Doped cobalt carbonate, doped tricobalt tetroxide and preparation methods thereof

A technology of cobalt tetroxide and cobalt carbonate, applied in the directions of cobalt carbonate, cobalt oxide/cobalt hydroxide, etc., can solve the problems of lower specific capacity, influence of cobalt carbonate spheroidization and particle size growth, and poor anti-overcharge performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Examples of the present invention provide a method for preparing doped cobalt carbonate, comprising the steps of:

[0023] Step S01: preparing cobalt carbonate;

[0024] Step S02: adding cobalt carbonate to the metal alkoxide and mixing to obtain cobalt carbonate coated with metal alkoxide, which is a physical adsorption process;

[0025] Step S03: drying the coated cobalt carbonate to obtain doped cobalt carbonate.

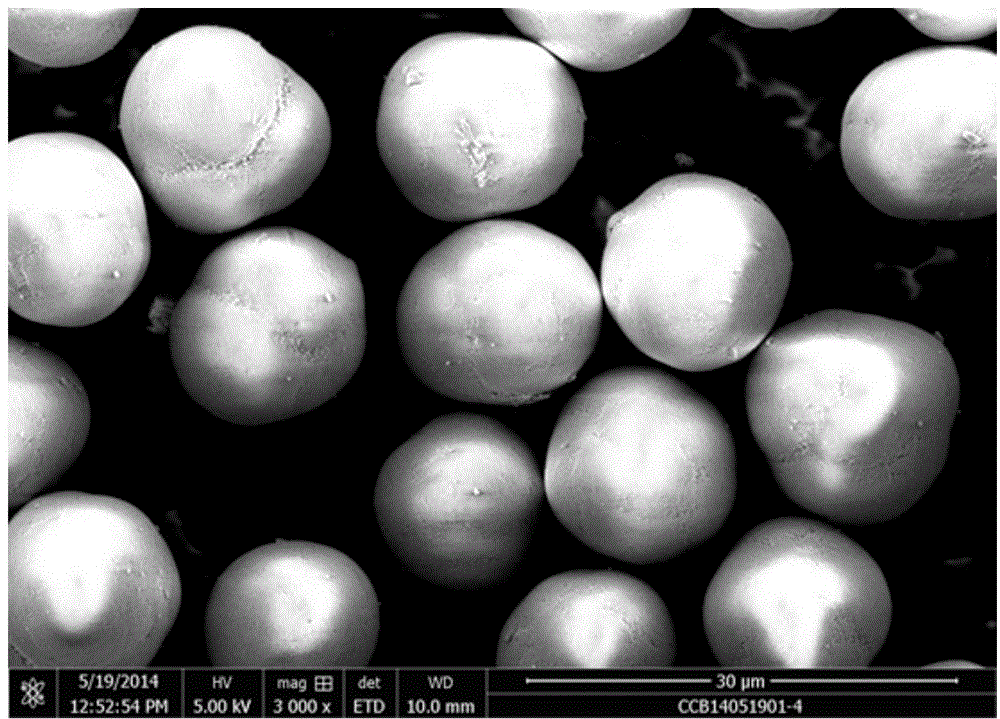

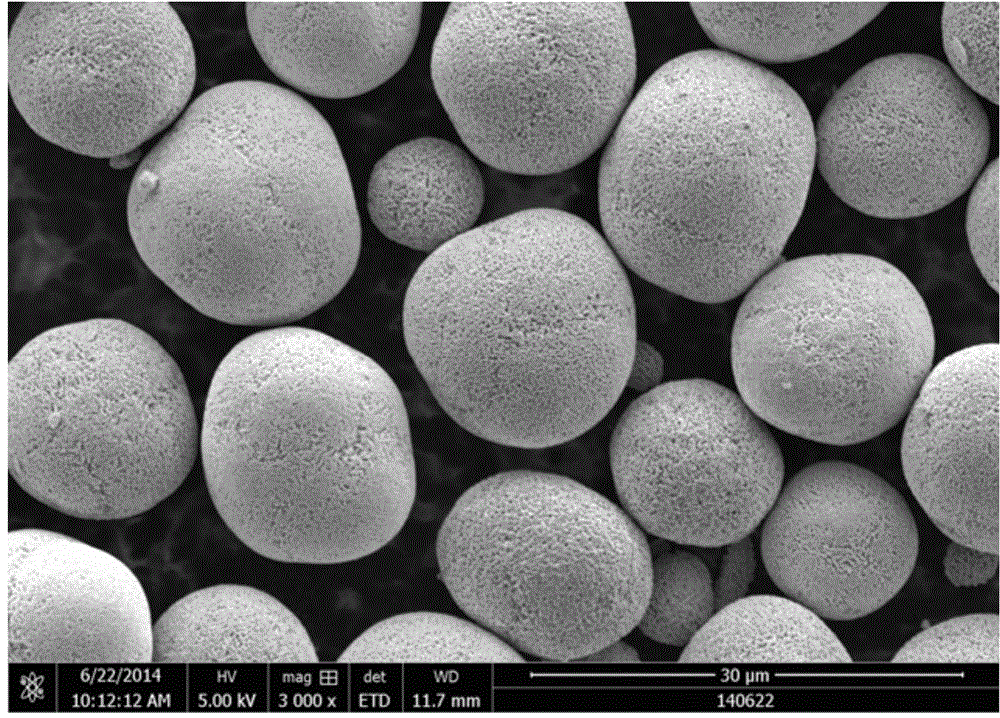

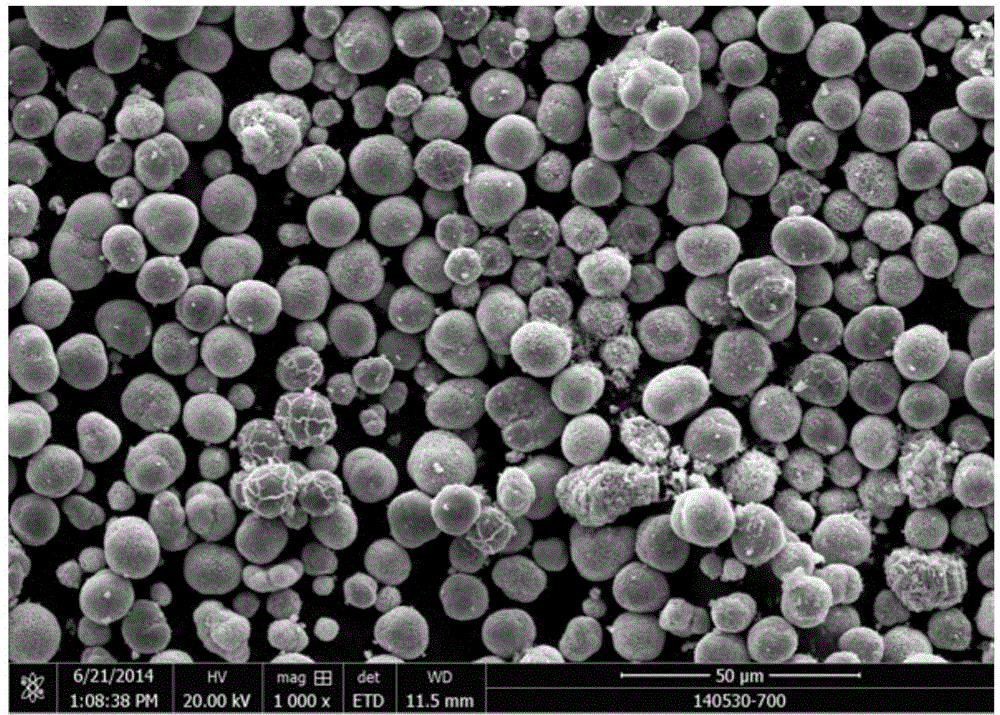

[0026] The preparation method of doped cobalt carbonate in the above-mentioned embodiment separates the process of preparing cobalt carbonate and doping, so that the doping process will not affect the growth of cobalt carbonate particles, and it is easy to control the morphology and particle size growth of cobalt carbonate, and can prepare Cobalt carbonate doped with uniform particle size, uniform coating and large particle size.

[0027] Specifically, the metal alkoxide solution is at least one of magnesium ethoxide solution, aluminum ethoxide solution ...

Embodiment 1

[0059] Step S01: preparing cobalt carbonate. The process of step S01 includes the following specific steps:

[0060] Step S01-1: Prepare the base solution.

[0061] Use pure water and ammonium bicarbonate as the bottom solution, control the carbonate concentration in the bottom solution to 3g / L, and the temperature at 48°C.

