Preparation of micro-nano structure bionics valve, surface congeal-resistance and drag reduction testing method thereof

A technology of bionic valves and micro-nano structures, which is applied in the field of medical implants, can solve problems such as film or coating shedding and affect performance, and achieve the effect of stable surface structure, preventing the formation of thrombus, and not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

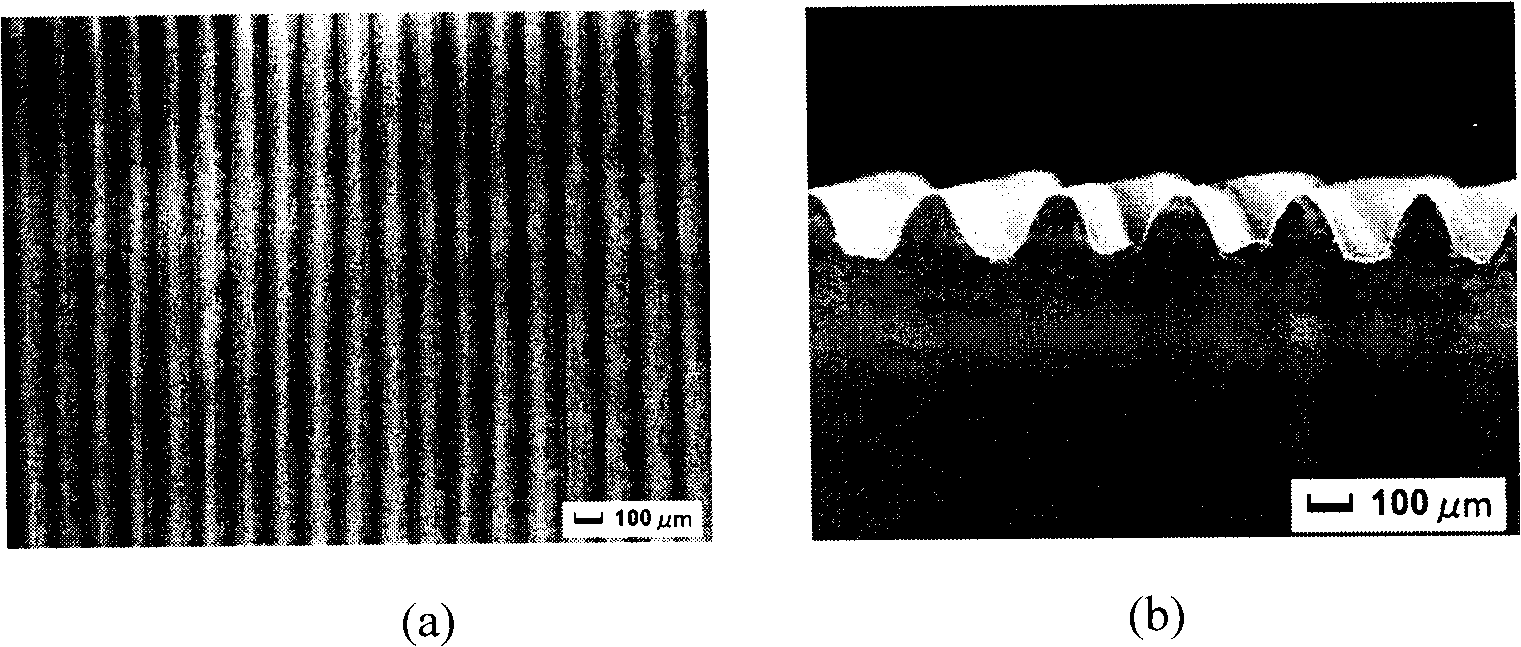

[0024] Example 1: Artificial heart valve with grating structure

[0025] 1. Design of microstructure of valve surface

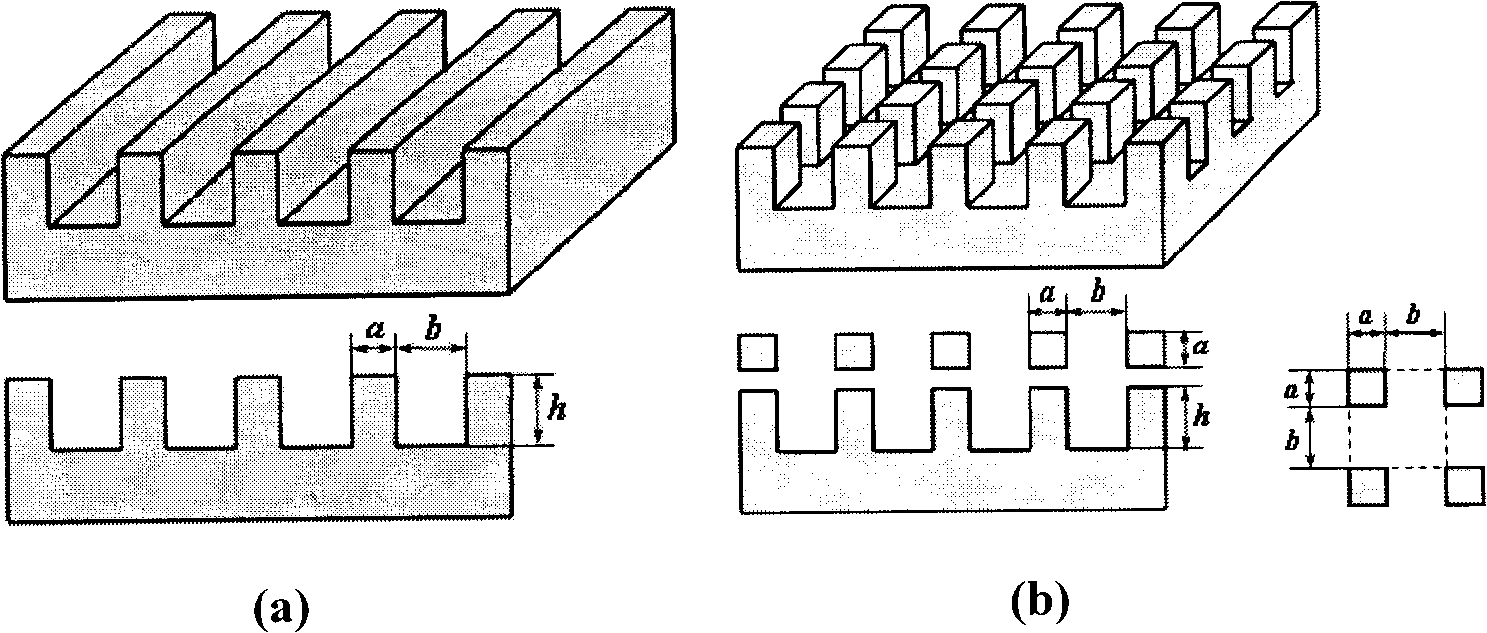

[0026] Grating structure parameters such as figure 1 As shown in (a), a and b are the ridge width and groove width of the grating, respectively, and h is the ridge depth. According to the formula of Wenzel theory and Cassie theory in classical wetting theory cos θ r w = r cos