Rubber sheet dewatering device

A film and the same technology are applied in the direction of progressive dryers, dryers, lighting and heating equipment, etc., which can solve the problems of high noise, high energy consumption of water removal by air pumps, and low-energy water removal devices, so as to achieve convenient maintenance and avoid High-power motor, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

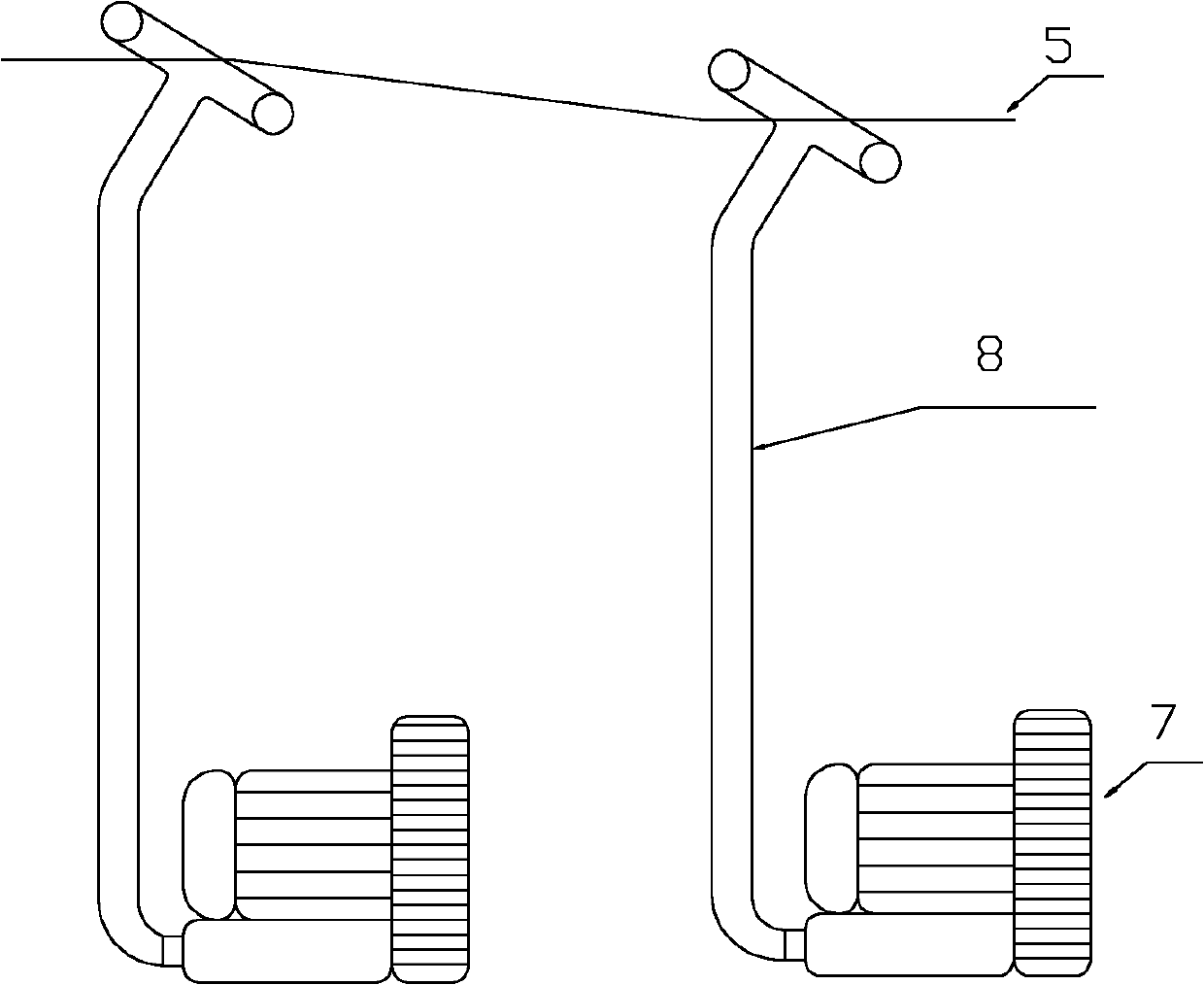

[0021] combine Figure 4 and Figure 5 , Figure 4 is the schematic diagram of the existing water removal device, Figure 5 It is a partially enlarged schematic diagram of the existing water removal device. It can be known that the existing water removal device generally dries the water on the film through the airflow generated by the vortex air pump. The power of the air pump is about 4kW. Sometimes two air pumps are needed to ensure the effect. The air pump dewaters high energy consumption and noise.

