Ozone catalyst preparation method

A catalyst and ozone technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of affecting catalytic performance and service life, low ozone utilization rate, catalytic Solve problems such as component dissolution, achieve good catalytic performance, ensure effective utilization, and achieve the effect of large specific surface area and pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] In order to achieve the purpose of the above invention, the present invention provides a method for preparing an ozone catalyst, comprising the following steps: mixing amorphous alumina powder, catalyst powder, and a pore-forming agent to form a catalytic mixture; Put it into the ball forming machine, spray the binder to form the alumina cue ball; put the alumina cue ball and the catalytic mixture into the ball forming machine, spray the binder to form the catalyst shaped sphere; the prepared catalyst into the sphere Drying and roasting are carried out to obtain an ozone catalyst. The two steps of preparing the catalytic mixture and forming the alumina cue ball are not in any order, and can also be carried out at the same time.

[0023] The weight proportions of amorphous alumina powder, catalyst powder and pore forming agent in the catalytic mixture are respectively: 89.5%-97.5%, 2%-8% and 0.5%-2.5%. The content of amorphous alumina powder in the catalytic mixture is ...

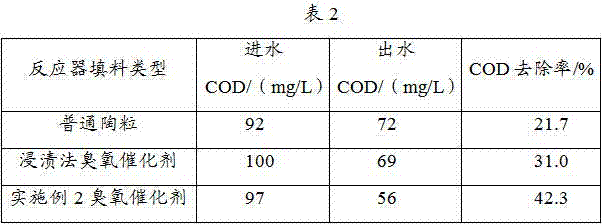

Embodiment 1

[0032] Amorphous alumina powder is taken to prepare alumina cue balls.

[0033] Separately take amorphous alumina powder, ferric oxide powder, cerium oxide powder, and polyethylene glycol and mix them uniformly at a mass ratio of 94%: 3%: 1.5%: 1.5% to form a catalytic mixture, which is used in the alumina cue ball Catalyst shaped spheres were prepared on the basis of. Among them, the particle size of ferric oxide powder and cerium oxide powder is 0.1mm~0.5mm.

[0034]Put the amorphous alumina powder into the ball forming machine, spray into the binder formed by boric acid and water with a mass ratio of 1:2, and roll into balls. 8%, prepared into alumina cue balls with a particle size of 2.5mm~3mm.

[0035] The catalytic mixture and the prepared alumina cue ball are put into the ball forming machine according to the mass ratio of 2.5:1, and the binder boric acid and water formed by boric acid and water with a mass ratio of 1:2 are sprayed. The addition amount is 10% of the ...

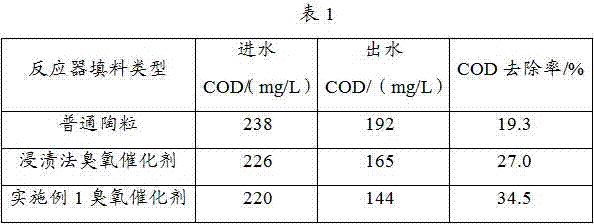

Embodiment 2

[0043] Amorphous alumina powder is taken to prepare alumina cue balls.

[0044] In addition, amorphous alumina powder, copper oxide powder, titanium dioxide powder, and polyvinyl alcohol are mixed uniformly at a mass ratio of 93%: 2.5%: 2.5%: 2% and used as a catalytic mixture for preparation on the basis of alumina cue balls Catalyst shaped spheres. Among them, the particle size of copper oxide powder and titanium dioxide powder is 0.2mm~0.5mm.

[0045] Put the shaped alumina powder into the ball forming machine, spray the binder formed by boric acid and water with a mass ratio of 1:3, and roll it into a ball. The amount of the binder added is 8% of the mass of the shaped alumina powder ,, Prepare alumina cue balls with a particle size of 2mm~2.5mm.

[0046] Put the catalytic mixture and the prepared alumina cue ball into the ball forming machine according to the mass ratio of 3.375:1, spray into the binder formed by boric acid and water with a mass ratio of 1:3, the amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com