Preparation method of artificial rock core of jointing shale

An artificial core and rational technology, applied in the field of preparation of jointed shale artificial core, can solve the problem that the length and size of artificial core cannot meet the experimental requirements, and achieve the effect of simple operation, efficient development, and simple materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

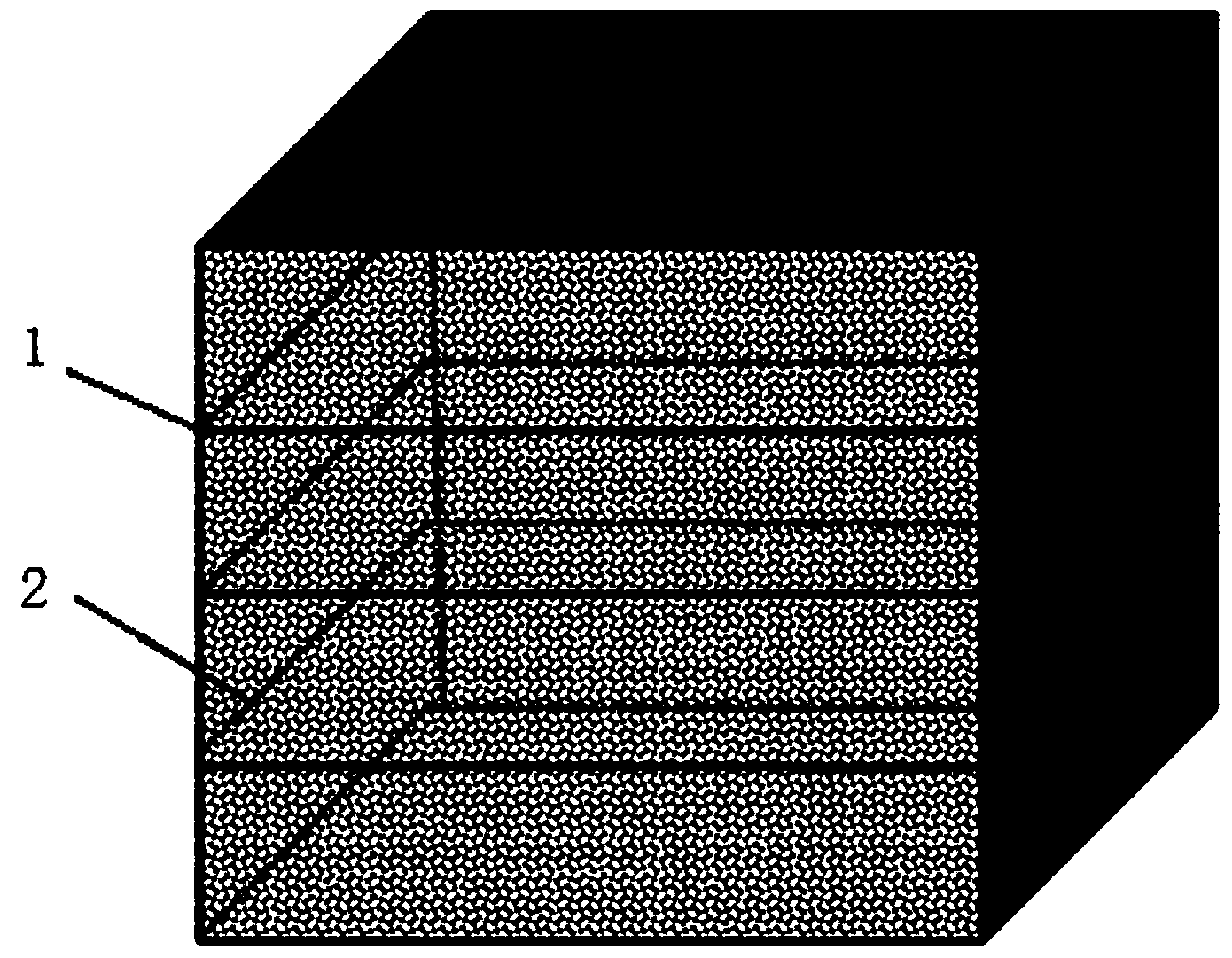

[0033] A method for preparing a jointed shale artificial core, comprising the steps of:

[0034] (1) Mix cement, quartz sand, clay and gypsum powder;

[0035] (2) Add a small amount of oatmeal, shredded paper to the mixture in step (1), add water and stir evenly;

