SLA (stereo lithography) technology of light curing stereo homocentric sphere

A molding process and technology of concentric spheres, which is applied in the field of SLA molding technology of light-cured three-dimensional concentric spheres, can solve the problems of complex post-processing, adding more supports, and affecting the appearance of products, so as to achieve convenient post-processing, increase product hardness, and beautify products surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

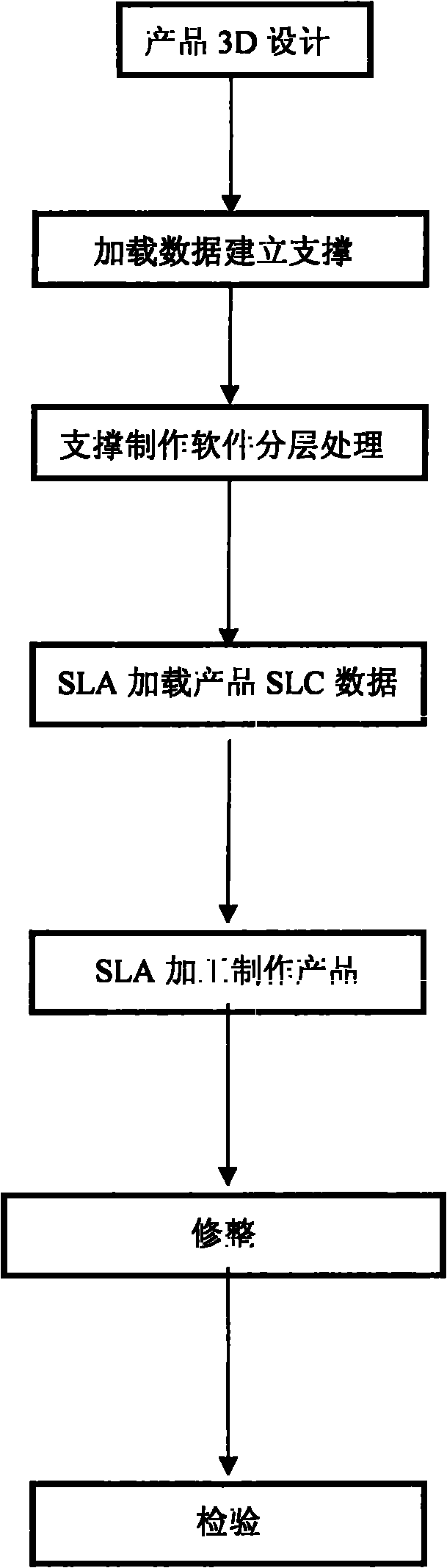

[0019] Depend on figure 1 Known, a kind of SLA molding process of light-cured three-dimensional concentric sphere, comprises the following steps: 1, utilize 3D modeling software to carry out 3D design to product (concentric sphere), design finishes, export its STL data.