θ e , cos θ r C = - 1 + f ( cos θ e + 1 ) The relationship between the geometric parameters of the valve surface and the apparent contact angle of the grating fine structure can be determined as

[0027] ...

Embodiment 2

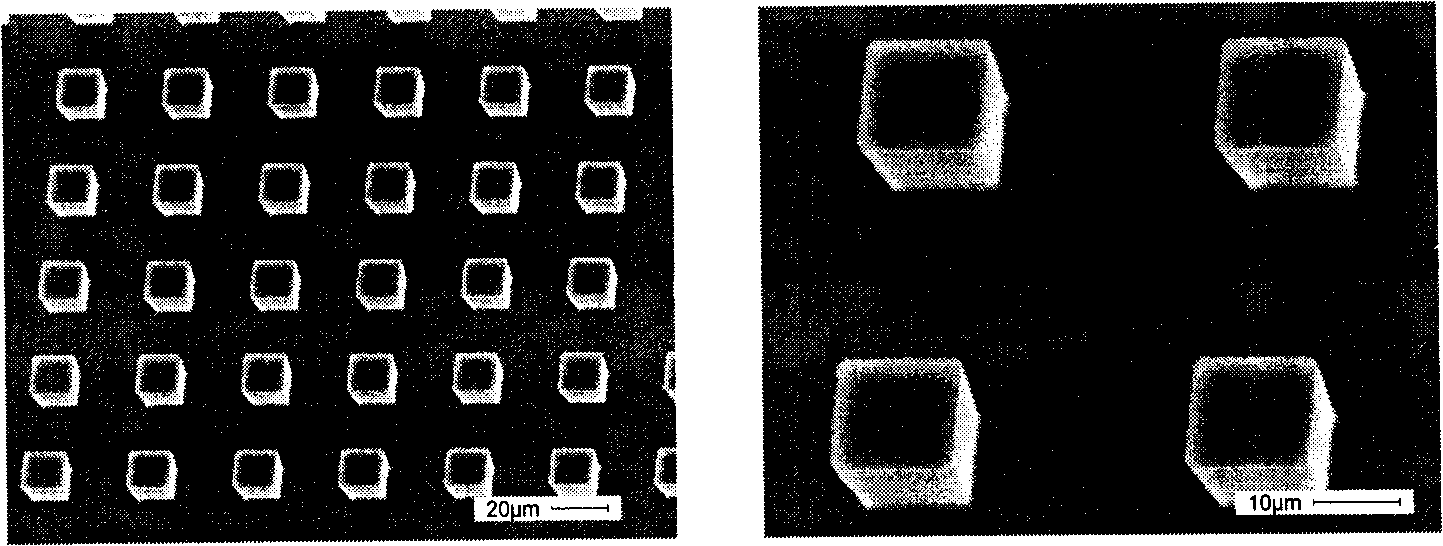

[0046] Example 2: Prosthetic heart valve with square microcolumn structure

[0047] 1. Design of microstructure of valve surface

[0048] The structural parameters of periodic regular arrangement of square micropillars are as follows: figure 1 As shown in (b), a is the side length of the square column, b is the distance between the square columns, and h is the height of the square column (that is, the depth of the groove). According to the Wenzel formula cos θ r w = r cos θ e and the Cassie formula, cos θ r C = - 1 + f ( cos θ e + 1 ) The relationship between the geometric parameters and the apparent contact angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com