Method for preparing efficient stable fuel cell catalyst

A fuel cell and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, battery electrodes, etc., can solve the problems of low catalyst performance and poor stability, achieve high specific surface area, avoid corrosion, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

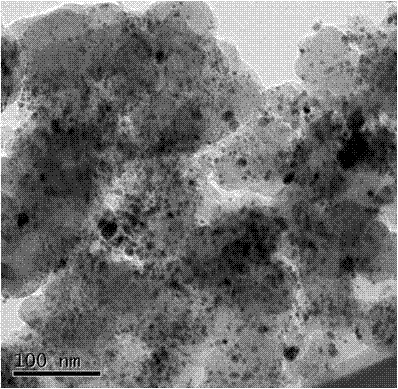

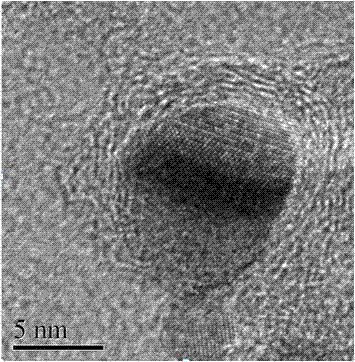

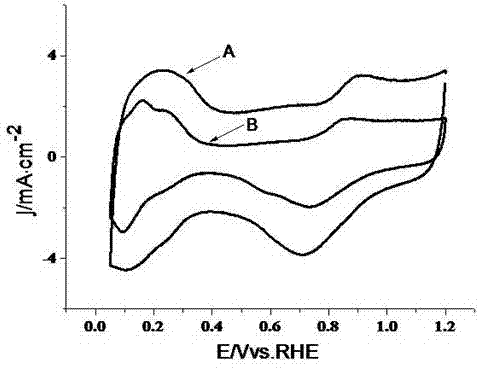

Image

Examples

Embodiment 1

[0030] (1) In situ synthesis of polyaniline modified Pt / C catalyst

[0031] Weigh the Pt / C catalyst and aniline according to the mass ratio of Pt / C catalyst: aniline as 1:1, and weigh according to the mass ratio of aniline: iron precursor: cobalt precursor: ammonium persulfate as 1:4:0.7:3 Ferric chloride, cobalt nitrate and ammonium persulfate; first add aniline monomer to 0.5 mol / L sulfuric acid aqueous solution, after ultrasonic stirring for 20 minutes, add Pt / C catalyst, continue ultrasonic stirring for 24 hours, wait for the Pt / C catalyst to disperse After uniformity, slowly add ammonium persulfate, ferric chloride and cobalt nitrate dissolved in 0.5mol / L sulfuric acid aqueous solution into the mixed solution of Pt / C catalyst and aniline under the condition of stirring at 0°C, and the dropping time is controlled at After 30 minutes, after the dropwise addition was completed, the reaction was continued for 24 hours under the condition of stirring at 0° C.; then the product...

Embodiment 2

[0042] (1) In situ synthesis of polyaniline modified Pt / C catalyst

[0043] Weigh the Pt / C catalyst and aniline according to the mass ratio of Pt / C catalyst: aniline as 1:0.7, and weigh according to the mass ratio of aniline: iron precursor: cobalt precursor: ammonium persulfate as 1:6:1:1 Ferric nitrate, cobalt chloride and ammonium persulfate; first add aniline monomer to 0 mol / L sulfuric acid aqueous solution, after ultrasonic stirring for 10 minutes, add Pt / C catalyst, continue ultrasonic stirring for 10 hours, wait for the Pt / C catalyst to disperse After uniformity, ammonium persulfate, ferric nitrate and cobalt chloride dissolved in 0 mol / L sulfuric acid aqueous solution were slowly added dropwise to the mixed solution of Pt / C catalyst and aniline under the condition of stirring at 15°C, and the dropping time was controlled at After 5 minutes, after the dropwise addition was completed, the reaction was continued for 10 hours under stirring at 15° C.; then the product was...

Embodiment 3

[0050] (1) In situ synthesis of polyaniline modified Pt / C catalyst

[0051] Weigh the Pt / C catalyst and aniline according to the mass ratio of Pt / C catalyst: aniline as 1:1.5, and weigh according to the mass ratio of aniline: iron precursor: cobalt precursor: ammonium persulfate as 1:2:0.5:4 Iron sulfate, cobalt sulfate and ammonium persulfate; first add aniline monomer to 1.5 mol / L sulfuric acid aqueous solution, after ultrasonic stirring for 30 minutes, add Pt / C catalyst, continue ultrasonic stirring for 28 hours, until the Pt / C catalyst is uniformly dispersed Finally, under the condition of stirring at 10°C, ammonium persulfate, iron sulfate and cobalt sulfate dissolved in 1.5 mol / L sulfuric acid aqueous solution were slowly added dropwise to the mixed solution of Pt / C catalyst and aniline, and the dropping time was controlled at 60 minutes. After the dropwise addition, the reaction was continued for 48 hours under stirring at 10° C.; then the product was dried and ground t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com