Preparation method of copper-zinc catalyst

A catalyst and copper-zinc technology, which is applied in the field of copper-zinc catalyst preparation, can solve the problems of low active center density, small surface active metal content, complex process, etc., and achieve high active site density, good coordination, and thermal stability. good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

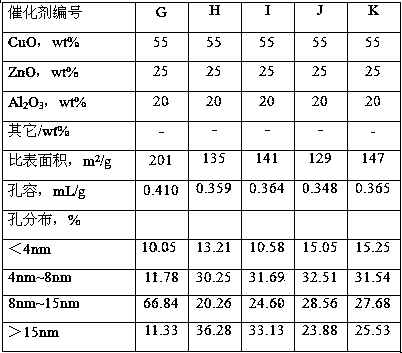

Embodiment 1

[0032] Weigh Cu(NO 3 ) 2 ·3H 2 O168g, AlCl 3 ·6H 2 O95g, dissolved in 850mL deionized water to make working solution A, and Na 2 CO 3 Dissolve in 1000ml deionized water to prepare solution B. The molar ratio of sodium carbonate in solution B to copper and aluminum in solution A is 1.2. 500ml of water is added to the reaction tank and the temperature rises to 60°C. Under the condition of stirring, the solution A and the solution B are co-flowed into the reaction tank, the gel forming time is 1 hour, and the pH value of the gel slurry is controlled to be 7.4±0.2. Start aging while stirring, add 26g of nano zinc oxide, pH is 7.4±0.2 during aging, temperature is 75℃, aging for 2 hours, after aging, the material is filtered, and the filter cake is subjected to hydrothermal treatment under water vapor containing urea. The conditions of the heat treatment are: the molar ratio of urea to the total amount of active metal atoms is 5:1, the temperature is 230℃, the pressure is 4.5MPa, the ...

Embodiment 2

[0034] According to the method of Example 1, according to the composition ratio of the catalyst B in Table 1, copper nitrate and aluminum nitrate were added to the dissolution tank 1 to prepare working solution A, and sodium carbonate was added to the solution tank 2 to prepare working solution B , The molar ratio of sodium carbonate in solution B to copper and aluminum in solution A is 1.1, 600 mL of water is added to the reaction tank, and the temperature rises to 55°C. Under the condition of stirring, the solution A and the solution B are co-flowed into the reaction tank, the gel forming time is 1.2 hours, and the pH value of the gel slurry is controlled to be 7.2±0.2. Start aging under stirring. Add nano zinc oxide according to the component content of catalyst B in Table 1. When aging, the pH is 7.0 ± 0.2, the temperature is 70 ℃, and the aging is 3 hours. After aging, the material is filtered and the filter cake contains Hydrothermal treatment of urea is carried out under...

Embodiment 3

[0036] According to the method of Example 1, according to the component content ratio of catalyst C in Table 1, add copper nitrate, aluminum chloride, and manganese chloride to dissolving tank 1 to prepare working solution A, and add sodium carbonate to solution tank 2. Prepare working solution B. The molar ratio of sodium carbonate in solution B to copper and aluminum in solution A is 1.0. 800 mL of water is added to the reaction tank and the temperature is raised to 65°C. Under the condition of stirring, the solution A and the solution B are co-flowed into the reaction tank, the gel forming time is 1.5 hours, and the pH value of the gel slurry is controlled to be 7.4±0.2. Start aging under stirring. Add nano-zinc oxide according to the component content of catalyst B in Table 1. When aging, the pH is 7.2±0.2, the temperature is 80℃, and the aging is 2.5 hours. After aging, the material is filtered and the filter cake contains Hydrothermal treatment of urea is carried out unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com