Double-component low-hardness silicone rubber and preparation method thereof

A low-hardness, two-component technology, applied in the field of silicone rubber manufacturing, can solve the problems of inability to meet various use requirements, influences, single components of low-hardness silicone rubber, etc., to achieve easy operation, improve tensile strength and tear resistance. Strength, simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

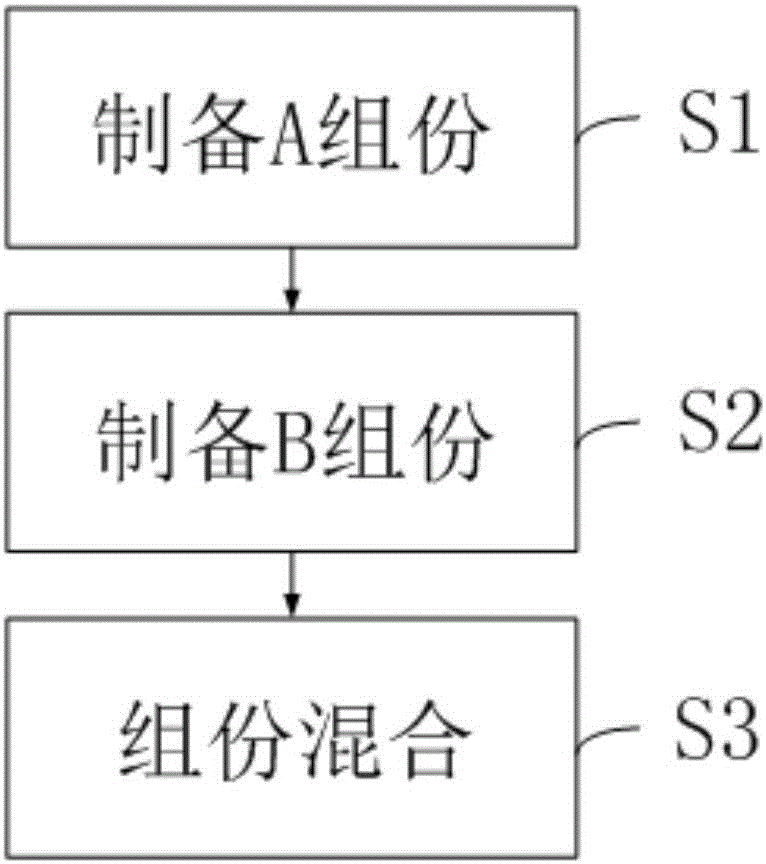

[0028] A two-component low-hardness silicone rubber, the preparation method of which is as follows:

[0029] (1) Preparation of component A

[0030] ①Mix 100Kg of octamethylcyclotetrasiloxane and 1.5Kg of tetramethyldivinyldisiloxane, add 0.2Kg of catalyst tetramethylammonium hydroxide under stirring state, heat up to 120°C and polymerize for 4 hours , and then raised the temperature to 200°C, delowering the molecule for 6 hours under a vacuum of 0.08-0.09MPa, and obtained vinylpolysiloxane after cooling, with a viscosity of 11000mPa.s and a vinyl content of 0.42%.

[0031] ②Add 300Kg of vinyl polysiloxane, 34Kg of hexamethylsilazane and 240Kg of the specific surface area to 380m2 into a 1000L kneader 2 / g fumed silica powder, stir to form a group and continue to stir at room temperature for 2 hours; heat up to 160-170°C, stir for 3 hours under vacuum 0.8MPa, then stop the vacuum, add 100Kg vinyl polysiloxane after cooling down; add 1. 28Kg platinum complex, stir evenly to o...

example 2

[0039] A two-component low-hardness silicone rubber, the preparation method of which is as follows:

[0040] (1) Preparation of component A

[0041]①Mix 100Kg of octamethylcyclotetrasiloxane and 1.5Kg of tetramethyldivinyldisiloxane, add 0.2Kg of catalyst tetramethylammonium hydroxide under stirring state, heat up to 120°C and polymerize for 4 hours , and then raised the temperature to 200°C, delowering the molecule for 6 hours under a vacuum of 0.08-0.09MPa, and obtained vinylpolysiloxane after cooling, with a viscosity of 11000mPa.s and a vinyl content of 0.42%.

[0042] ②Add 290Kg of vinyl polysiloxane, 28.76Kg of hexamethylsilazane and 203Kg of the specific surface area to 380m2 into a 1000L kneader 2 / g fumed silica powder, stir at room temperature and continue to stir for 2 hours after stirring into agglomerates; raise the temperature to 160-170°C, stir for 3 hours under a vacuum of 0.8MPa, then stop the vacuum, add 183.67Kg vinyl polysiloxane after cooling down; Add 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com