Patents

Literature

33results about How to "Avoid failure mode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

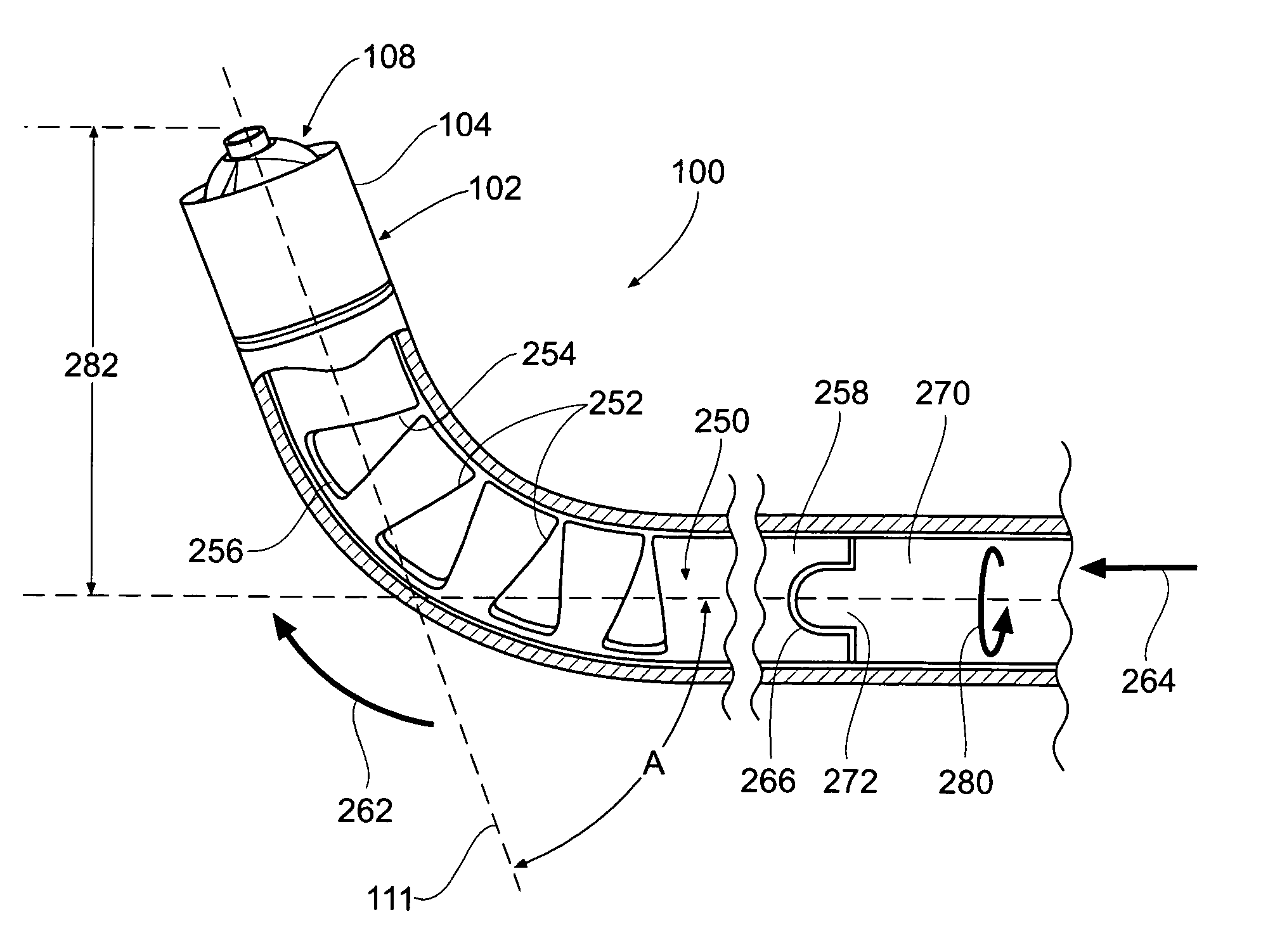

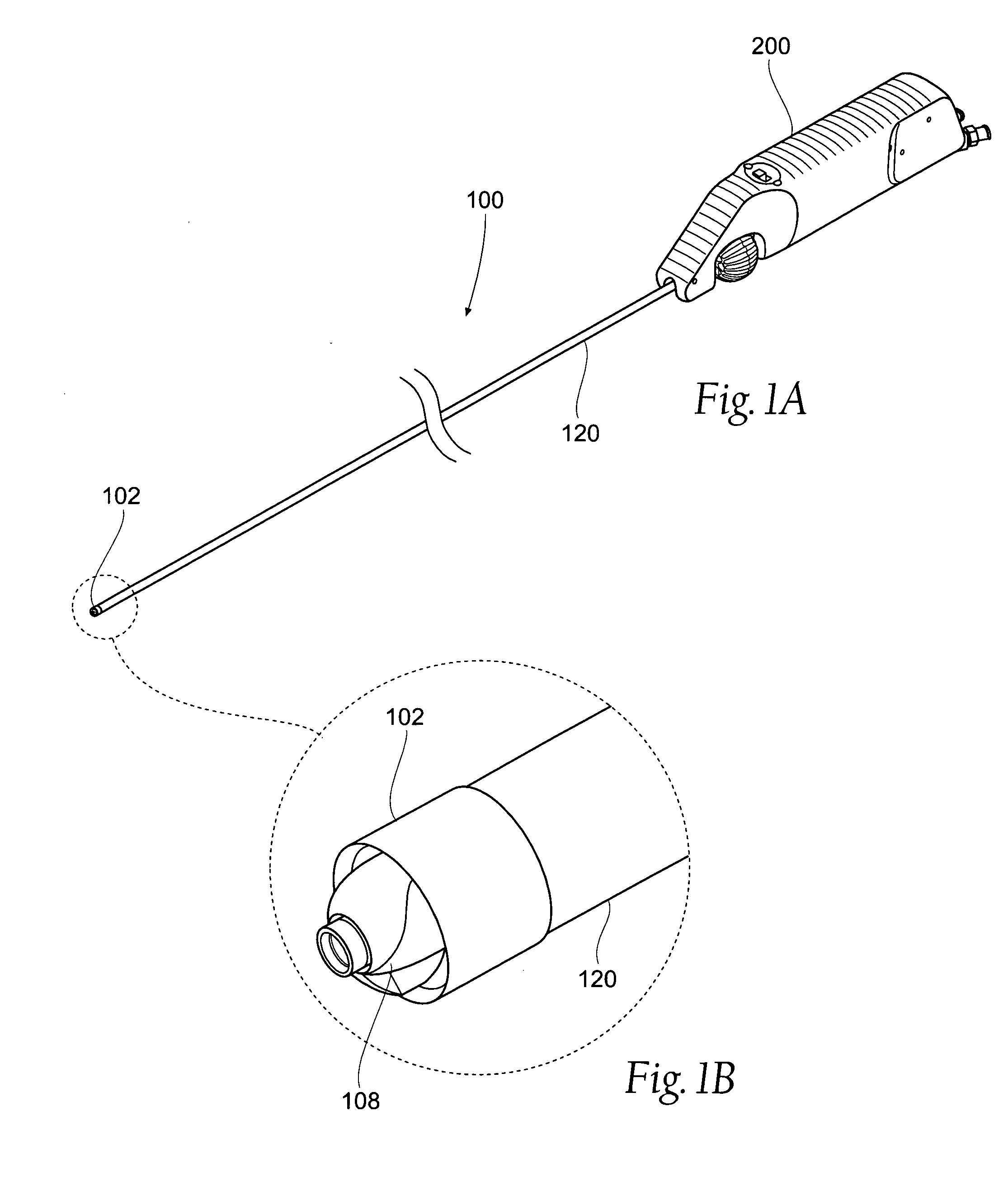

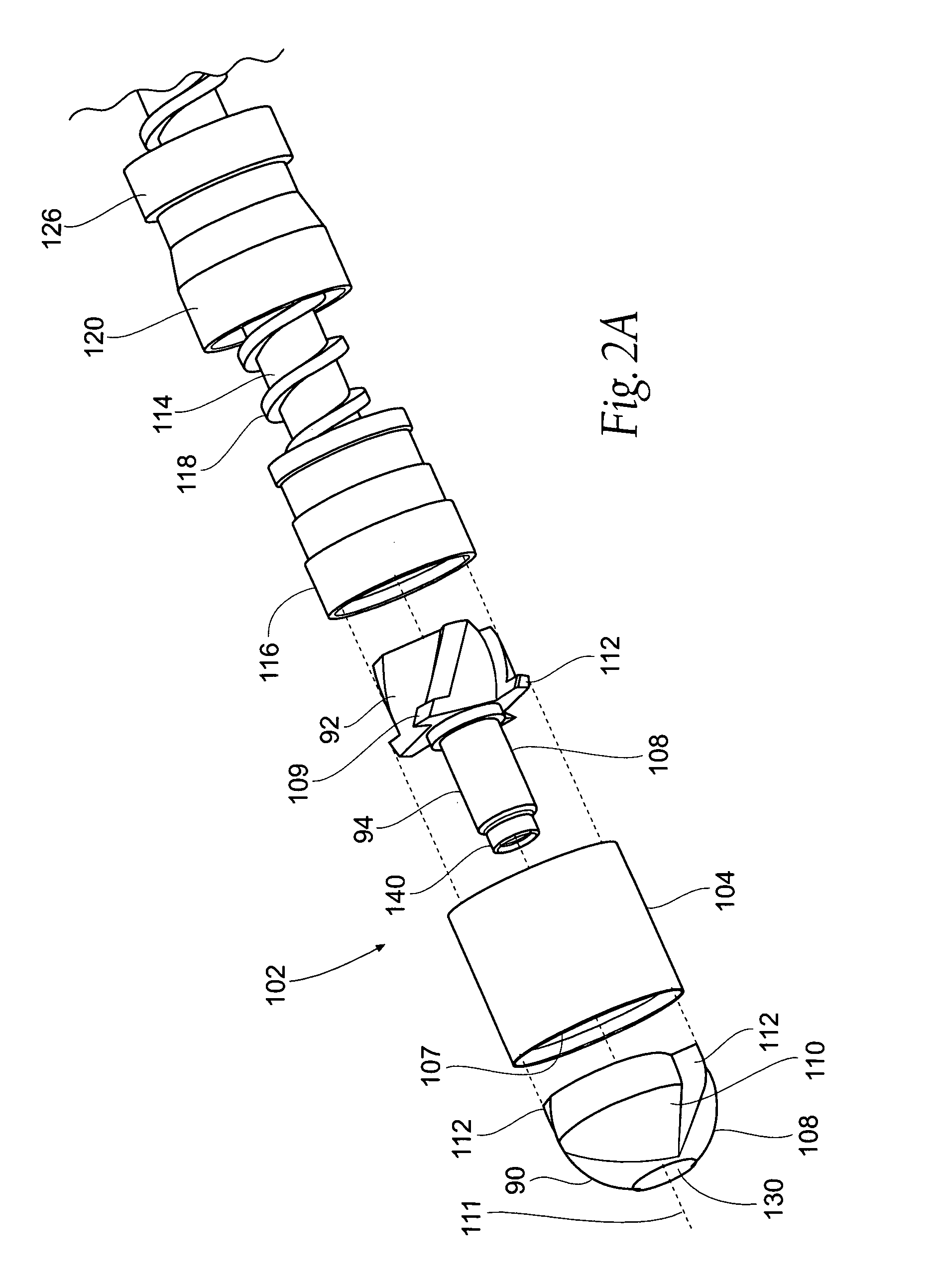

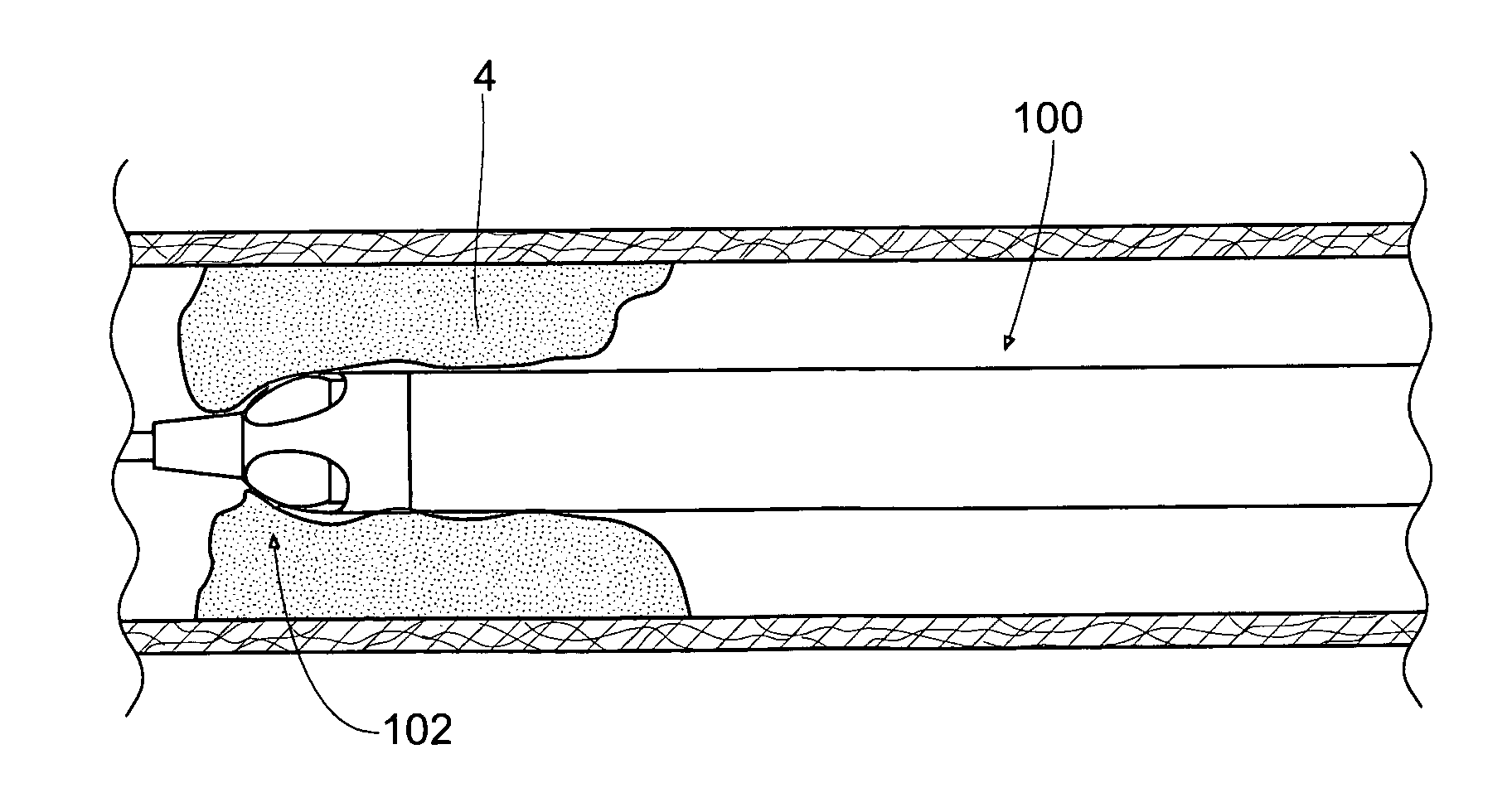

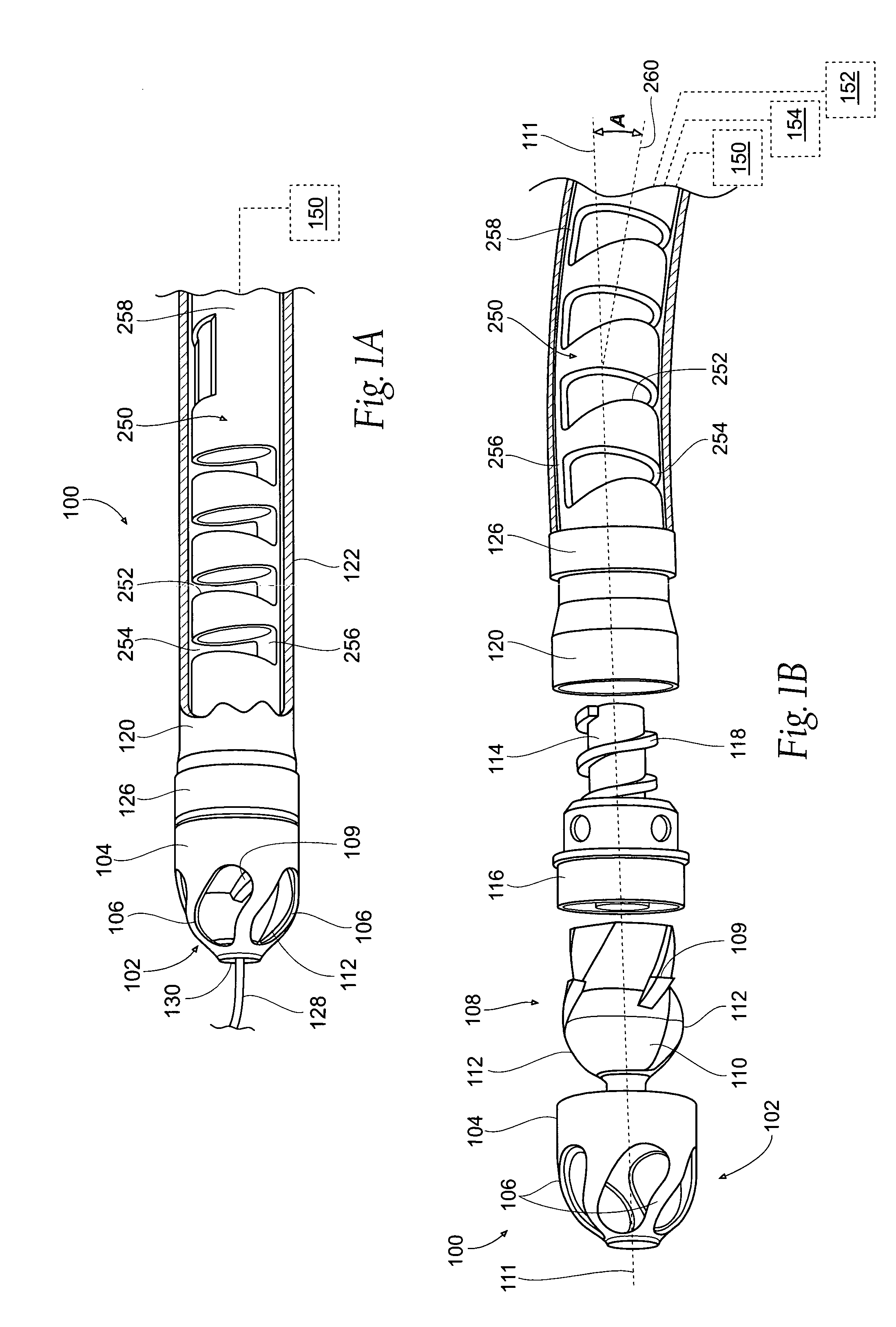

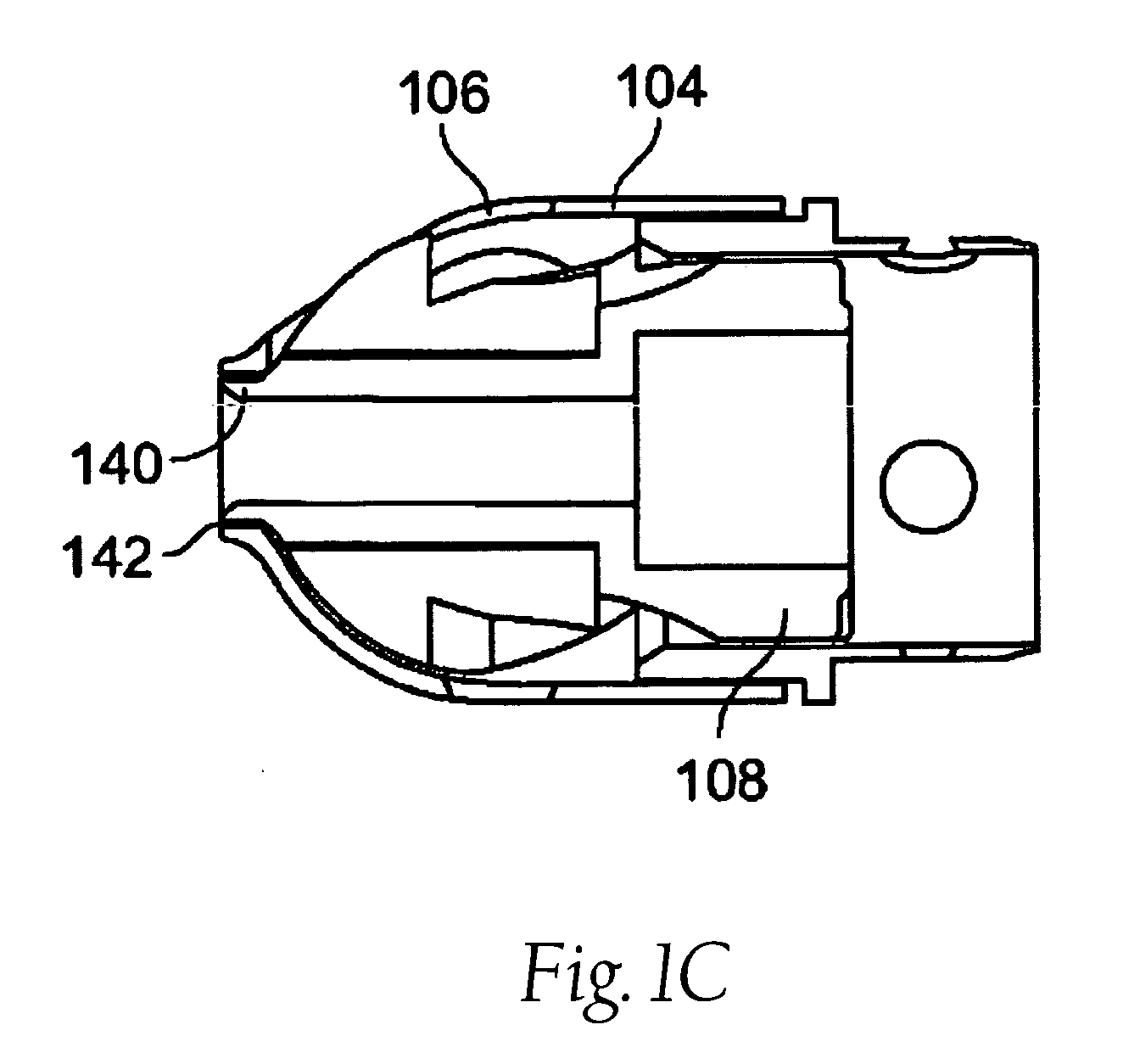

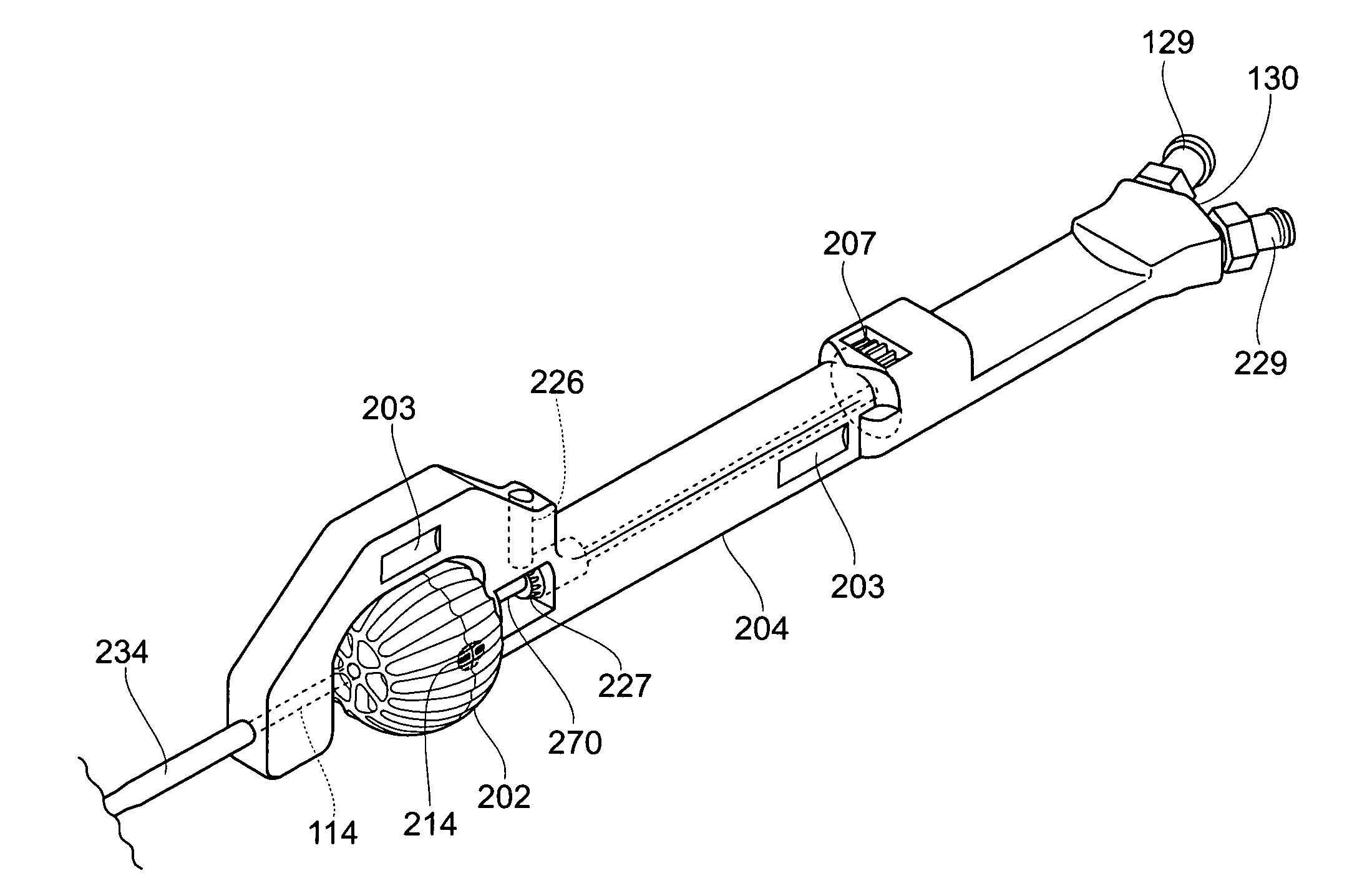

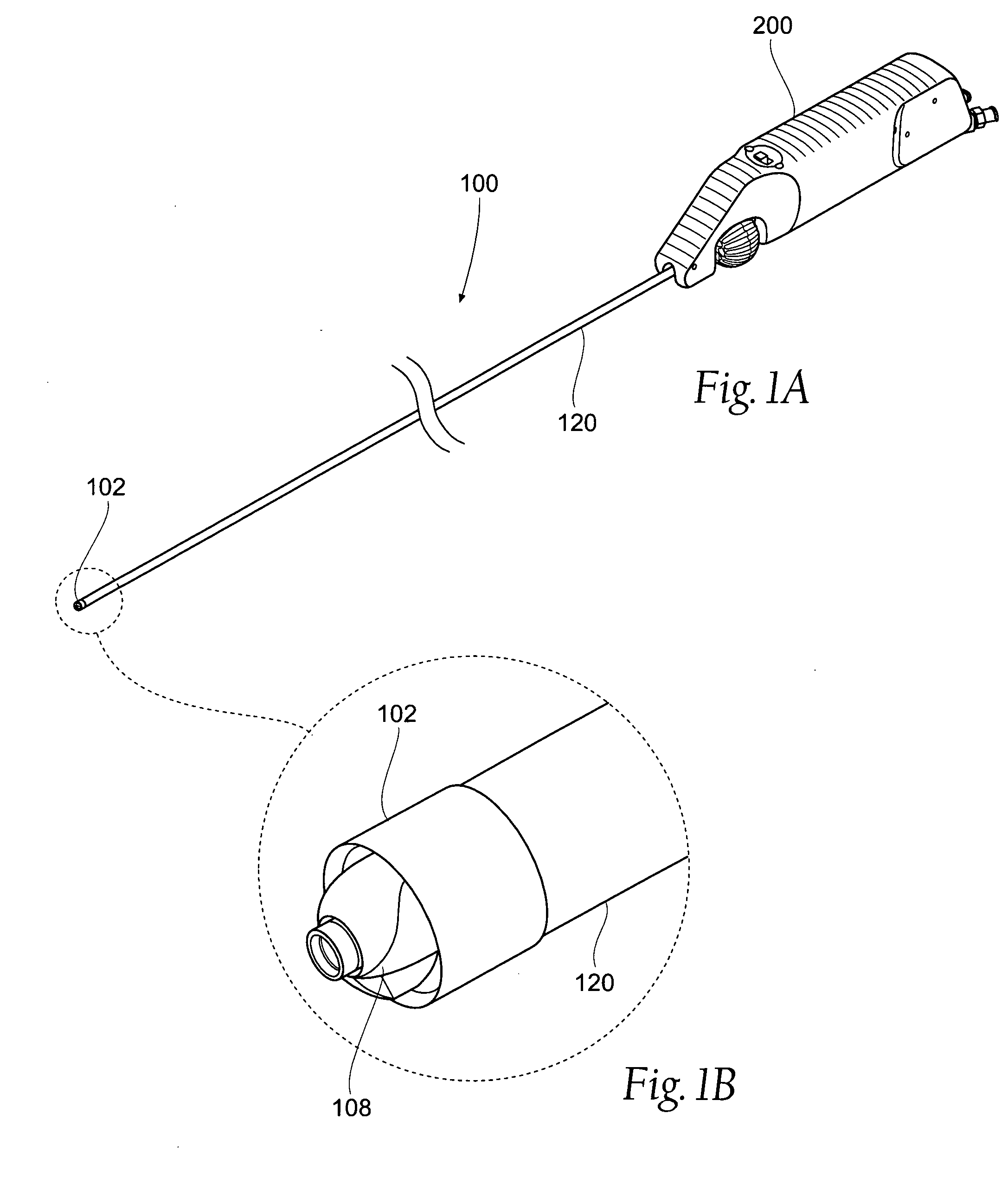

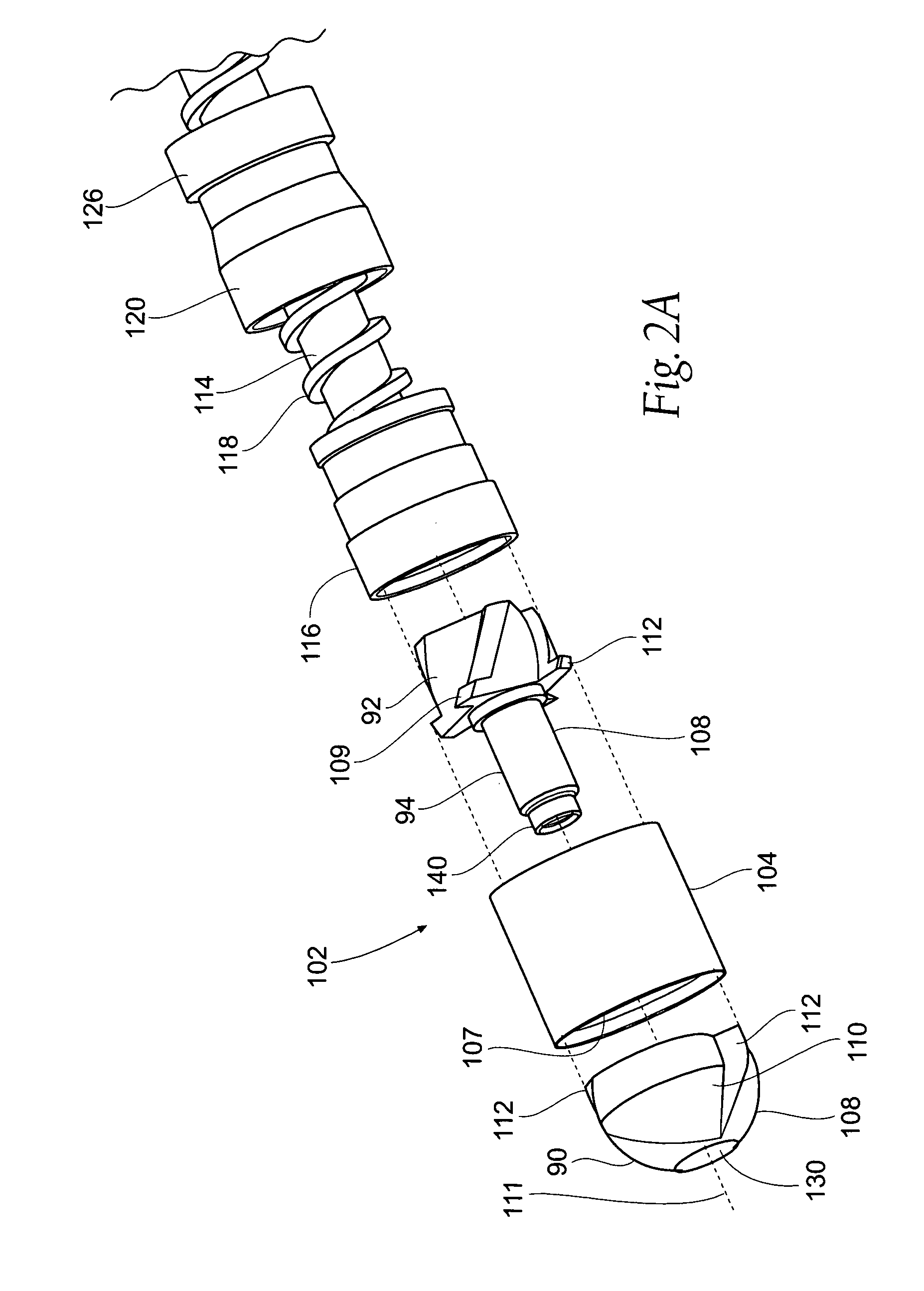

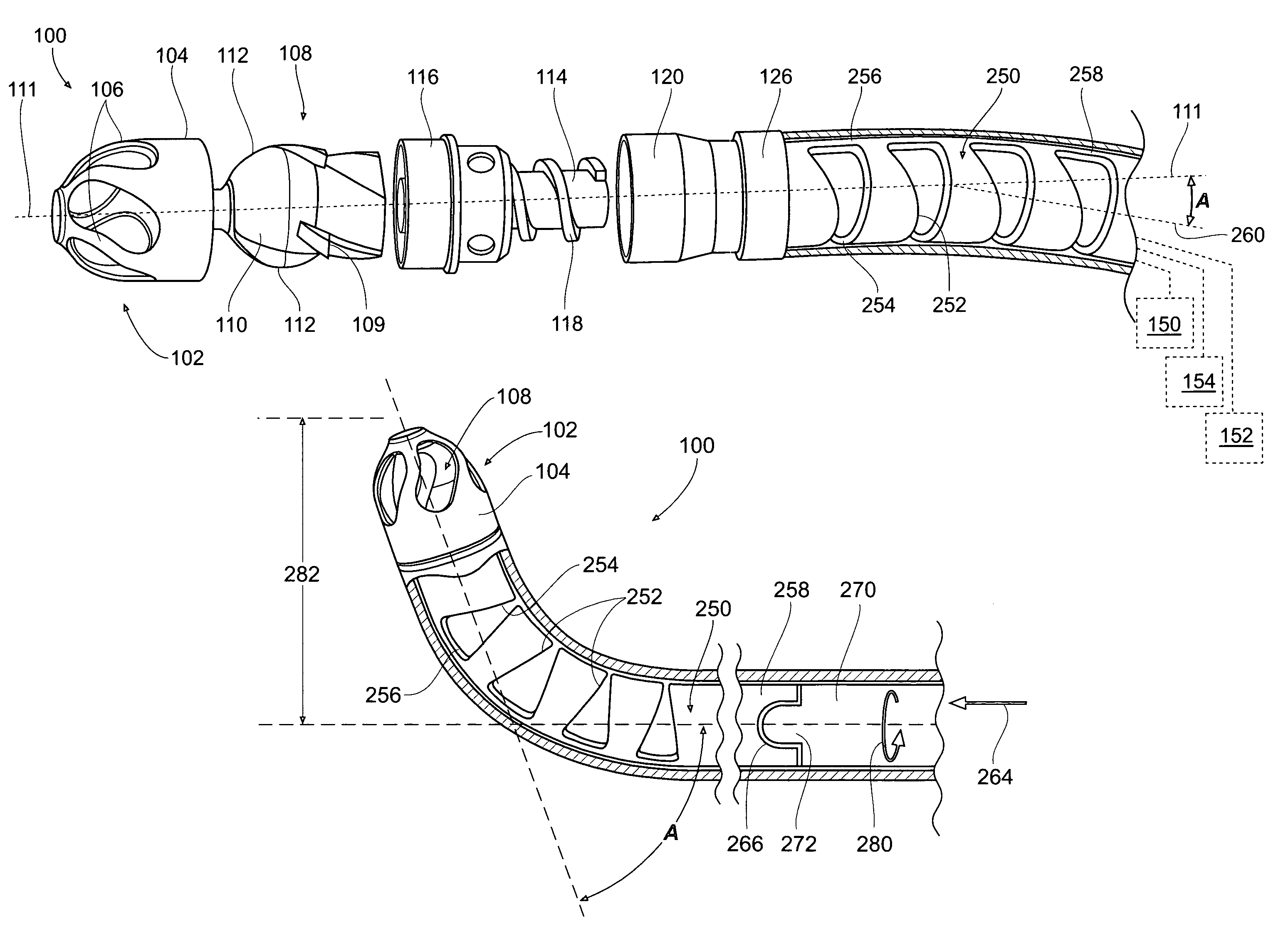

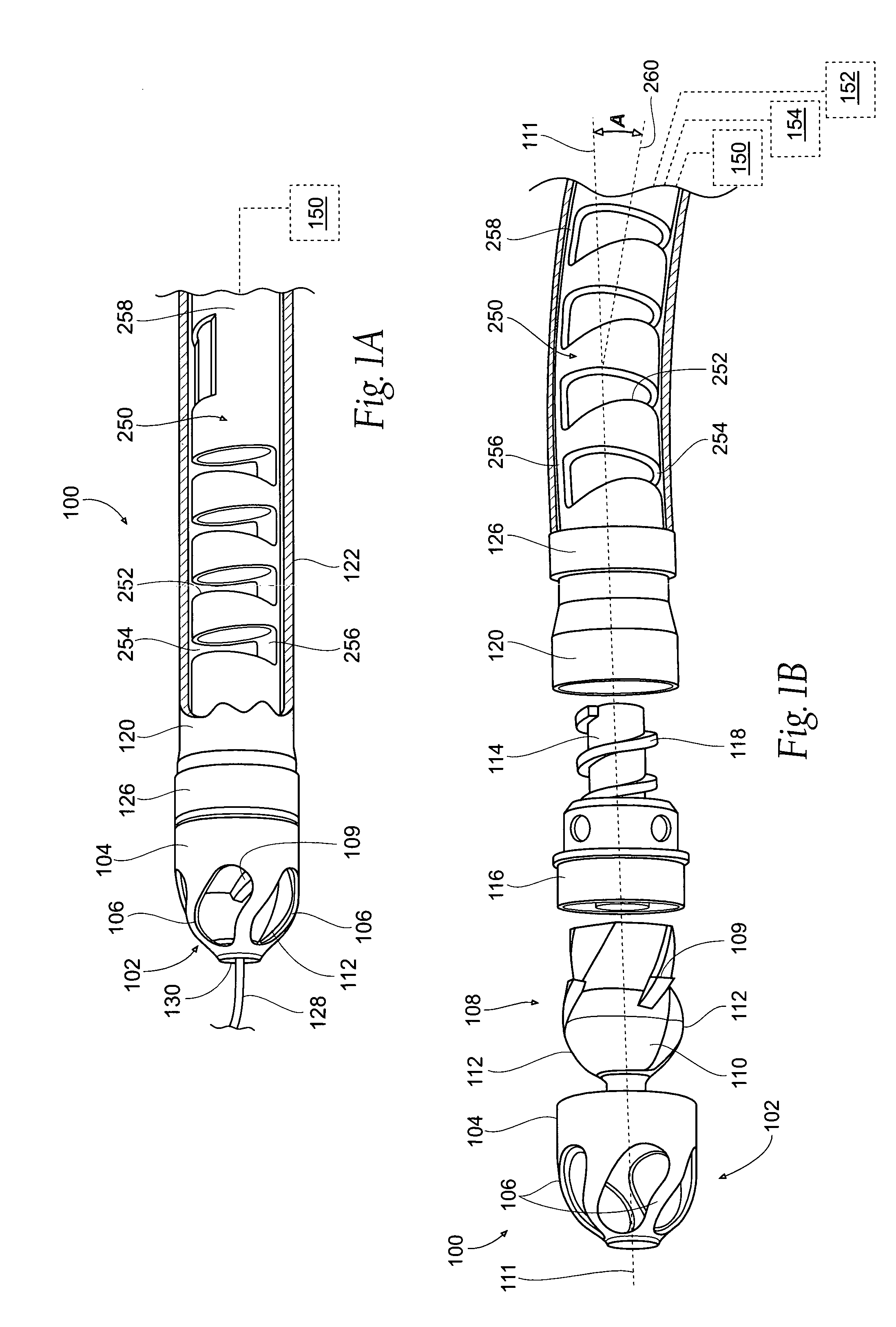

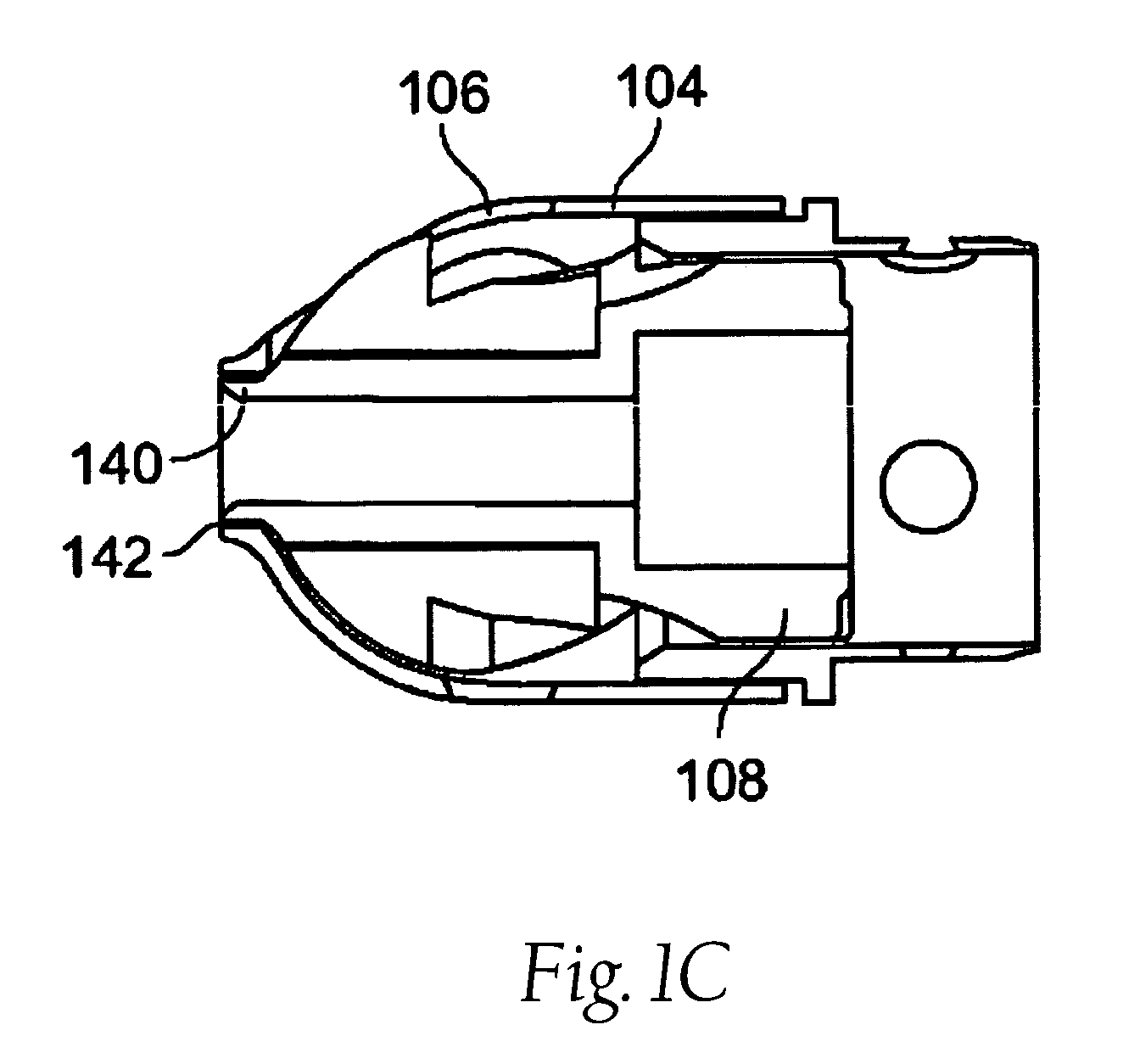

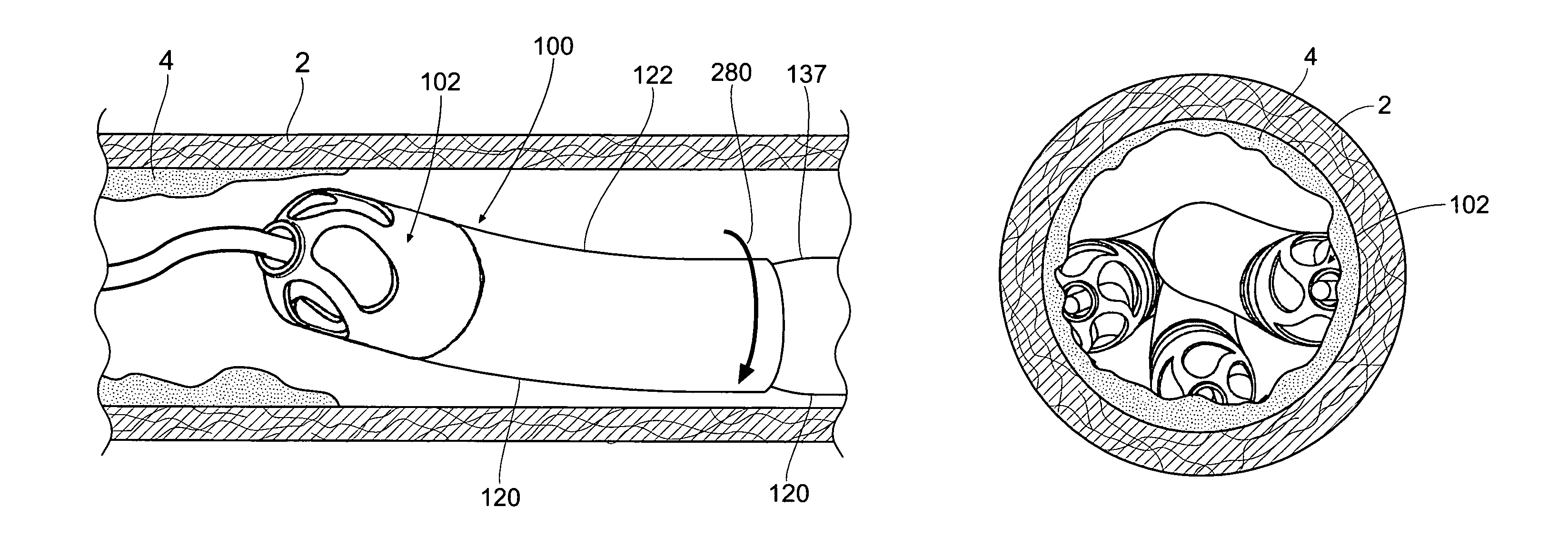

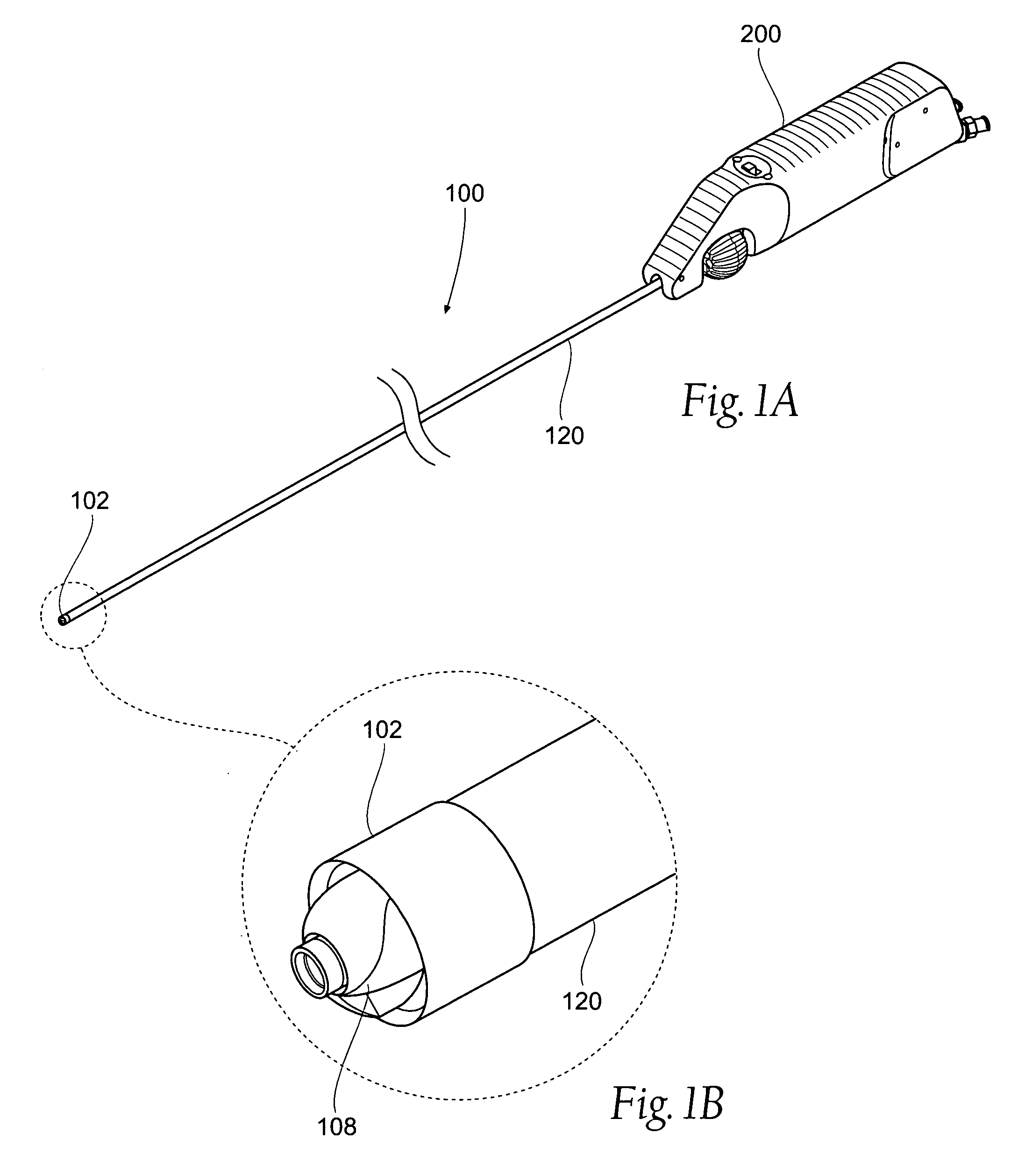

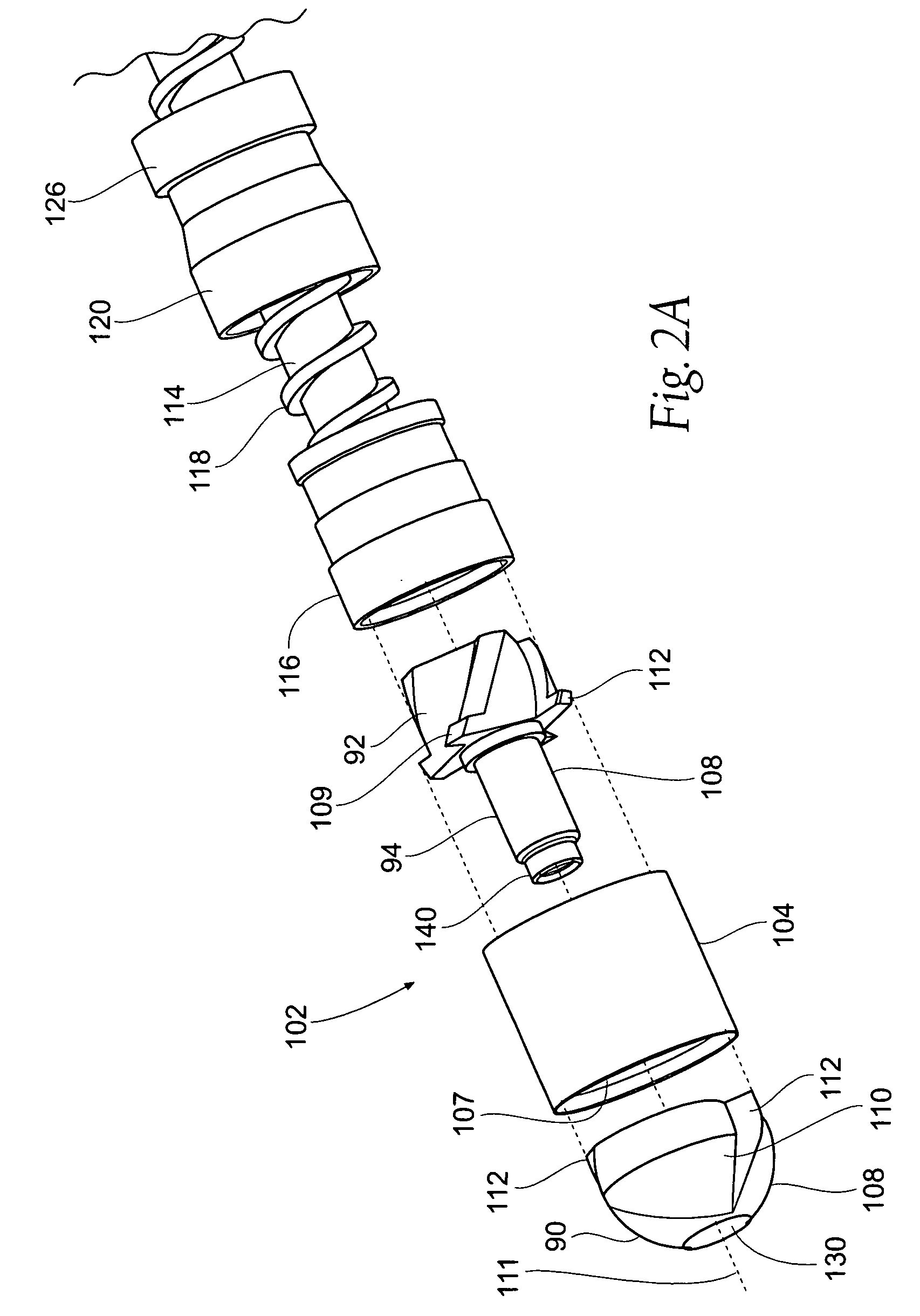

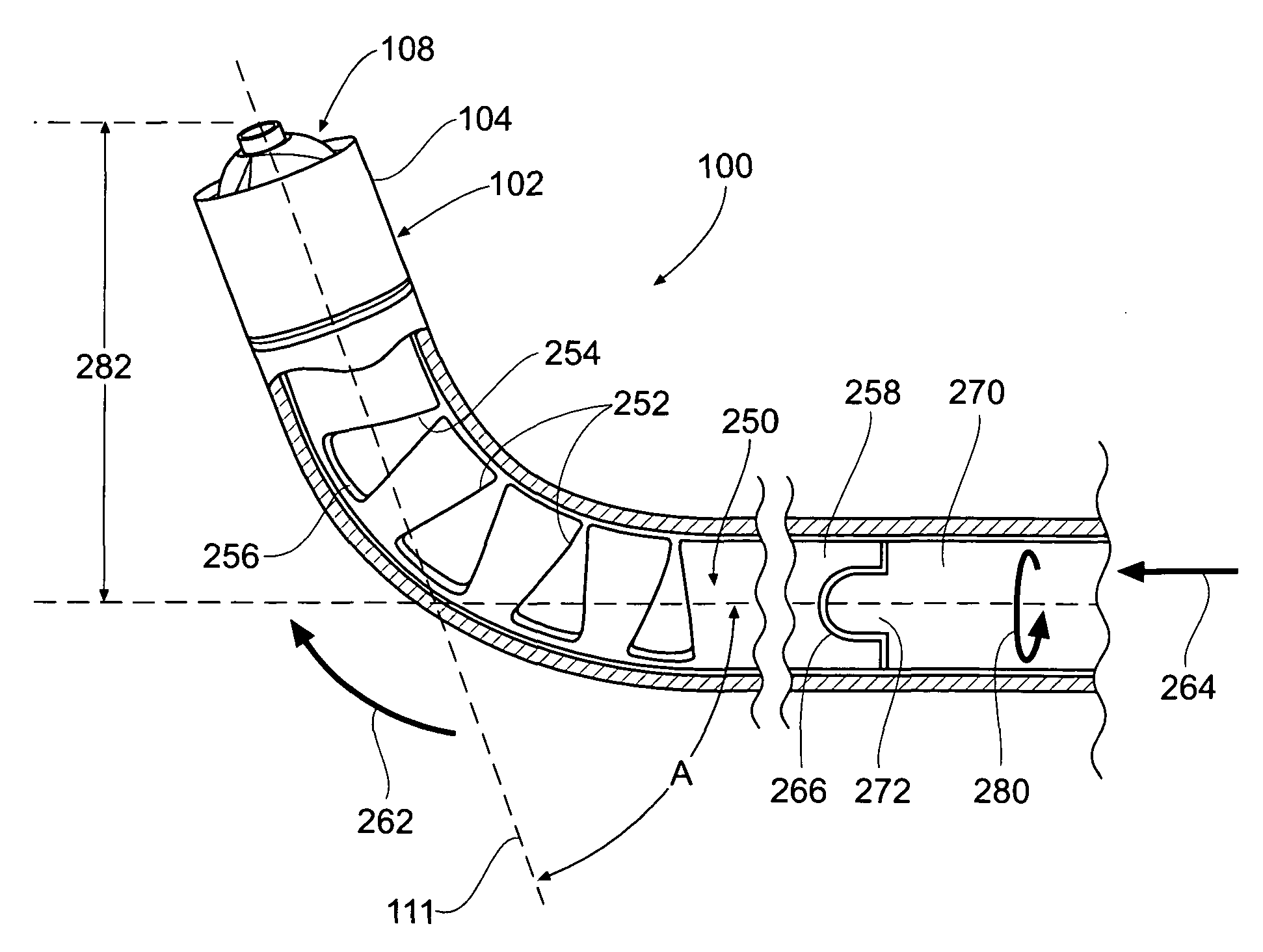

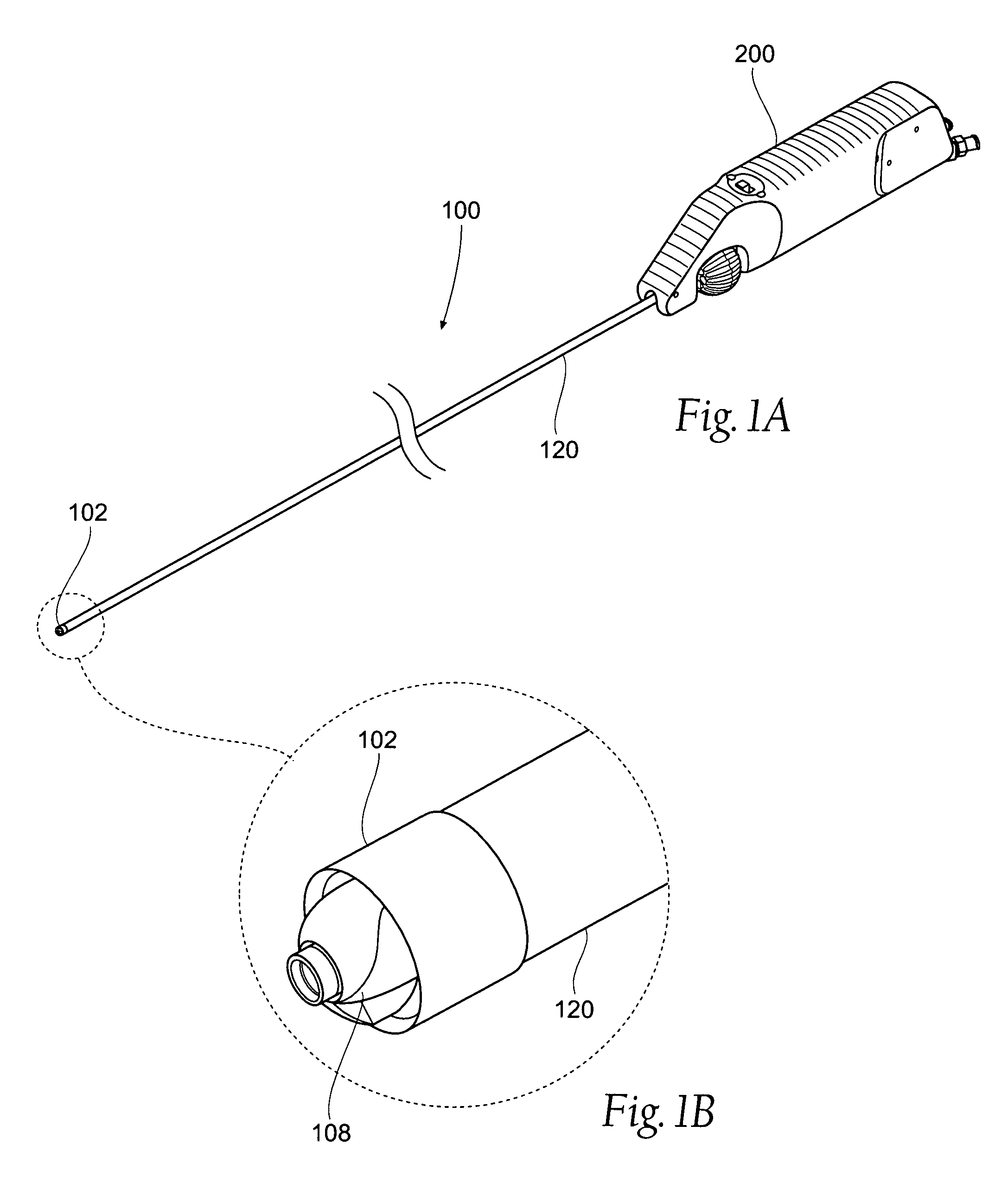

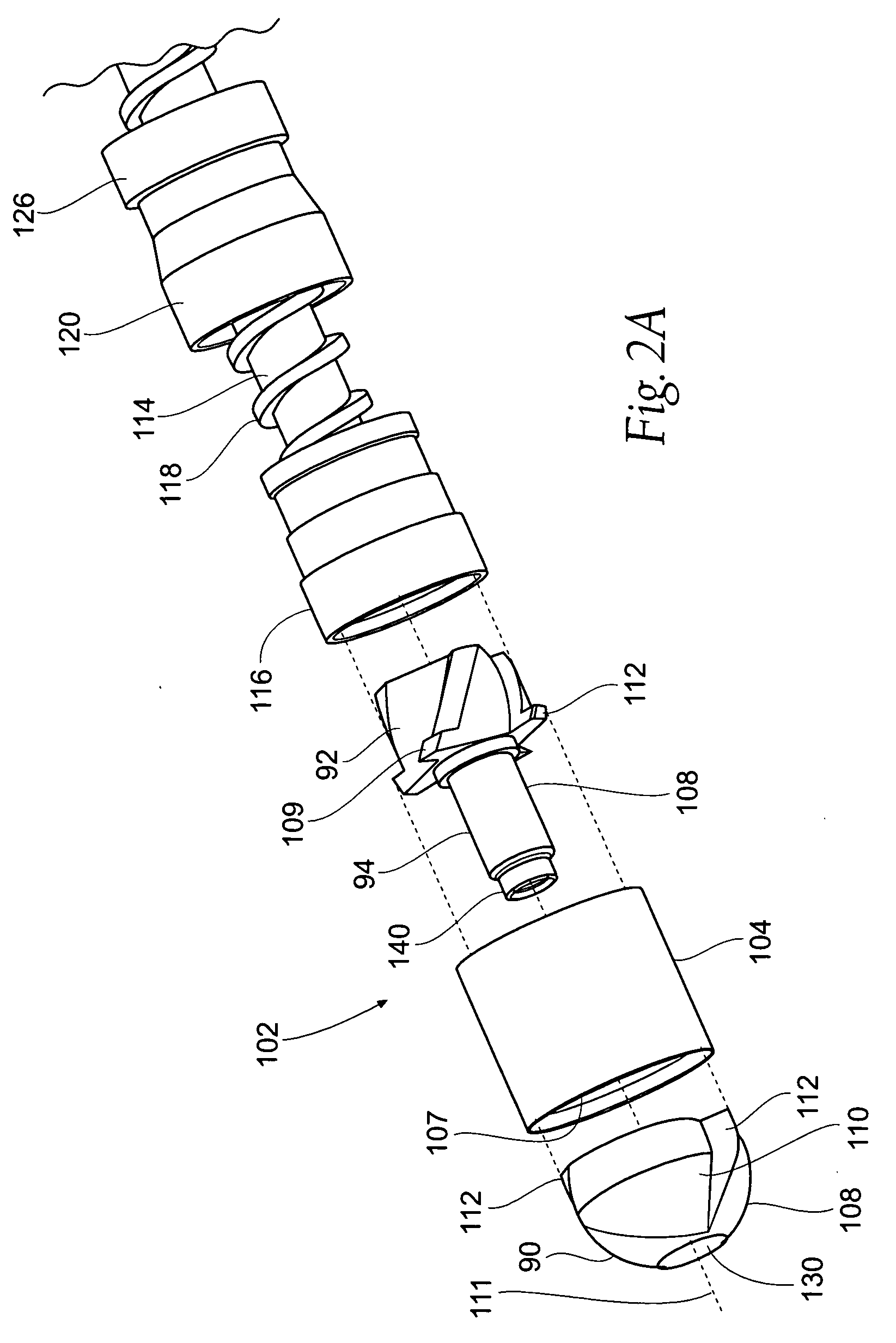

Atherectomy devices, systems, and methods

Owner:ATHEROMED

Atherectomy devices and methods

ActiveUS20100049225A1Prevent accidental cuttingIncrease blockingCannulasCatheterMedicineBiomedical engineering

Owner:ATHEROMED

Atherectomy devices, systems, and methods

