Modified lithium ion battery positive electrode material and preparation method therefor

A lithium-ion battery, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as battery flatulence, hindering the charge transfer process at the interface of electrode materials, affecting the electrochemical performance of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

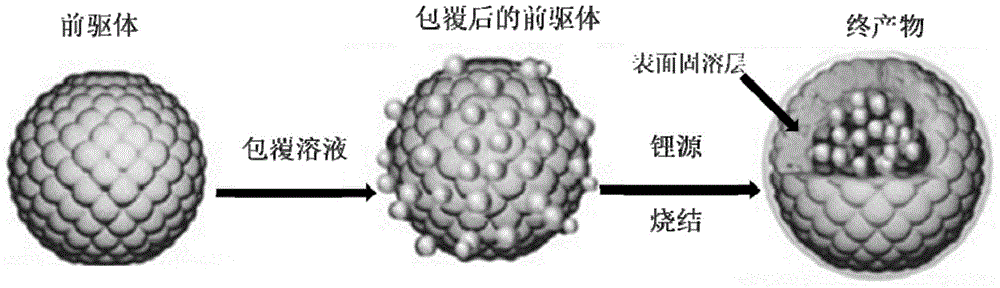

[0039] The present invention also provides a kind of preparation method of modified lithium-ion battery cathode material, is characterized in that, comprises the following steps:

[0040] a), the Ni 0.8 co 0.15 al 0.05 (OH) 2.05 After ultrasonic dispersion with the first solvent, the first solution is obtained;

[0041] b) Mix the first solution obtained in the above steps with the second solution, obtain a third solution after ultrasonic dispersion, and then dry to obtain a mixed powder; the second solution includes an aqueous solution or an ethanol solution of the coating ;

[0042] c), calcining after mixing the above-mentioned mixed powder with the lithium source compound to obtain a positive electrode material for a modified lithium-ion battery;

[0043] In the present invention, Ni 0.8 co 0.15 al 0.05 (OH) 2.05 After ultrasonically dispersing with the first solvent, the first solution is obtained; the first solvent is preferably one or more of water, ethanol and...

Embodiment 1

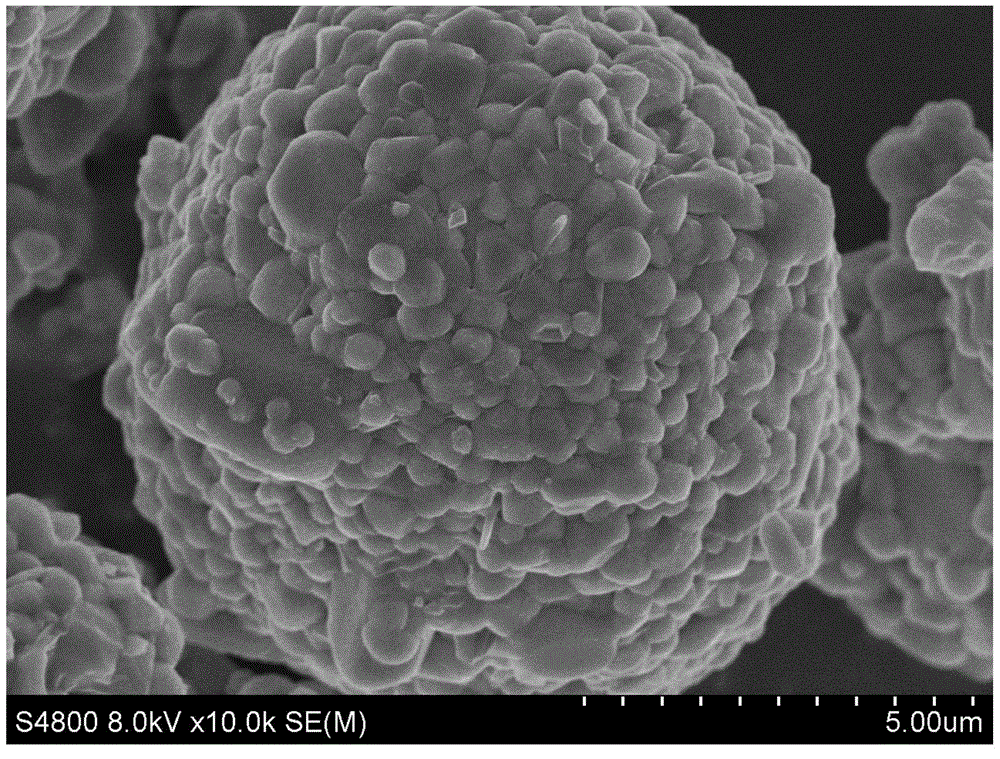

[0064] First, 1.38g of Ni 0.8 co 0.15 Al 0.05 (OH) 2.05 and 20mL of absolute ethanol for 30min ultrasonic dispersion to obtain the first solution.

[0065] Then weigh 0.8976g of isopropyl titanate and 0.3034g of acetylacetone to prepare 20ml of absolute ethanol solution to obtain the second solution; take 15ml of the second solution and drop it into the first solution, and ultrasonically disperse it for 30min to obtain the third solution; the third solution was magnetically stirred in a water bath at 40°C, and after the solvent evaporated, the powder was dried in a vacuum oven at 120°C for 4 hours to obtain a mixed powder.

[0066] Then weigh 0.5749g of Li 2 CO 3 Grind and mix with the above mixed powder, place the mixed powder in a vacuum tube furnace, and 3 / h in an oxygen-enriched atmosphere, pre-calcined at 3°C / min to 500°C for 6h, then raised to 750°C at 1°C / min for 12h, and finally annealed at 2°C / min to 500°C for 3h, and obtained 0.98LiNi after cooling 0.8 co 0....

Embodiment 2

[0072] First, 1.38g of Ni 0.8 co 0.15 Al 0.05 (OH) 2.05 and 15 mL of deionized water for ultrasonic dispersion for 30 min to obtain the first solution.

[0073] Then weigh 0.2049g of LiOH·H 2 O was made into 25ml aqueous solution to obtain the aqueous solution of the hydrolysis initiator, and then weighed 0.5809g of NH 4 h 2 PO 4 Make 25ml of aqueous solution to obtain the aqueous solution of the coating; take 1.5ml of the aqueous solution of the coating and drop it into the first solution, ultrasonically disperse it for 30 minutes, and then drop it into the aqueous solution of the hydrolysis initiator to obtain the third solution; put the third solution in Stir magnetically in a water bath at 40°C. After the solvent evaporates, dry the powder in a vacuum oven at 120°C for 4 hours to obtain a mixed powder.

[0074] Then weigh 0.5708g of Li 2 CO 3 Grind and mix with the above-mentioned dried powder, put the mixed powder in a vacuum tube furnace, under the oxygen flow o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com