Metal organic skeleton structure material load platinum catalyst, as well as preparation method and application thereof

A metal-organic framework and structural material technology, applied in the preparation of organic compounds, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., to achieve good activity and selectivity, environmental friendliness, high efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

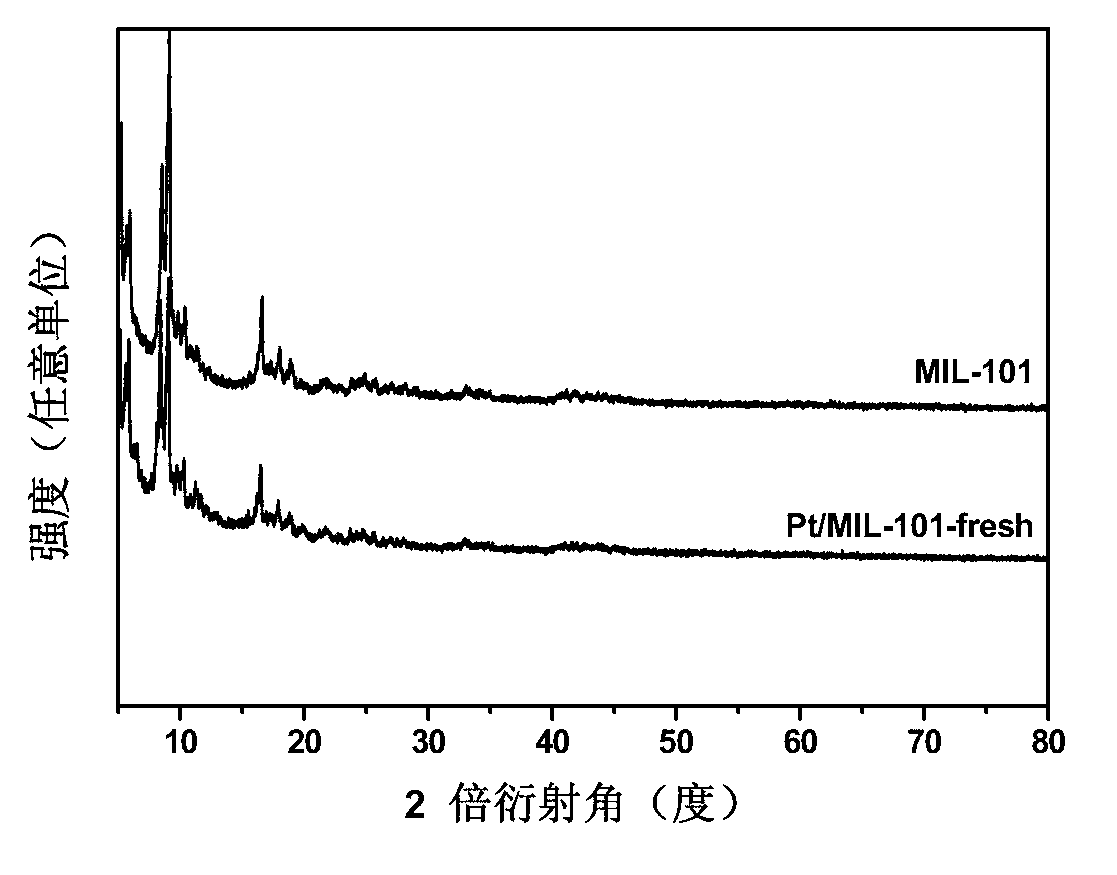

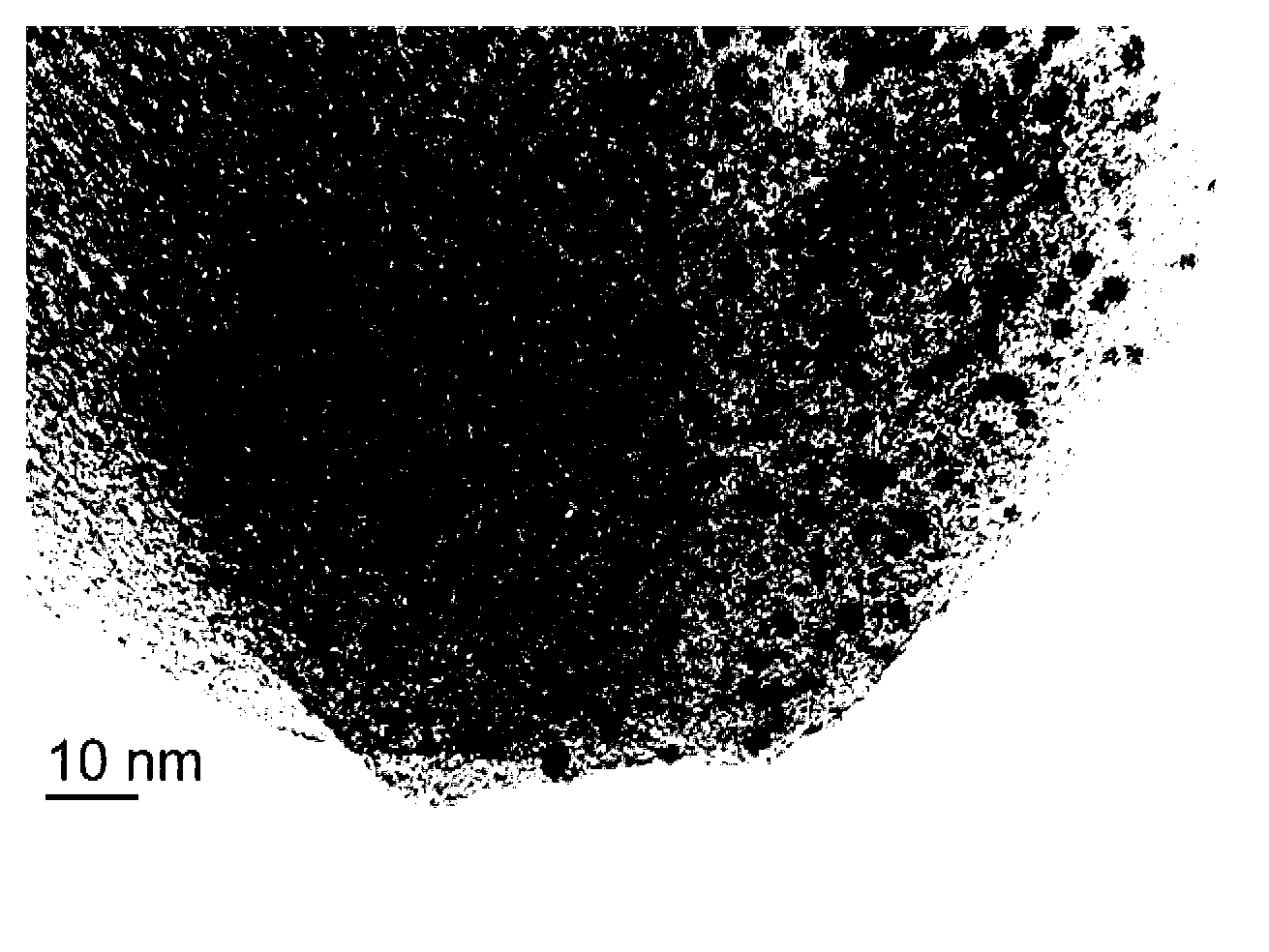

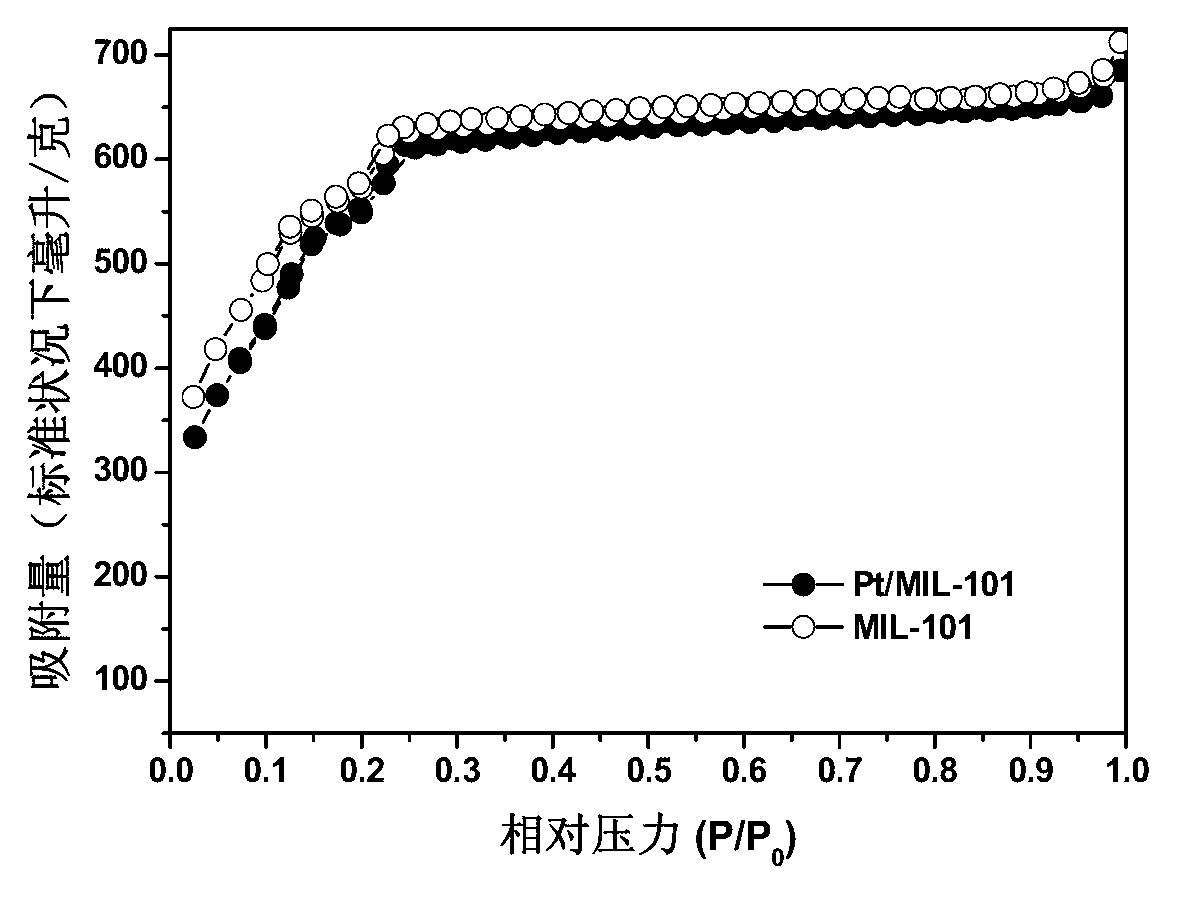

[0027] Cr(NO 3 ) 3 9H 2 O, HF, terephthalic acid and deionized water were reacted in a hydrothermal reactor at a constant temperature of 493K for 8 hours at a molar ratio of 1:1:1:265; naturally cooled to room temperature and then filtered to obtain a green solid powder; Then the solid powder is washed with organic solvent and small molecule alcohol respectively, filtered while hot after each washing, and finally dried in a constant temperature drying oven to obtain MIL-101 powder which is the metal organic framework material MIL-101. 