ActiveUS20090024085A1Easy to optimizeSet were undesirableMedical devicesCatheterMedicineBlood vessel

Owner:ATHEROMED

Atherectomy devices and methods

ActiveUS8236016B2Prevent radial twistingAvoid distortionCannulasCatheterBiomedical engineeringBlood vessel

Owner:ATHEROMED

Atherectomy devices, systems, and methods

ActiveUS8628549B2Prevent radial twistingAvoid distortionBalloon catheterEar treatmentVascular deviceBlood vessel

The devices and methods generally relate to treatment of occluded body lumens. In particular, the present devices and methods relate to removal of the occluding material from the blood vessels as well as other body lumens. In some variations, the methods comprise providing a vascular device comprising a catheter body, a cutter assembly, a drive mechanism, a torque shaft, and a deflecting mechanism. The methods may further comprise operating the drive mechanism to cut occlusive material, operating the deflecting mechanism to deflect the cutter assembly, and rotating the distal end of the catheter body to sweep the cutter assembly.

Owner:ATHEROMED

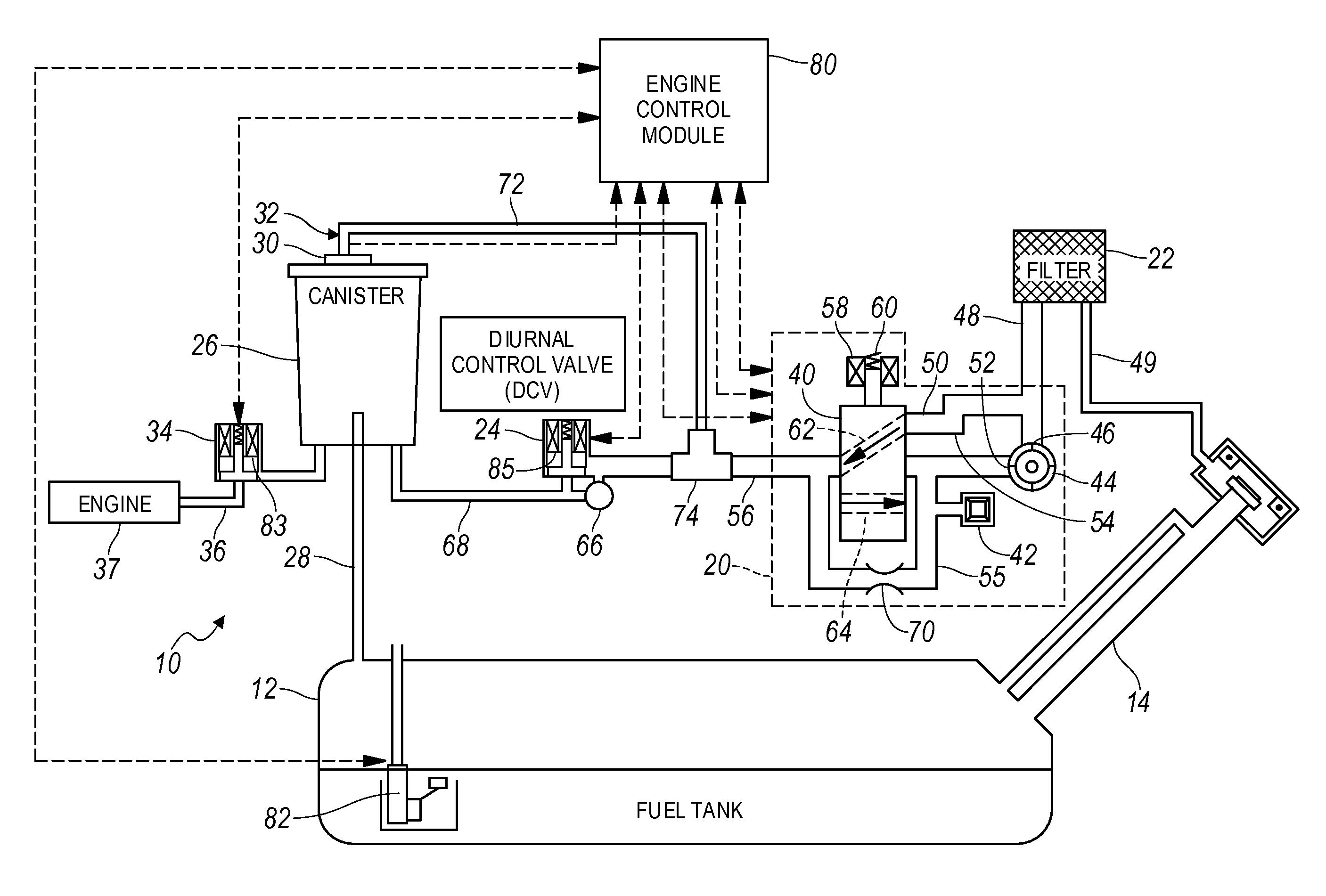

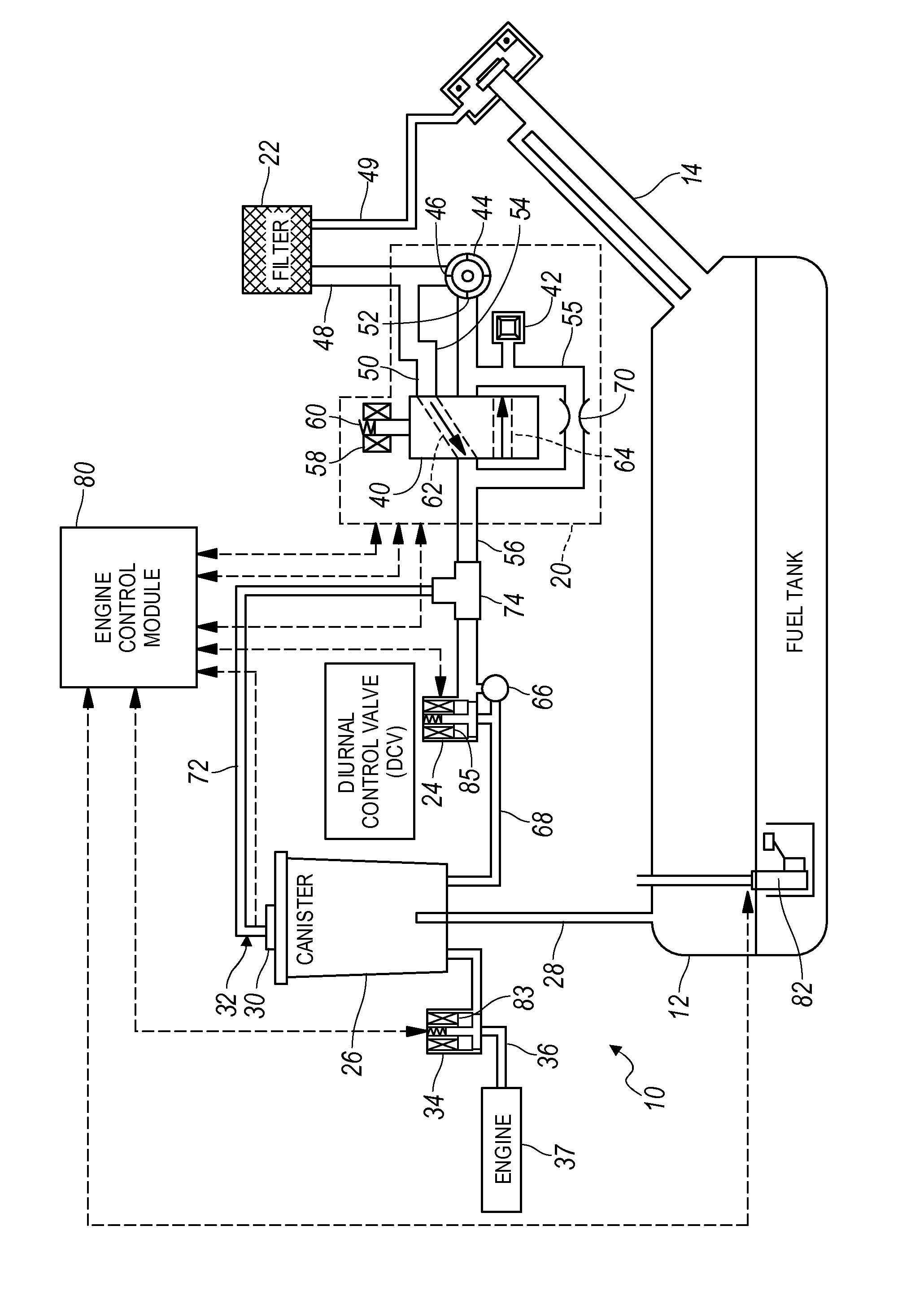

