Preparation method and application of porous nano metal organic framework material

A nano metal and organic framework technology is applied to the preparation of porous nano metal organic framework materials and the application field of adsorption and separation, which can solve the problems of cumbersome production steps, high economic cost and low yield, and achieves improved uniformity and synthesis. Efficiency, high surface area, large pore volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

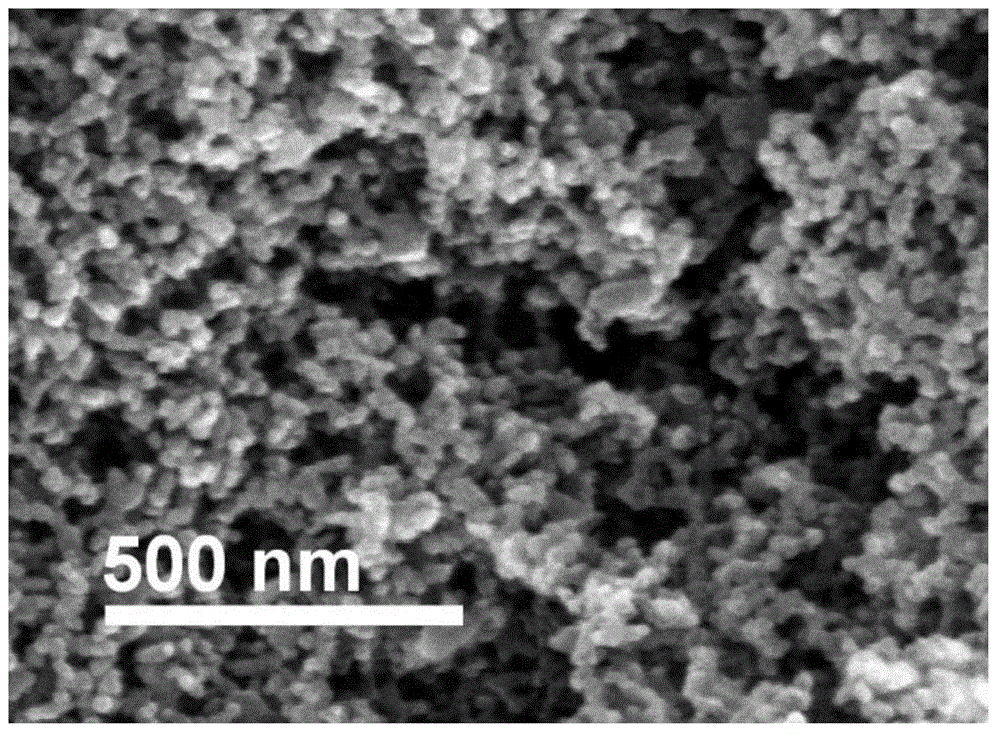

[0033] Embodiment 1: Synthesis of nanometer Zn-dimethylimidazole framework

[0034] Dissolve 6g of polyvinylpyrrolidone (PVP) in 450g of water, then add 26g of ZnSO 4 .7H 2 O forms a zinc sulfate solution; dissolve 15g of 2-methylimidazole in 300g of methanol; add the 2-methylimidazole methanol solution dropwise into the zinc sulfate solution within 30 minutes under stirring conditions, mix well, and react at 60°C 5 hours. Cool down naturally, filter the white precipitate, and wash twice with 150ml of water. The filter cake was dried at 100°C for 6 hours and then at 130°C for 8 hours under vacuum (0.2 bar) to obtain 21 g of product;

[0035] The product after washing with water is dispersed in ethanol, and its particle size distribution measured in a Malvern ZS90 particle size analyzer is 120-260nm.

[0036] Product N after drying 2 The specific surface area is 1476m 2 / g (as determined by the Langmuir method).

