Temperature rise analytical method for predicting temperature of permanent magnet in permanent magnet synchronous motor

A permanent magnet synchronization and analysis method technology, applied in the direction of motor generator testing, thermometers, measuring devices, etc., can solve the problems of permanent magnet heating, high conductivity, poor heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The principle and specific implementation of the present invention will be described below in conjunction with the accompanying drawings.

[0051] Table 1 is the parameters and material properties of the simulated motor used in the embodiment of the present invention, which is a test motor.

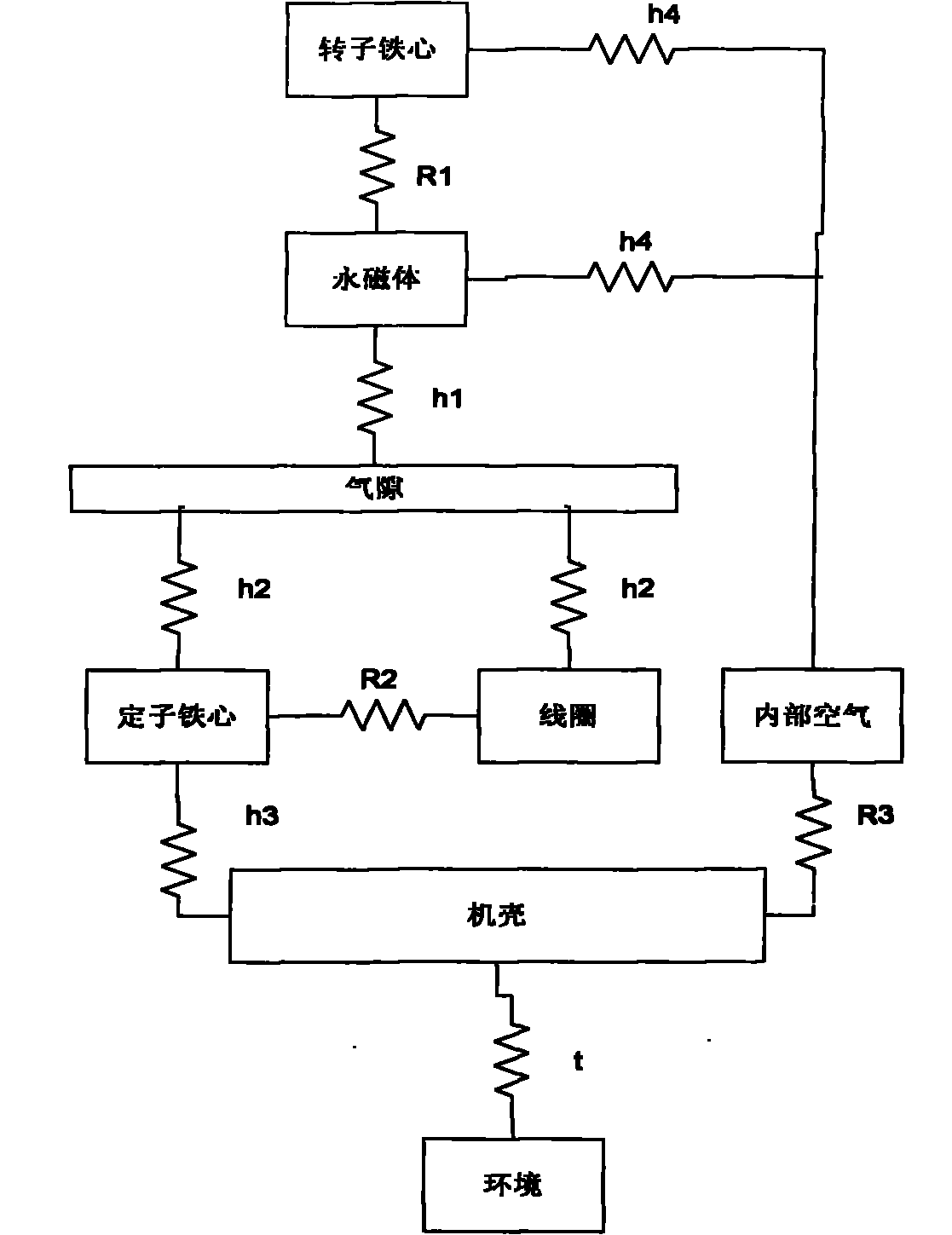

