Process of precious metal recovery and color removal from an organosilicon product-containing liquid reaction medium

A liquid reaction, precious metal technology that is commercially viable and economical to solve problems such as the recovery of precious metal catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

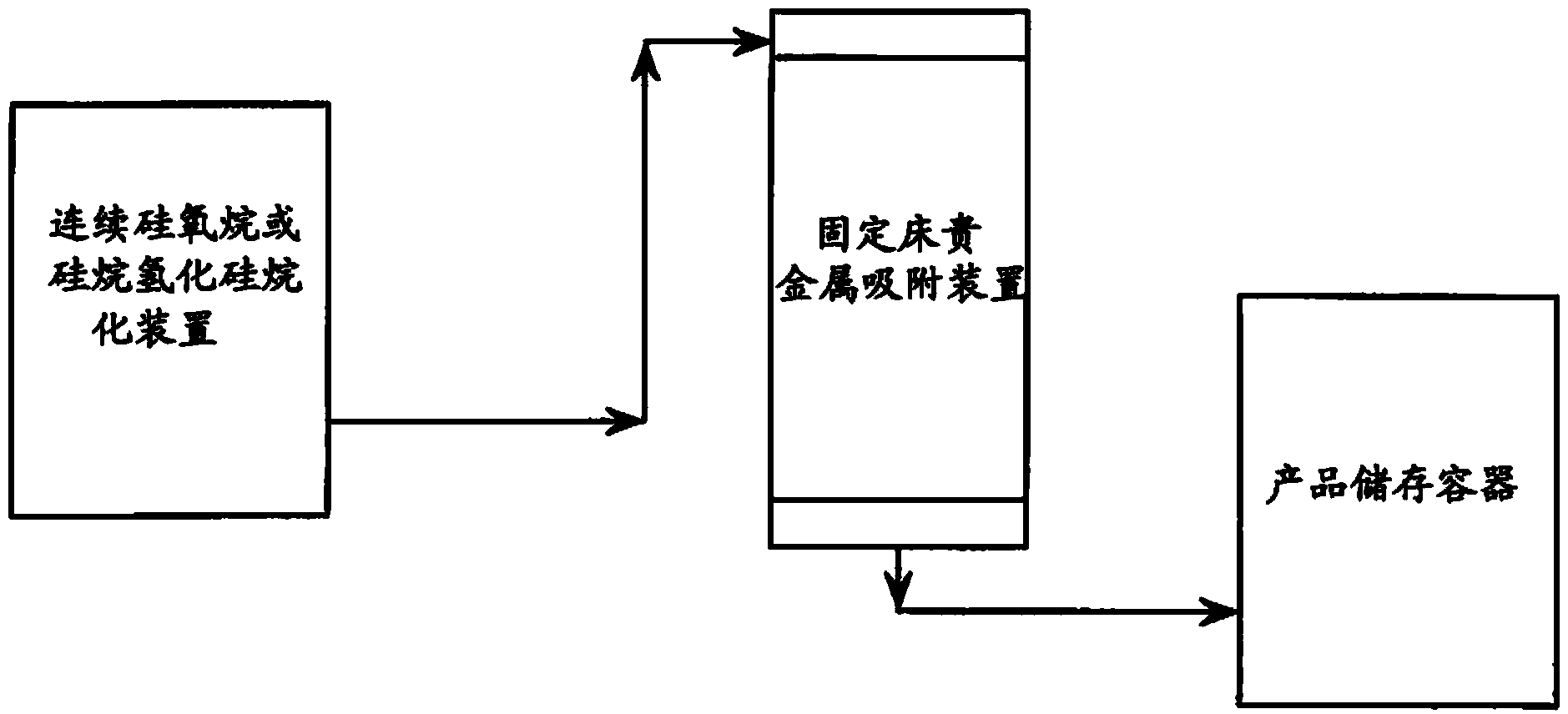

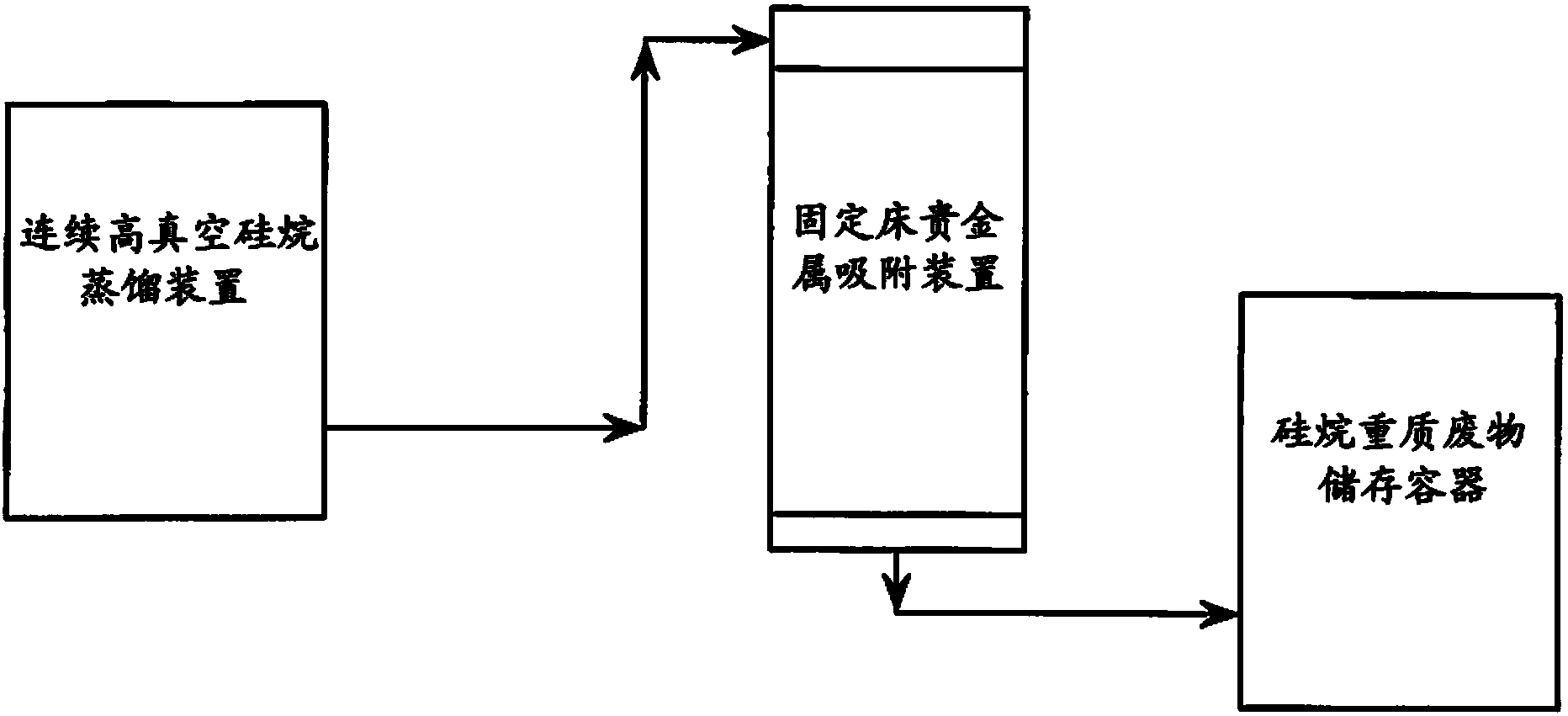

[0023] According to one embodiment of the present invention, directly at the source of the liquid reaction medium containing the noble metal catalyst containing the organosilicon product, such as a continuous siloxane copolymer device, a continuous silane hydrosilylation device or a continuous silane distillation device and product or waste storage When a fixed-bed precious metal adsorption device is installed between the vessels, the liquid reaction medium containing the organic silicon product passes through the source of the liquid reaction medium containing the organic silicon product and is directly fed into the fixed-bed precious metal adsorption device. The fixed-bed precious metal adsorption device and pipe between the source of the liquid reaction medium containing the organic silicon product and the fixed-bed precious metal adsorption device are insulated to maintain the high temperature of the liquid reaction medium, thereby adsorbing the precious metal onto the adsorb...

