Method for preparing nitrogen-doped porous carbon material

A technology of nitrogen-doped porous carbon and carbon tetrachloride, which is applied in the field of inorganic nanomaterials and electrochemistry, can solve the problem that the capacitance of the material cannot meet expectations, and achieve excellent electrochemical capacitance performance, large pore volume, and microporous The effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 4.4g ethylenediamine, 10.8g carbon tetrachloride, and 1.0g mesoporous silica SBA-15 template were mixed, magnetically stirred for two hours, heated to 90°C, stirred and refluxed for 6 hours. The obtained sample was dried at 100°C, and then placed in a tube furnace. The temperature was raised to 600°C at a temperature increase rate of 5K / min under a nitrogen atmosphere, and the temperature was kept for 6 hours, then the sample was taken out. After removing the silicon template with 8% HF acid, it is washed with ethanol and water several times, and separated by filtration. Finally, it is dried in air at 100°C, and the product obtained is ordered mesoporous carbonitride, abbreviated as MCN-1. The prepared ordered mesoporous carbon-nitrogen material and potassium hydroxide are mixed in a mass ratio of 1:3, fully stirred and mixed in the aqueous solution, and dried, and then the sample is placed in a tube furnace, under Ar atmosphere The temperature is increased to 750°C at a ra...