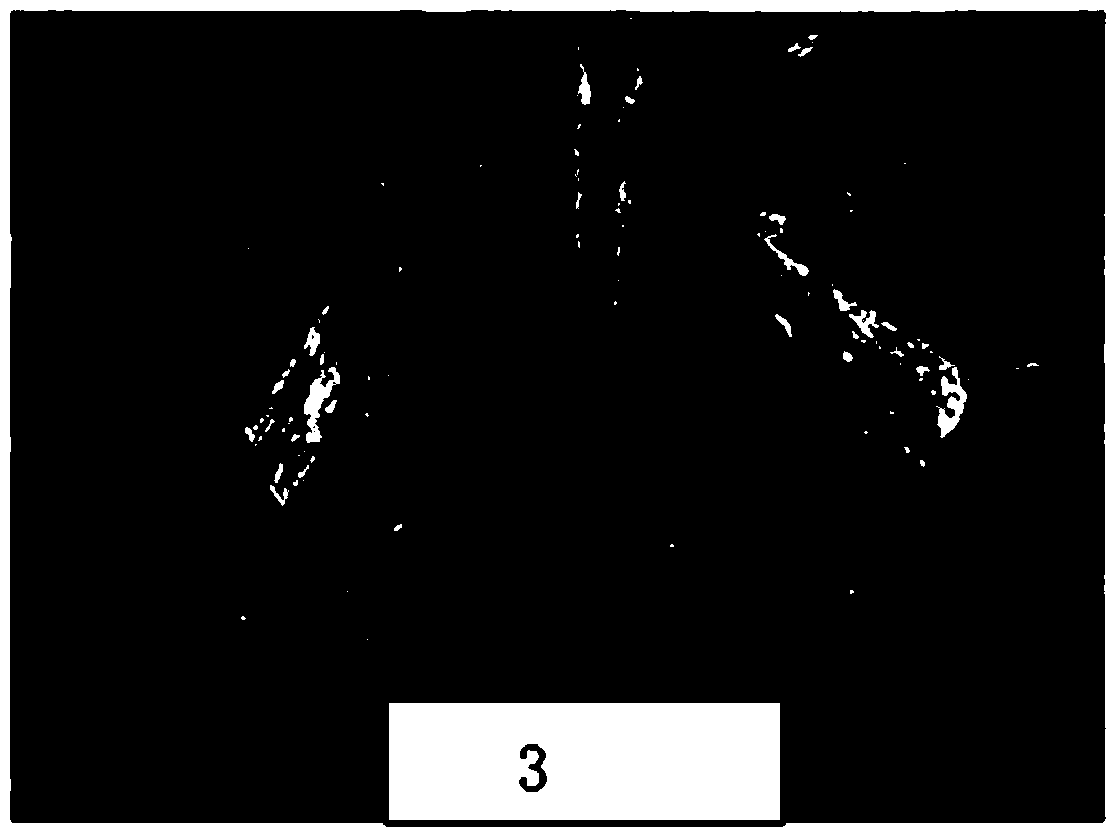

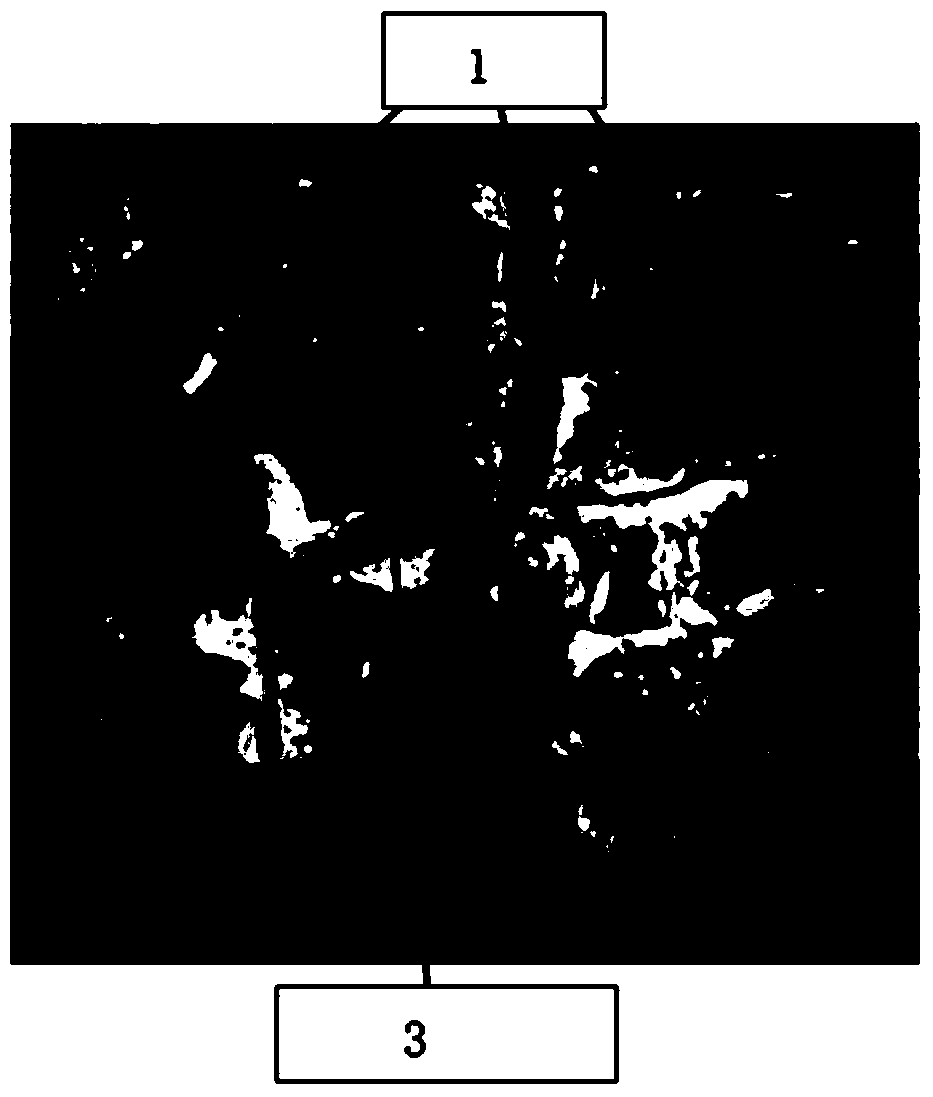

[0036] (3) The mixture in step (2) is cast into cement samples in layers, and a layer of lubricating oil is applied between the layers. After the cement samples are dried and formed, the jointed shale artificial core can be obtained.

[0037] In this embodiment, the volume ratio of the cement, quartz sand, clay, and gypsum powder is 4.5:4.5:1:1.

[0038] In this embodiment, the mass percentage of the oatmeal in the artificial core is 0.1%.

[0039] In this embodiment, the mass percentage of the shredded paper pieces in the artificial core is 0.05%.

[0040] In this embodiment, the water accounts for 19% by mass of the artificial core.

[0041] In this embodiment, the cement is composite Portland cement. The com...

Embodiment 2

[0053] A method for preparing a jointed shale artificial core, comprising the steps of:

[0054] (1) Mix cement, quartz sand, clay and gypsum powder;

[0055] (2) Add a small amount of oatmeal, shredded paper to the mixture in step (1), add water and stir evenly;

[0056](3) The mixture in step (2) is cast into cement samples in layers, and a layer of lubricating oil is applied between the layers. After the cement samples are dried and formed, the jointed shale artificial core can be obtained.

[0057] In this embodiment, the volume ratio of the cement, quartz sand, clay, and gypsum powder is 4: 5:0.8:0.8.

