Low-density and high-strength cement paste

A high-strength cement slurry and low-density technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems that the cement slurry cannot maintain the design density, the comprehensive performance of the cement slurry deteriorates, and cannot meet the engineering needs, etc., to achieve The thickening time is adjustable, the formation pollution is small, and the effect of widening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

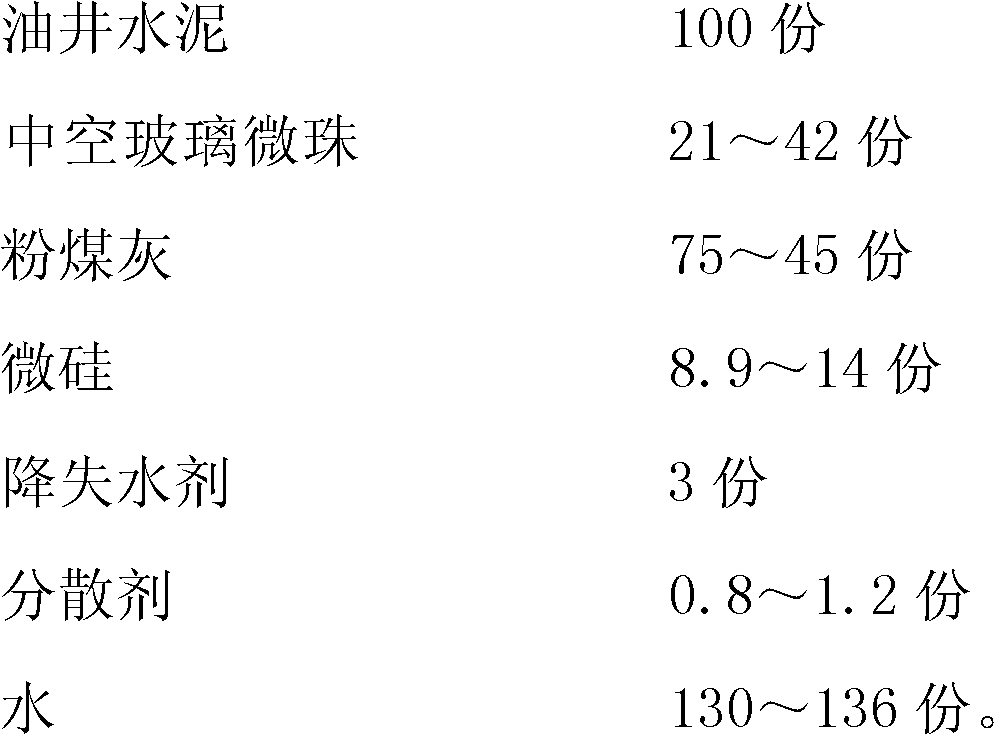

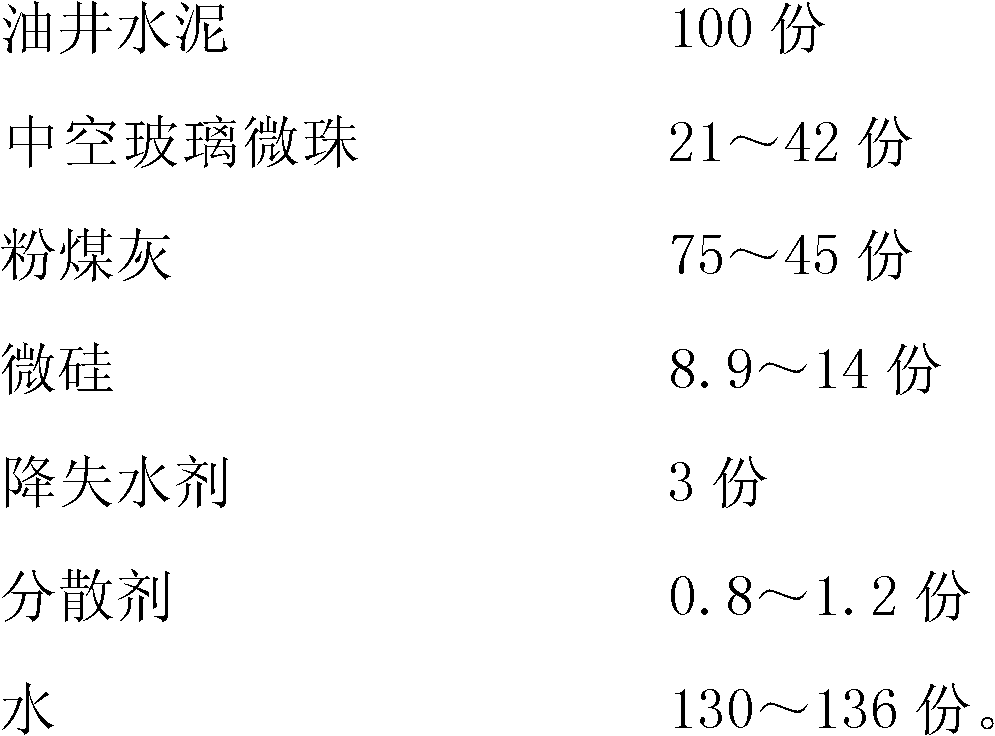

Method used

Image

Examples

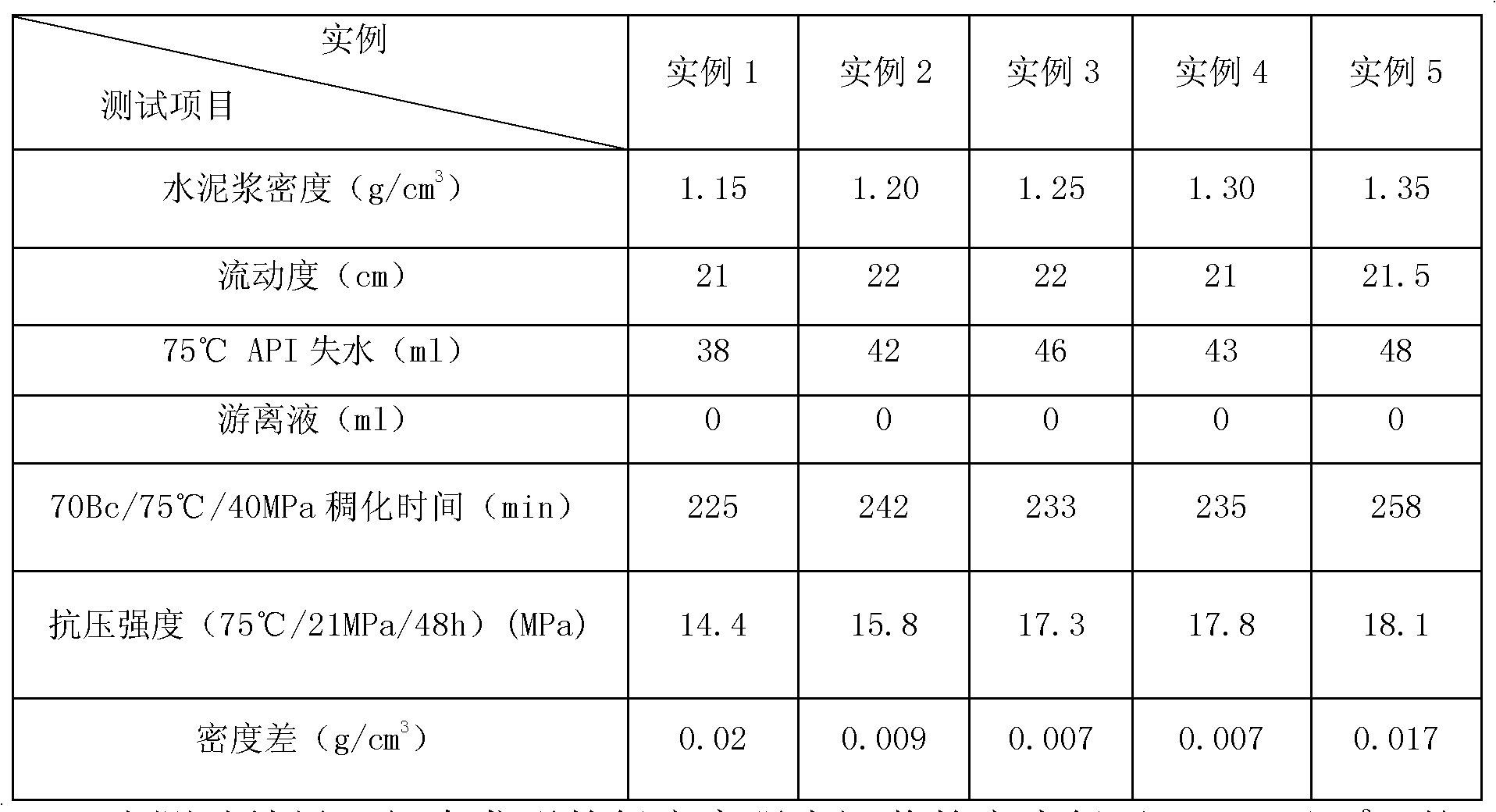

Embodiment 1

[0023] 240 parts of G grade portland oil well cement, 110 parts of fly ash, 100 parts of HGS18000 glass microspheres, 31.6 parts of micro silicon, 7.2 parts of G33S, 2.9 parts of USZ, 327 parts of water are mixed in proportion and then used on a rotational viscometer with 4000 Stir at rpm speed for 60 seconds, and test various properties according to API specifications, and the test results are shown in Table 1.

Embodiment 2

[0025] 250 parts of Portland G grade oil well cement, 112 parts of fly ash, 90.5 parts of HGS18000 glass microspheres, 29 parts of microsilicon, 7.2 parts of G33S, 2.9 parts of USZ, 318 parts of water are mixed in proportion and then used on a rotational viscometer with 4000 Stir at rpm speed for 60 seconds, and test various properties according to API specifications, and the test results are shown in Table 1.

Embodiment 3

[0027] 260 parts of Portland G grade oil well cement, 143 parts of fly ash, 81 parts of HGS18000 glass microspheres, 30.2 parts of microsilicon, 7.7 parts of G33S, 3.1 parts of USZ, 332 parts of water are mixed in proportion and used on a rotational viscometer with 4000 Stir at rpm speed for 60 seconds, and test various properties according to API specifications, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com