Rock material true triaxial test numerical simulation method considering intermediate principal stress effect

A technology of numerical simulation and principal stress, applied in the field of numerical simulation, can solve problems of little practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

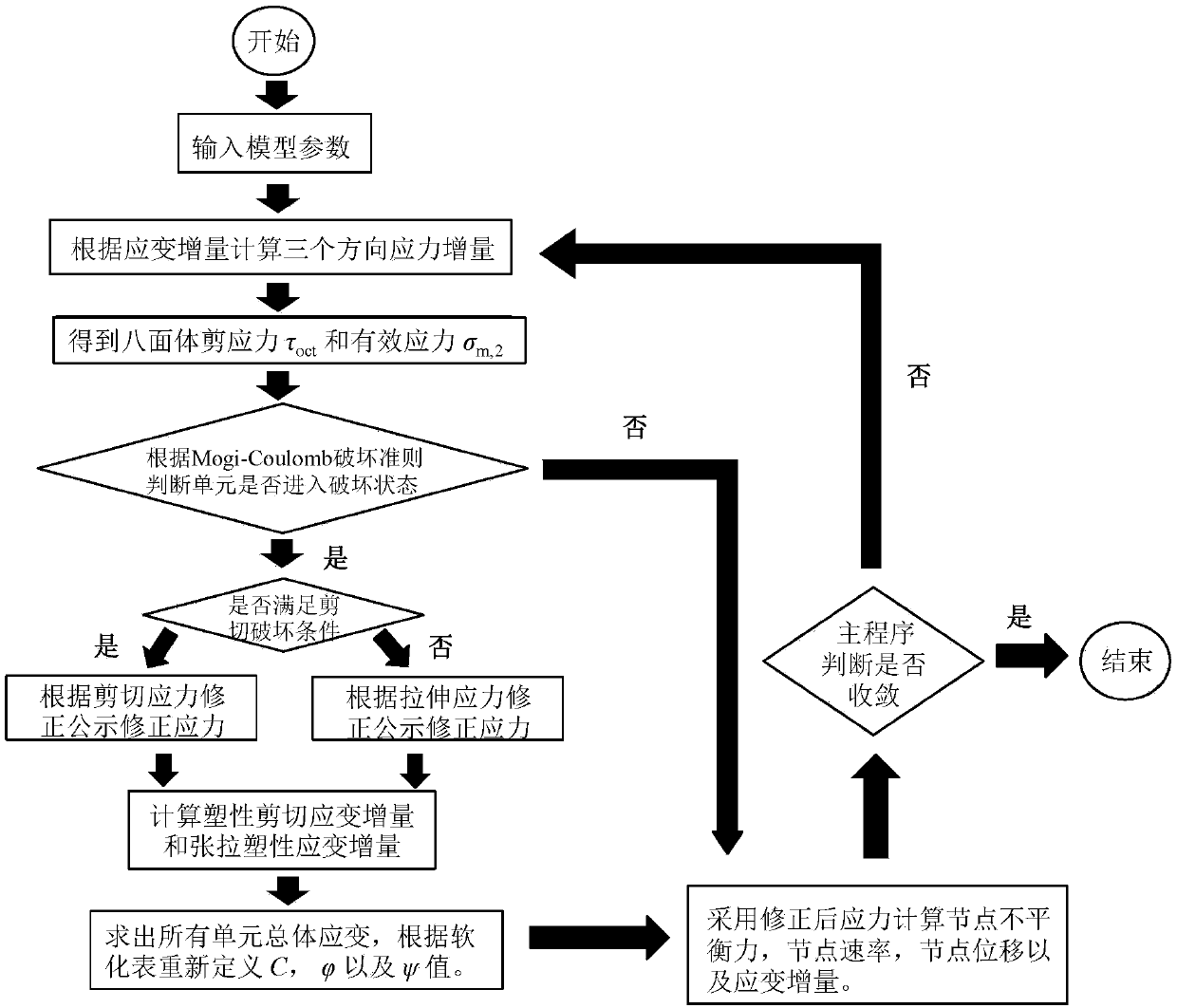

[0103] See attached figure 1 It can be known from 6 to 6 that, according to the Mogi-Coulomb strength criterion, the derived finite difference incremental iterative calculation format is embedded in the finite difference software FLAC3D to realize the secondary development and application of the Mogi-Coulomb constitutive model in FLAC3D software; The main members of FLAC3D such as: Calculate the stress tensor function Run() function according to the strain increment, which is the most important function in the whole model development process, and it must be called in every cycle and every sub-unit in the FLAC3D unit calculation; among them , program writing mainly includes five parts: ①Description of base class; ②Description of member function; ③Registration of model; ④Information exchange between model and FLAC3D; Please refer to the attached flow chart figure 1 . Specific embodiments of the present invention are published in the monograph "Experimental RockMechanics" publi...

