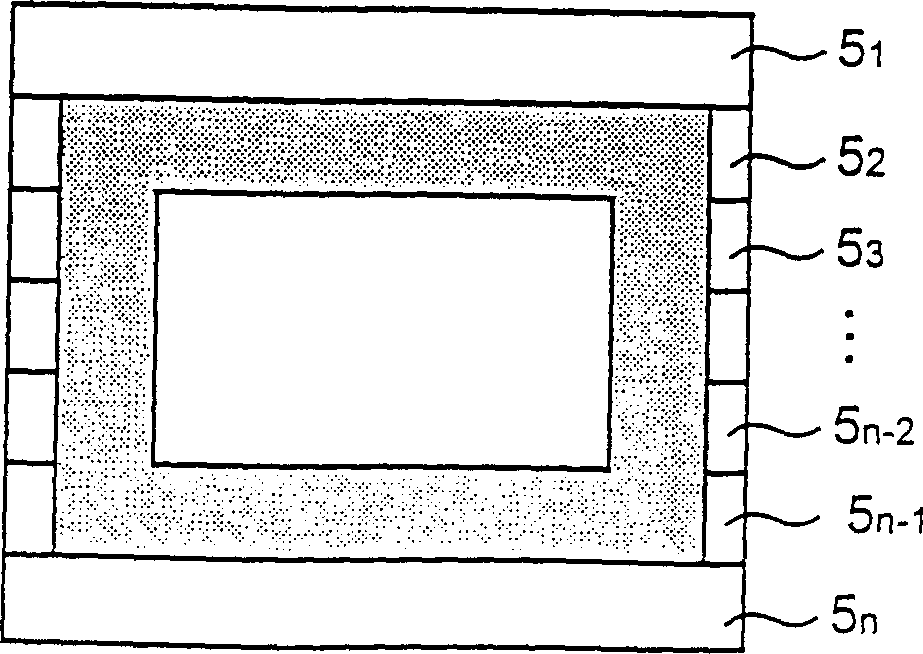

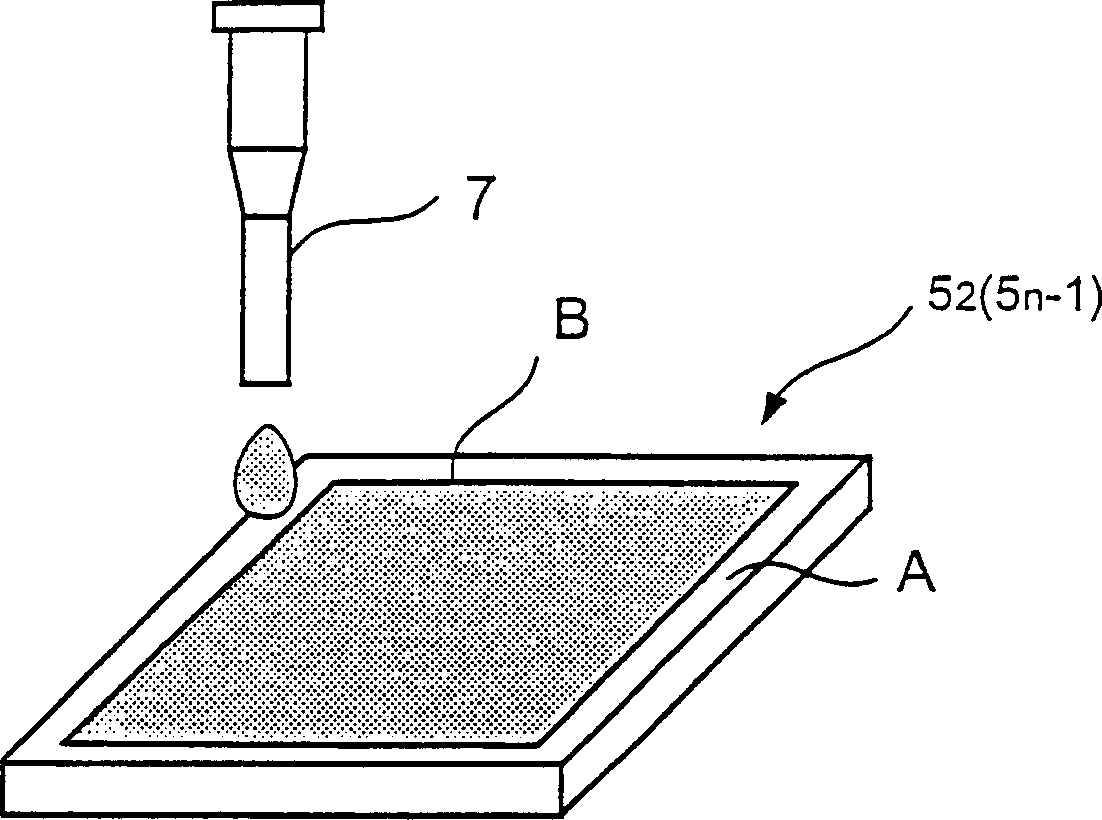

[0032] The above-mentioned colored molded article is a molded article formed by synthesizing photocurable resin layers, and its overall shape is not limited to a specific shape, and even if it is viewed from above or below, it can be assumed to be a rectangle (square) or a circle. shape, ellipse and other shapes. The above-mentioned colored moldings, such as figure 2 Shown, the top layer 5 1 and bottom level 5 n It is a layer (normal layer) composed of uncolored photocurable resin, and the uppermost layer 5 1 with bottom 5 n The layers laminated between them are respectively layers (colored layers) composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com