Flexible pouch filling and heat sealing line for flexible pouches and containers for supporting and moving the flexible pouches

a technology for flexible pouches and heat sealing lines, which is applied in the direction of food preservation, containers, tray containers, etc., can solve the problems of spoiling products, unusable products, and difficult handling, and achieve the effect of facilitating the transmission of light and facilitating the determination of whether the seal has been properly formed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

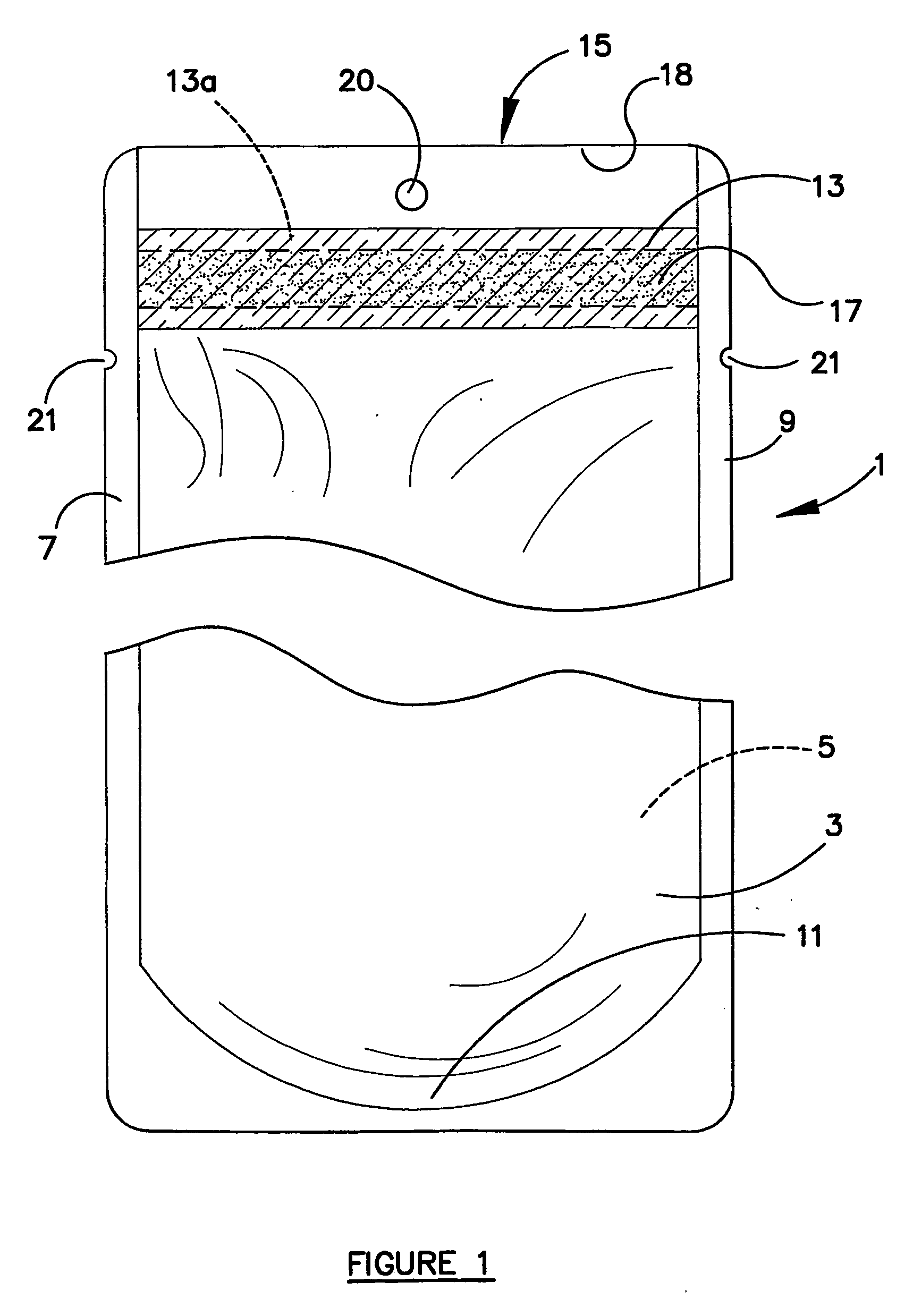

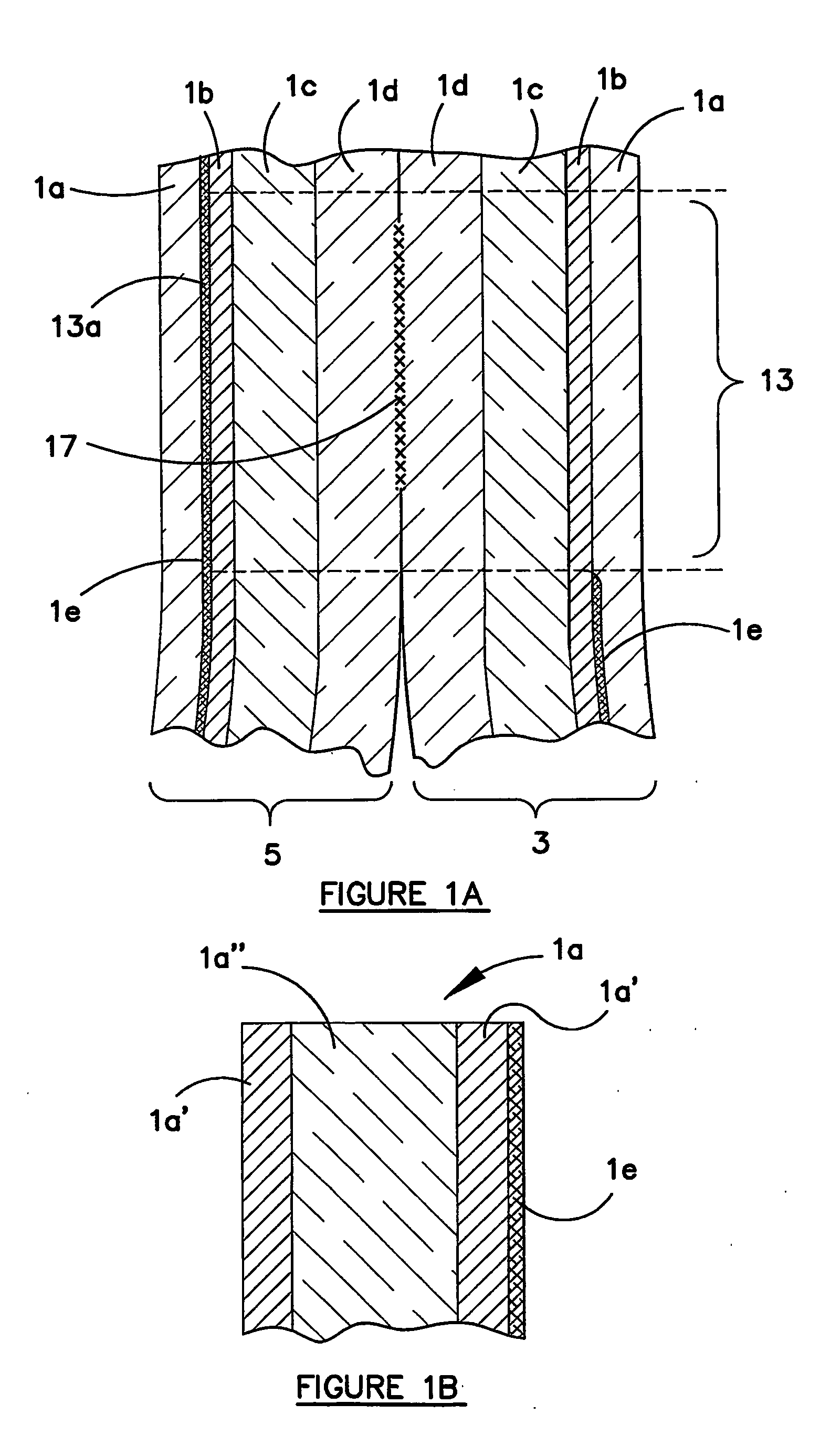

[0265] With reference to FIG. 1, a front view of a flexible pouch, also called a doy pouch or pillow pouch, is shown. The pouch 1 has a front panel 3 and an opposite rear panel 5. The panels 3 and 5 are coupled together along the opposite edges 7 and 9 by heat sealing the panels together or by any other suitable method of connecting the panels 7 and 9 along their opposed edges. A gusset 11 is provided in the base of the pouch and is also joined to the front and back panels 3 and 5. The panels 3 and 5 and the gusset 11 may be formed from a single piece of material, or alternatively, can be formed from three separate pieces of material. The pouch 1 is closed by sealing the panels 3 and 5 together to form a seal 17. Preferably this is achieved by a heat sealing technique, but other sealing methods could be used. The above described pouch structure is known and therefore does not need to be defined in any further detail. In other embodiments, the gusset need not be provided and the pouc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wave length | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com