Method for preparing hydro-treatment catalyst

A hydrogenation treatment and catalyst technology, applied in the direction of physical/chemical process catalysts, catalyst carriers, chemical instruments and methods, etc., can solve the problems of low sodium content, environmental pollution, large amount of waste water, etc., and achieve simple adjustment, no environmental pollution, The effect of concentrated hole distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

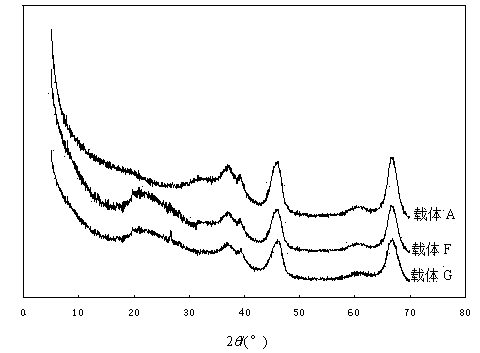

Image

Examples

Embodiment 1

[0037] (1) Preparation of silicon-containing alumina dry glue

[0038] Preparation of sodium metaaluminate solution concentration is 55gAl 2 o 3 / L, a total of 1L, heated to 70°C for use, the concentration of aluminum sulfate solution is 20gAl 2 o 3 / L, a total of 2L, heated to 70°C for use.

[0039] The original kaolin soil was roasted in a high-temperature furnace at a temperature of 800°C and kept at a constant temperature for 4 hours. After cooling, it was pulverized and passed through a 160-mesh sieve before being collected for use.

[0040] Add 1.0L of distilled water into the gel tank and heat to 70°C. Weigh 30 grams of sieved kaolin respectively and put them into sodium metaaluminate solution and aluminum sulfate solution, and flow into the above two slurries to keep the pH value at 9.0, and the solid-liquid ratio in the gelling tank is 50g / L No change, calculate the time for adding water in parallel, and add 1.5L of distilled water in parallel, and keep the tempe...

Embodiment 2

[0045] The other conditions of the silicon-containing alumina dry glue are the same as in Example 1, except that the amount of kaolin after roasting is increased to 50 grams to prepare silicon-containing alumina.

[0046] The preparation method of the carrier and the catalyst is the same as in Example 1, and the carrier B and the catalyst T-B are prepared.

Embodiment 3

[0048] The preparation method of silicon-containing aluminum hydroxide is the same as in Example 1.

[0049] Weigh 100g of the prepared silicon-containing alumina dry glue (70wt% silicon-containing alumina), add 1.4g carbon black and 2.8g scallop powder, mix well, weigh 2.8g ammonium dihydrogen phosphate and 5.6g polyethylene glycol , respectively add 55g of distilled water to dissolve completely, and then sequentially add to the mixed raw materials, knead and extrude to shape, then dry at 110°C for 4h, and roast at 650°C for 3h to obtain carrier C.

[0050] Weigh 22.22g of phosphoric acid, add 450mL of distilled water, then sequentially add 78.44g of molybdenum oxide and 25.44g of basic nickel carbonate, heat and stir until completely dissolved, then adjust the solution to 500mL with distilled water to obtain solution L-2. Saturatedly impregnate the above support with L-2 solution, dry at 120°C for 2h, and calcinate at 430°C for 3h to obtain catalyst T-C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com