[0062] Step S01-2: Prepare cobalt salt solution and ammonium bicarbonate solution.

[0063] Preparation cobalt salt concentration is the cobalt salt solution of 60g / L, and ammonium bicarbonate concentration is the ammonium bicarbonate solution of 100g / L.

[0064] Step S01-3: preparing cobalt carbonate wet material.

[0065] According to the molar ratio of the cobalt salt in the cobalt salt solution and the ammonium bicarbonate in the ammonium bicarbonate solution is 1:2, the cobalt salt solution and the ammonium bicarbonate solution are added into the bottom liquid in parallel and reacted under stirring conditions to obtain a cobalt carbonate wet mater...

Embodiment 2

[0077] Step S01: preparing cobalt carbonate. The process of step S01 includes the following specific steps:

[0078] Step S01-1: Prepare the base solution.

[0079] Use pure water and ammonium bicarbonate as the bottom liquid, control the carbonate concentration in the bottom liquid to 5g / L, and the temperature to 36°C.

[0080] Step S01-2: Prepare cobalt salt solution and ammonium bicarbonate solution.

[0081] Preparation cobalt salt concentration is the cobalt salt solution of 180g / L, and ammonium bicarbonate concentration is the ammonium bicarbonate solution of 300g / L.

[0082] Step S01-3: preparing cobalt carbonate wet material.

[0083] According to the molar ratio of the cobalt salt in the cobalt salt solution and the ammonium bicarbonate solution in the ammonium bicarbonate solution is 1:3, the cobalt salt solution and the ammonium bicarbonate solution are added into the bottom liquid in parallel and reacted under stirring conditions to obtain a cobalt carbonate wet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com