Carbon nano tube/graphene composite negative pole material, preparation method thereof and lithium battery

A graphene composite and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of composite material structure instability, low electronic conductivity, long process cycle, etc., achieve fast heating speed and reduce production costs , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

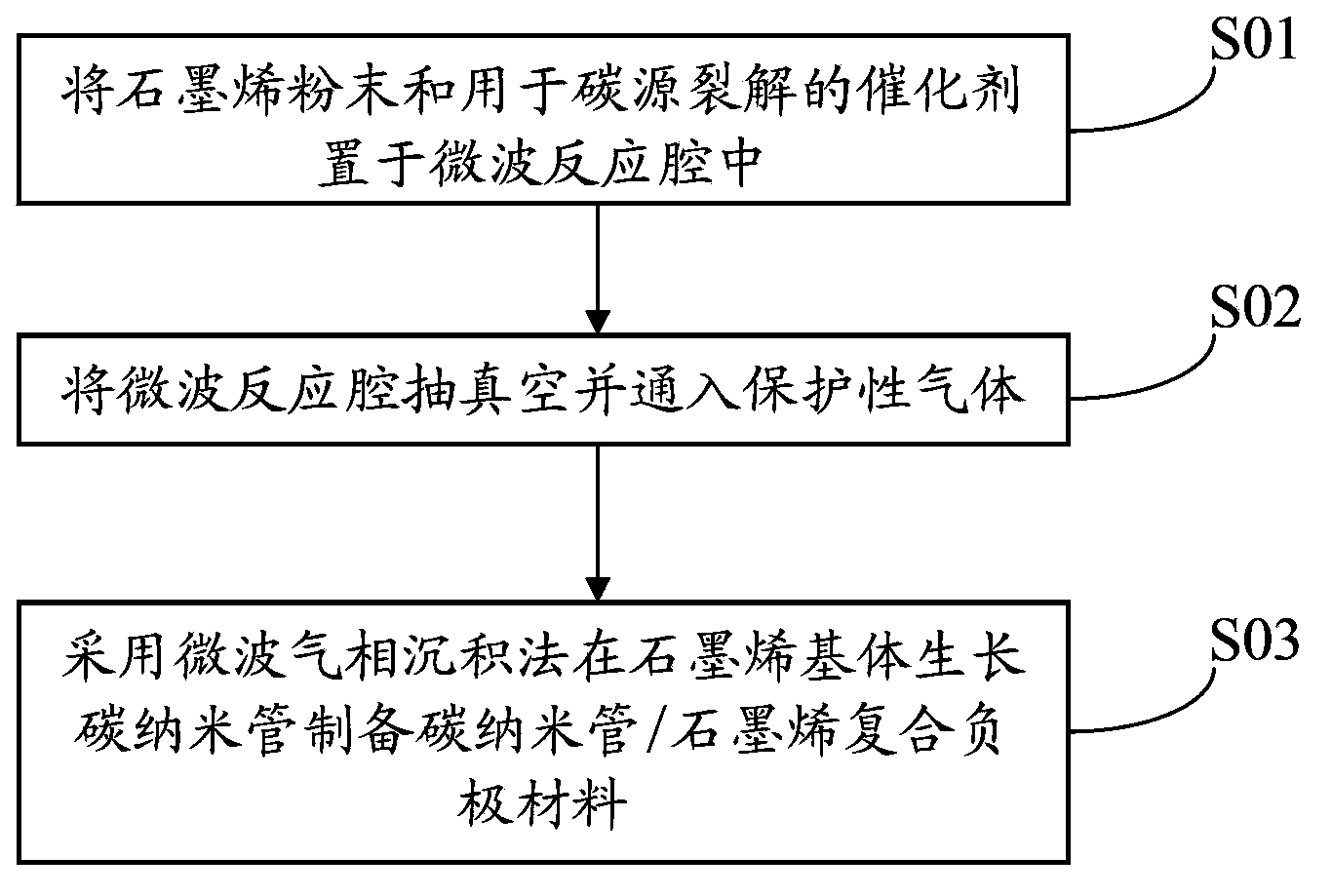

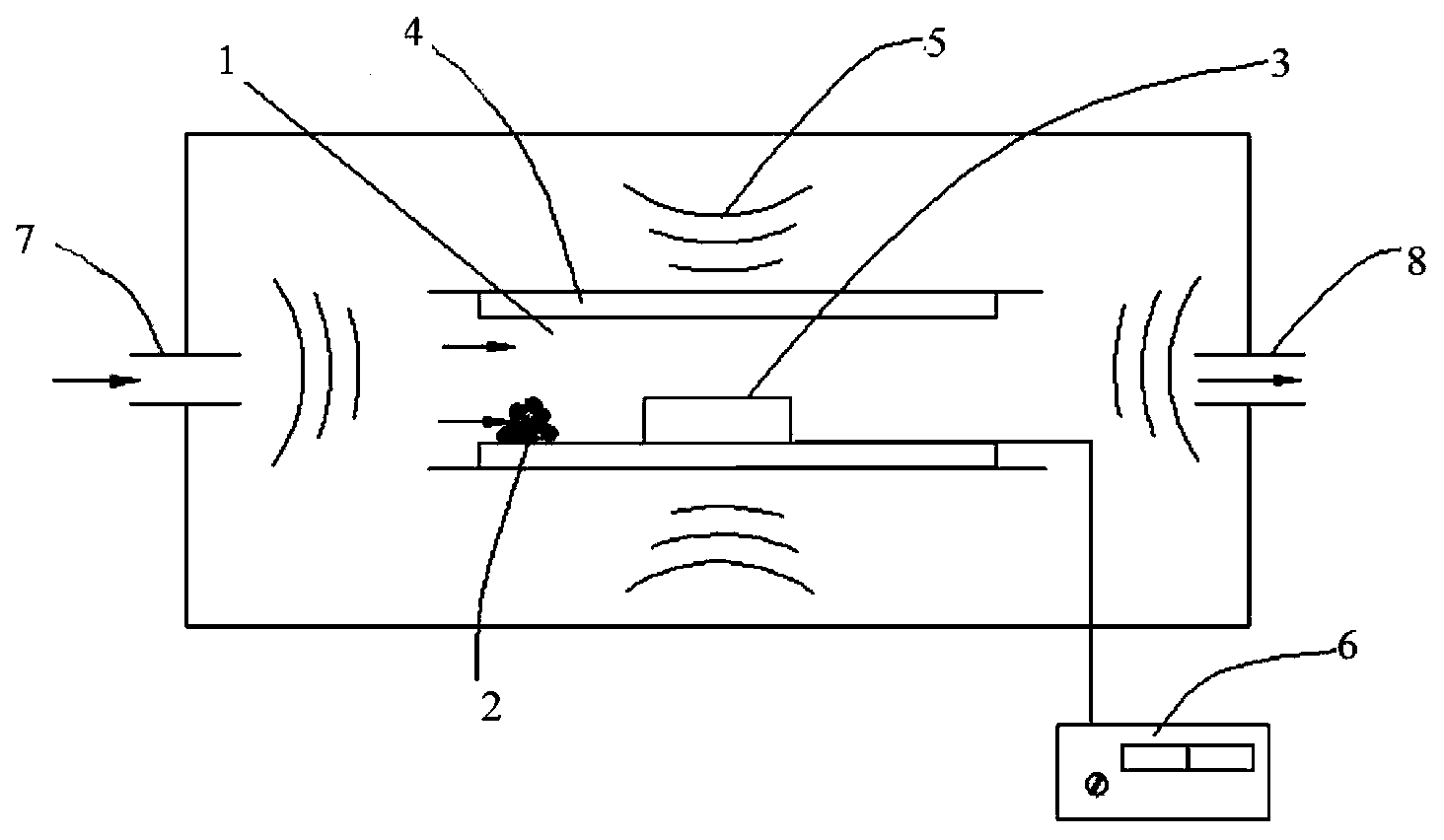

[0022] The example of the present invention provides a method for preparing a carbon nanotube / graphene composite negative electrode material with high efficiency, low cost and stable structure. The technology of this carbon nanotube / graphene composite negative electrode material preparation method is as follows figure 1 As shown, it includes the following steps:

[0023] Step S01. Place the graphene powder and the catalyst for carbon source cracking in the microwave reaction chamber; wherein, the graphene powder is placed in the central area of the microwave reaction chamber, and the catalyst is placed at the gas inlet end of the microwave reaction chamber ;

[0024] Step S02. Vacuumize the microwave reaction chamber and inject protective gas into it;

[0025] Step S03. Using microwave vapor deposition to grow carbon nanotubes on graphene substrates to prepare carbon nanotube / graphene composite anode materials: use microwaves to heat the reaction chamber to 400-1000°C, and...

Embodiment 1

[0046] The preparation method of the carbon nanotube / graphene composite negative electrode material of the present embodiment comprises the following specific steps:

[0047] 1) In this example, 0.2g of graphene is selected and dried in an oven at 100°C;

