Method for synthesizing Beta molecular sieve by organic-free template

A technology without organic template and molecular sieve, applied in the field of catalytic chemistry, can solve the problems of application restriction, energy consumption, increased cost, etc., and achieve the effect of rapid synthesis and improvement of crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: rapid synthesis of Beta molecular sieve without template

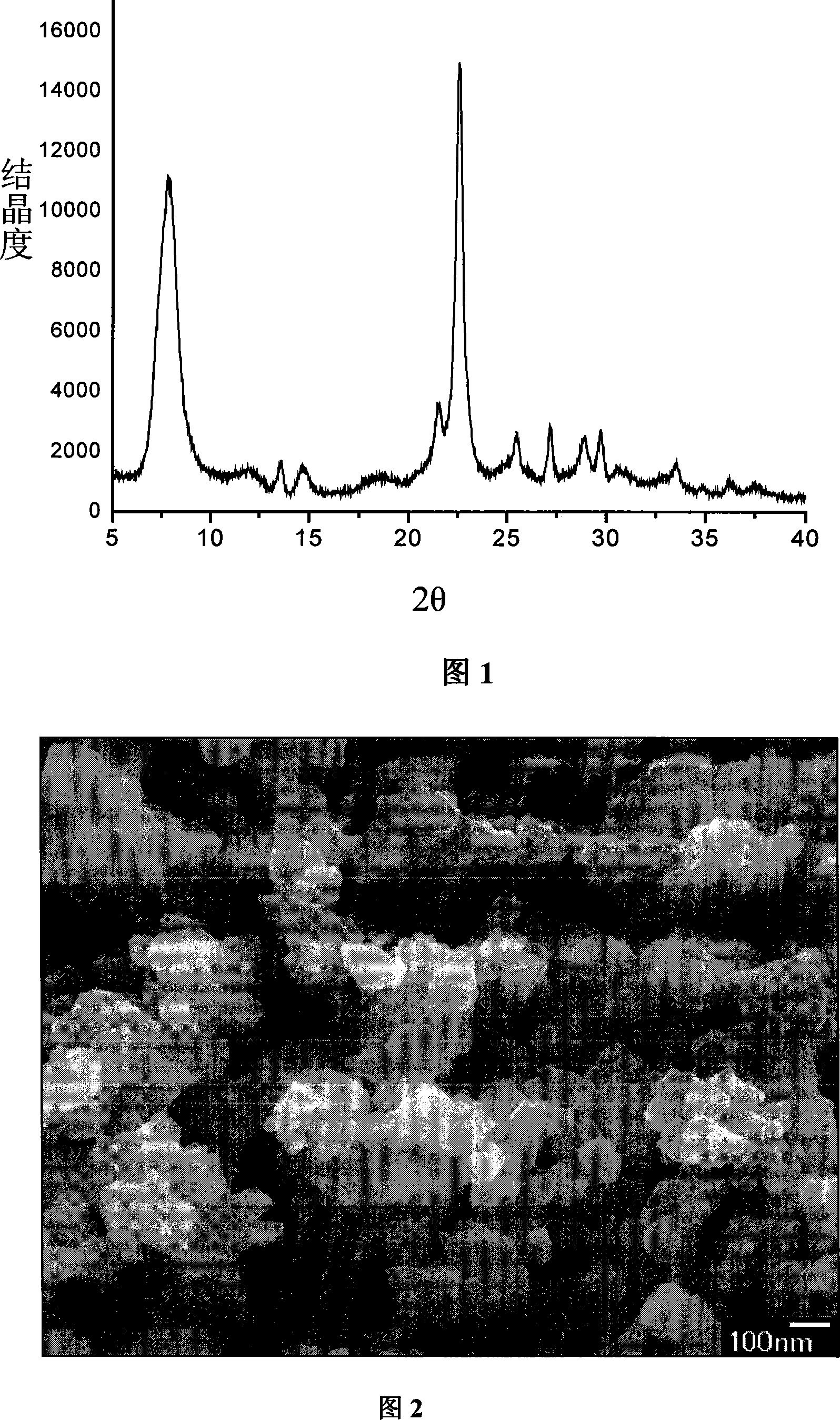

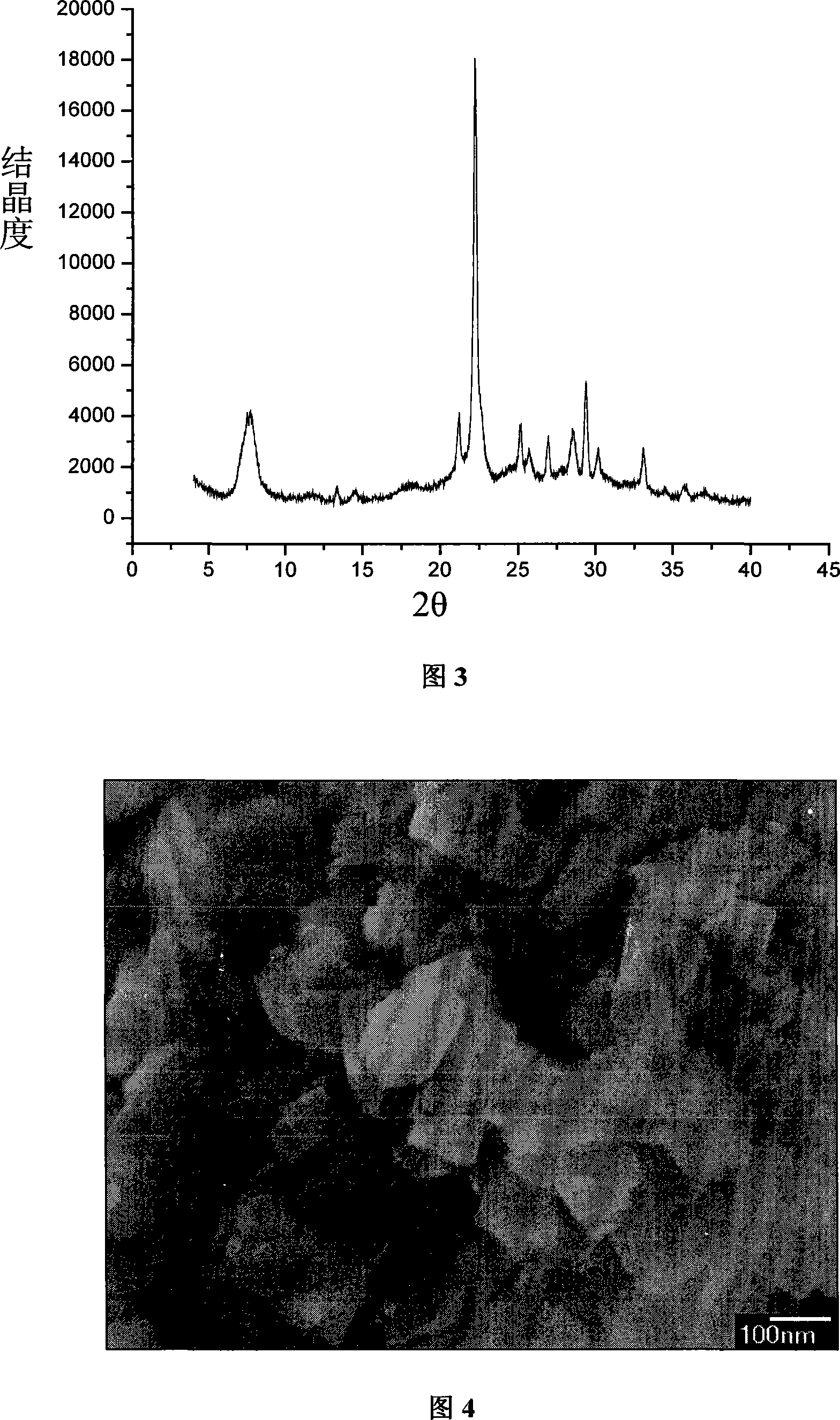

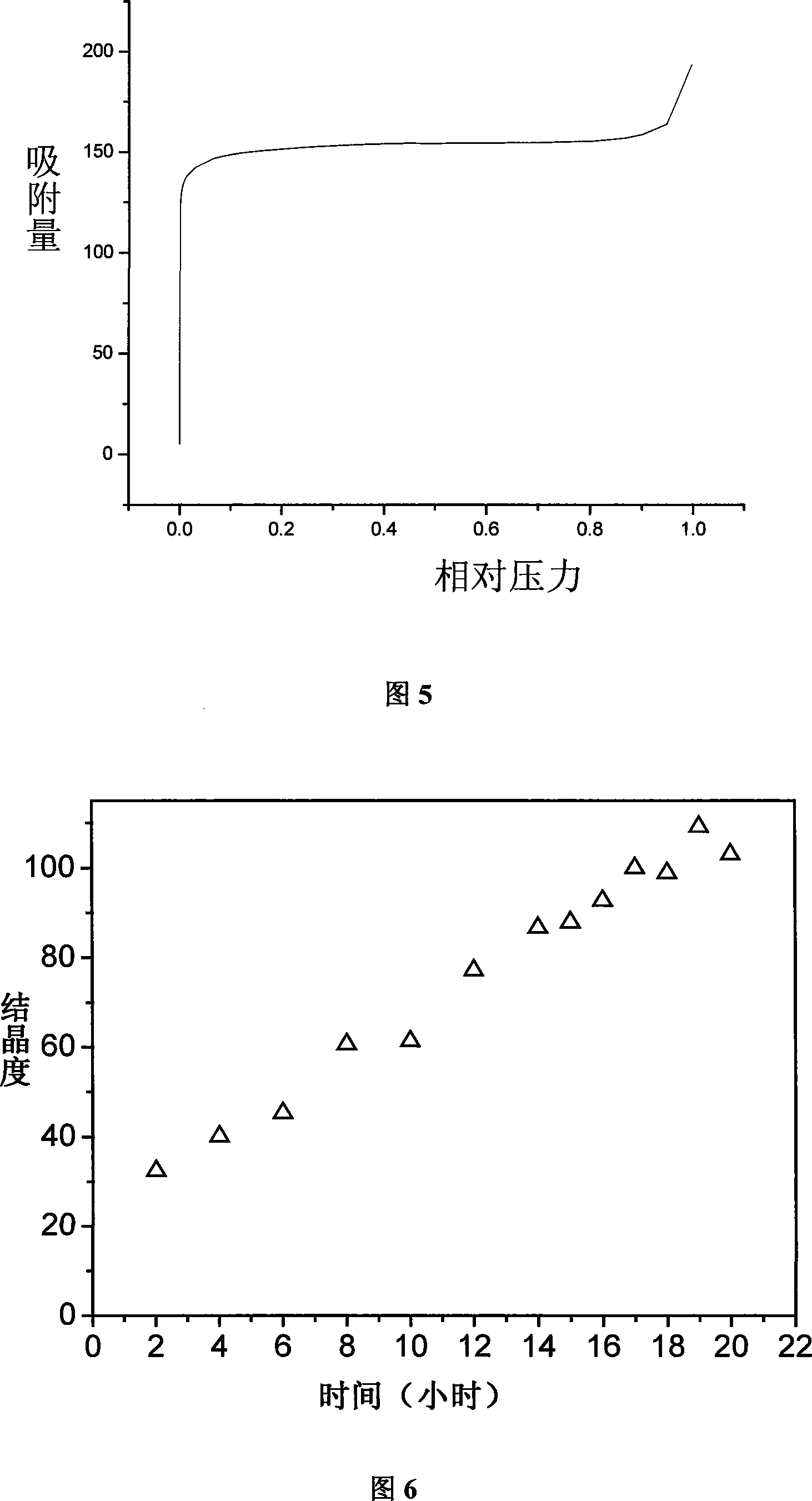

[0029] The starting material molar ratio of Beta molecular sieve synthesis is as follows: 40.28SiO 2 / 1.00Al 2 o 3 / 10.46Na 2 O / 566.66H 2 O, where NaOH / SiO 2 =0.45,H 2 O / SiO 2 About 14. The specific synthesis process is as follows: 0.117g of NaAlO 2 and 0.36g of NaOH dissolved in 5.04ml of H 2 O, after being dissolved, 1.2g of white carbon black was added to the above solution. After stirring for about 10-15 minutes, 0.12g Beta zeolite seed crystals (provided by Sinopec, SiO 2 / Al 2 o 3 =22, SEM and XRD (as shown in Figure 1 and Figure 2) were added to the above gel, and continued to stir at