Method for synthesizing phosphorus-silicate-aluminum molecular sieve with metal-amine-complex as template

A technology of phosphorus-silicon-aluminum molecular sieve and template agent, which is applied in the direction of molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicon-aluminophosphate, etc., can solve the problems of insufficient dispersion and many metals, and achieve low cost, high specific surface area and simple method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of Cu-SAPO-34 sample

[0029] First add boehmite to water, add phosphoric acid drop by drop, and after stirring for one hour, a viscous gel is obtained, then add amorphous silicon dioxide, stir to form a gel, add copper sulfate pentahydrate, and fully stir Then add tetraethylenepentamine, and after stirring for one hour, add n-propylamine to the above system, stir at room temperature for 12 hours, put it into a polytetrafluoroethylene-lined steel reactor, and react at 200 degrees for two days. The chemical ratio of the system is as follows: 1 Al 2 o 3 : 1.14P 2 o 5 : 0.57 SiO 2 : 75 H 2 O: 0.3 Cu-R1: 2.4 R2. After the reaction was completed, the obtained product was fully washed with deionized water and dried overnight at 80°C.

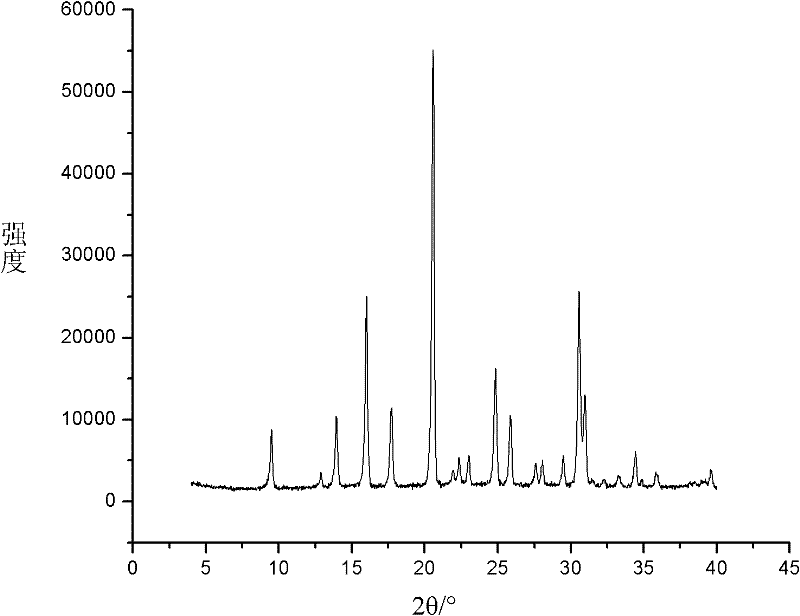

[0030] attached figure 1 According to the XRD characterization results of the product, it can be seen that the product has a typical SAPO-34 structure and has a high degree of crystallinity.