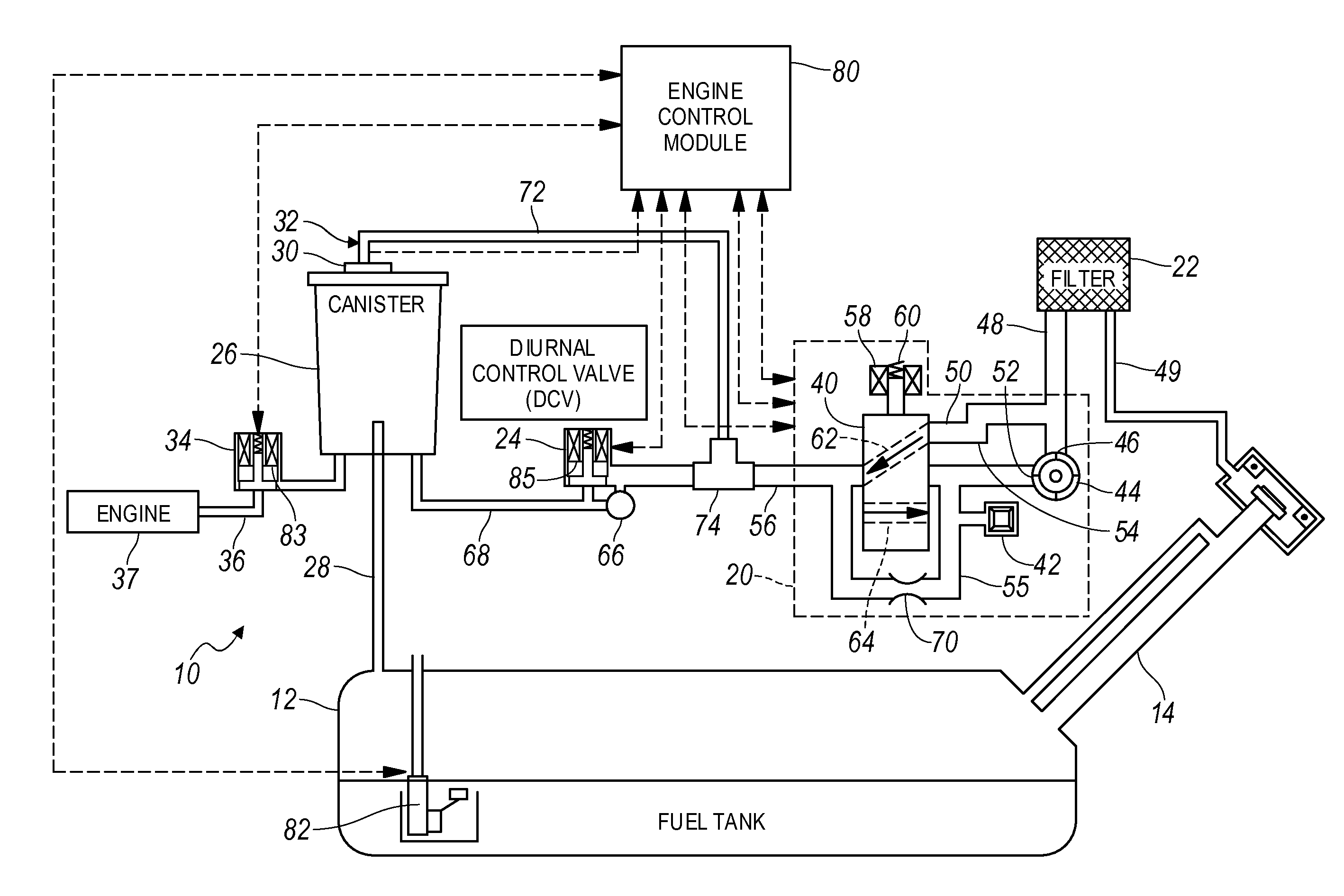

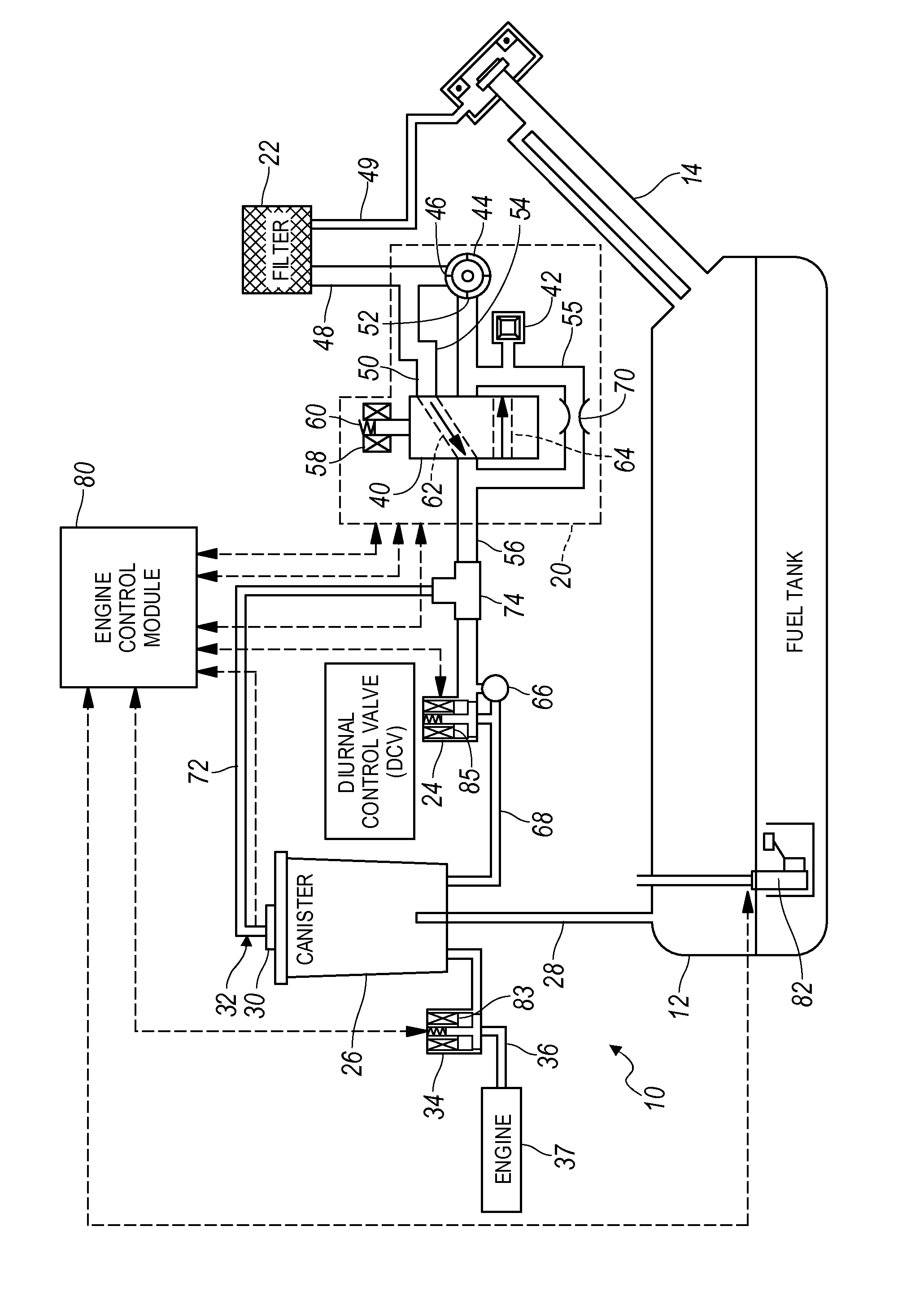

Checking functionality of fuel tank vapor pressure sensor

InactiveUS8342157B2Reliable checkEmission reductionNon-fuel substance addition to fuelMachines/enginesAtmospheric airFuel tank

A vehicle fuel emissions system includes a fuel tank, a tank pressure sensor indicating a pressure differential between the tank and a port communicating with the atmosphere, a pump for selectively producing vacuum in the tank, and a passage connecting the pump and a pressure sensor air reference port external to the system.

Owner:GM GLOBAL TECH OPERATIONS LLC

Checking Functionality of Fuel Tank Vapor Pressure Sensor

InactiveUS20110197862A1Reliable checkEmission reductionNon-fuel substance addition to fuelMachines/enginesAtmospheric airFuel tank

A vehicle fuel emissions system includes a fuel tank, a tank pressure sensor indicating a pressure differential between the tank and a port communicating with the atmosphere, a pump for selectively producing vacuum in the tank, and a passage connecting the pump and a pressure sensor air reference port external to the system.