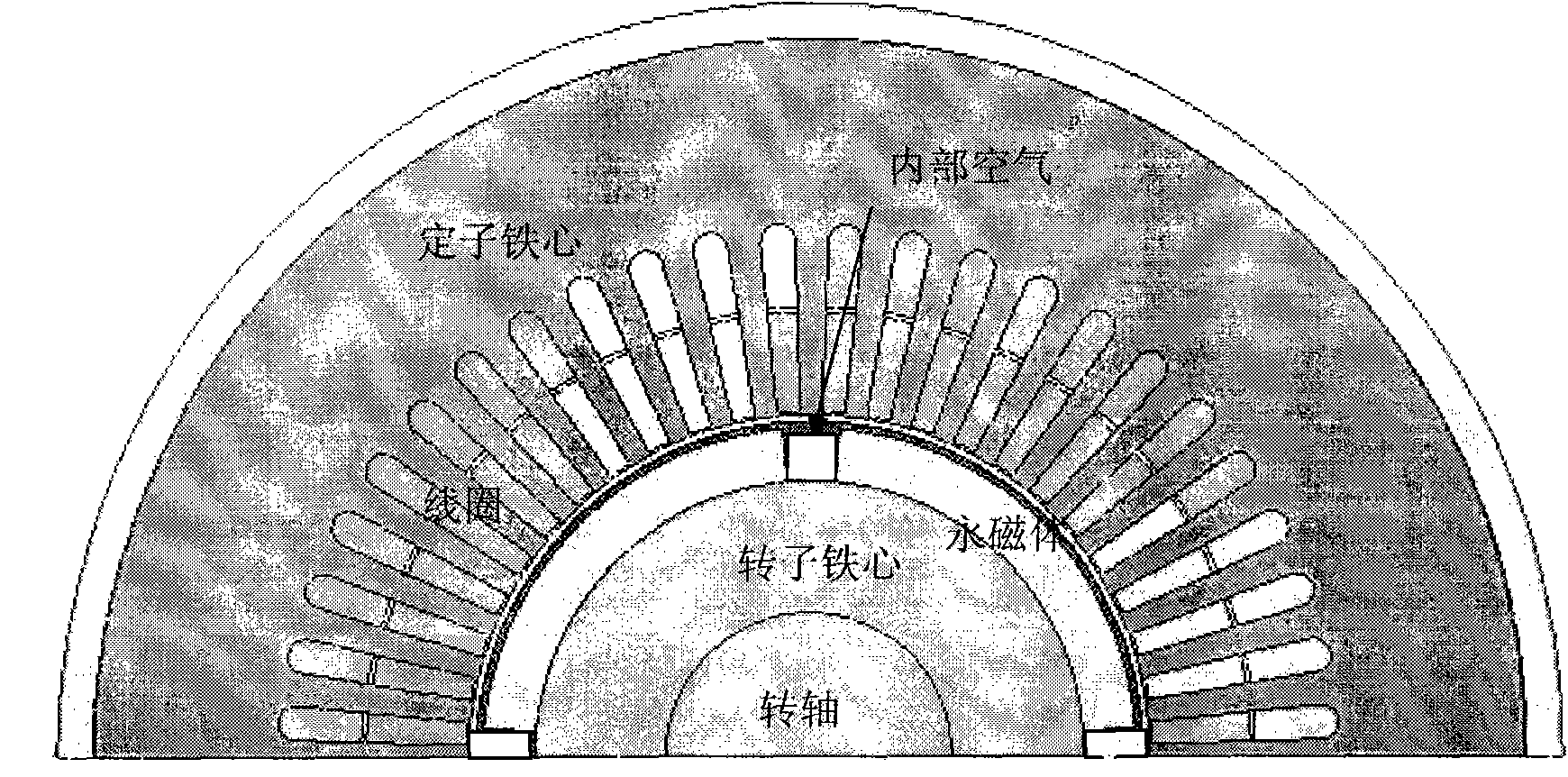

[0052] figure 1 is the equivalent thermal network combined with the finite element model selected in the embodiment of the present invention. Each module is the corresponding finite element part of each component in the motor, and they are connected with each other through various thermal elements, forming an organic whole. The main heat flow paths are: most of the eddy current loss heat source in the permanent magnet will flow to the stator core through forced convection with the air gap and then flow to the casing, and a small part of it will be transferred to the casing through convection with the internal air; the copper in the coil The loss and iron loss in the stator core w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com