Embodiment 2

[0037] Embodiment 2: Synthetic nanometer Zn-dimethylimidazole frame

[0038] Dissolve 1g of zinc acetate in 150g of methanol, stir, and reflux at 60°C until the solution becomes turbid to form a mixed solution A; dissolve 4g of PVP in 450g of water, and then add 26g of ZnSO 4 .7H 2 O forms a solution, and then is added dropwise to the A mixture to form a suspension B; dissolve 15g of 2-methylimidazole in 150g of methanol, and then dropwise add it to the B suspension and stir for 30min, after mixing evenly, at 60°C React for 5 hours. Cool down naturally, filter the white precipitate, and then wash twice with 150ml of water. The filter cake was dried at 100°C for 6 hours and then at 130°C for 8 hours under vacuum (0.2 bar) to obtain 20 g of product;

[0039] The product after washing with water is dispersed in ethanol, and its particle size distribution measured in a Malvern ZS90 particle size analyzer is 100-510 nm.

[0040] Product N after drying 2 The specific surface ar...

Embodiment 3

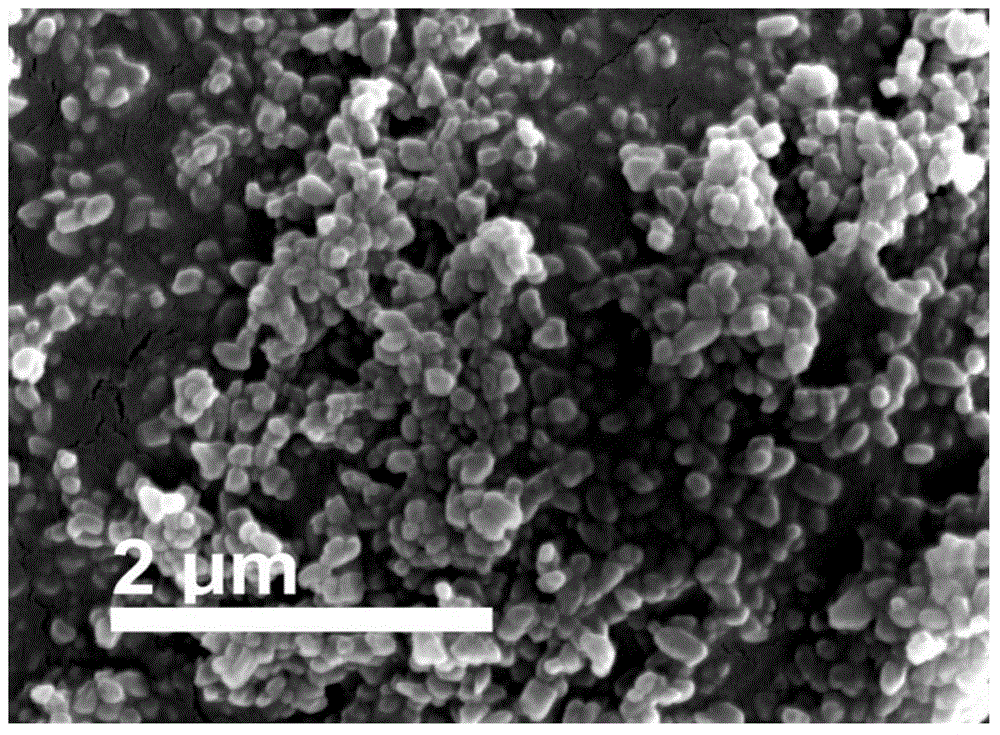

[0041] Embodiment 3: Synthetic nano Zn-dimethylimidazole frame

[0042] Dissolve 8g of polyvinyl alcohol in 300g of methanol, stir, add 20g of zinc acetate dihydrate, and reflux at 60°C until the solution is milky white mixed solution A; dissolve 15g of 2-methylimidazole in 300g of methanol to form solution B, and stir 2-Methylimidazole methanol solution B was added dropwise to the mixture A within 50 min under the condition, and the reaction was continued for 5 hours under the condition of 60°C. Cool down naturally, filter the white precipitate, and then wash twice with 150ml of water. The filter cake was dried at 100°C for 6 hours and then at 110°C for 12 hours under vacuum (0.2 bar) to obtain 20 g of product;

[0043] The product washed with water was dispersed in ethanol, and its particle size distribution was measured in a Malvern ZS90 particle size analyzer to be 50-250nm.

[0044] Product N after drying 2 The specific surface area is 1303m 2 / g (as determined by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com