Owner:GM GLOBAL TECH OPERATIONS LLC

Atherectomy devices, systems, and methods

ActiveUS9314263B2Prevent radial twistingAvoid distortionCannulasExcision instrumentsBlood vesselBiomedical engineering

Owner:ATHEROMED

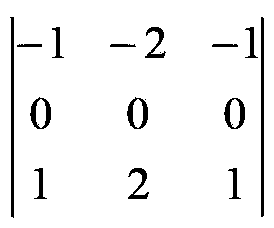

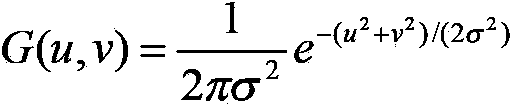

Digital image automatic speckle-removing method

ActiveCN103440633ASave operating timeAvoid failure modeImage enhancementContrast enhancementDigital image

The invention discloses a digital image automatic speckle-removing method. The method is characterized in that: obtaining a result D by successively performing graying, contrast enhancing, gradient maximum searching, skin eliminating, isolation point eliminating, Gauss blurring, threshold processing and region list summation on an image A; and finally performing Poisson equation processing on the speckles in the image A according to the result D and the result of the gradient maximum searching so as to achieve the final effects of automatic acne removing and speckle removing. According to the technical scheme, the hand-operated actions in digital image speckle-removing operation are completely eliminated, the whole process can be automatically finished, no hand-operated speckle calibration and selection are needed, and the operation time and procedures are saved.

Owner:MEITU

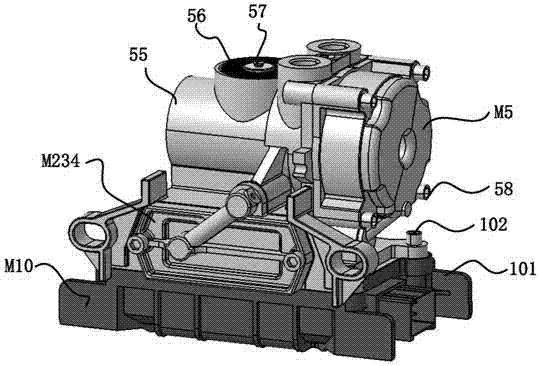

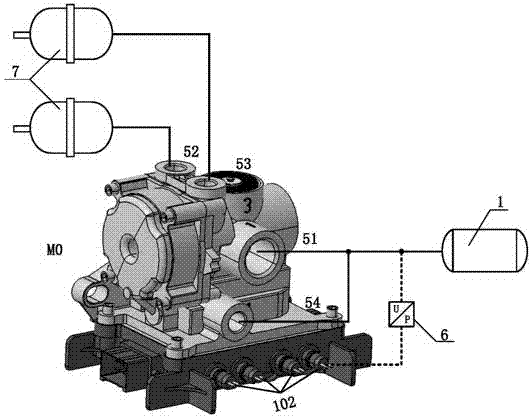

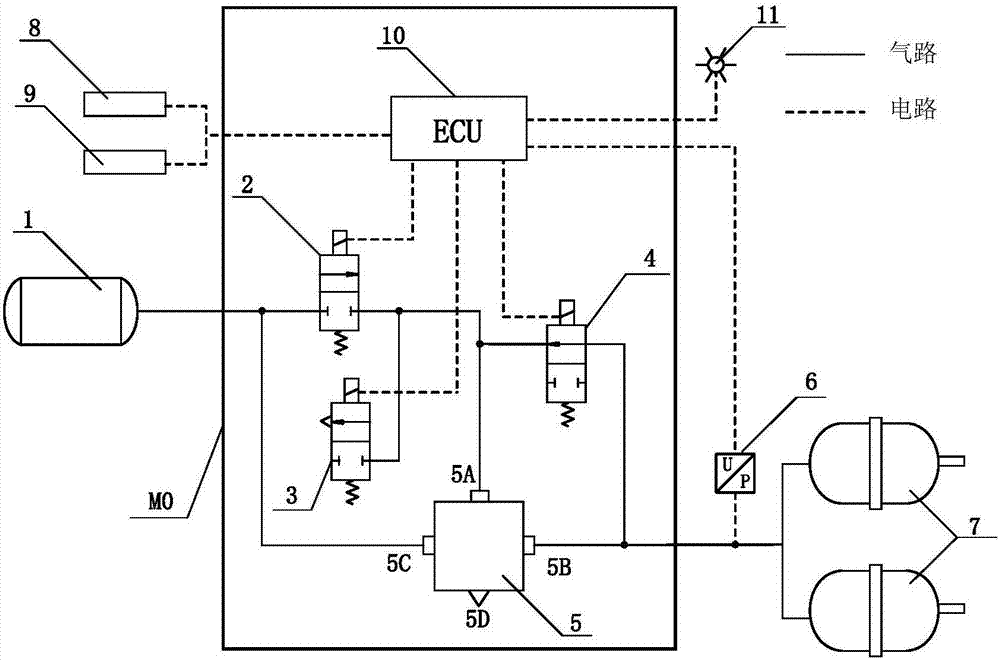

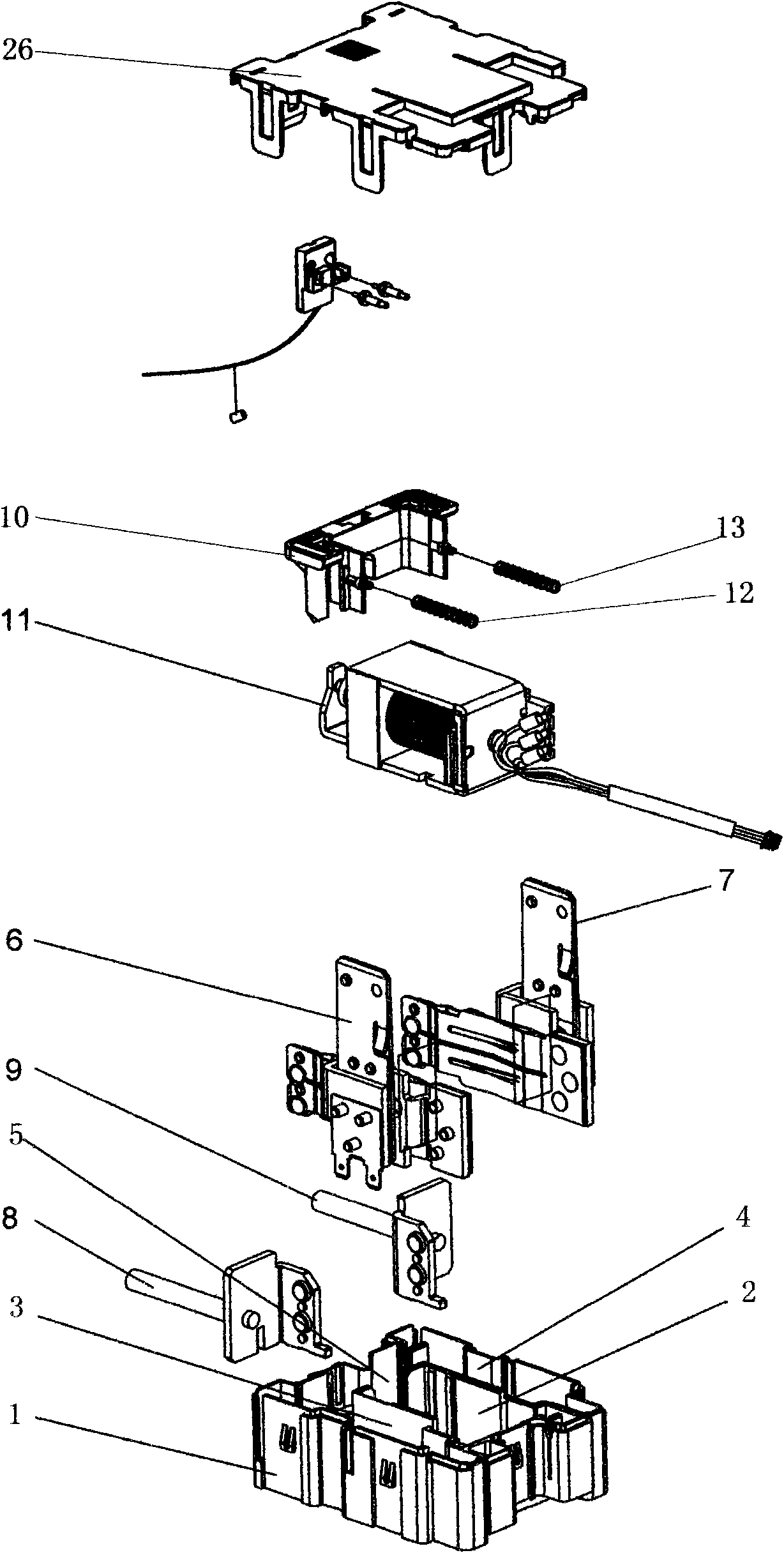

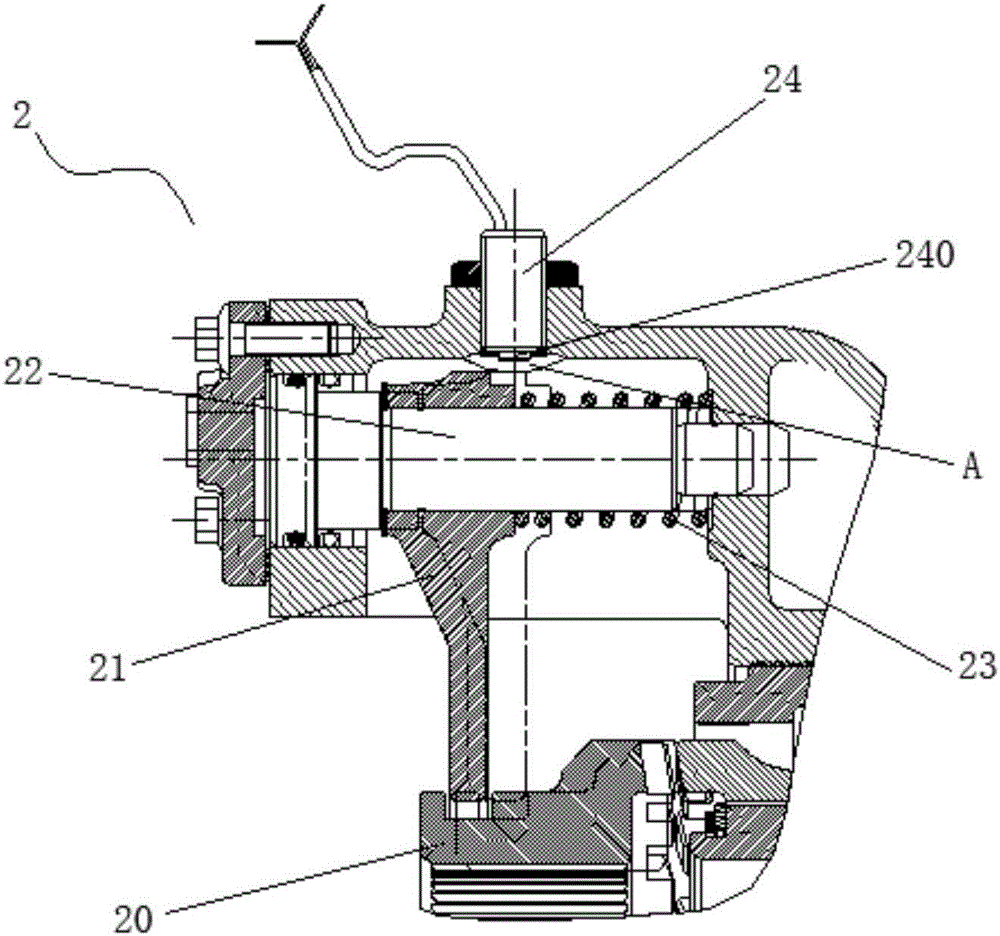

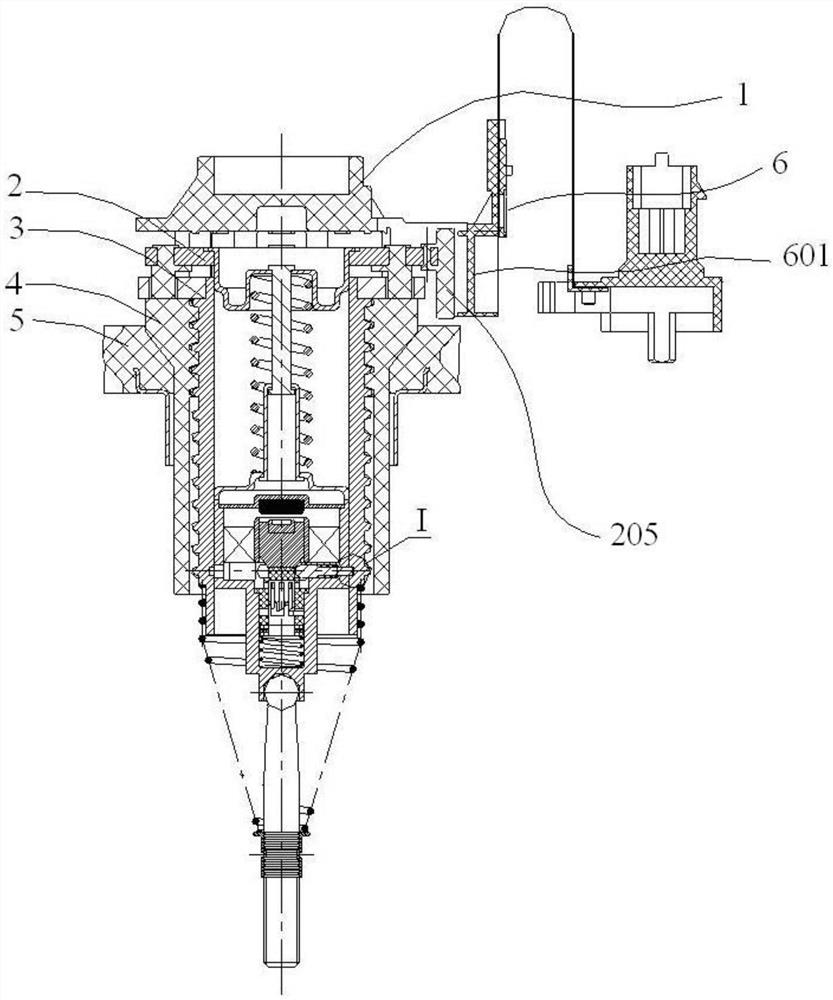

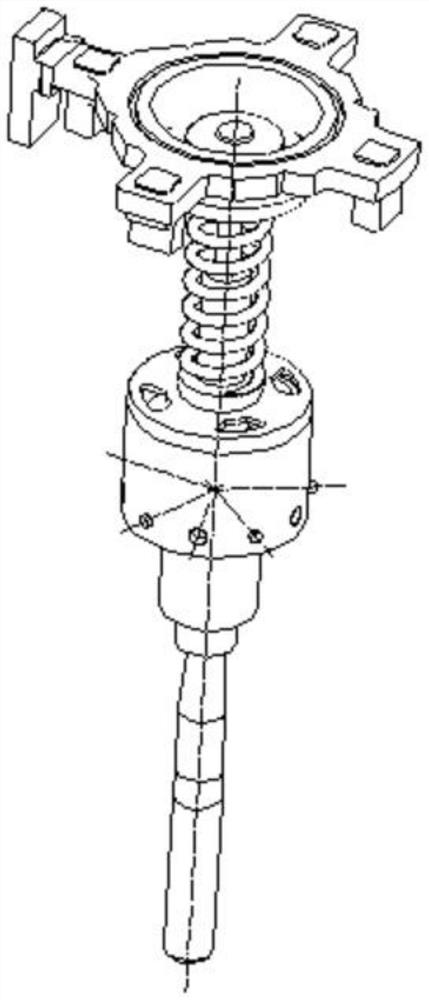

Pneumatic electronic parking brake integrated valve

PendingCN107215327AReduce in quantitySave installation spaceBraking action transmissionApplication and release valvesRelay valveSolenoid valve

The invention discloses a pneumatic electronic parking brake integrated valve which is used for connecting with an air storage tank and a parking brake air chamber. The integrated valve comprises a relay valve assembly (M5), a solenoid valve assembly (M234), a parking brake controller assembly (M10), an upper shell (55) and a lower shell (101), the relay valve assembly (M5) comprises a relay valve (5), the solenoid valve assembly (M234) comprises a first solenoid valve (2), a second solenoid valve (3) and a third solenoid valve (4), the parking brake controller assembly (M10) comprises a parking brake controller (10), the upper shell (55) is detachably and fixedly connected with the lower shell (101), the solenoid valve assembly (M234) is adjacent to the relay valve assembly (M5), the mounting surface of the solenoid valve assembly (M234) is mutually perpendicular to that of the relay valve assembly (M5), both the solenoid valve assembly (M234) and the relay valve assembly (M5) are arranged in the upper shell (55), and the parking brake controller assembly (M10) is arranged at the bottom of the integrated valve and mounted in the lower shell (101). According to the integrated valve, the parking brake controller, three solenoid valves and the relay valve are effectively integrated, pipeline connection is simplified, manufacturing and assembling of components are simplified, and the integrated valve is compact in structure, low in cost and reliable in performance.

Owner:NANJING UNIV OF SCI & TECH

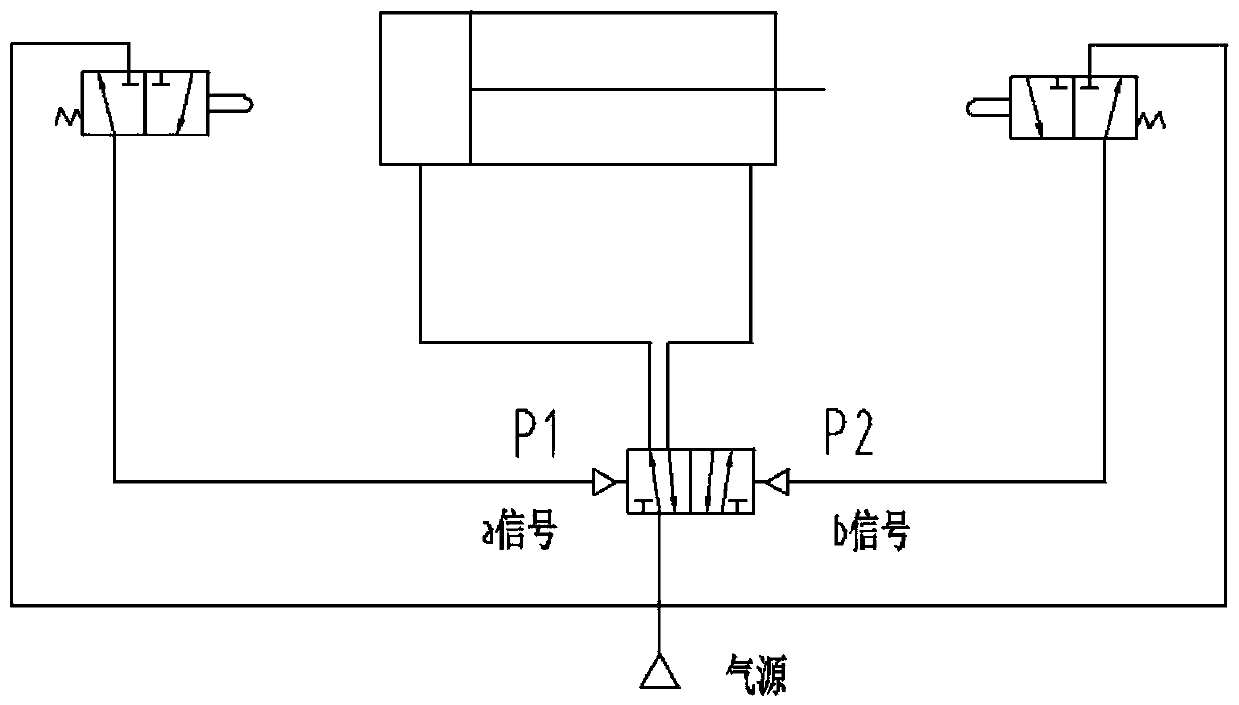

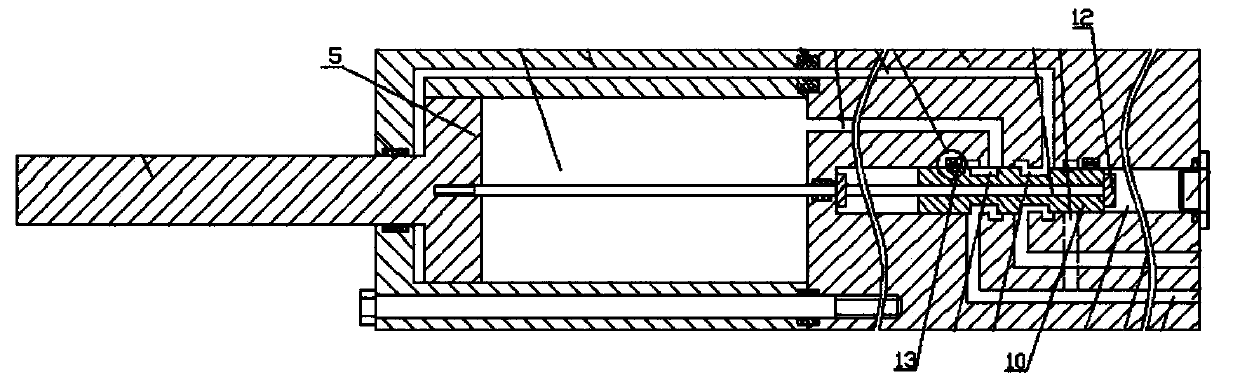

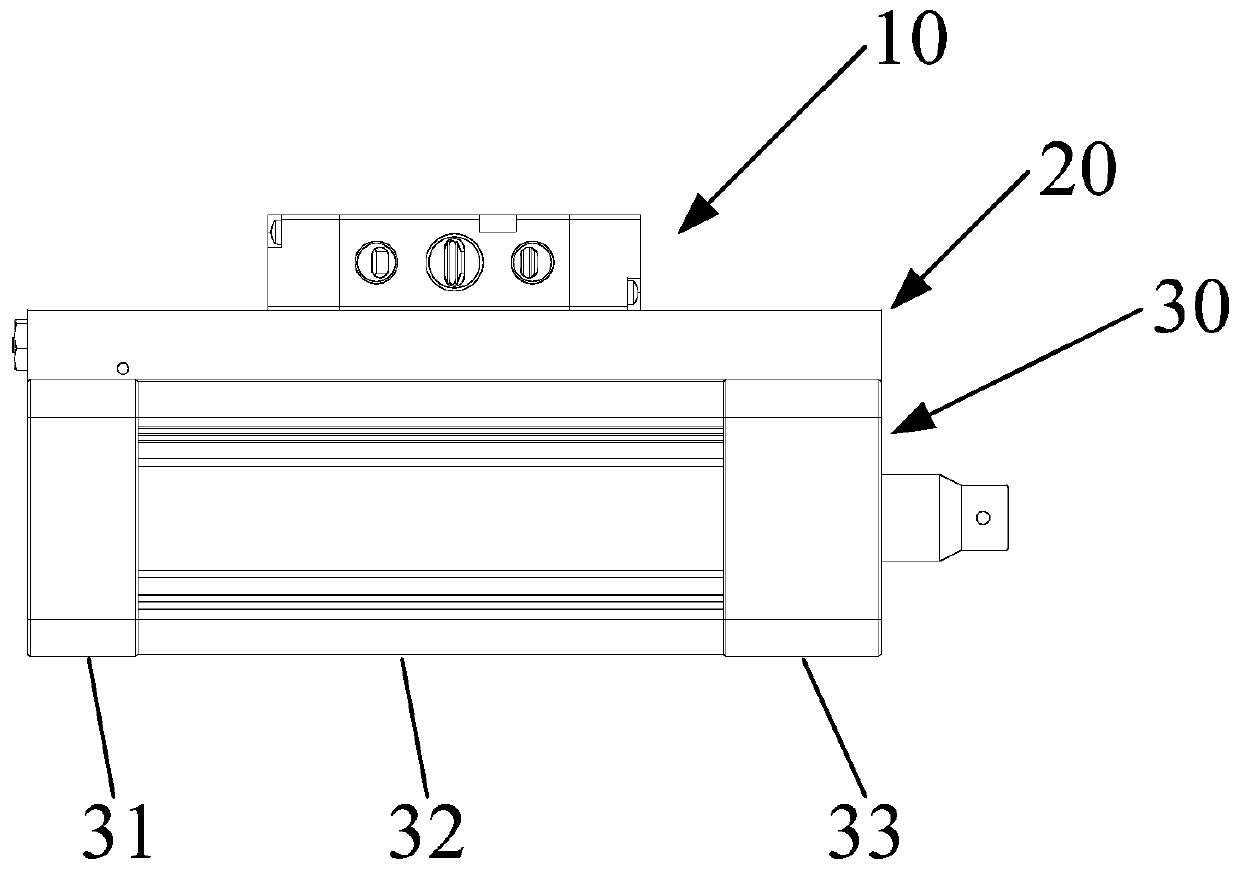

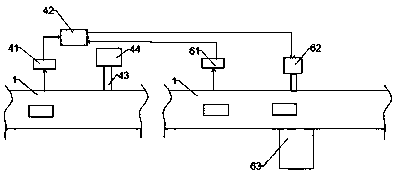

Integrated pilot differential pressure control type automatic reciprocating cylinder

PendingCN110873088AIncrease diversityAvoid failure modeServomotor componentsEngineeringCylinder block

The invention relates to an integrated pilot differential pressure control type automatic reciprocating cylinder. The integrated pilot differential pressure control type automatic reciprocating cylinder comprises a pneumatic control valve module, an air path connecting plate module and a cylinder module, wherein the pneumatic control valve module is connected with the air path connecting plate module through a screw rod, and the air path connecting plate module is connected with the cylinder module through a screw rod; the cylinder module comprises a cylinder rear cover part, a cylinder body part and a cylinder front cover part, wherein the cylinder rear cover part is provided with a rear cover air path and a rear cover pilot air path, and the cylinder front cover part is provided with a front cover air path and a front cover pilot air path; and the integrated pilot differential pressure control automatic reciprocating cylinder further comprises two contact valves, and the two contactvalves are correspondingly assembled and connected with the rear cover pilot air path and the front cover pilot air path. According to the integrated pilot differential pressure type control automaticreciprocating cylinder, a modular design idea is adopted; when the stroke of the cylinder is lengthened, only the length of an air path connecting plate needs to be lengthened; and when the use formof the cylinder is changed, only the design form of the contact valves in a cylinder cover does not change, the integrated pilot differential pressure control type automatic reciprocating cylinder canbe used for changing any cylinder form, and the product diversity is increased.