[0048] 2) In this example, 20mg of ferrocene was selected and dried in an oven at 80°C;

[0049] 3) Place the dried ferrocene and graphene in the front and center of the reaction chamber respectively, vacuumize to make the absolute pressure in the furnace lower than 1kPa, pass nitrogen to normal pressure and then vacuum, repeat this process three times. Before turning on the microwave, flow nitrogen gas into the reaction chamber to remove the oxygen remaining in the reaction chamber;

[0050] 4) Heat the reaction chamber with microwaves. When the temperature rises rapidly to the reaction temperature of 600°C, open the valve of the gas flow bottle, and feed methane gas and nitrogen gas at a volume ratio of 1:4, with a total ...

Embodiment 2

[0052] The preparation method of the carbon nanotube / graphene composite negative electrode material of the present embodiment comprises the following specific steps:

[0053] 1) In this example, 0.5g of graphene is selected and dried in an oven at 100°C;

[0054] 2) In this example, 60mg of ferrocene was selected and dried in an oven at 80°C;

[0055] 3) Place the dried ferrocene and graphene in the front and center of the reaction chamber respectively, vacuumize to make the absolute pressure in the furnace lower than 1kPa, pass nitrogen to normal pressure and then vacuum, repeat this process three times. Turn on the microwave and go to the reaction chamber to pass flowing nitrogen gas first to remove the oxygen remaining in the reaction chamber;

[0056] 4) Heat the reaction chamber with microwaves. When the temperature rises rapidly to the reaction temperature of 800°C, open the valve of the gas flow bottle, and feed methane gas and nitrogen gas at a volume ratio of 1:1, wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com