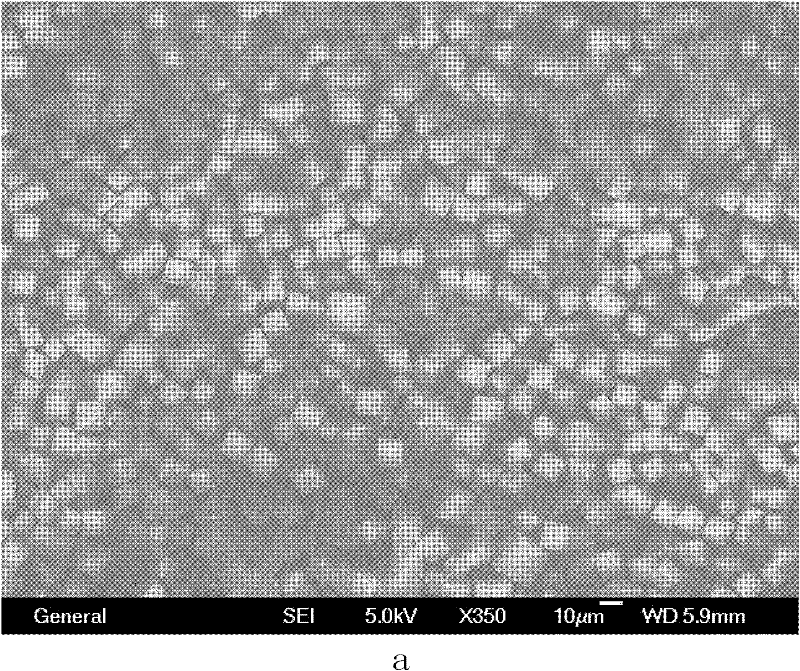

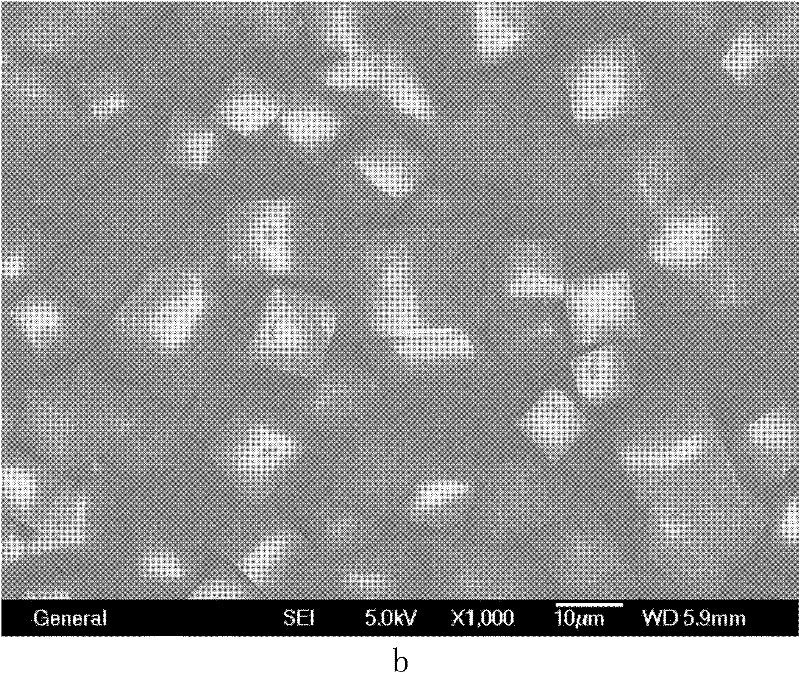

[0031] attac...

Embodiment 2

[0034] Embodiment 2: the preparation of Cu-SAPO-34 sample

[0035] The addition sequence and stirring time of gel preparation are the same as in Example 1. The chemical ratio of the system is: 1 Al 2 o 3 : 1.14P 2 o 5 : 0.57 SiO 2 : 85 H 2 O: 0.3 Cu-R1: 4.5 R2. React at 150 degrees for two days. After the reaction was completed, the obtained product was fully washed with deionized water and dried overnight at 80°C.

[0036] attached Figure 5 According to the XRD characterization results of the product, it can be seen that the product has a typical SAPO-34 structure and has a high degree of crystallinity.

[0037] attached Figure 6 It is the solid ultraviolet-visible absorption spectrum of the product.

Embodiment 3

[0038] Embodiment 3: the preparation of Cu-SAPO-34 sample

[0039] First add aluminum hydroxide to water, add phosphoric acid drop by drop, and after stirring for one hour, a viscous gel is obtained, then add amorphous silicon dioxide, stir to form a gel, add copper sulfate pentahydrate, after fully stirring Then add tetraethylenepentamine, and after stirring for one hour, add n-propylamine to the above system, stir for 12 hours at room temperature, put it into a polytetrafluoroethylene-lined steel reactor, and react at 200 degrees for two days. The chemical ratio of the system is as follows: 1 Al 2 o 3 : 1.14P 2 o 5 : 0.57 SiO 2 : 80 H 2 O: 0.3 Cu-R1: 2.4 R2. After the reaction was completed, the obtained product was fully washed with deionized water and dried overnight at 80°C.

[0040] attached Figure 7 According to the XRD characterization results of the product, it can be seen that the product has a typical SAPO-34 structure and has a high degree of crystallinity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com