Owner:ZHEJIANG EASUN PNEUMATIC SCI & TECH

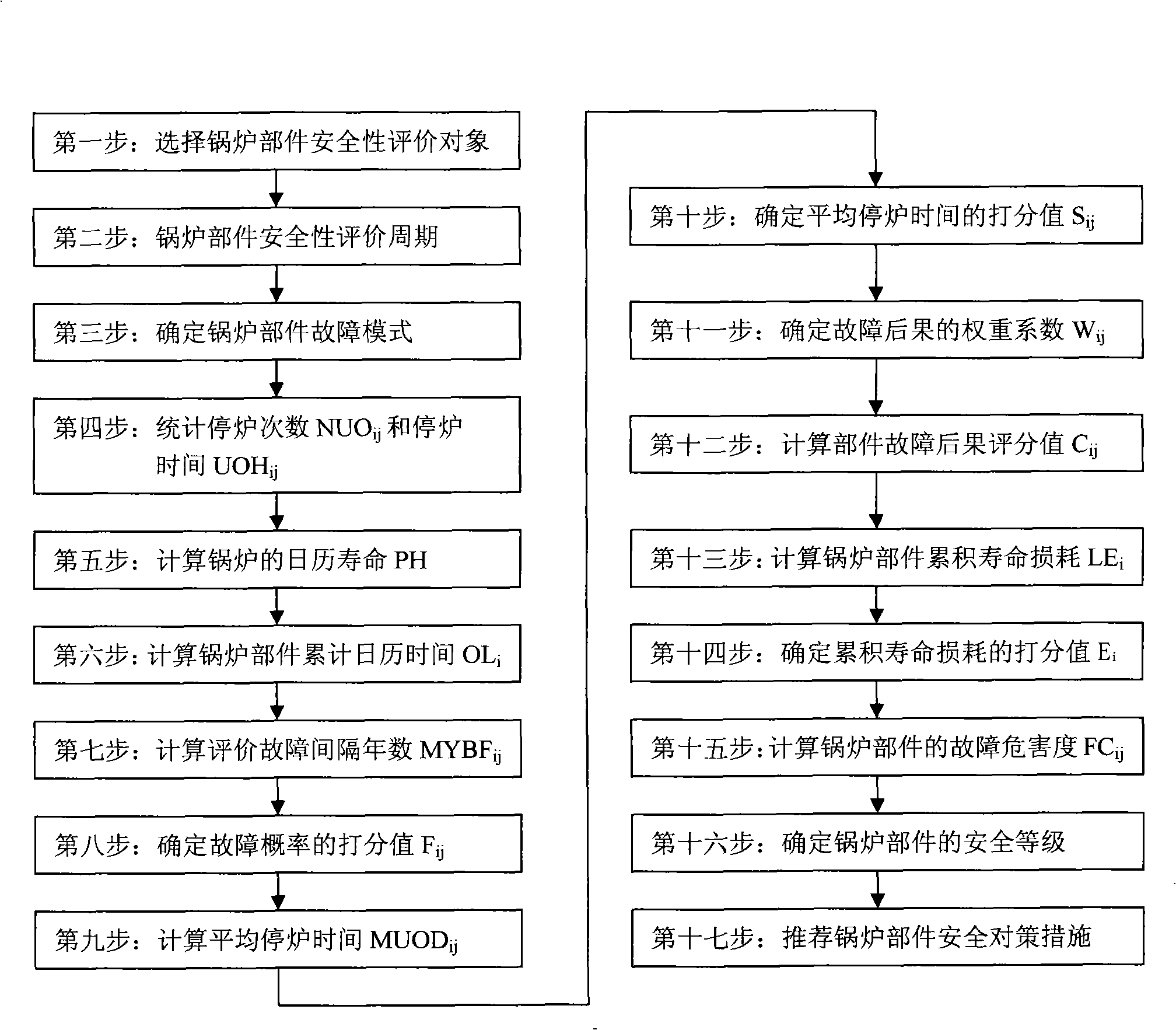

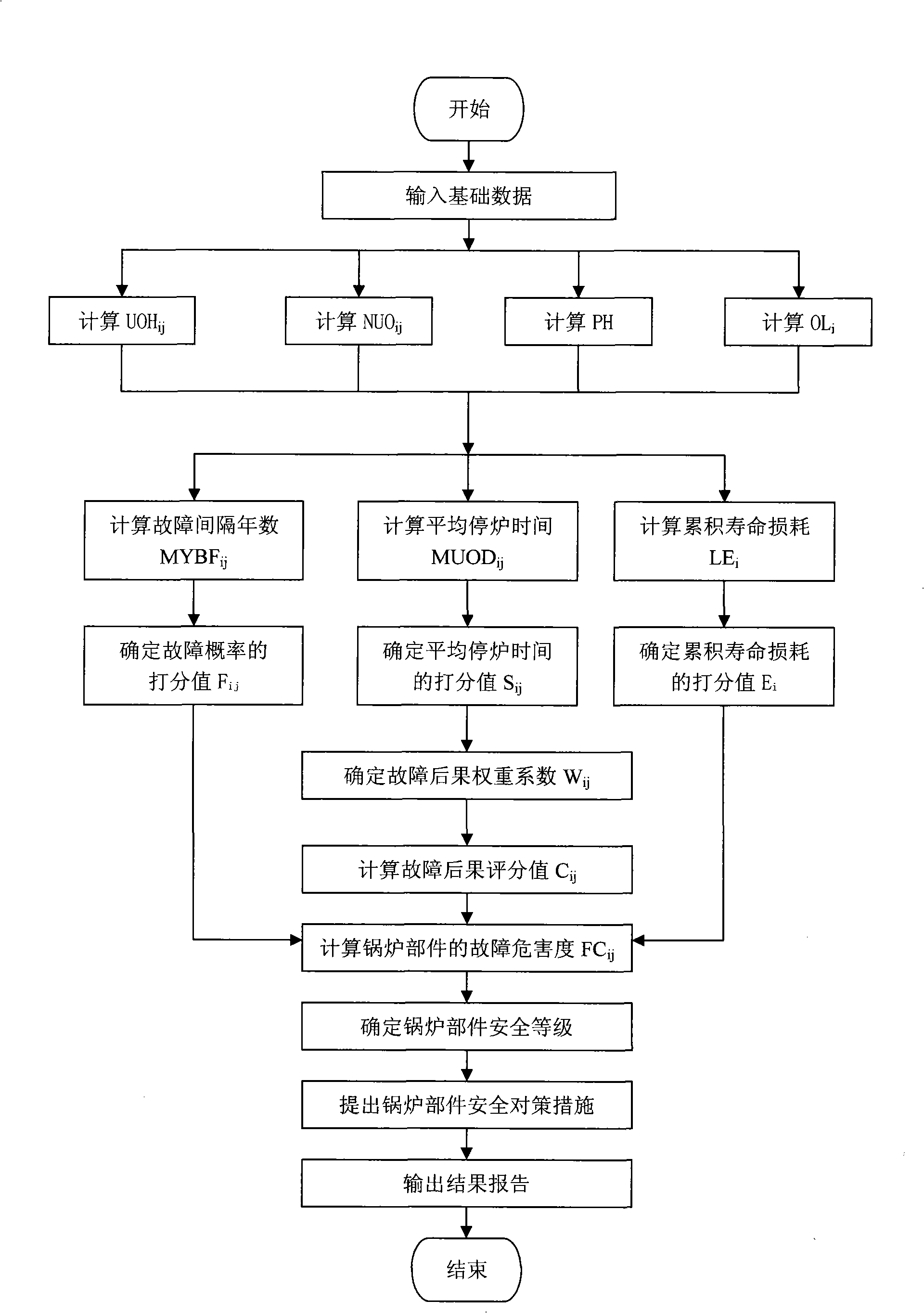

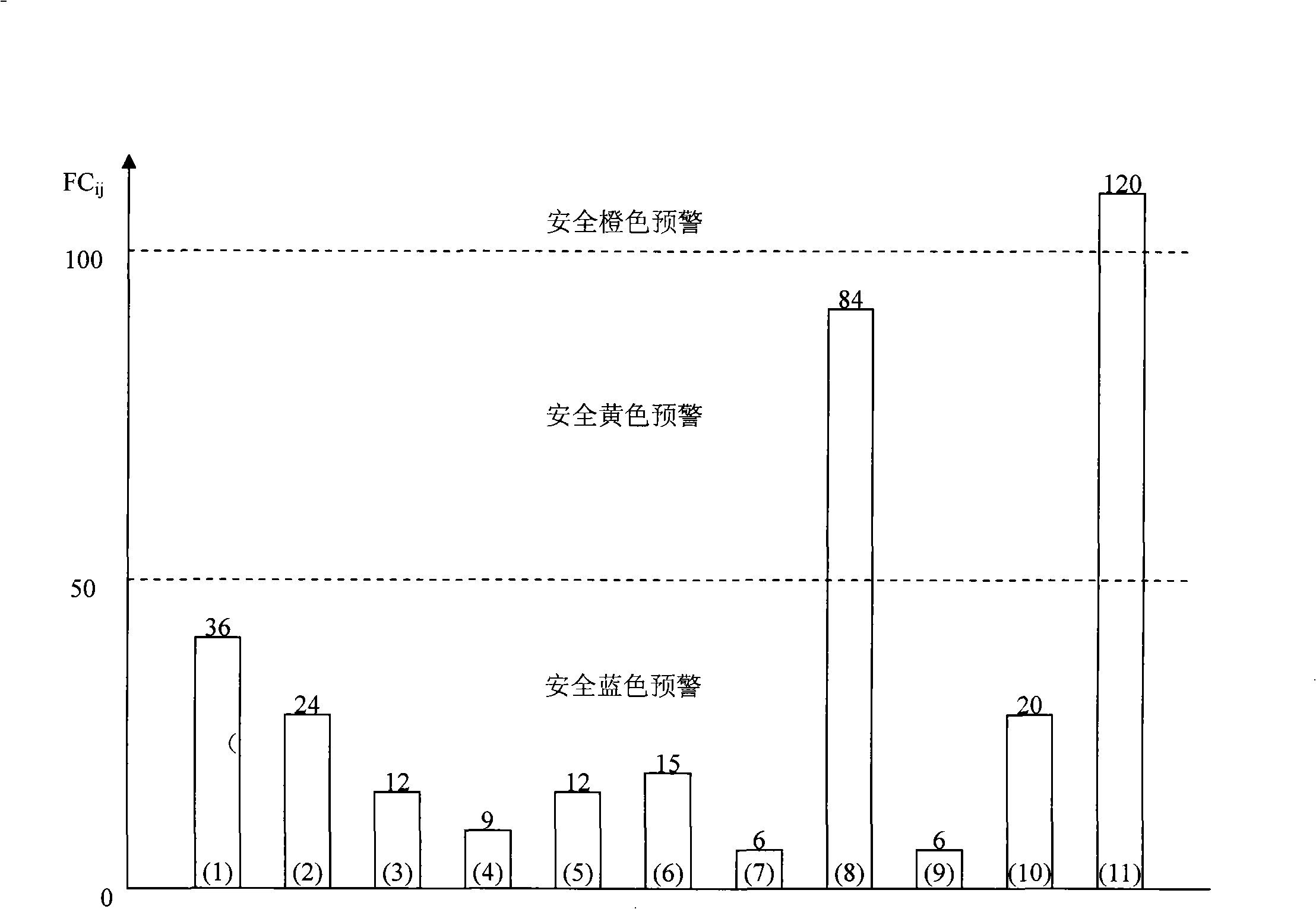

Method for quantitatively evaluating safety of boiler parts

InactiveCN101408910AImprove securityAvoid failure modeFurnace-tube steam boilersSpecial data processing applicationsReliability engineering

Owner:SHANGHAI POWER EQUIP RES INST +1

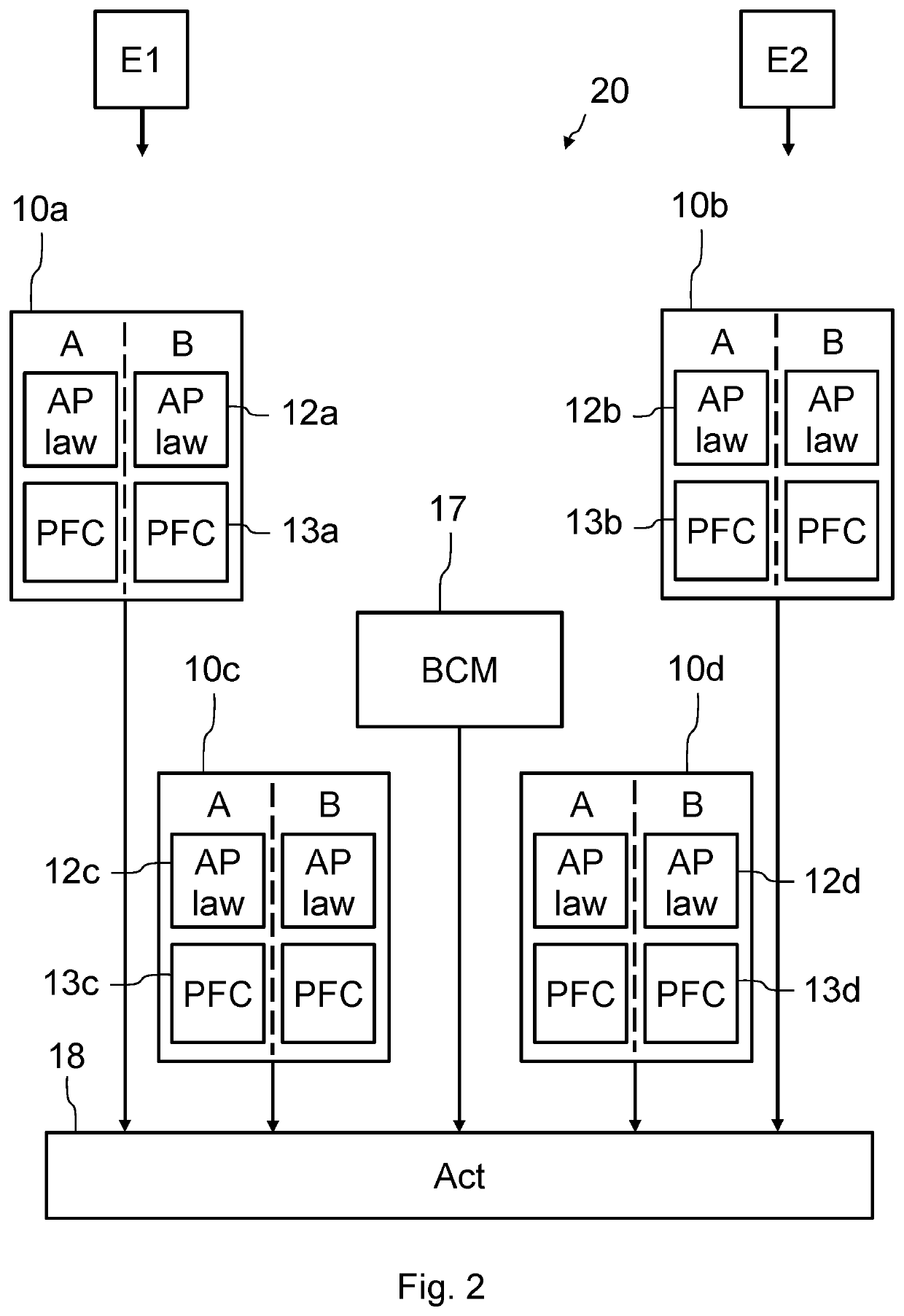

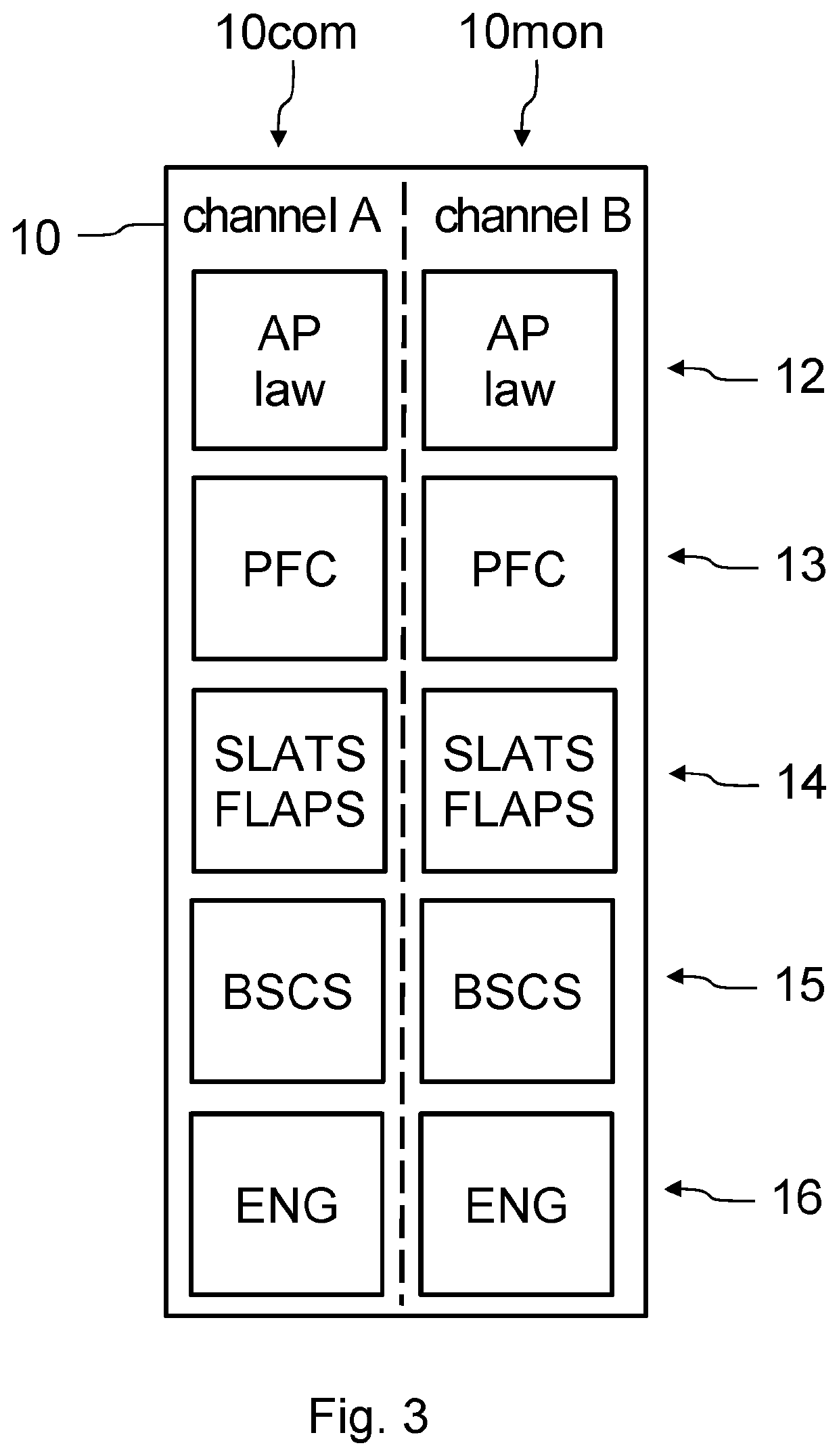

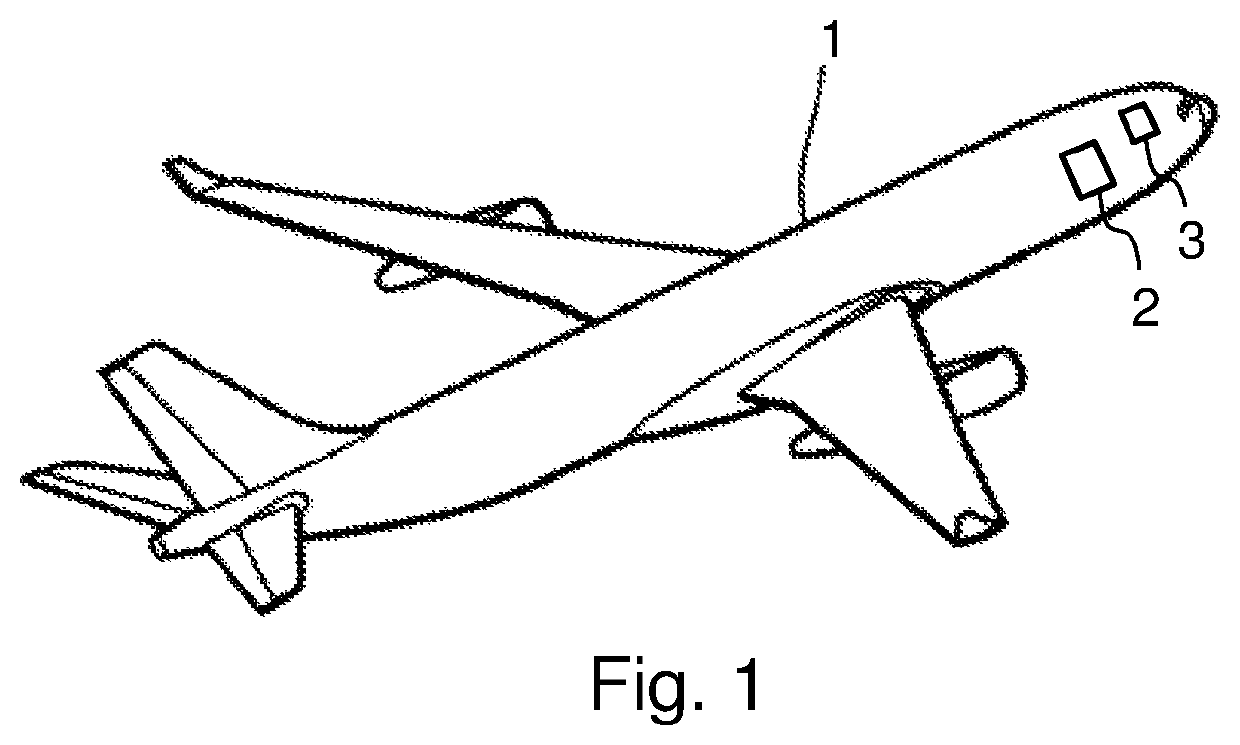

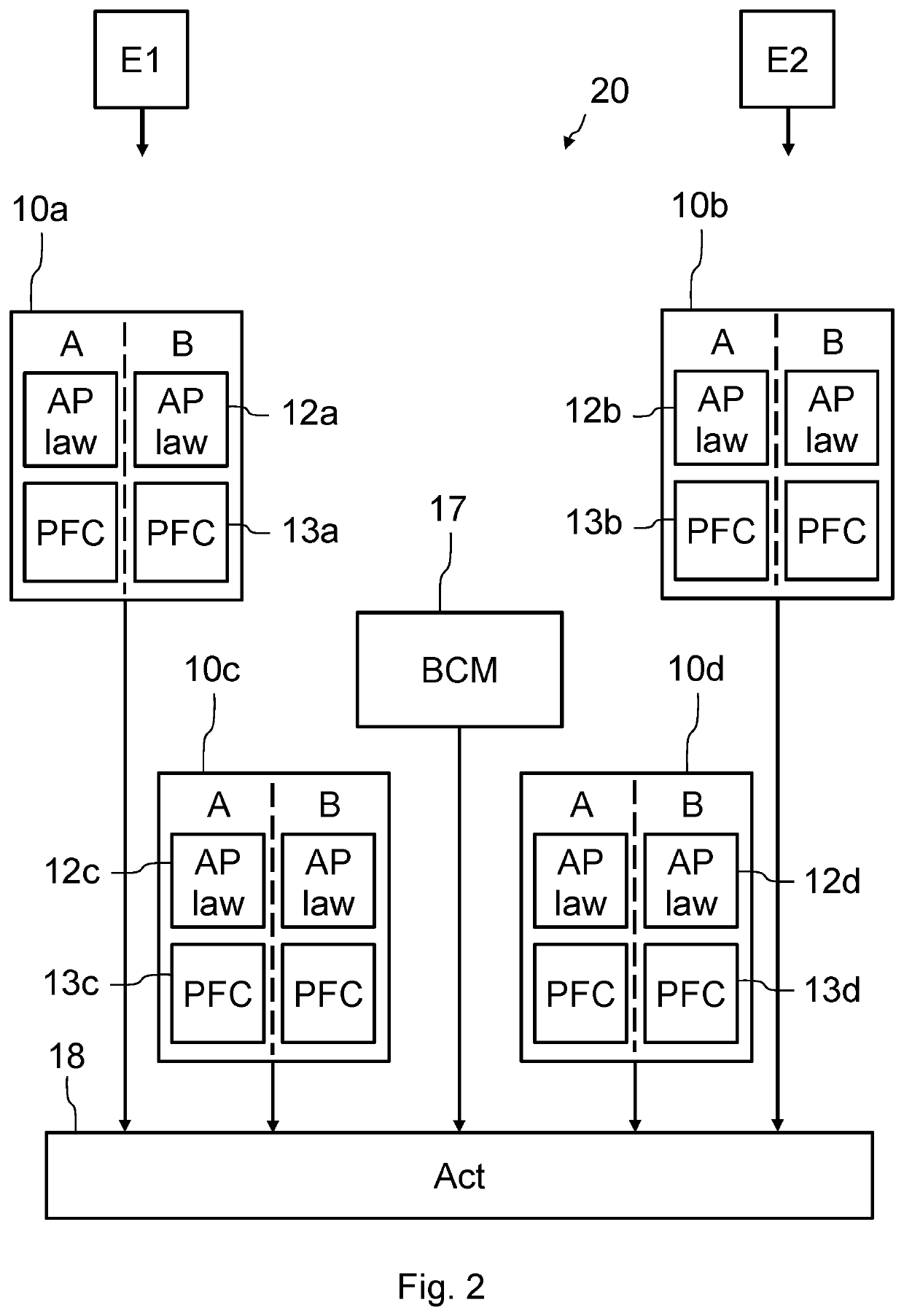

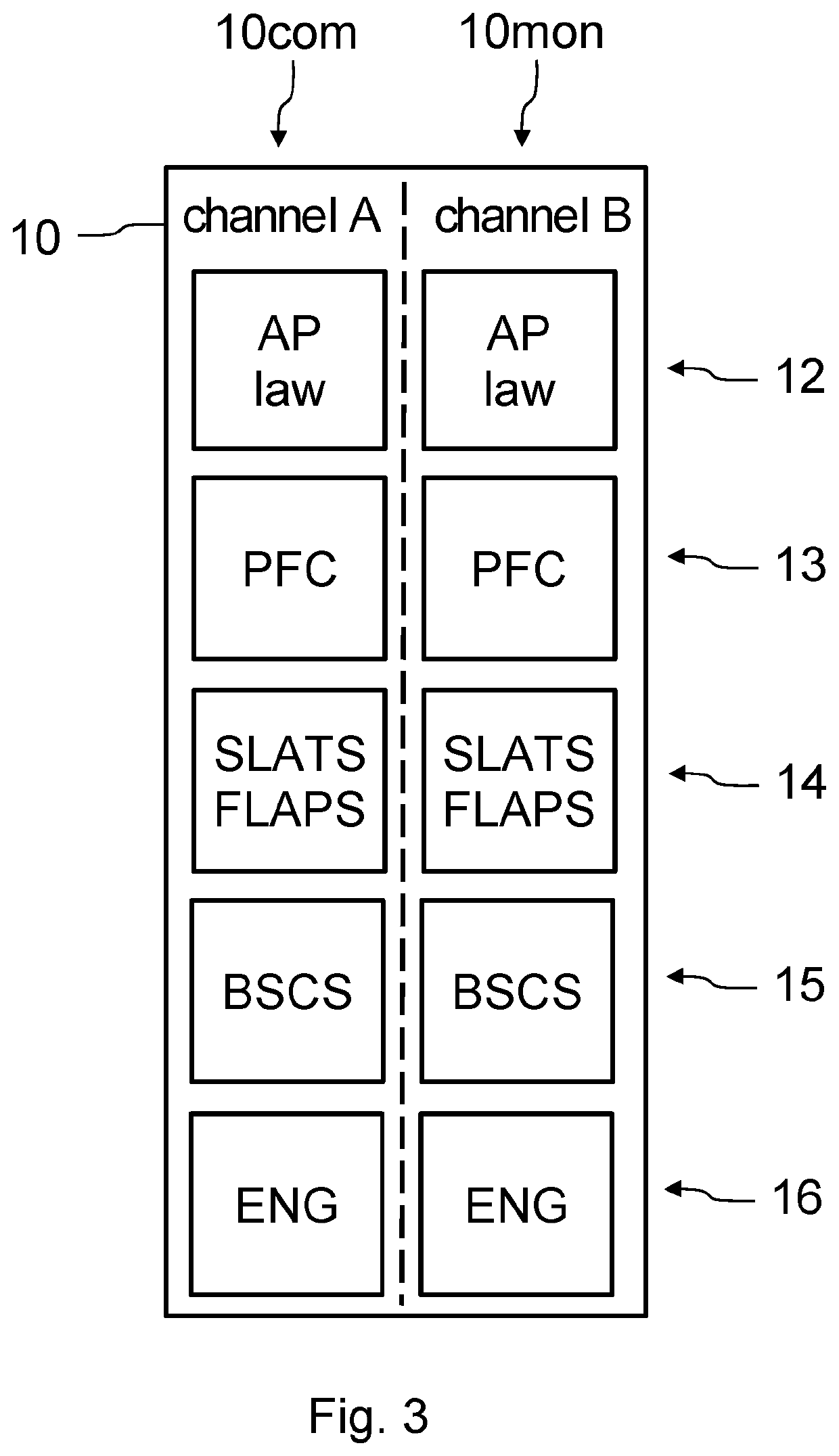

Flight control system for an aircraft

ActiveUS20200164965A1High precisionImprove usabilityConjoint controlsSafety arrangmentsFlight vehicleActuator

A flight control system for an aircraft comprises a set of actuators for controlling the aircraft and a set of flight control computers only made up of a set of duplex type main computers and of at least one backup computer. All the main computers are configured to implement auto-pilot laws for the aircraft. The set of main computers comprises two computers from a first hardware type, configured to control actuators of the set of actuators as per a first tolerance level and two computers from a second hardware type, different from the first hardware type, configured to control actuators of the set of actuators as per a second tolerance level, less stringent than the first tolerance level.