0.5mL H 2 PtCl 6 Ethanol solution (1g chloroplatinic acid hexahydrate dissolved in ethanol to prepare 25mL solution) was added dropwise to 1.500g of the above-prepared MIL-101 powder, then 10-12mL of ethanol was added, stirring and impregnating at room temperature for 4-6 hours, the stirring speed was about 600 rev / min. After impregnation, evaporate the solvent to dryness and dry at 353-393K. Then add appropriate amount of sodium formate an...

Embodiment 2

[0029] In this embodiment, the Pt / MIL-101 catalyst with a Pt loading of 5wt.% is prepared according to the preferred conditions:

[0030] The preparation method of the metal-organic framework material MIL-101 is basically the same as that of Example 1. 2.0mL H 2 PtCl 6 Ethanol solution (1g of chloroplatinic acid hexahydrate dissolved in ethanol to prepare 25mL of chloroplatinic acid ethanol solution) was added dropwise to 573.4mg of MIL-101 powder, and then 5-8mL of ethanol was added, stirring and impregnating at room temperature for 4-6 hours, and the stirring speed was about at 600 rpm. After impregnation, evaporate the solvent to dryness and dry at 353-393K. Then add appropriate amount of sodium formate and deionized water according to the molar ratio of platinum and sodium formate as 1:10, reflux and reduce at 368K for 2 hours, wash with a large amount of deionized water after cooling to remove chloride ions, and then dry at 353-393K to obtain a loading capacity of 5wt ...

Embodiment 3

[0035] The preparation method of the metal-organic framework material MIL-101 is basically the same as that of Example 1. 3.0mL H 2 PtCl 6 Ethanol solution (1g chloroplatinic acid hexahydrate dissolved in ethanol to prepare 25mL chloroplatinic acid ethanol solution) was added dropwise to 407mg MIL-101 powder, then 4-7mL ethanol was added, stirring and impregnating at room temperature for 4-6 hours, the stirring speed was about 600 rpm. After impregnation, evaporate the solvent to dryness and dry at 353-393K. Then add appropriate amount of sodium formate and deionized water according to the molar ratio of platinum and sodium formate as 1:10, reflux and reduce at 368K for 2 hours, wash with a large amount of deionized water after cooling to remove chloride ions, and dry at 353-393K to obtain a loading capacity of 10wt. % Pt / MIL-101 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com