Embodiment 2

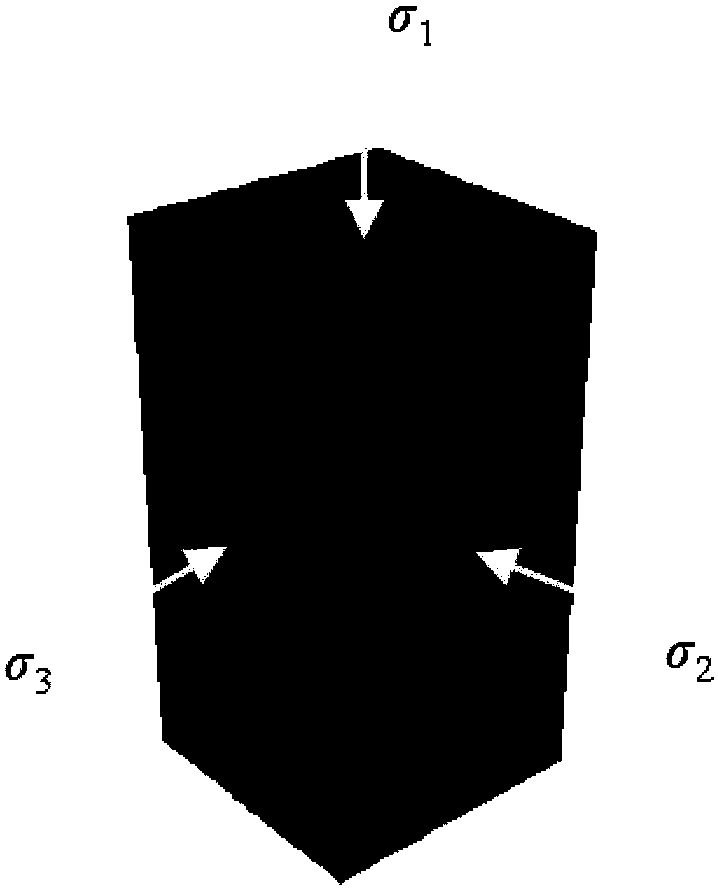

[0119] See attached figure 1 , Figure 7 shows that, according to the Mogi-Coulomb strength criterion, the derived finite difference incremental iterative calculation format is embedded in the finite difference software FLAC3D to realize the secondary development and application of the Mogi-Coulomb constitutive model in FLAC3D software . The specific implementation of the present invention is based on biaxial compression (in fact also a kind of true triaxial stress condition, namely another minimum principal stress σ 3 is 0, the purpose is to better reflect the influence of the intermediate principal stress on the failure mode of the sample) Miluo granite sample failure mode is taken as an example, the specific steps are as follows:

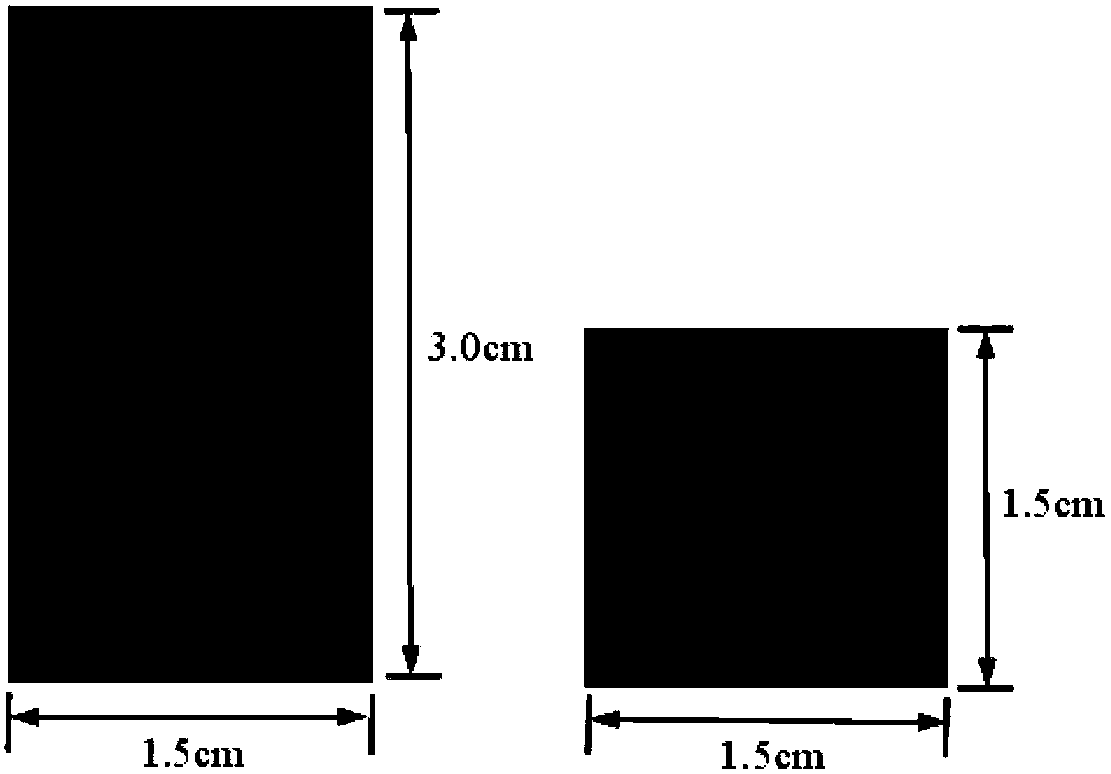

[0120] (1) Establish a three-dimensional numerical model of cuboid rock samples

[0121] A hexahedral mesh numerical model was established for the Miluo granite sample. The size of the sample is 5cm×5cm×5cm, the number of grids and nodes in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com