Owner:AIRBUS OPERATIONS (SAS)

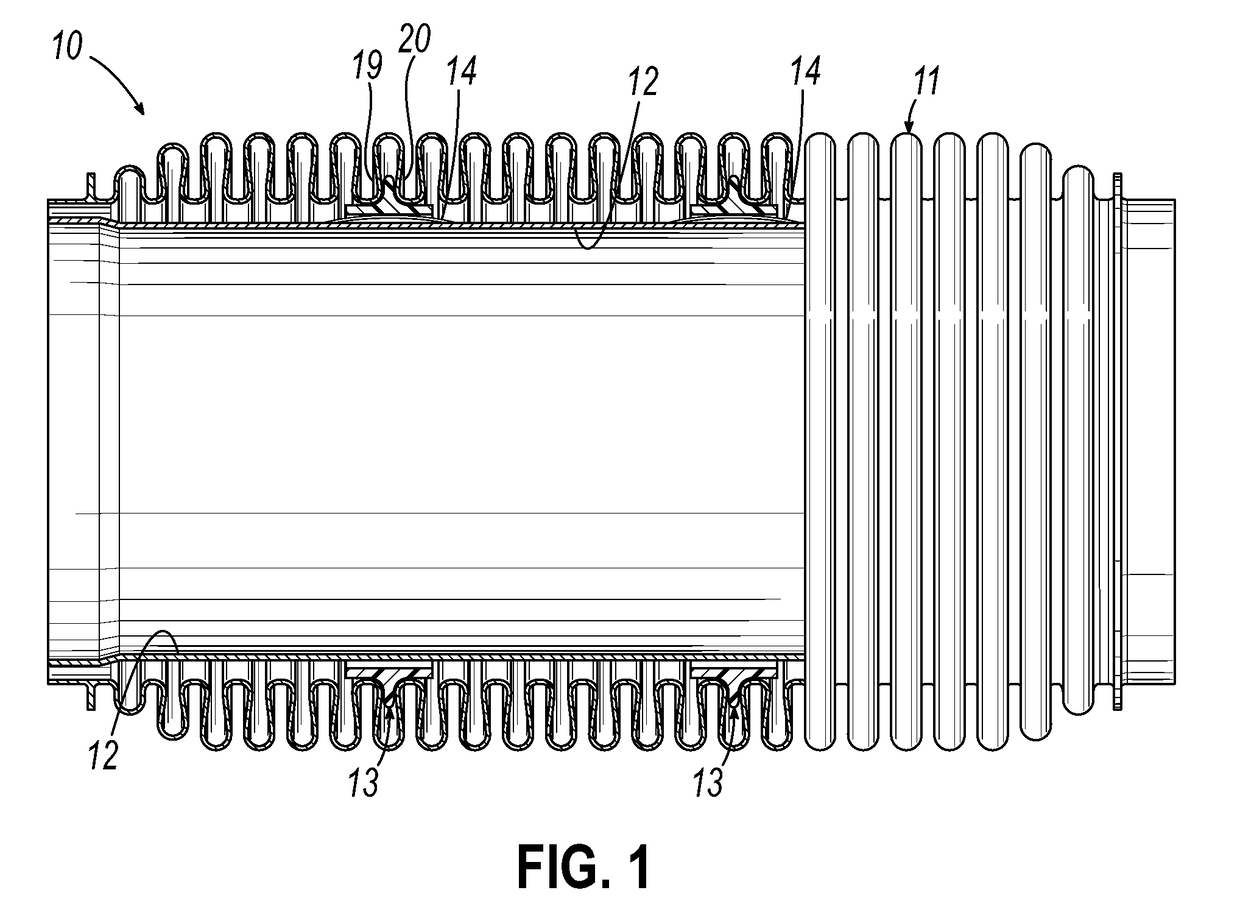

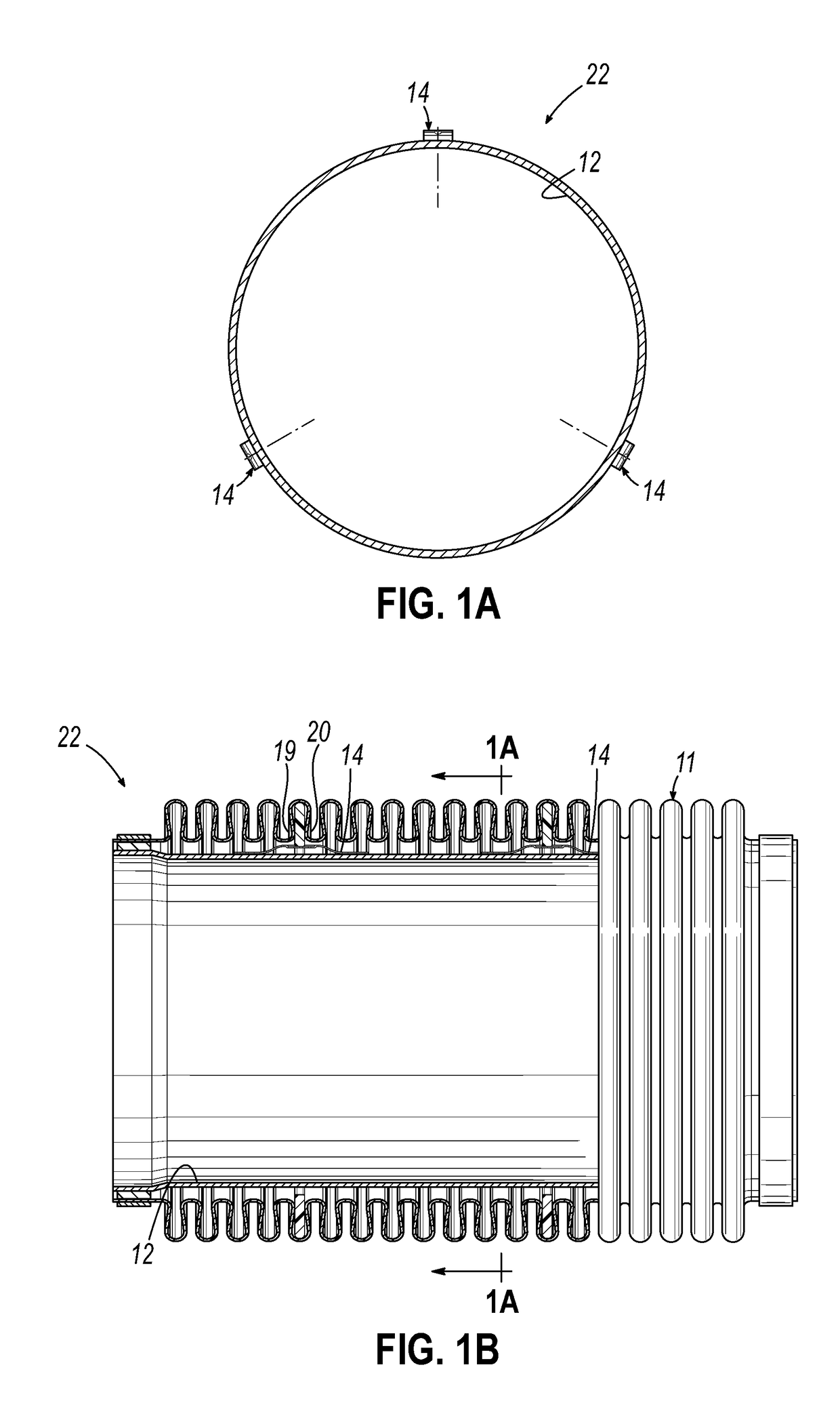

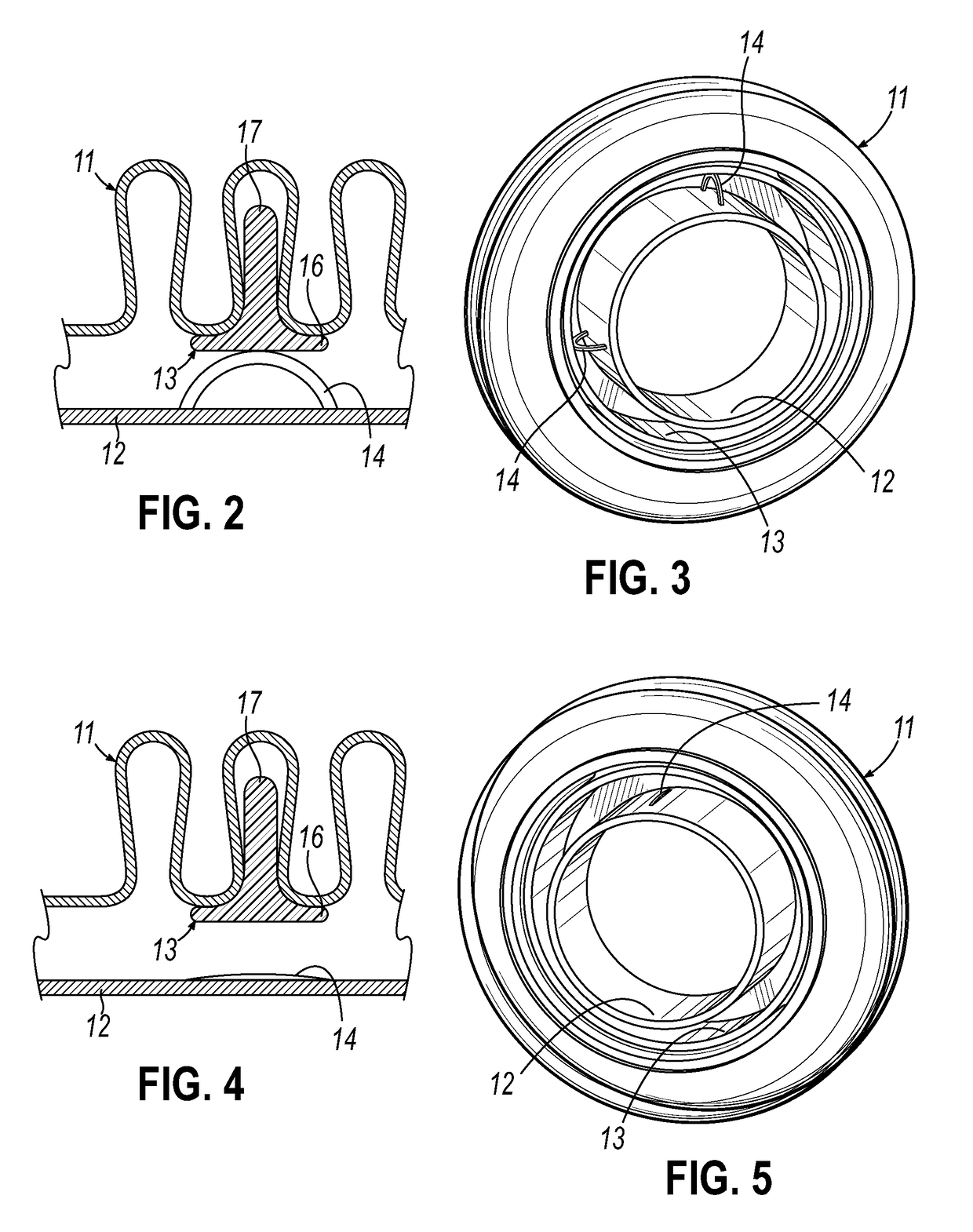

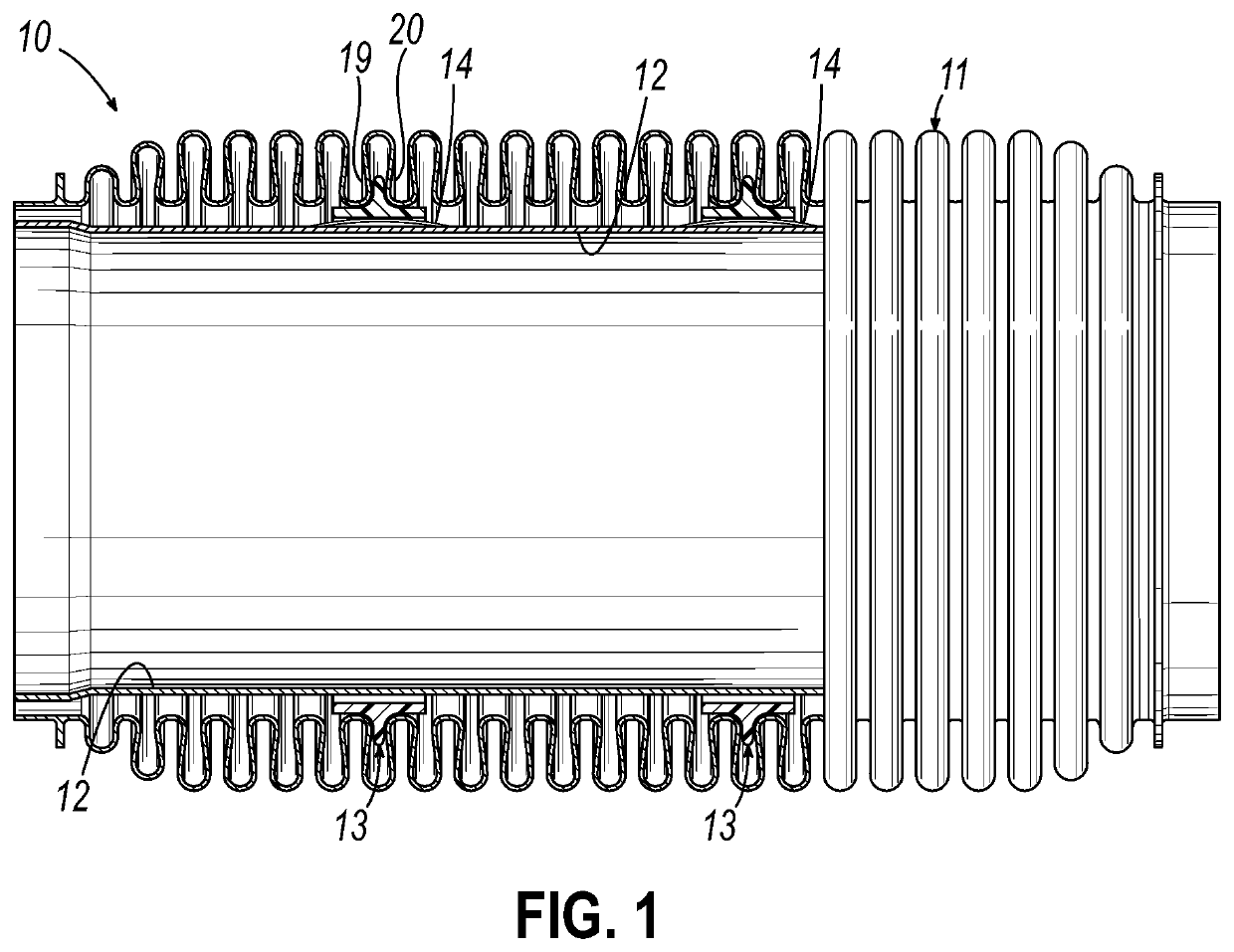

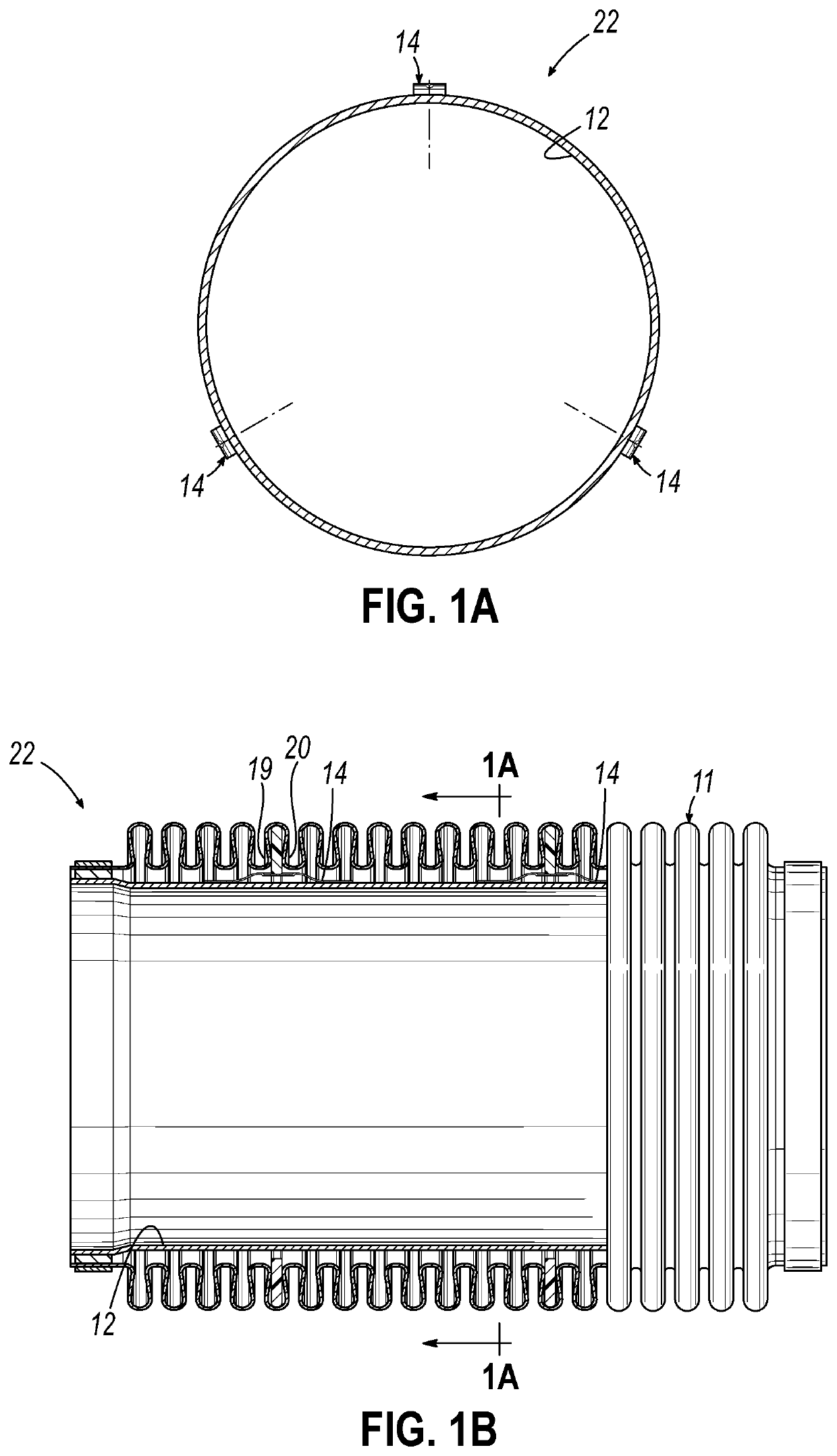

Self-restraining abrasion prevention exhaust conduit

ActiveUS20190010856A1Reduce stepsOut energyPipeline expansion-compensationSilencing apparatusEngineeringCatheter

A multiple component hot gas flowing conduit has an elongated, convoluted bellows, an interlock liner, frequency dampers and elastic spacers engaging the dampers and biasing the dampers into respective bellows convolution with no contact of bellows and liner for all operating states of the conduit. Assembly pretension of the interlock liner preferably flattens out the elastic spacers permitting assembly of the liner into the bellows and upon relaxation of the liner, the spacers extend radially outwardly to engage and bias the dampers into the bellows. The bellows is convoluted throughout, or may have convoluted ends with an integral smooth-wall tube therebetween. Components are isolated from abrasion against one another.

Owner:AMERICAN BOA

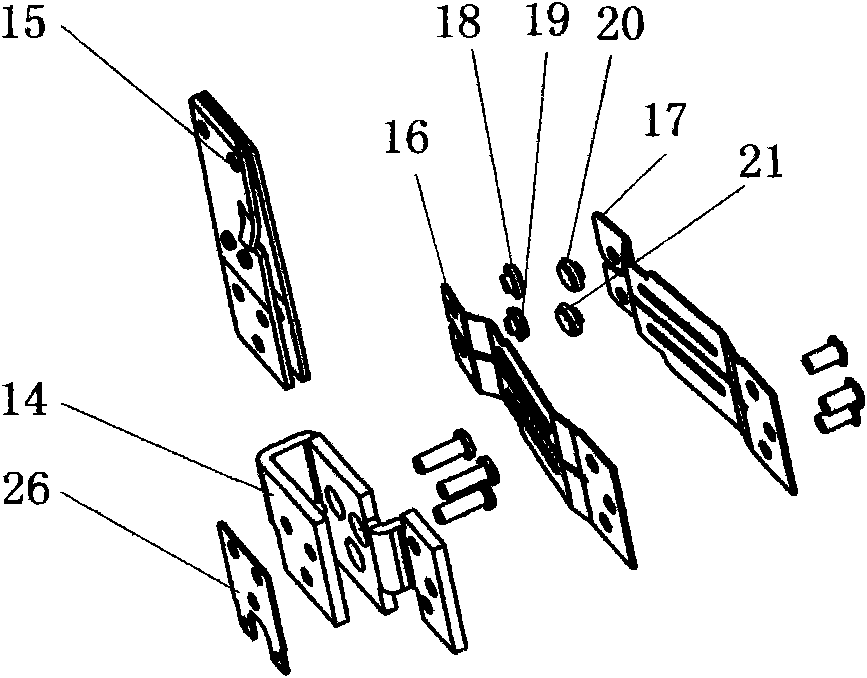

Double-conducting-piece-set magnetic latching relay

InactiveCN101923986AReduce current densityReduce material requirementsElectromagnetic relay detailsNon-polarised relaysEngineeringMaterial requirements

The invention discloses a double-conducting-piece-set magnetic latching relay which comprises a base, a left conducting piece assembly, a right conducting piece assembly, a left static piece assembly, a right static piece assembly, a magnetic circuit part, a push rod, a spiral tube and an upper cover, wherein two sides of the push rod are respectively provided with the left static piece assembly and the right static piece assembly; the left conducting piece assembly comprises a connecting piece, a conducting piece and a double action reed; the middle of the conducting piece is riveted with the tail end of the connecting piece arranged in the vertical direction, and one side of the conducting piece is riveted with one end of the double action reed arranged in the horizontal direction; the other end of the double action reed is riveted with a movable contact; and the movable contact can be used for finishing the on-off of a contact together with a static contact on the static piece assembly. The invention has the advantages of novel structure and low material requirement on the reed, is suitable for various power relays and has wide market prospect.

Owner:SANYOU CORP LTD

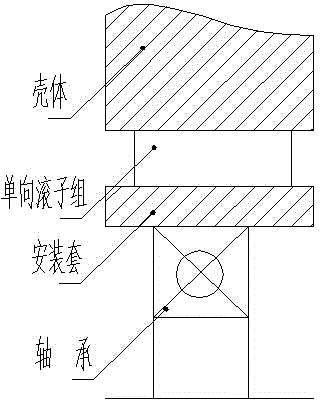

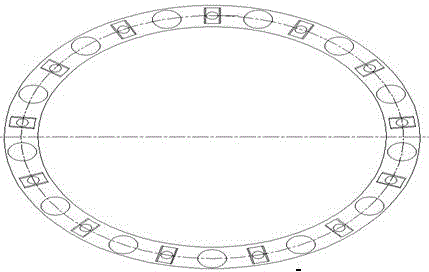

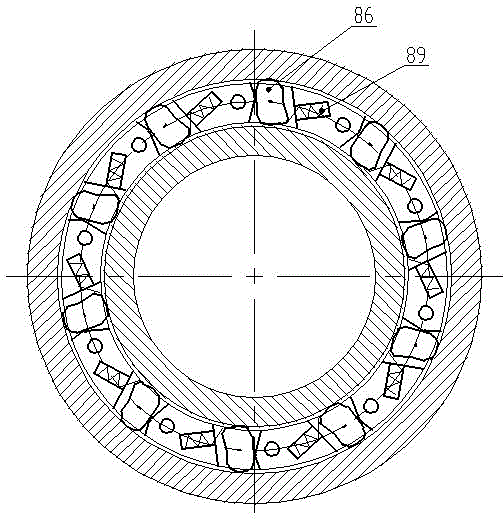

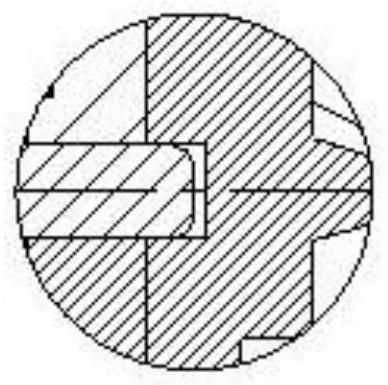

One-way clutch compact in structure

The invention discloses a one-way clutch compact in structure. The one-way clutch comprises a rolling bearing. The rolling bearing comprises an inner ring (02), an outer ring (01), a cage (46) and rolling bodies (04). The rolling bodies and ellipsoidal rollers (86) inside the cage are distributed in a staggered mode, the ellipsoidal rollers are arranged in an inclined mode, the two ends of the long axis of each ellipsoidal roller make contact with the inner ring and the outer ring respectively, open slots are formed in the positions, making contact with the inner ring, of the ellipsoidal rollers, and springs (89) are arranged inside the open slots and connected with the ellipsoidal rollers. When the ellipsoidal rollers move to the springs, the one-way clutch rotates freely, and when the ellipsoidal rollers move away from the springs, the inner ring and the outer ring are locked to lock the one-way clutch. The one-way clutch compact in structure has the advantages that the one-way rollers are moved into the rolling bearing and connected with the cage and the rolling bodies of the rolling bearing into a whole, in this way, finish machining and surface treatment do not need to be performed on the inner circle of a shell, the number of technological processes is reduced, and the cost is lowered; the material and structural design of original one-way rollers are changed, the structure is compact, and the using cost is lowered.