room temperature for about 10-15 minutes. Afterwards, the above-mentioned gel was put into a stainless steel reactor with polytetrafluoroethylene lining, and crystallized at 140° C. for about 19 hours. After cooling, filter at room temperature and dry overnight at 80°C to obtain the product. Acco...

Embodiment 2

[0031] Embodiment 2: rapid synthesis of Beta molecular sieve without template

[0032] The starting material molar ratio of Beta molecular sieve synthesis is as follows: 40.28SiO 2 / 1.00Al 2 o 3 / 11.46Na 2 O / 566.66H 2 O, where NaOH / SiO 2 =0.50,H 2 O / SiO 2 About 14. The specific synthesis process is as follows: 0.117g of NaAlO 2 and 0.40 g of NaOH dissolved in 5.04 ml of H 2 O, after being dissolved, 1.2 g of white carbon black was added to the above solution. After stirring for about 10-15 minutes, 0.084 g of Beta zeolite seed crystals (provided by Sinopec) were added to the above gel, and stirring was continued at room temperature for about 10-15 minutes. Afterwards, the above-mentioned gel was put into a stainless steel reaction kettle with polytetrafluoroethylene lining, and crystallized at 140° C. for 19 hours. After cooling, filter at room temperature and dry overnight at 80°C to obtain the product. According to X-ray diffraction characterization, the product ...

Embodiment 3

[0033] Embodiment 3: template-free rapid synthesis of Beta molecular sieves

[0034] The starting material molar ratio of Beta molecular sieve synthesis is as follows: 40.28SiO 2 / 1.00Al 2 o 3 / 11.46Na 2 O / 526.37H 2 O, where NaOH / SiO 2 =0.50,H 2 O / SiO 2 About 13. The specific synthesis process is as follows: 0.117g of NaAlO 2 and 0.40 g of NaOH dissolved in 4.68 ml of H 2 O, after being dissolved, 1.2 g of white carbon black was added to the above solution. After stirring for about 10-15 minutes, 0.12 g of Beta zeolite seed crystals (provided by Sinopec) were added to the above gel, and stirring was continued at room temperature for about 10-15 minutes. Afterwards, the above-mentioned gel was put into a stainless steel reaction kettle with polytetrafluoroethylene lining, and crystallized at 140° C. for 19 hours. After cooling, filter at room temperature and dry overnight at 80°C to obtain the product. It is known through X-ray diffraction characterization that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com