Embodiment 1A-1D

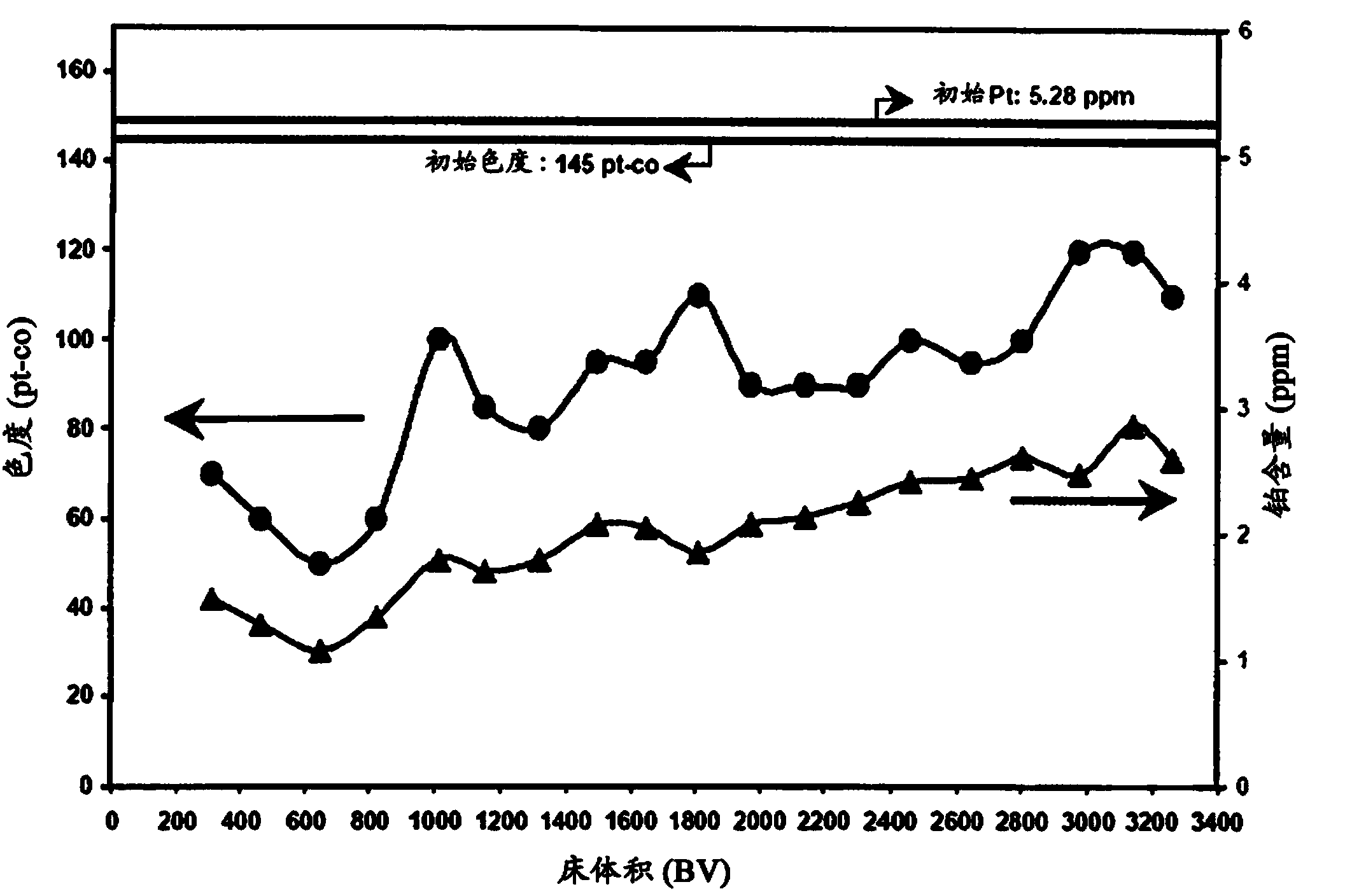

[0057] In Examples 1A-1D, a fixed bed adsorption device with the above specifications was used to treat siloxane-A at a specific temperature and residence time. The fixed-bed adsorption device with the above specifications is directly placed between the siloxane-A feed reservoir (that is, a continuous siloxane manufacturing device in large-scale commercial production) and the product storage container for siloxane liquid The reaction medium continuously passes through a fixed bed adsorption device to recover precious metals. Example 1A used relatively high temperature and relatively long residence time for recovery studies. Example 1B uses a shorter residence time than Example 1A to study the residence time effect. Example 1C uses a lower temperature than Example 1B to study the temperature effect. Example 1D used the same conditions as Example 1B, but the experiment was conducted with an extended period of time to study the durability of the adsorbent and evaluate the achiev...

Embodiment 1A

[0059] The recovery of platinum from the product siloxane-A by means of fixed bed adsorption treatment was completed at 75°C and a residence time of 74 minutes. In this experiment, 8.8Kg (BV=142) of siloxane-A was processed by a fixed bed adsorption device with the above specifications, and the result was:

[0060] Platinum content after treatment: 0.37ppm (recovery rate=93.0%)

[0061] Product color after treatment: 40pt-co

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| packed density | aaaaa | aaaaa |

| rate of recovery | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com