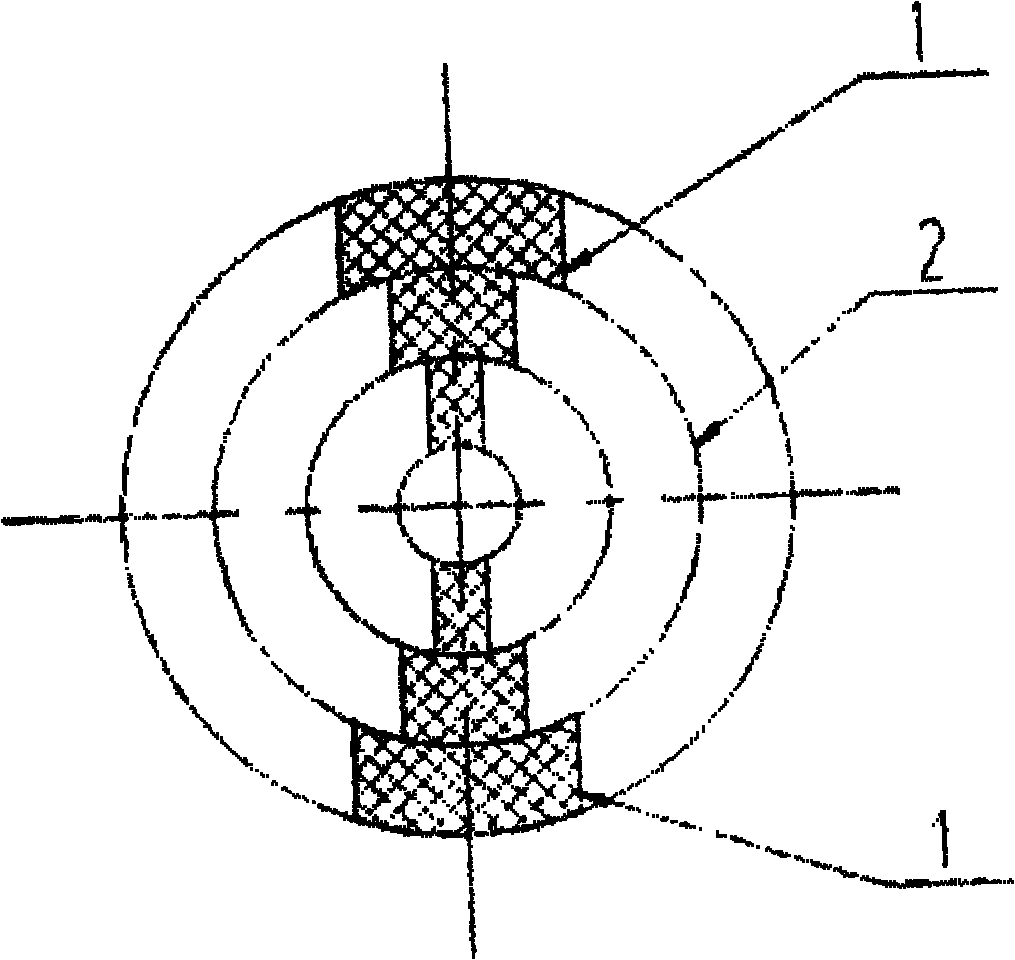

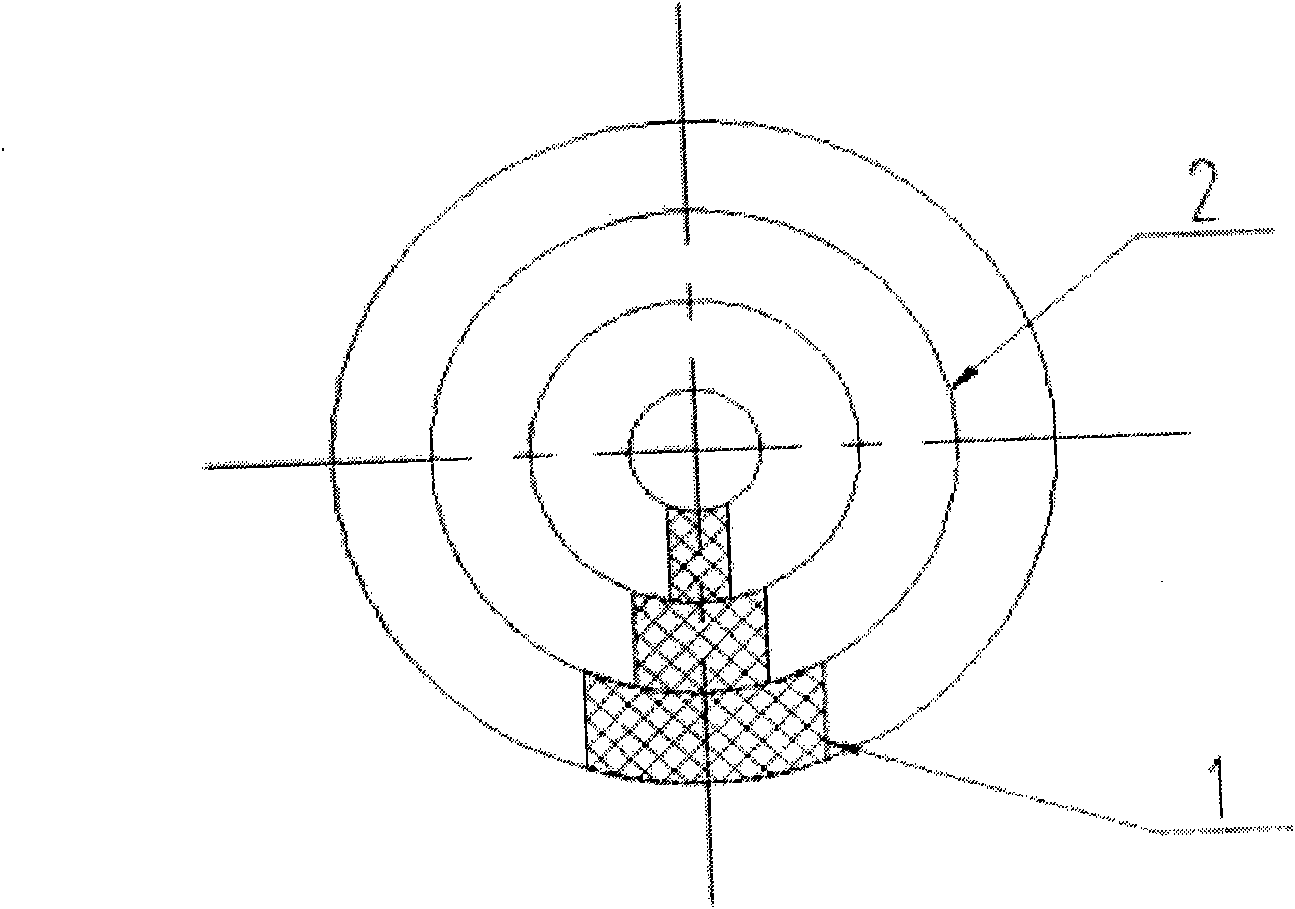

[0020] 2. Open the STL data of the concentric spheres in the support production software (RPData), place the product in the center, and place the side with the product wall thickness on each concentric sphere facing down, and then build the support. The bottom surface of each ball is provided with a small number of supports, and the supports are firm, which is convenient for post-processing and can reduce the cost of the product. (The improved support structure diagram is shown in the attached figure 2 ); After layered processing, simulate the product processing situation, check whether the support of the product is reasonable, and whether there are potential safety hazards, and export the product SLC file ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com