Concrete

A concrete, fineness modulus technology, applied to concrete. It can solve problems such as shortening of setting time, and achieve the effect of reducing concrete cracks, good water retention, and small slump loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

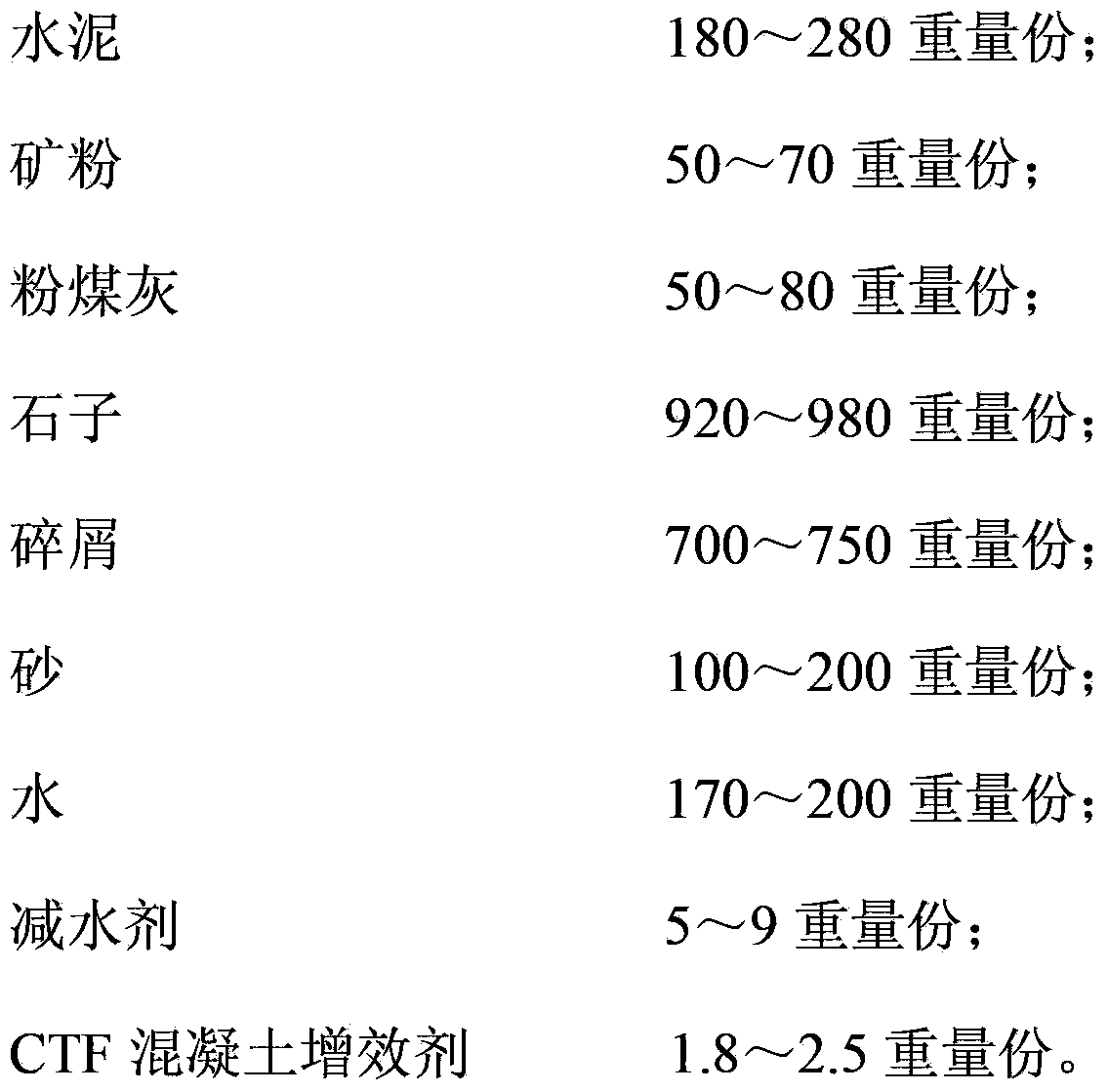

[0028] A kind of concrete embodiment 1 of the present invention comprises the following components, and each component is respectively according to parts by weight:

[0029]

[0030]

Embodiment 2

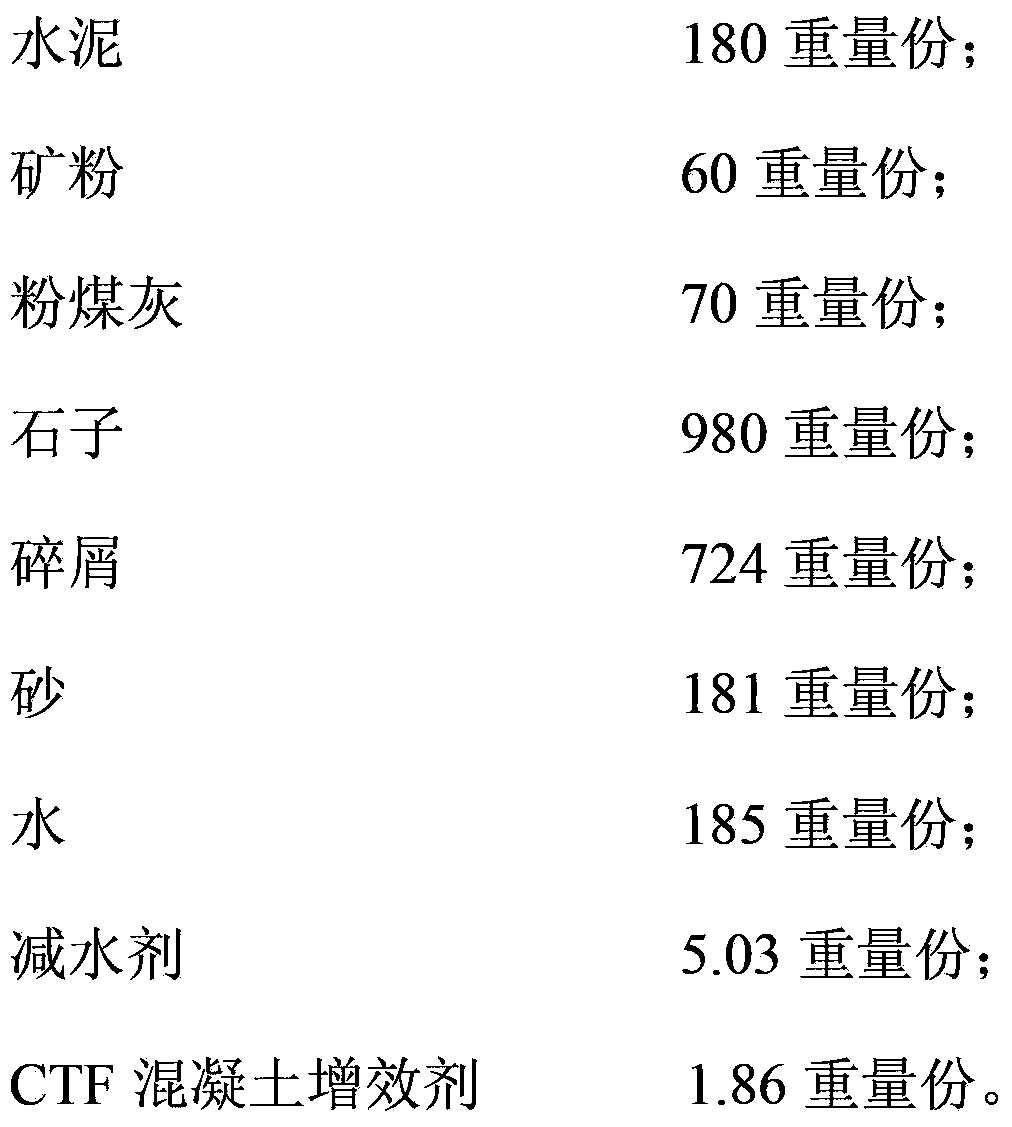

[0031] A kind of concrete embodiment 2 of the present invention comprises following components, and each component is respectively according to parts by weight:

[0032]

Embodiment 3

[0033] A kind of concrete embodiment 3 of the present invention comprises following components, and each component is respectively according to parts by weight:

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com