Owner:ANHUI RIFEI BEARING

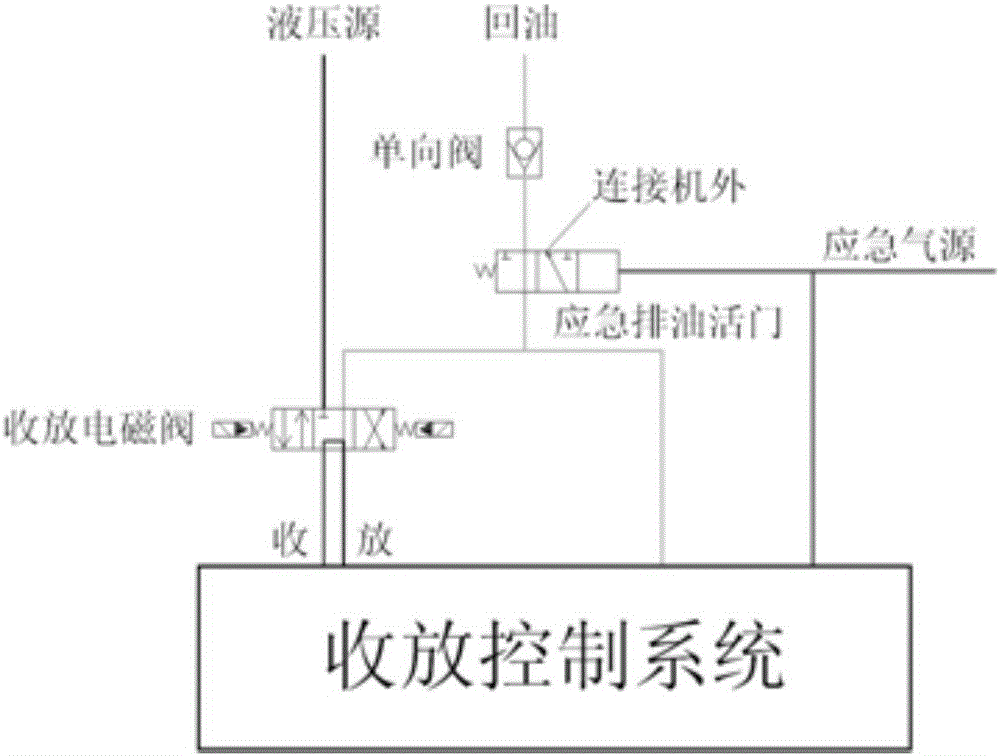

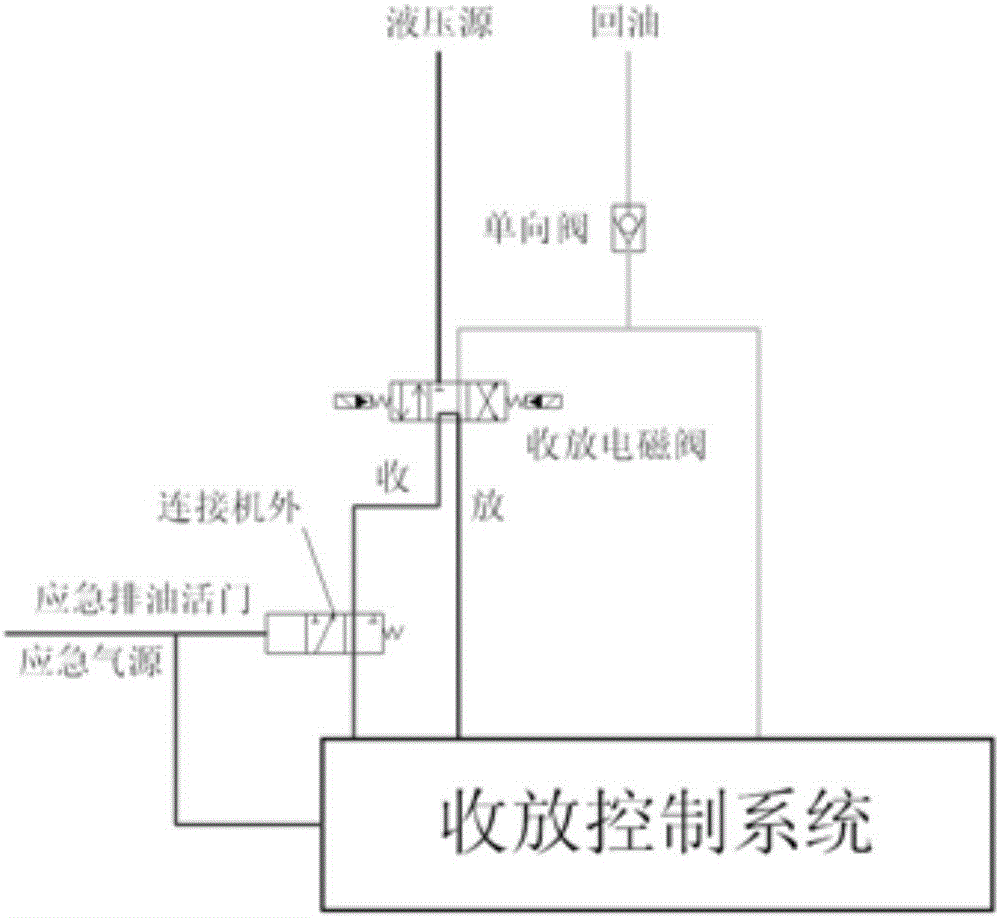

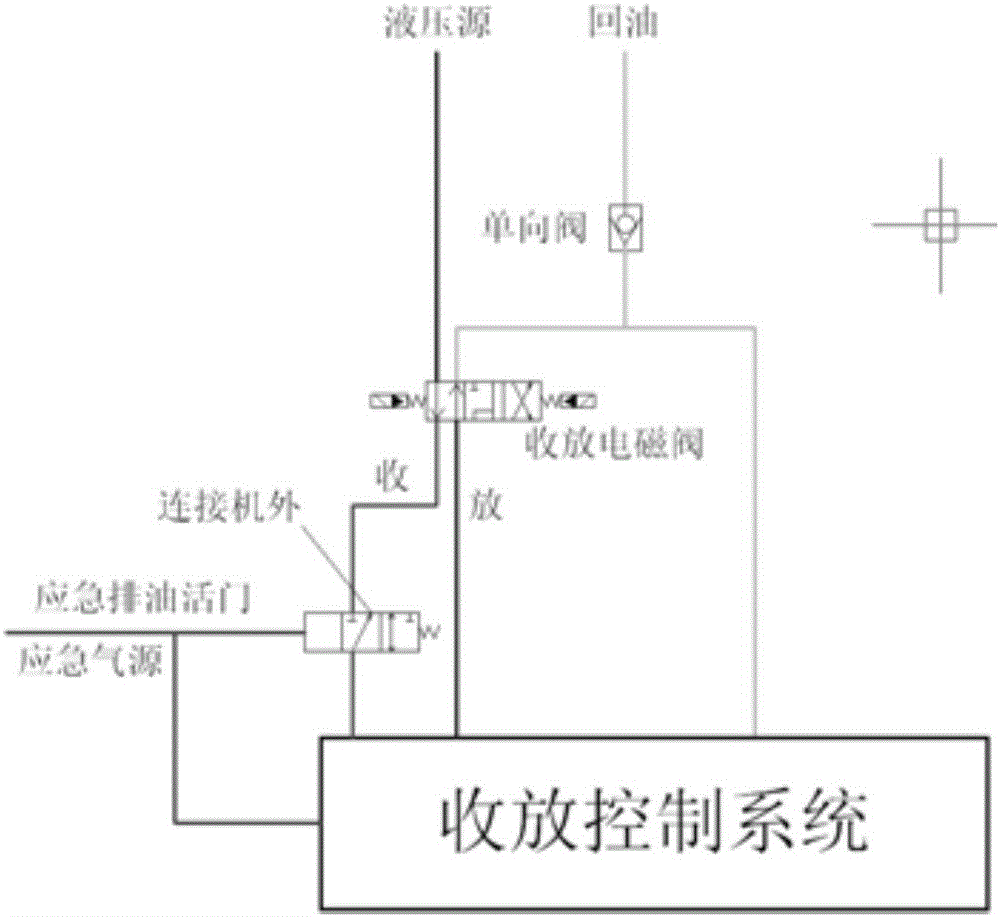

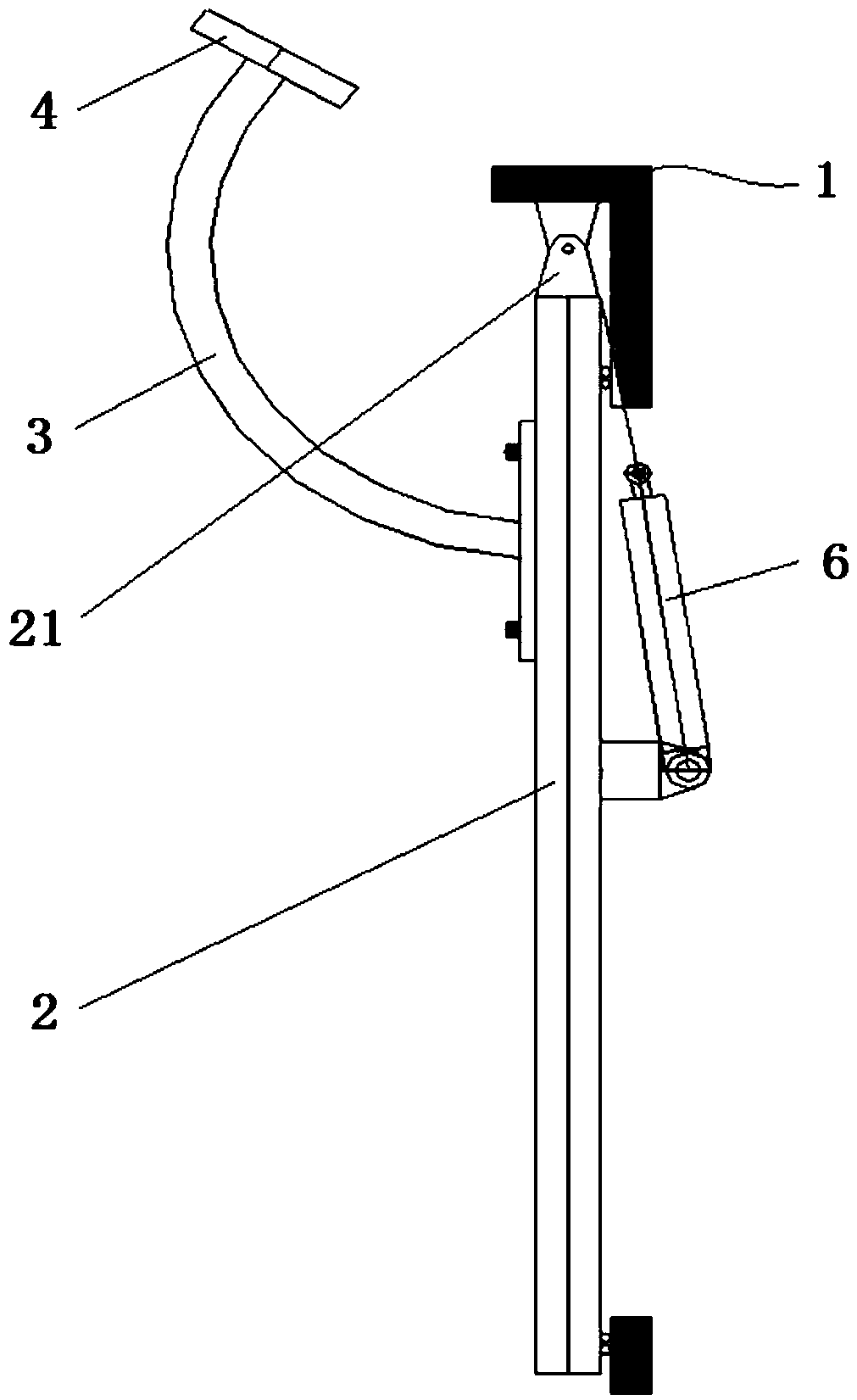

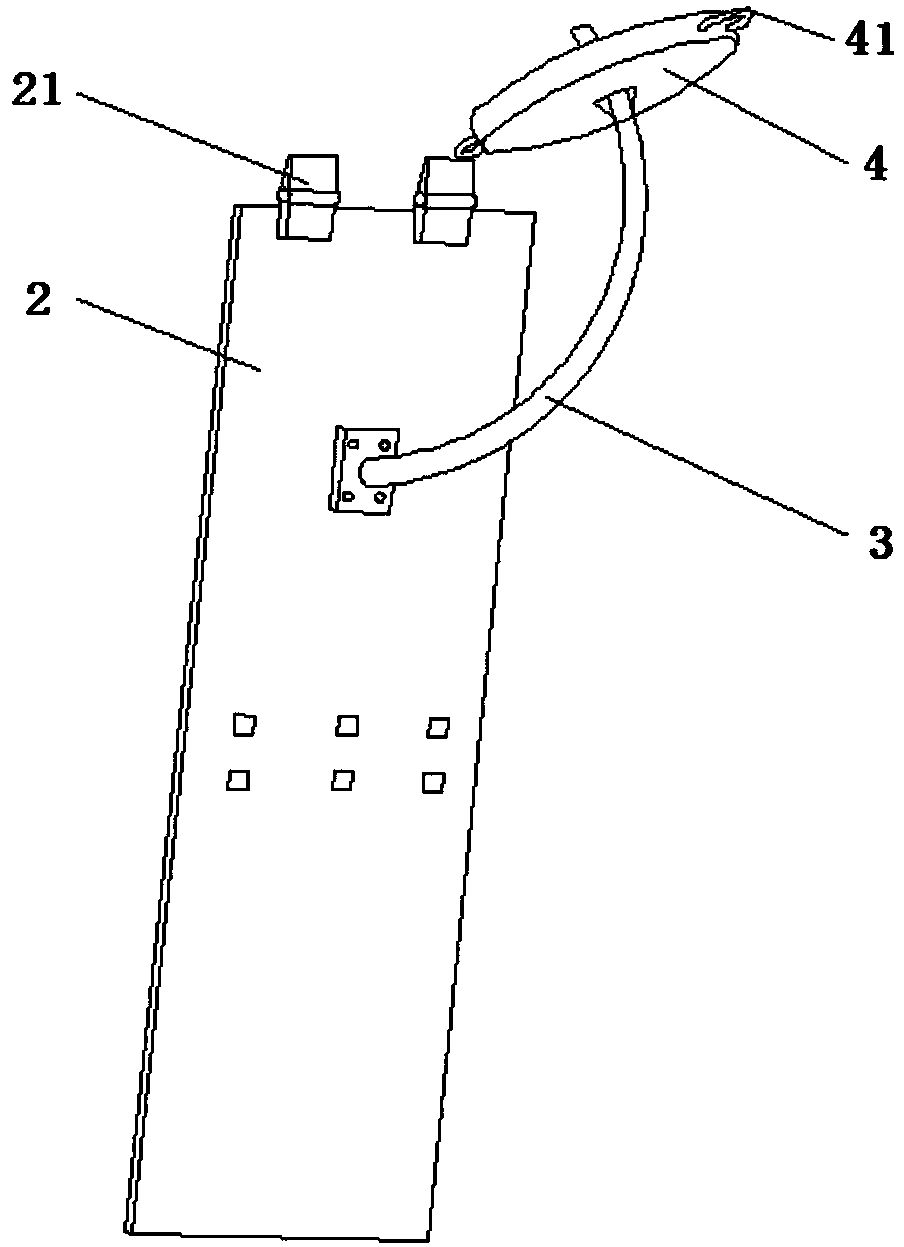

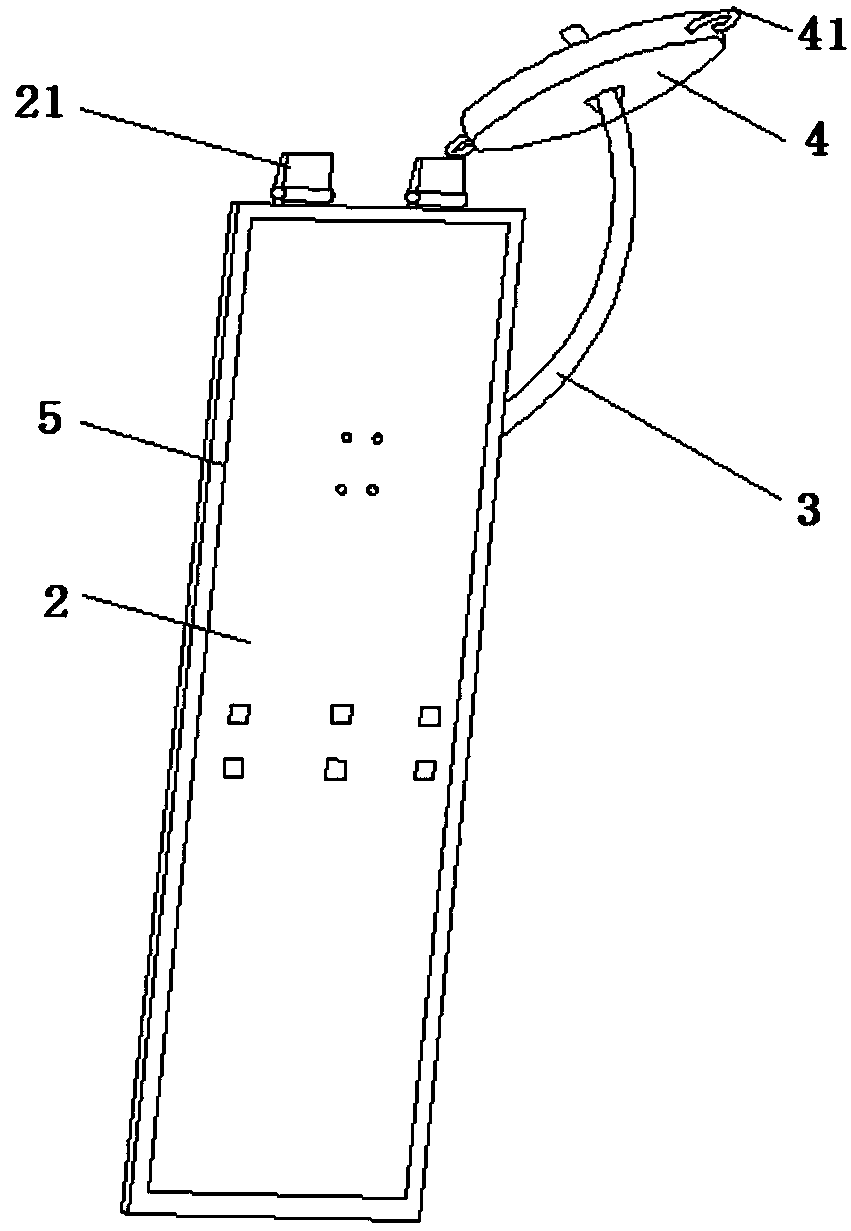

Retracting control system of aircraft landing gear

InactiveCN106697266AAvoiding Failure Modes of Emergency Discharge FailuresAvoid failure modeUndercarriagesSolenoid valveControl system

The invention discloses a retracting control system of an aircraft landing gear. An emergency oil discharging valve is connected onto a working pipeline at the downstream side of a solenoid valve; and in an emergency working process, an oil inlet of the emergency oil discharging valve is sealed. According to the retracting control system, a fault mode that emergency releasing of the landing gear is invalid, caused by the fact that the retracting solenoid valve is clamped in a retracting position, is avoided from the design; changes of the retracting control system are very small, and parts below the emergency oil discharging valve are not changed; new onboard equipment is not additionally arranged; the implementation cost of an improvement plan on an aircraft is small; and the improvement plan is easy to implement on the aircraft.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

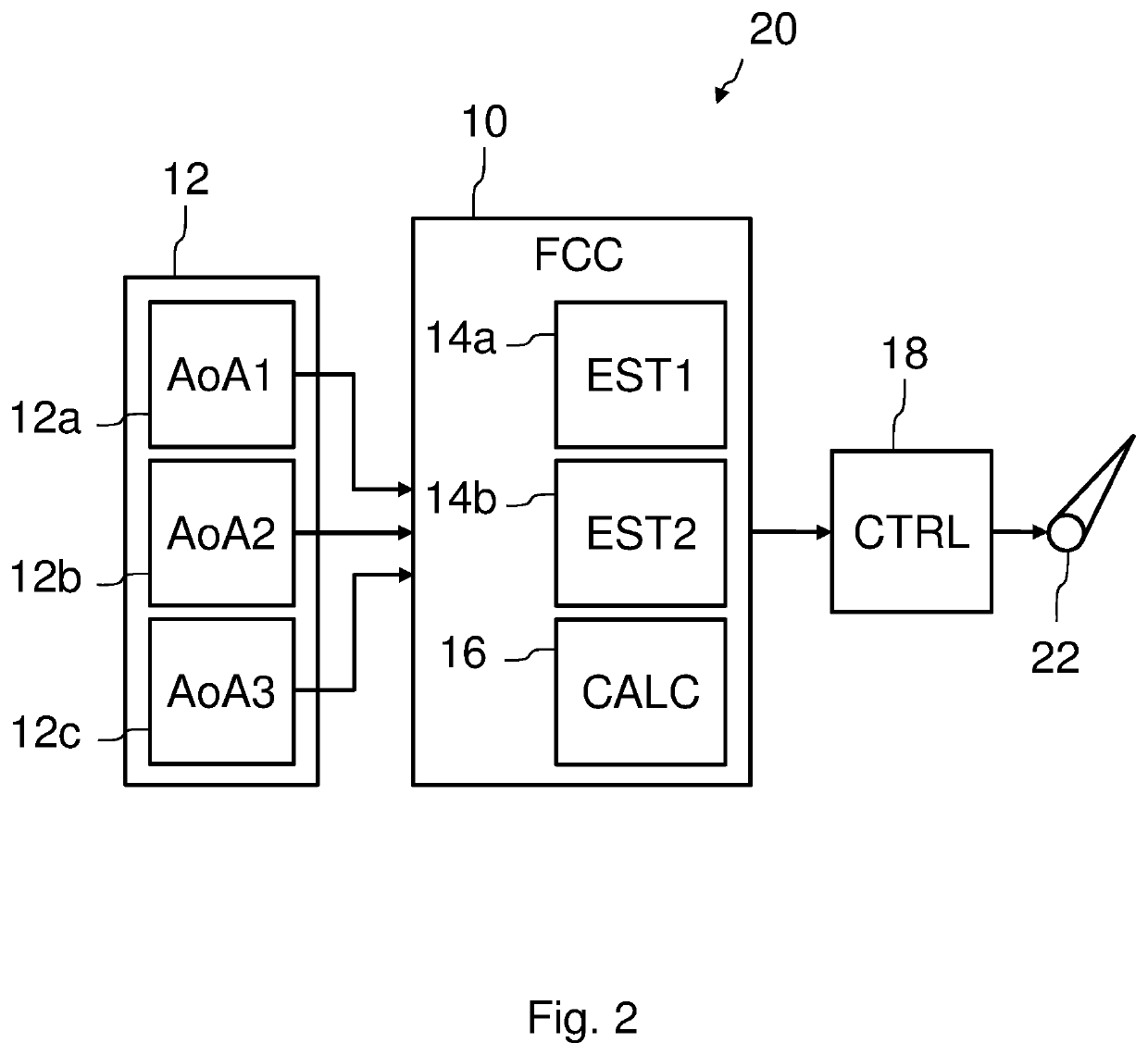

Flight control computer of an aircraft

ActiveUS10906633B2Avoid failure modeSafety arrangmentsRegistering/indicating working of vehiclesAngle of incidenceFlight vehicle

A flight control computer of an aircraft is likely to operate in a so-called incidence protection mode in which it is configured to compute the deflection orders of an elevator as a function of incidence angle values supplied by a set of incidence probes, so as to keep the incidence angle of the aircraft within a range of acceptable incidence angle values. The flight control computer is configured to, when only one incidence probe is operational: compute a first estimated incidence angle value of the aircraft, by a first estimator and a second estimated incidence angle value of the aircraft, by a second estimator unlike the first estimator; and keep the incidence protection mode activated as long as the incidence angle value supplied by the single operational incidence probe is consistent with at least one out of the first estimated incidence angle value and the second estimated incidence angle value.

Owner:AIRBUS OPERATIONS (SAS)

