Cementing granule contact anti-shearing and torsion resistant test device

A technology of cemented particles and testing devices, which is applied in the field of torsion resistance testing devices and shear resistance, and can solve the problems of not being able to measure the mechanical properties of shear and torsion at the contact point of cemented particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

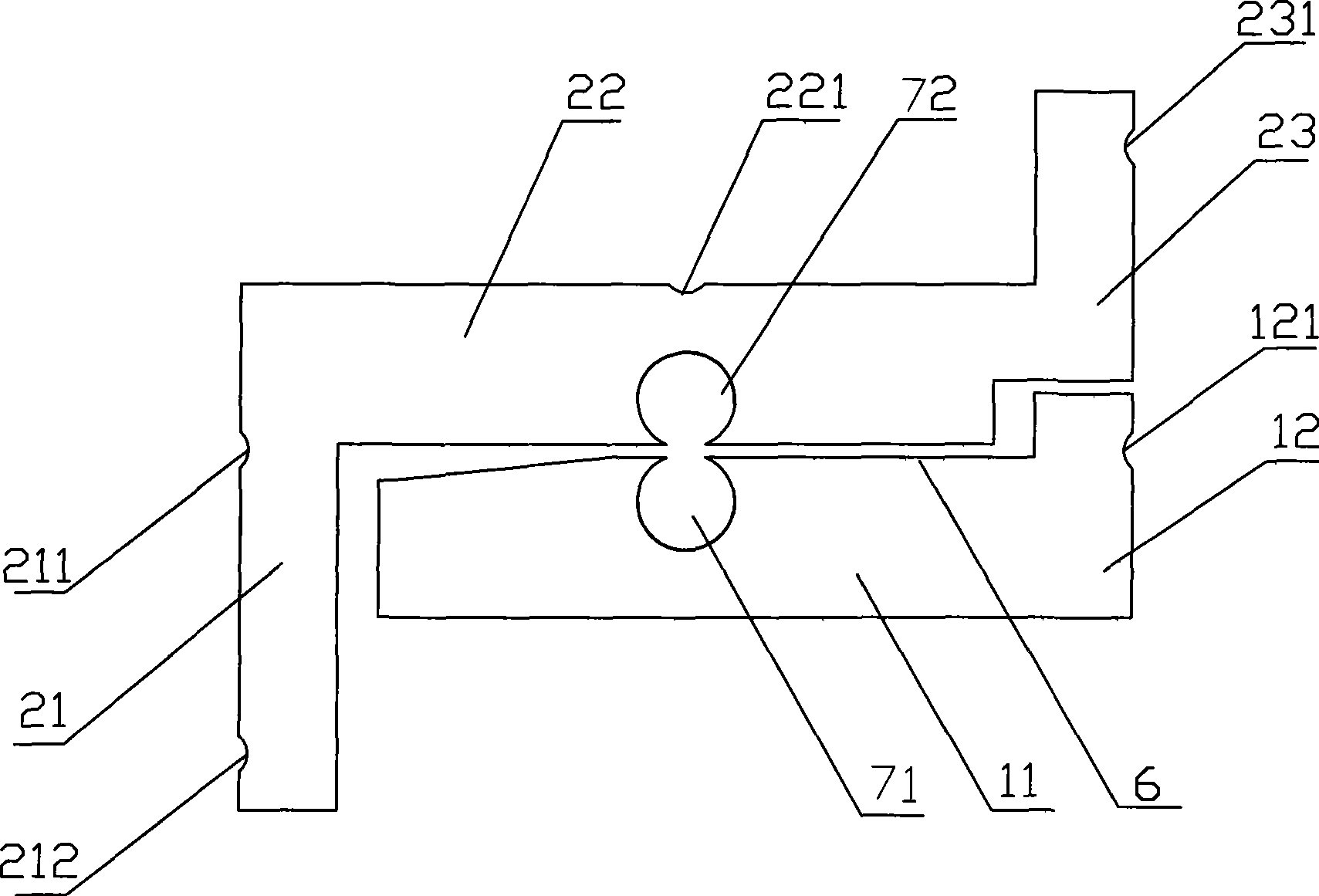

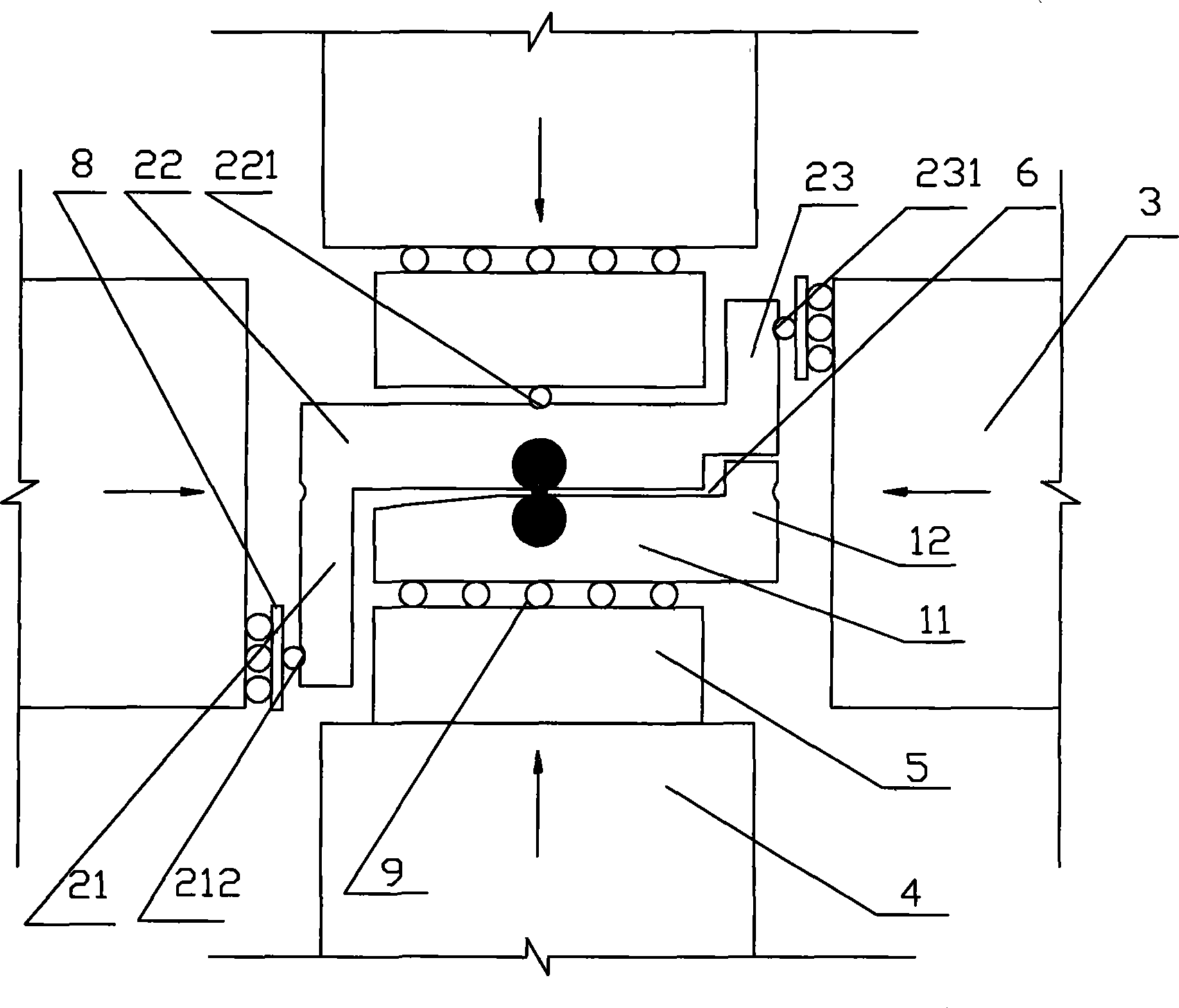

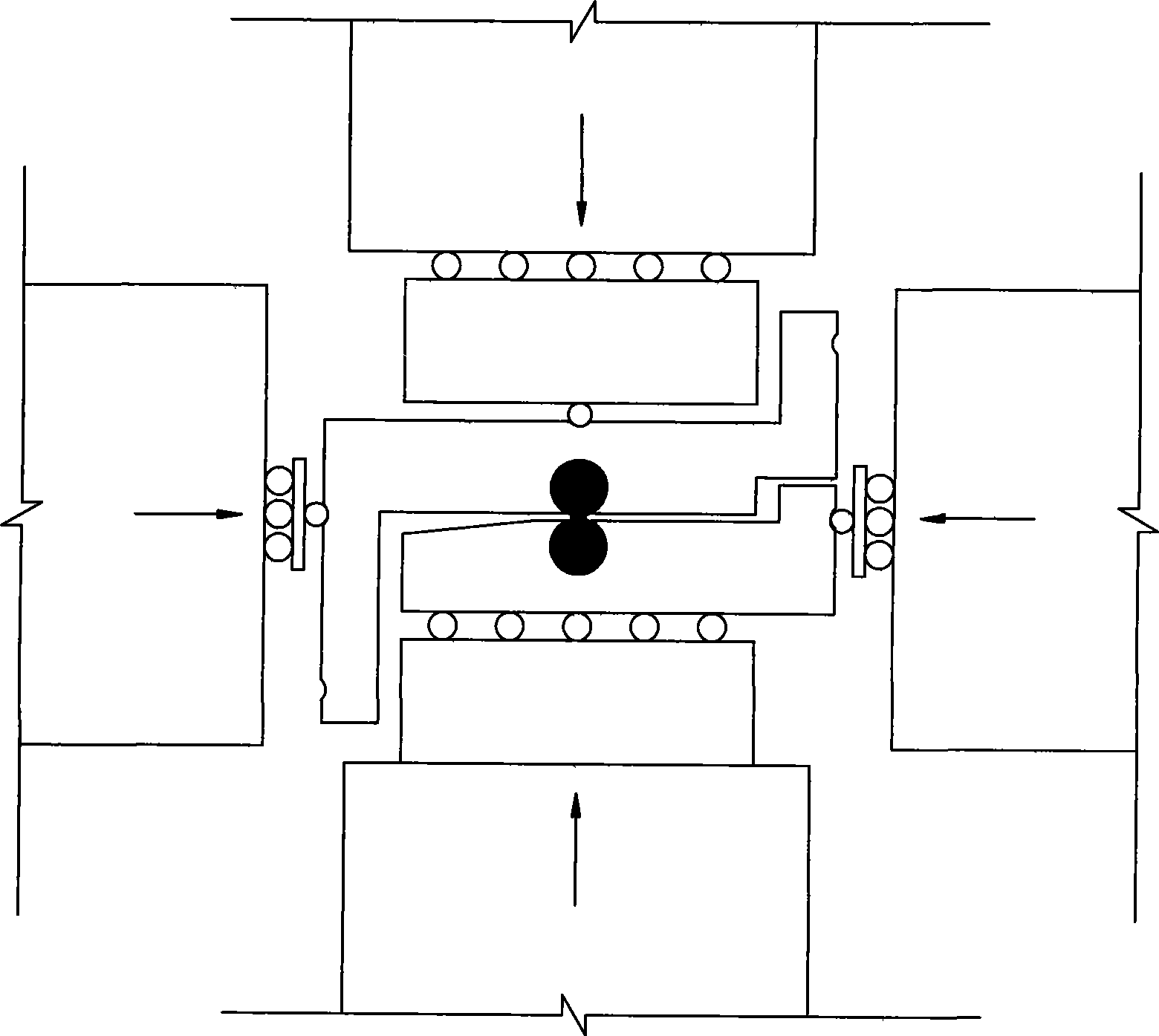

[0015] The cemented particle contact shearing and torsion test device includes an L-shaped part one and a Z-shaped part two. The part one is composed of a horizontal part 11 and a vertical part 12, and the part two is composed of a first vertical part 21, a first horizontal part 22 and The second vertical part 23 is composed of the first horizontal part 22 of the part two and the opposite surface 6 of the horizontal part 11 of the part one in the horizontal direction. Devices 71, 72, the connecting line between their centers is the vertical direction.

[0016] The fixing devices 71, 72 for fixing the cementing particles are respectively provided with a groove 73, 74 which can be put into the cementing particles on the opposite surface 6, and threaded through holes 75, 76 perpendicular to the grooves 73, 74 are set on the part one.

[0017] The second vertical part 23 of the second part and the horizontal part 11 of the first part are provided with gaps in the horizontal direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com