Embodiment 2

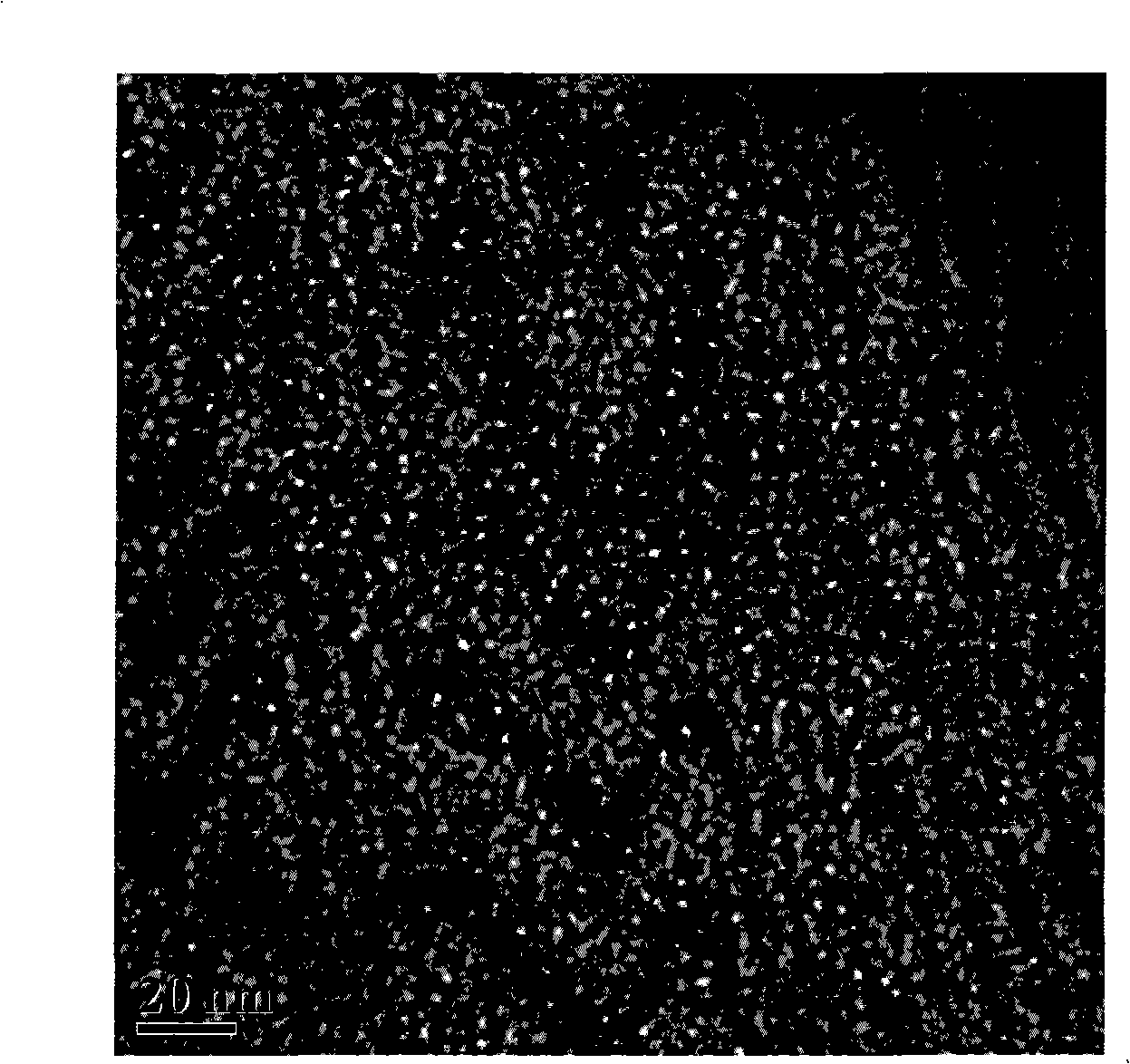

[0029] The method of this embodiment is basically the same as that of embodiment 1, except that the mass ratio of the ordered mesoporous carbon nitrogen material to potassium hydroxide is 1:5, which is named MCN-1-AC5. Then characterize its morphology, texture characteristics and electrochemical capacitance performance (the electrolyte is 6mol / L KOH). image 3 This is a TEM picture of the porous carbon-nitrogen material obtained in this example. This structure also has a fairly rich distribution of micropores. Unlike the porous carbon-nitrogen material obtained in Example 1, the porous carbon-nitrogen structure obtained in this example has a certain mesopore distribution. Connect effectively. Similarly, 77K nitrogen adsorption and desorption experiments also obtained mesoporous structures with a distribution of 2-5nm.

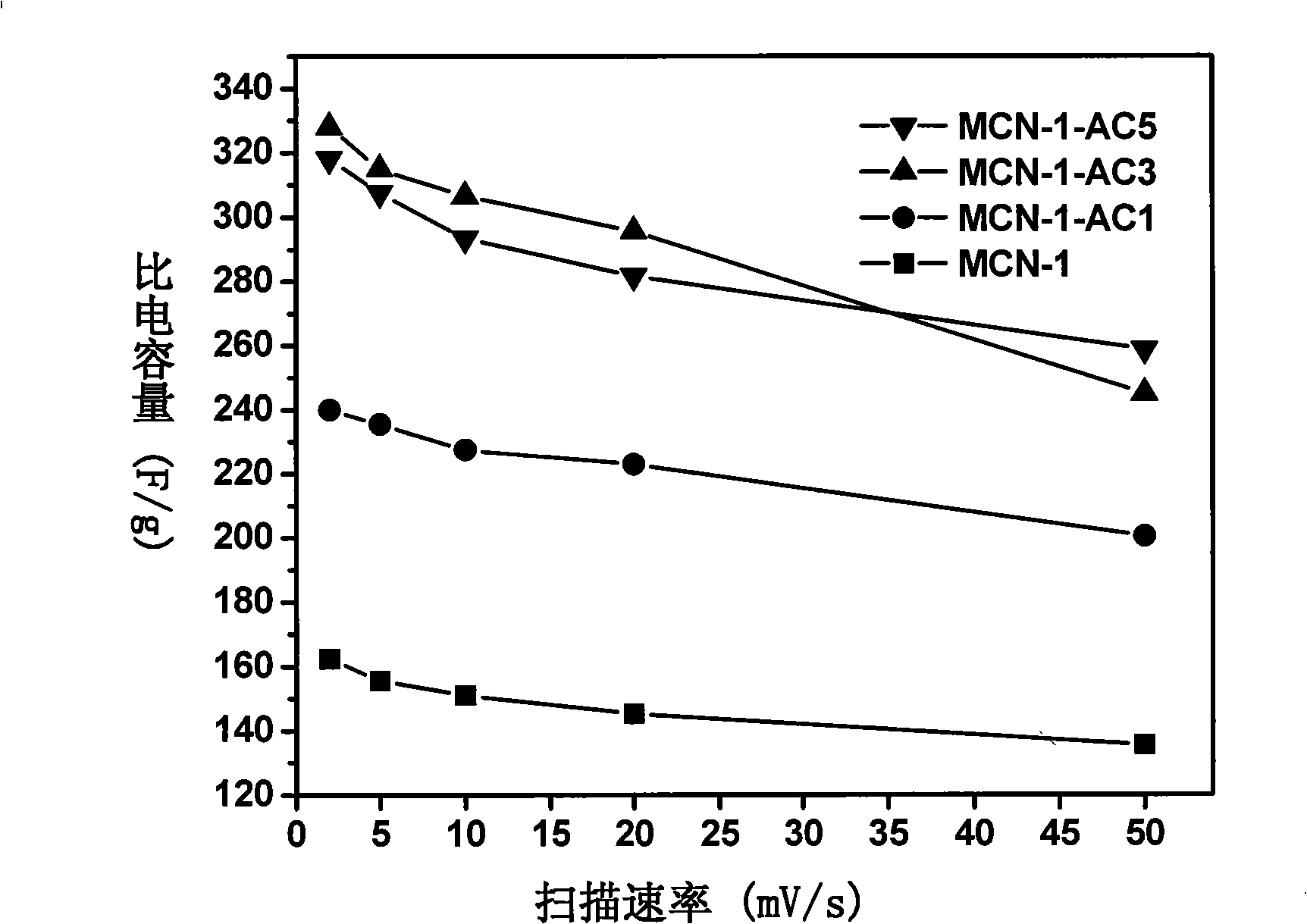

[0030] The change in specific capacitance of the electrode material at different scan rates is reflected in figure 2 In the curve represented by MCN-1-AC5. The sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com