Indoor vehicle ABS test-bed with variable adhesion coefficient

A technology of adhesion coefficient and test bench, which is used in vehicle testing, machine/structural component testing, force/torque/work measuring instruments, etc. The effect of saving test site costs, accurate test results, and convenient performance testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

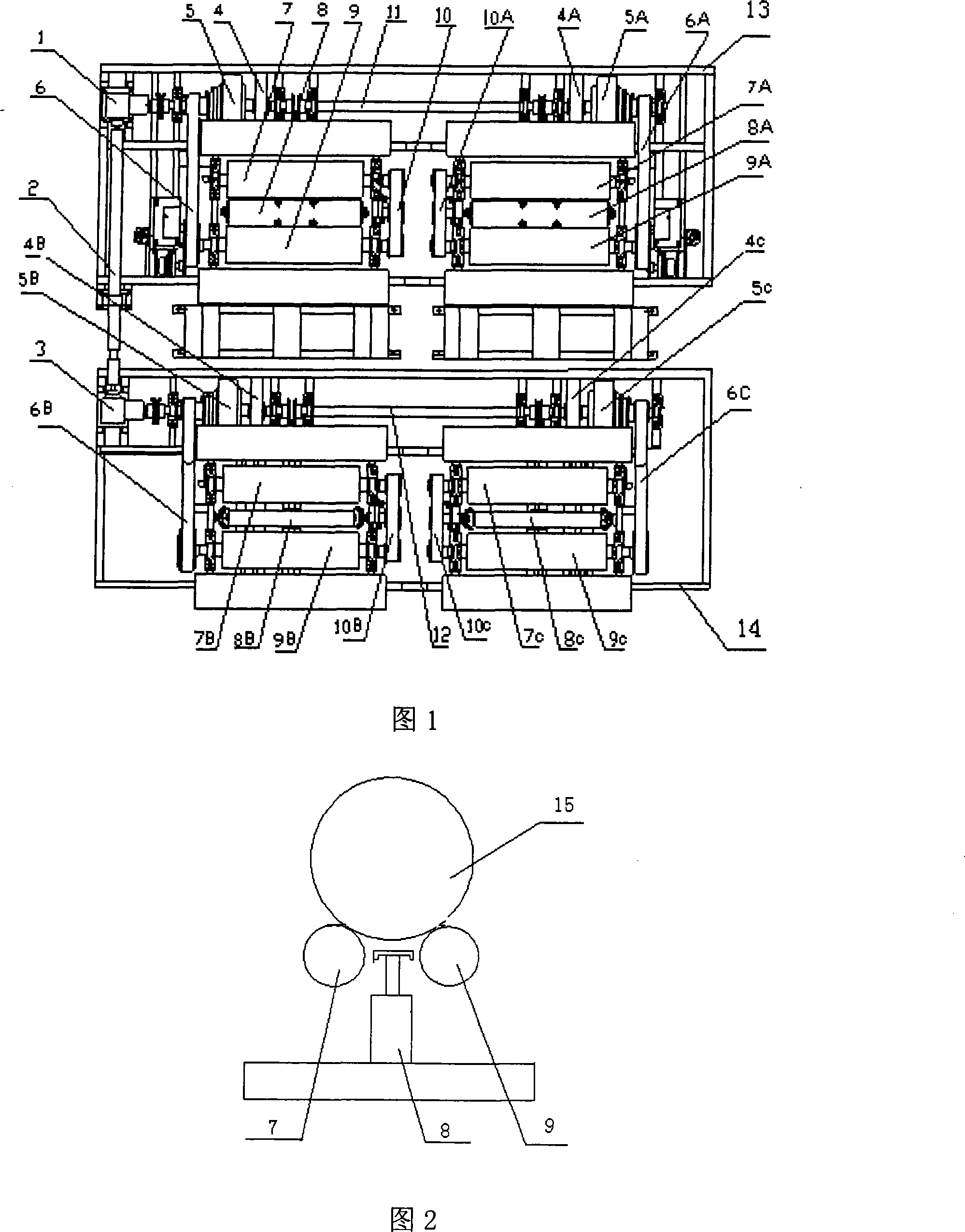

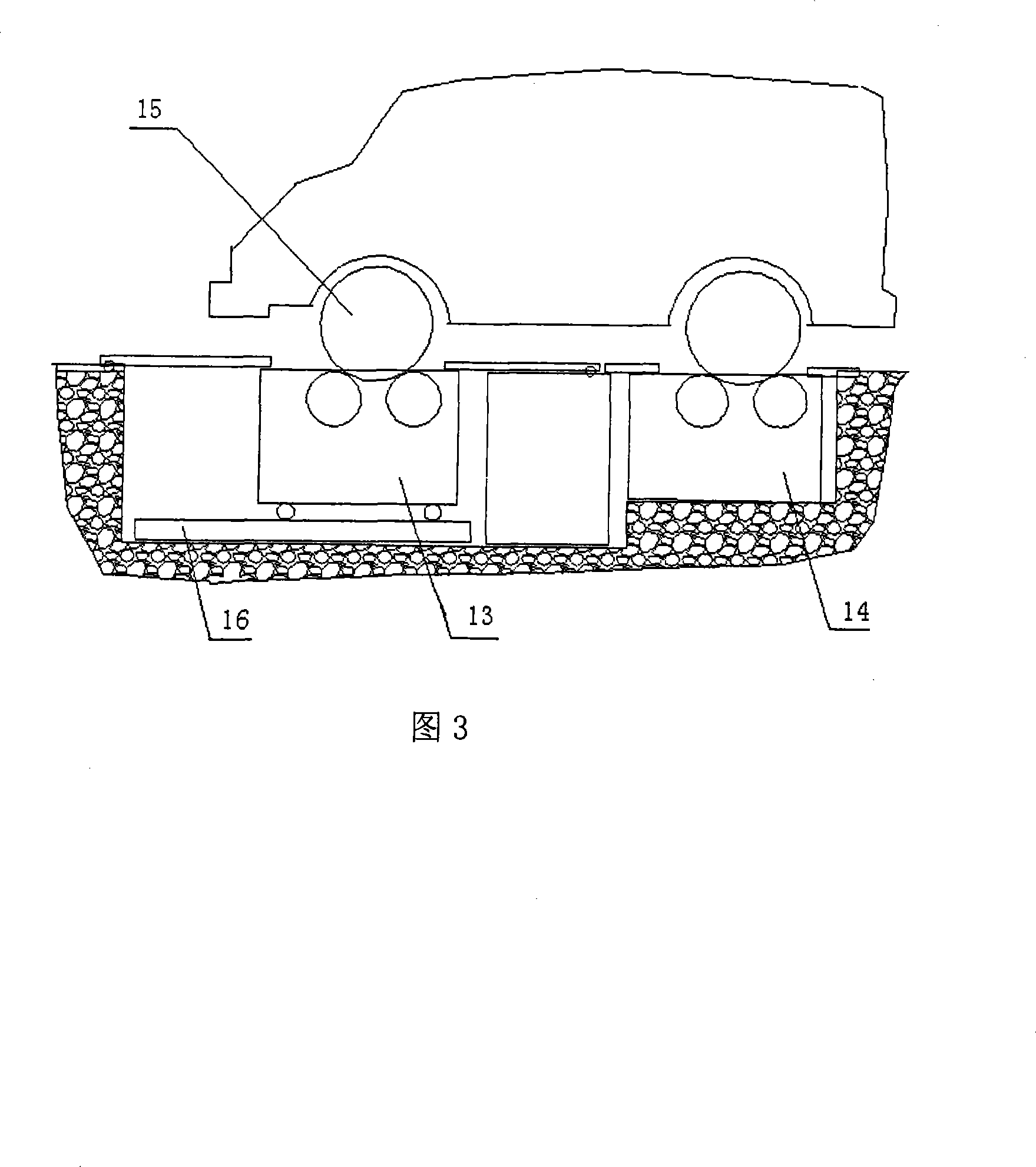

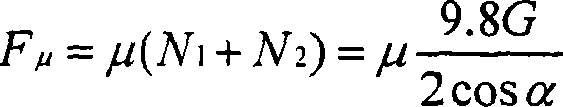

[0036] Referring to Fig. 1, the front and rear shaft frames 13 and 14 of the test bench are respectively symmetrically installed with exactly the same front left wheel, front right wheel, rear left wheel, and rear right wheel roller groups, and each roller group passes through the toothed transmission belt 6, 6A, 6B, 6C are connected to the output ends of the corresponding torque controllers 5, 5A, 5B, 5C, and the input ends of each torque controller are respectively rigidly connected to the corresponding front and rear flywheel shafts 11, 12. The front and rear flywheel shafts 11, 12 is connected with the telescopic transmission shaft 2 through the transmission box 1, 3 to realize mutual synchronization, and the rigidity and symmetry of the front and rear flywheel shafts 11, 12 are installed with four flywheels 4, 4A, 4B, 4C with the same moment of inertia, which are used to simulate waiting Measure the kinetic energy of the vehicle. The torque controller adopts the magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com