[0058] In this embodiment, the mass percentage of the oatmeal in the artificial core is 0.12%.

[0059] In this embodiment, the mass percentage of the shredded paper pieces in the artificial core is 0.1%.

[0060] In this embodiment, the water accounts for 18% by mass of the artificial core.

[0061] In this embodiment, the cement is composite Portland cement. The com...

Embodiment 3

[0072] A method for preparing a jointed shale artificial core, comprising the steps of:

[0073] (1) Mix cement, quartz sand, clay and gypsum powder;

[0074] (2) Add a small amount of oatmeal, shredded paper to the mixture in step (1), add water and stir evenly;

[0075] (3) The mixture in step (2) is cast into cement samples in layers, and a layer of lubricating oil is applied between the layers. After the cement samples are dried and formed, the jointed shale artificial core can be obtained.

[0076] In this embodiment, the volume ratio of the cement, quartz sand, clay, and gypsum powder is 5: 4: 1.2: 1.2.

[0077] In this embodiment, the mass percentage of the oatmeal in the artificial core is 0.2%.

[0078] In this embodiment, the mass percentage of the shredded paper pieces in the artificial core is 0.06%.

[0079] In this embodiment, the water accounts for 20% by mass of the artificial core.

[0080] In this embodiment, the cement is composite Portland cement. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com