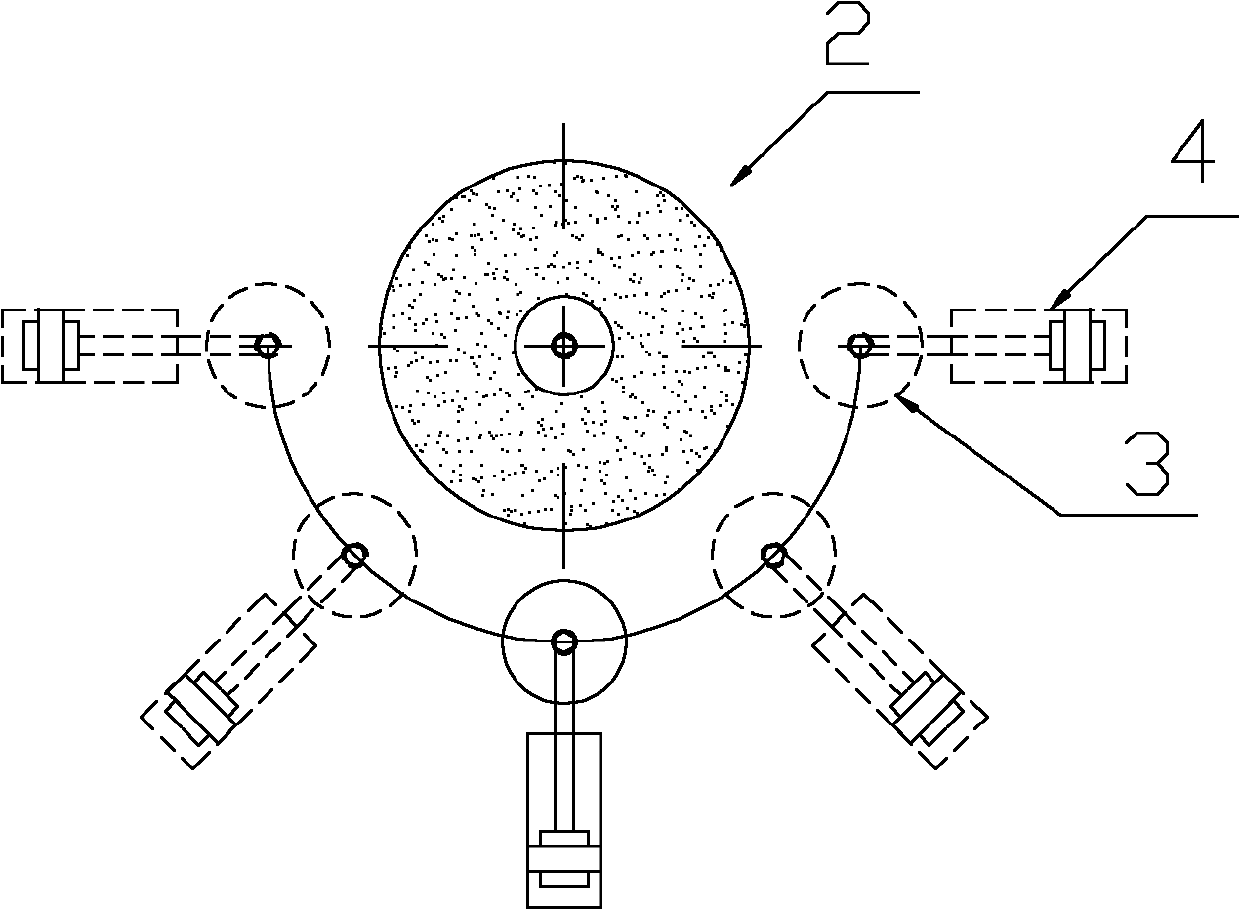

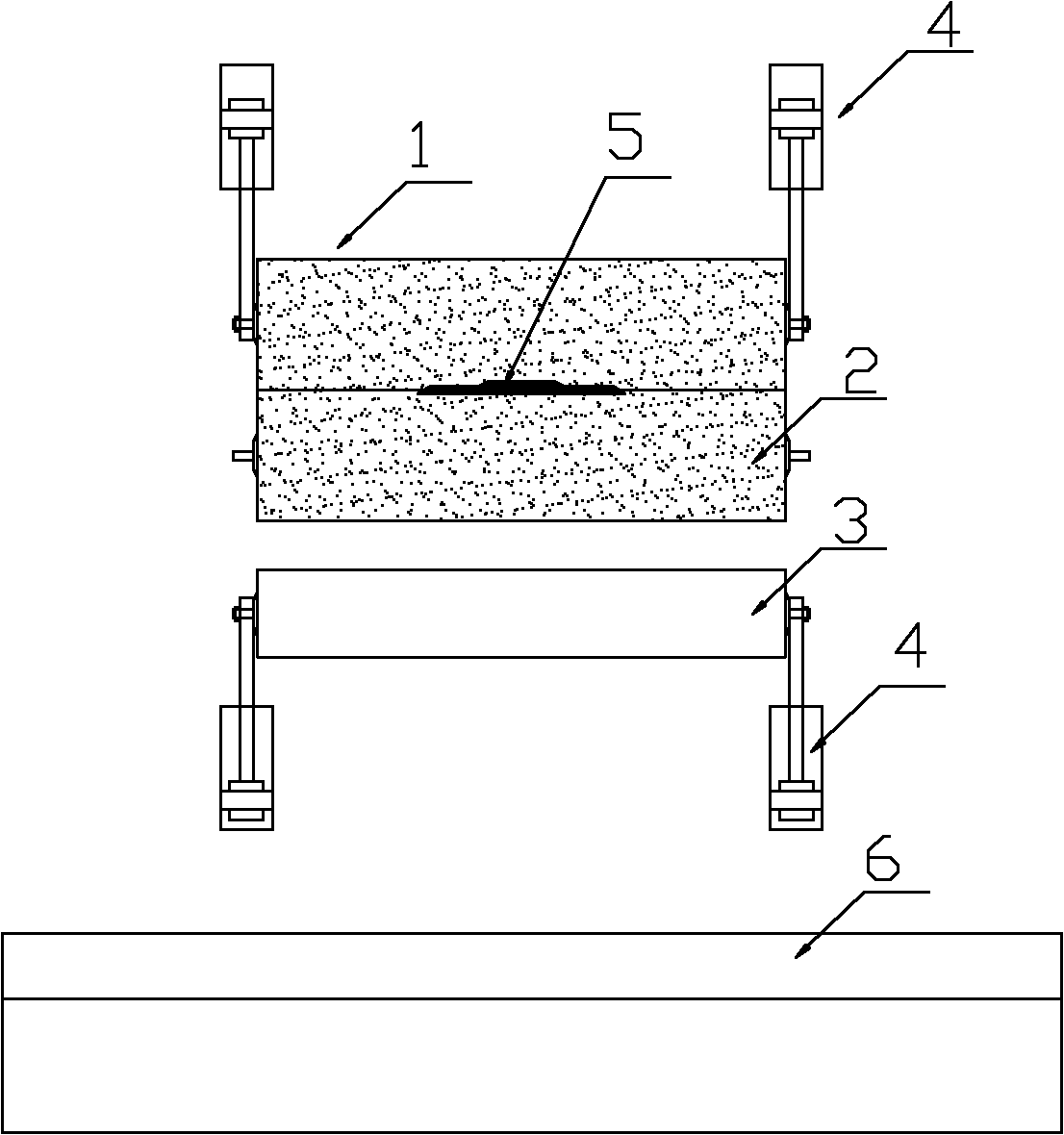

[0022] combine Figure 1 to Figure 3 , figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a schematic diagram of the lateral structure of the present invention, image 3 It is a schematic diagram of the position and state of the squeezing roller of the present invention. In this example, the upper water absorption pressure roller 1 is composed of sponge wrapped on the shaft surface, the upper water absorption pressure roller 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com