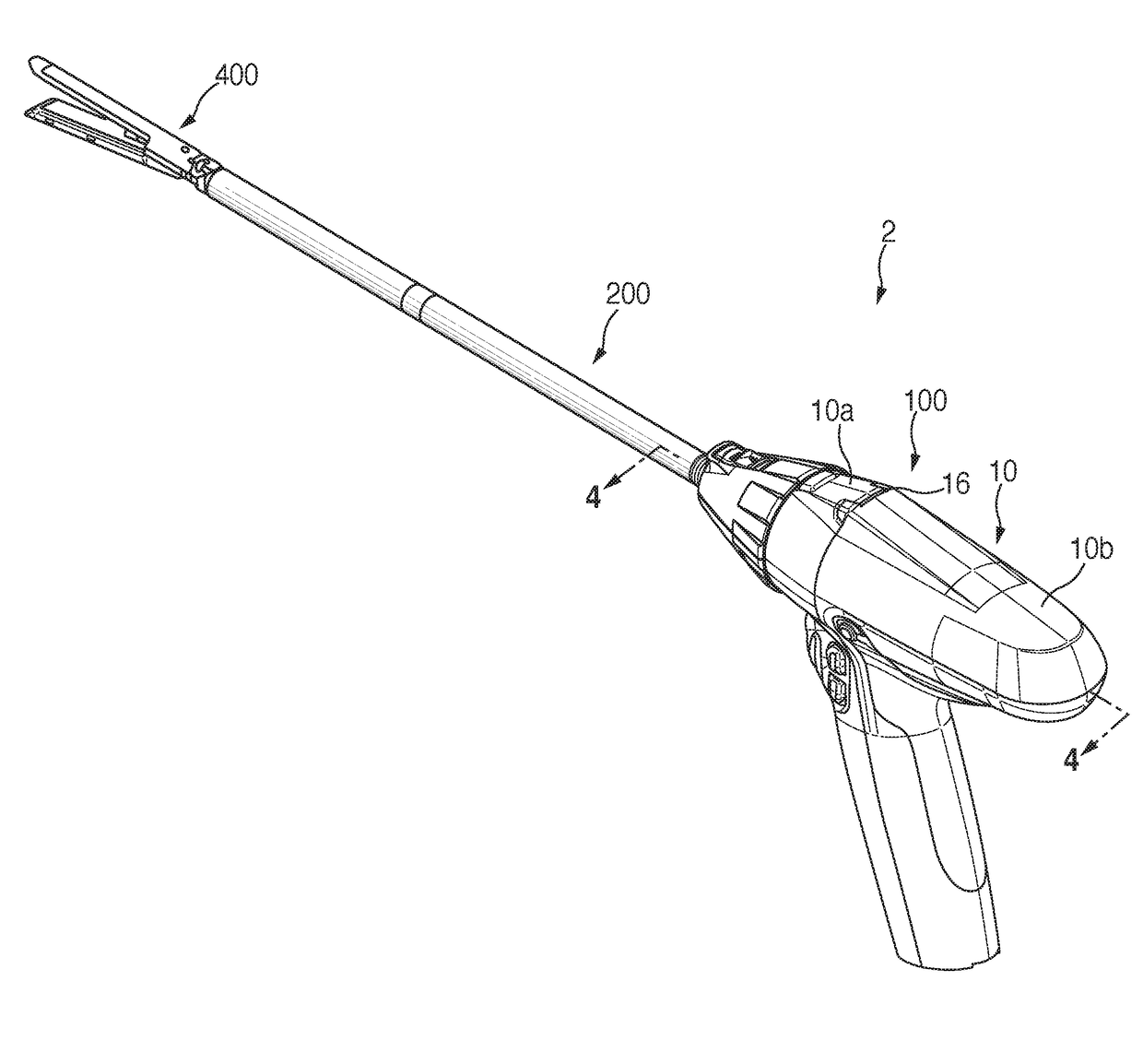

Autoclavable load sensing device

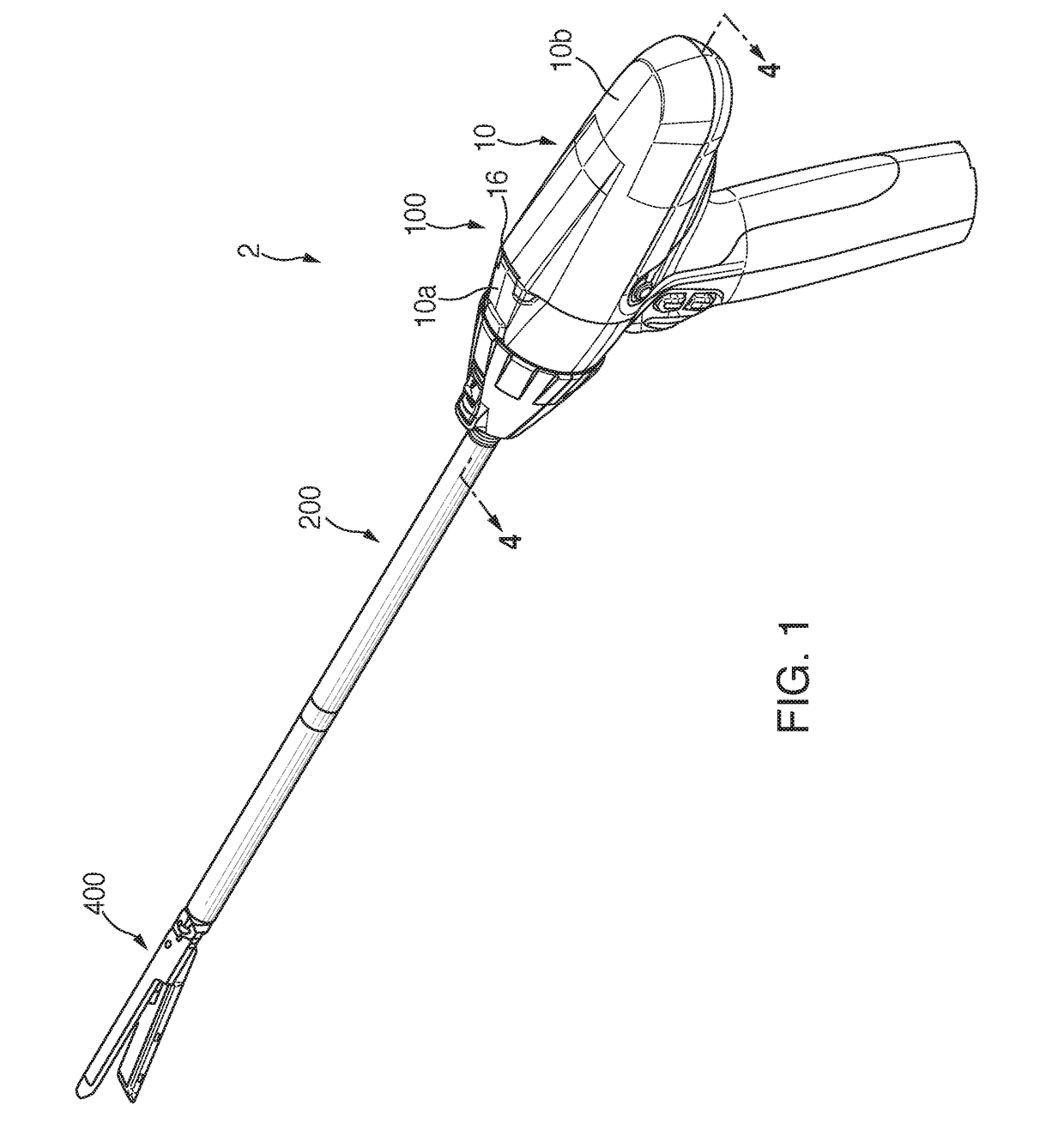

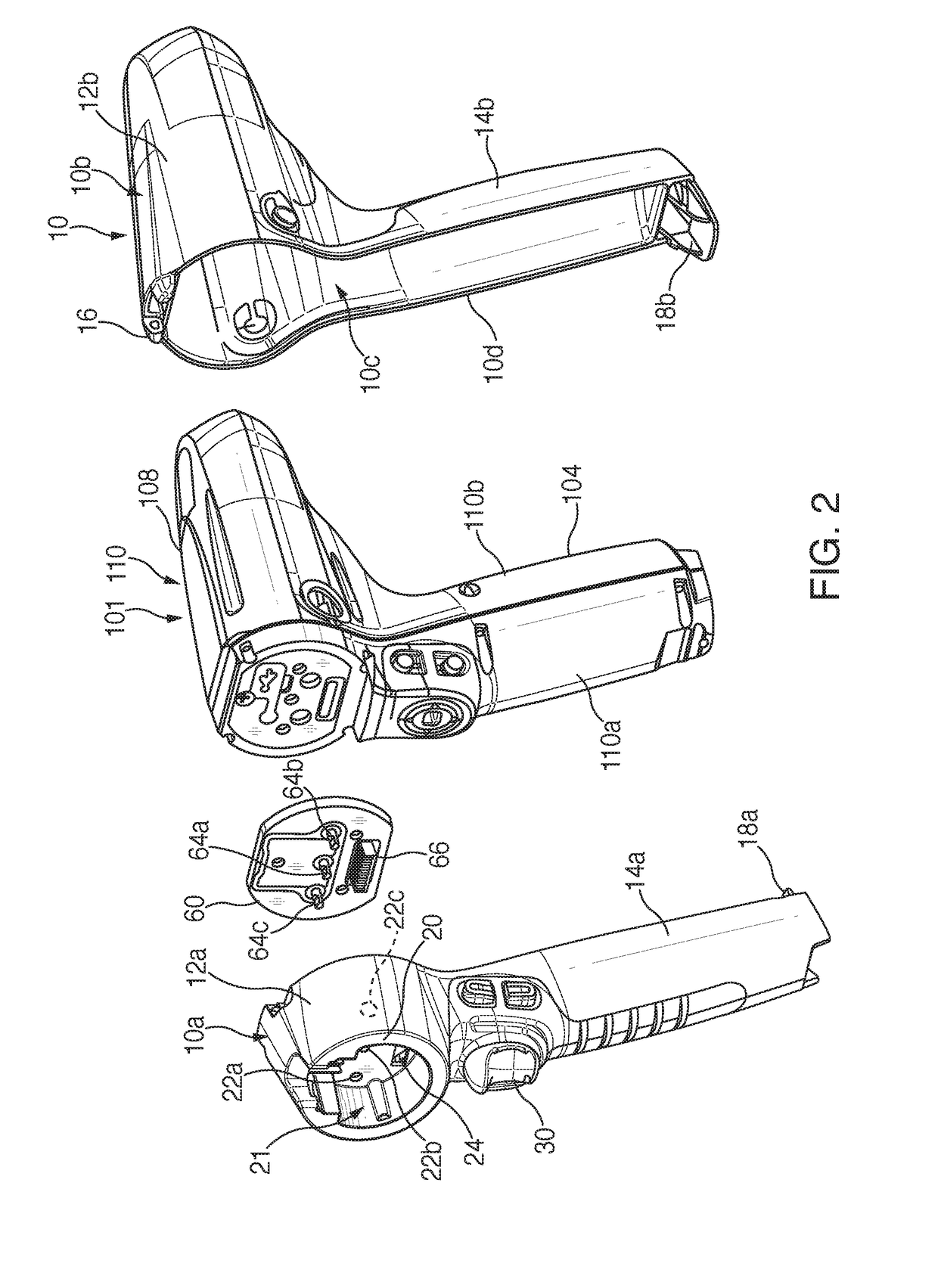

An adapter for interconnecting a surgical end effector to a surgical device includes: a drive shaft; and a load sensing device disposed about the draft shaft, the load sensing device configured to measure strain imparted on the drive shaft. The load sensing device includes a housing having: a tubular portion having a first end and a second end and defining a cavity therebetween; a first end cap disposed at the first end, the first end cap having a first opening; and a second end cap disposed at the second end, the second end cap having a second opening. The load sensing device also includes a conductive element wrapped at least partially about the tubular portion.

Owner:TYCO HEALTHCARE GRP LP

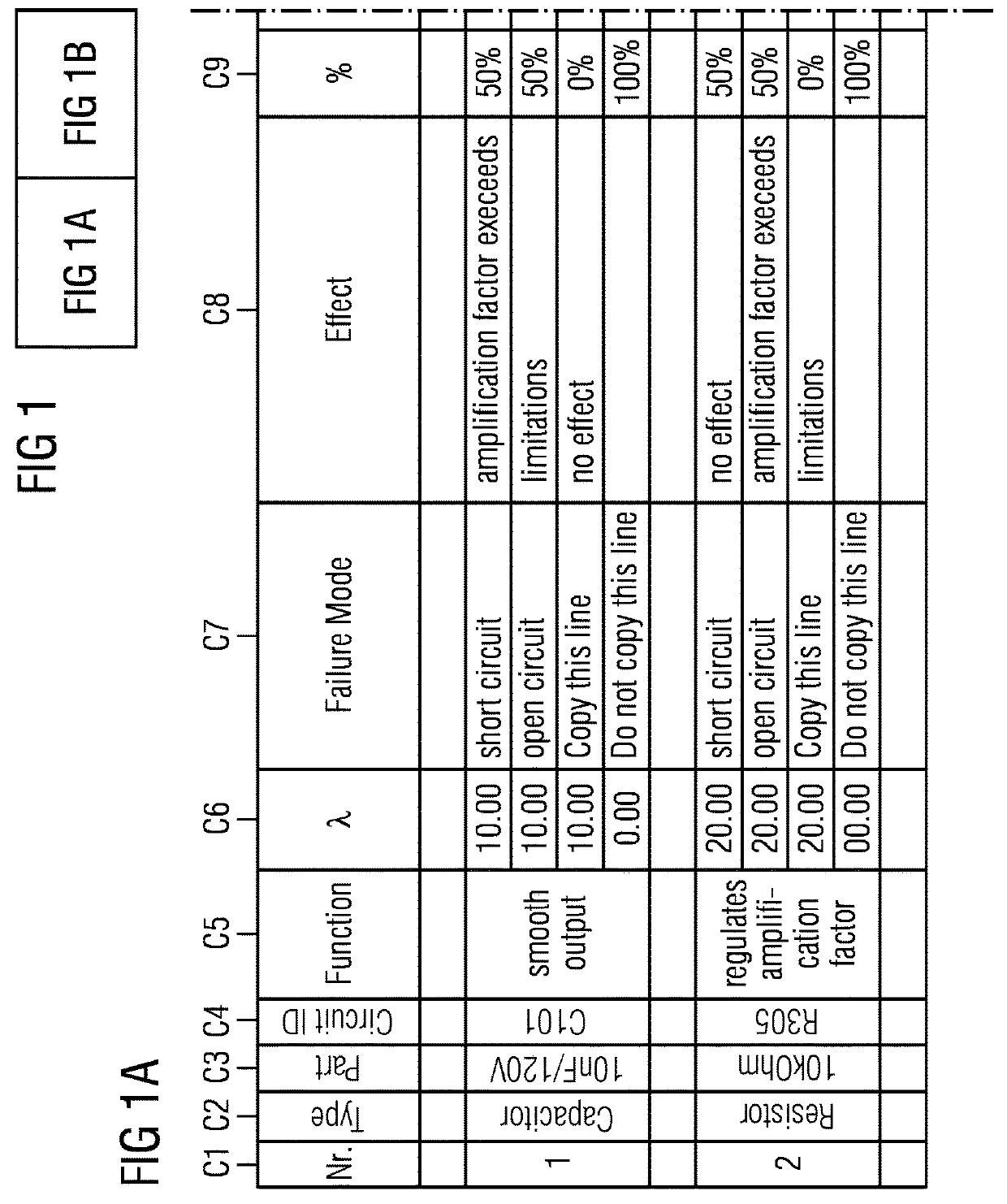

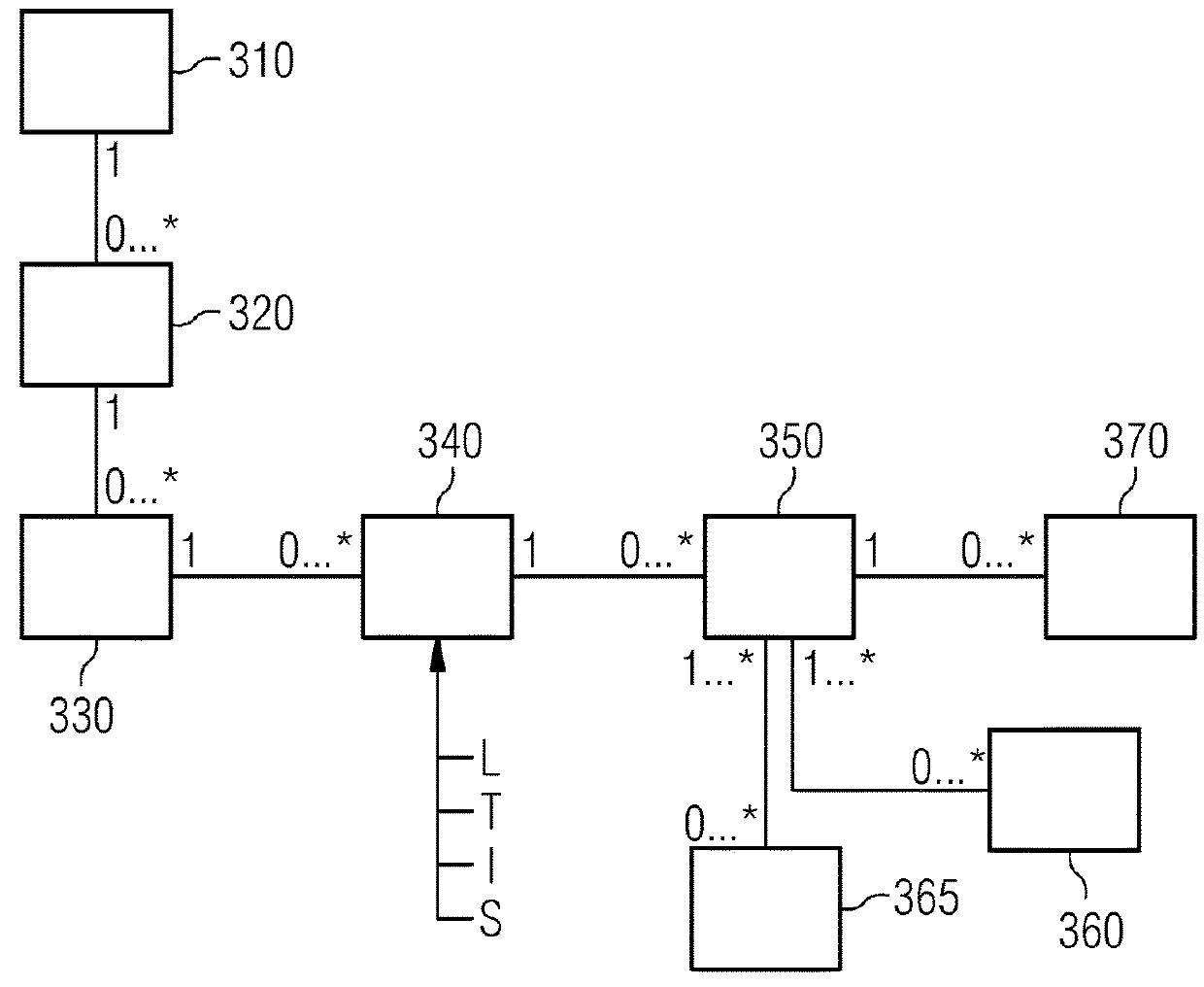

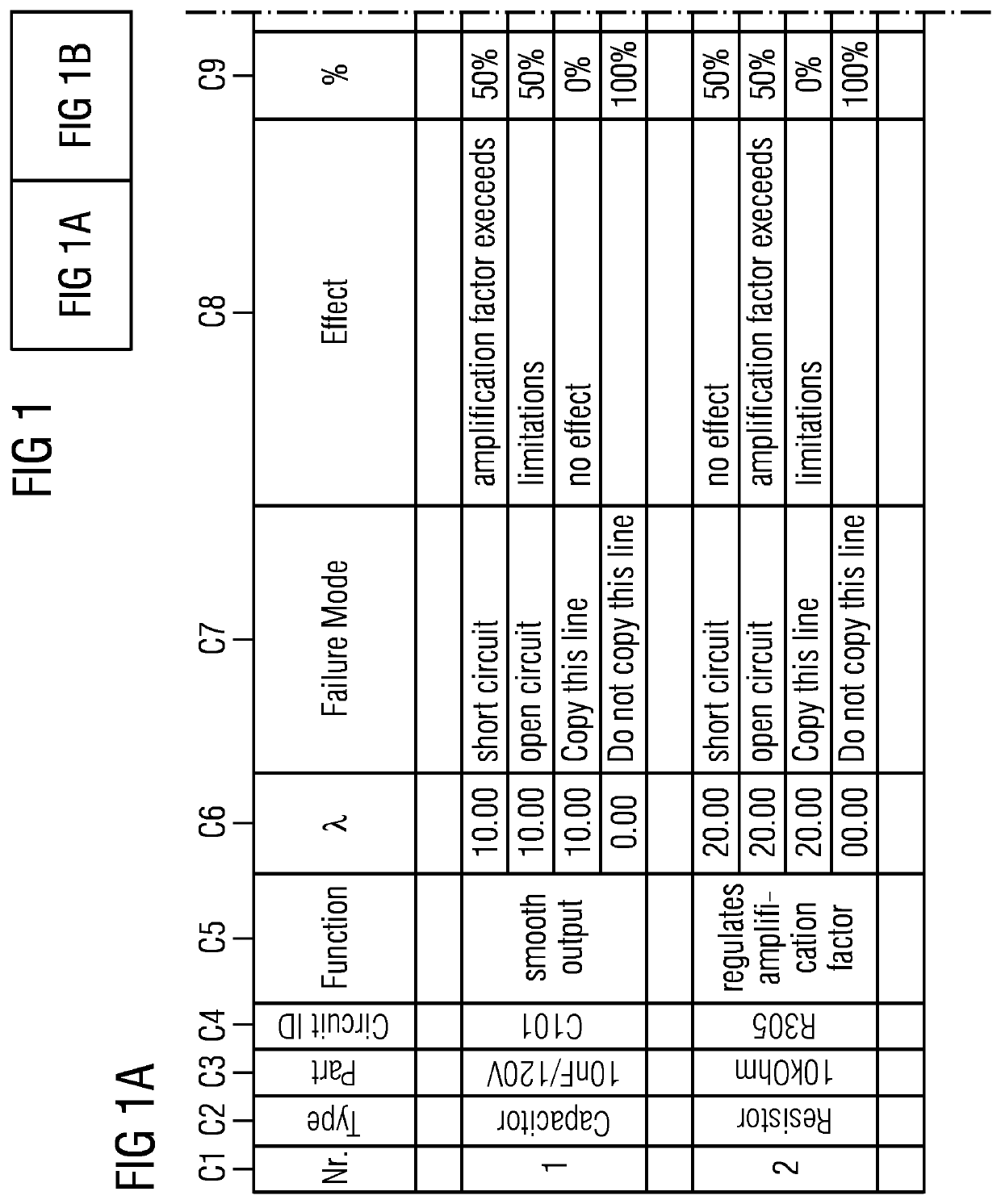

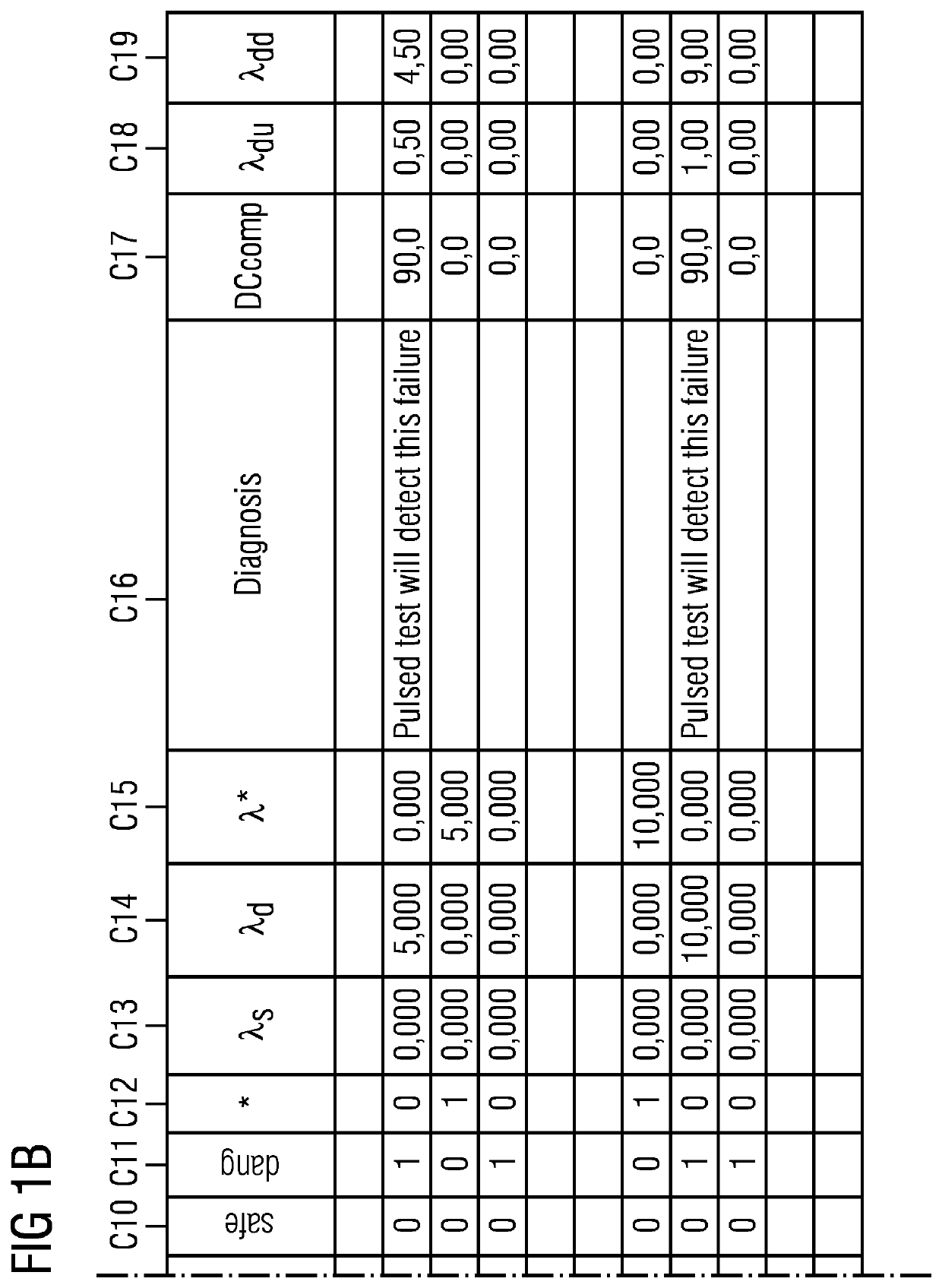

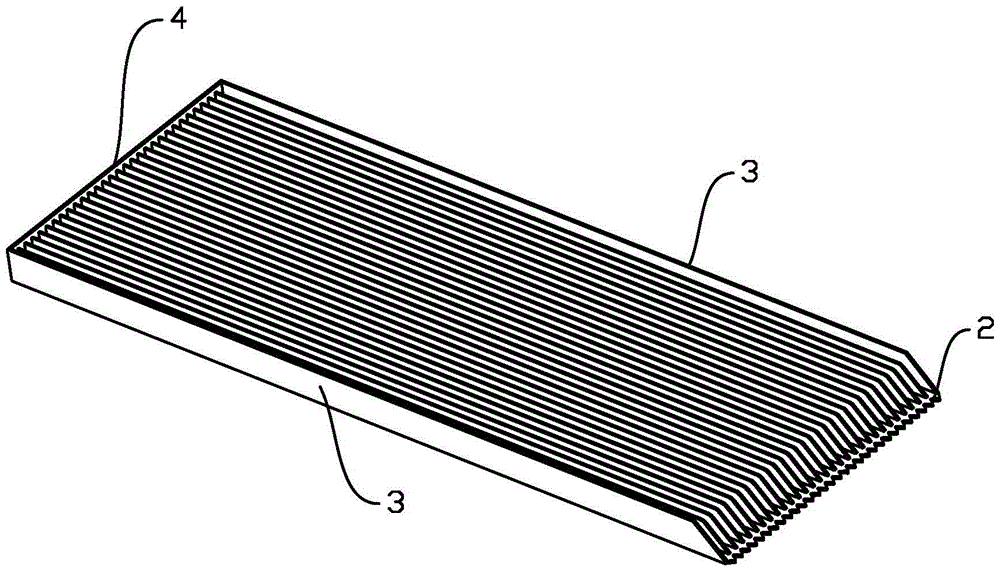

Apparatus and method for a reusable functional failure test for a specific technical system

ActiveUS20180267090A1Avoid inconsistenciesFast executionDigital data information retrievalElectronic circuit testingFailure rateLighting system

A computer based method for a reusable functional failure test for a specific technical system, e.g., a traffic light system is provided. The method avoids inconsistencies in the functional failure test and reuses items of the respective data structures. Furthermore, the embodiment can identify components or electronic devices that do exceed assumed failure rates and that might be repaired or replaced to keep implementations of the specific technical in the desired failure rate limitations of the analysis, which can be done during the operation of the specific technical system.

Owner:SIEMENS AG

Flight control system for an aircraft

ActiveUS11247768B2High precisionImprove usabilityConjoint controlsSafety arrangmentsFlight vehicleActuator

A flight control system for an aircraft comprises a set of actuators for controlling the aircraft and a set of flight control computers only made up of a set of duplex type main computers and of at least one backup computer. All the main computers are configured to implement auto-pilot laws for the aircraft. The set of main computers comprises two computers from a first hardware type, configured to control actuators of the set of actuators as per a first tolerance level and two computers from a second hardware type, different from the first hardware type, configured to control actuators of the set of actuators as per a second tolerance level, less stringent than the first tolerance level.

Owner:AIRBUS OPERATIONS (SAS)

An environmental chamber with pressure balance control

The invention relates to the field of design of environmental test chambers, in particular to an environmental chamber with a pressure balance control function.The environmental chamber comprises a regulation window opening, a window body and a counterweight mechanism.The regulation window opening is penetratingly formed in one wall of the environmental chamber; the window body identical to the regulation window opening in shape is in hermetical fit with the regulation window opening, the top of the window body is hinged to the wall, and the window body is capable of rotating around a hinge point with the wall towards a direction away from an inner cavity of the environmental chamber; the counterweight mechanism is detachably arranged on one lateral side, away from the inner cavity of the environmental chamber, of the window body and has a preset weight.The environmental chamber with the pressure balance control function has the advantages that when an acting force of an internal air pressure of the environment chamber on the window body is larger than a pressure force jointly formed by the window body and the counterweight mechanism, the window body can be pushed to rotate around the hinge point with the wall to open automatically, and accordingly air in the environmental chamber can be released for pressure relief; the window body can be hermetically reclosed when pressure balance is reached.

Owner:CHINA AIRPLANT STRENGTH RES INST

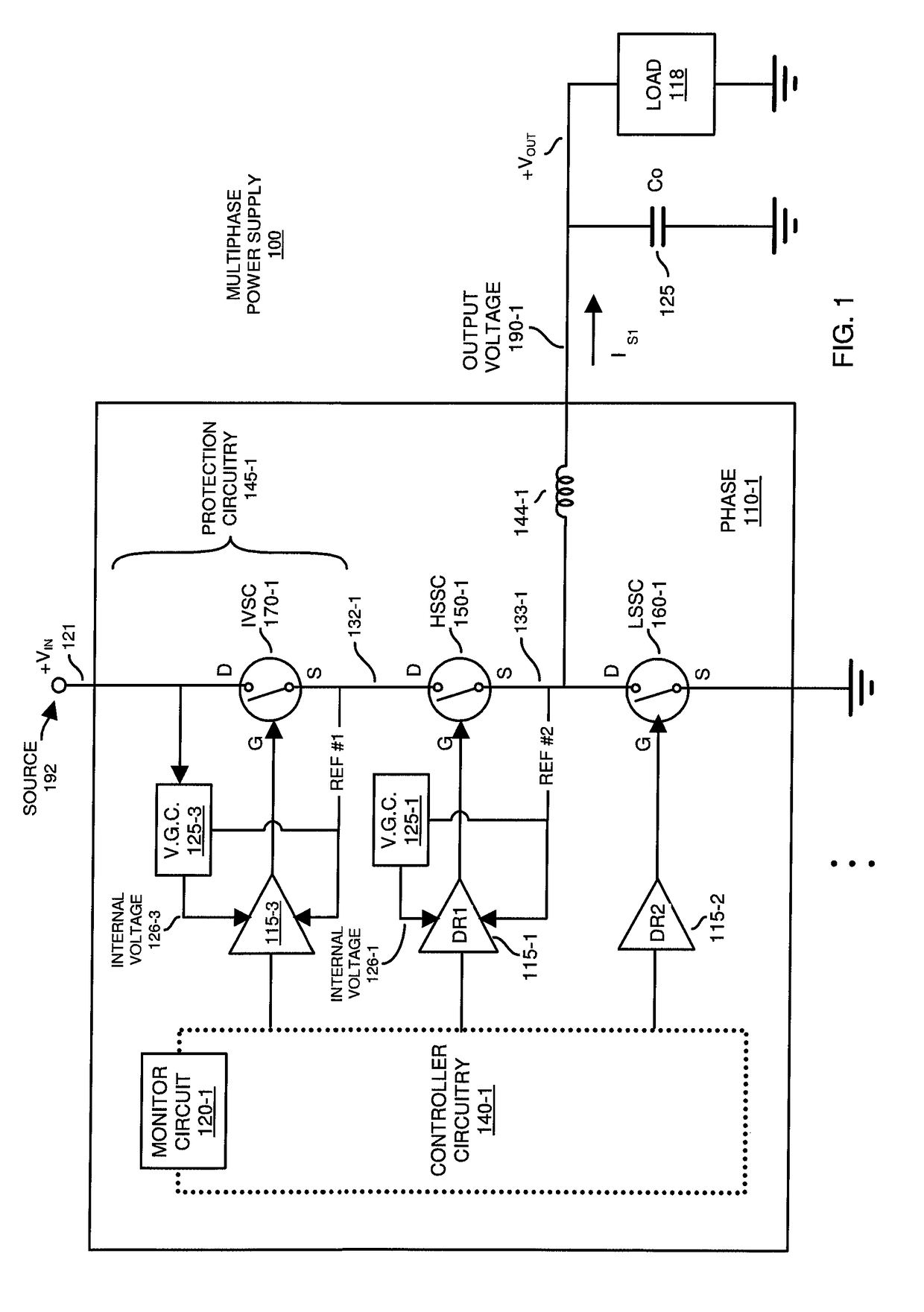

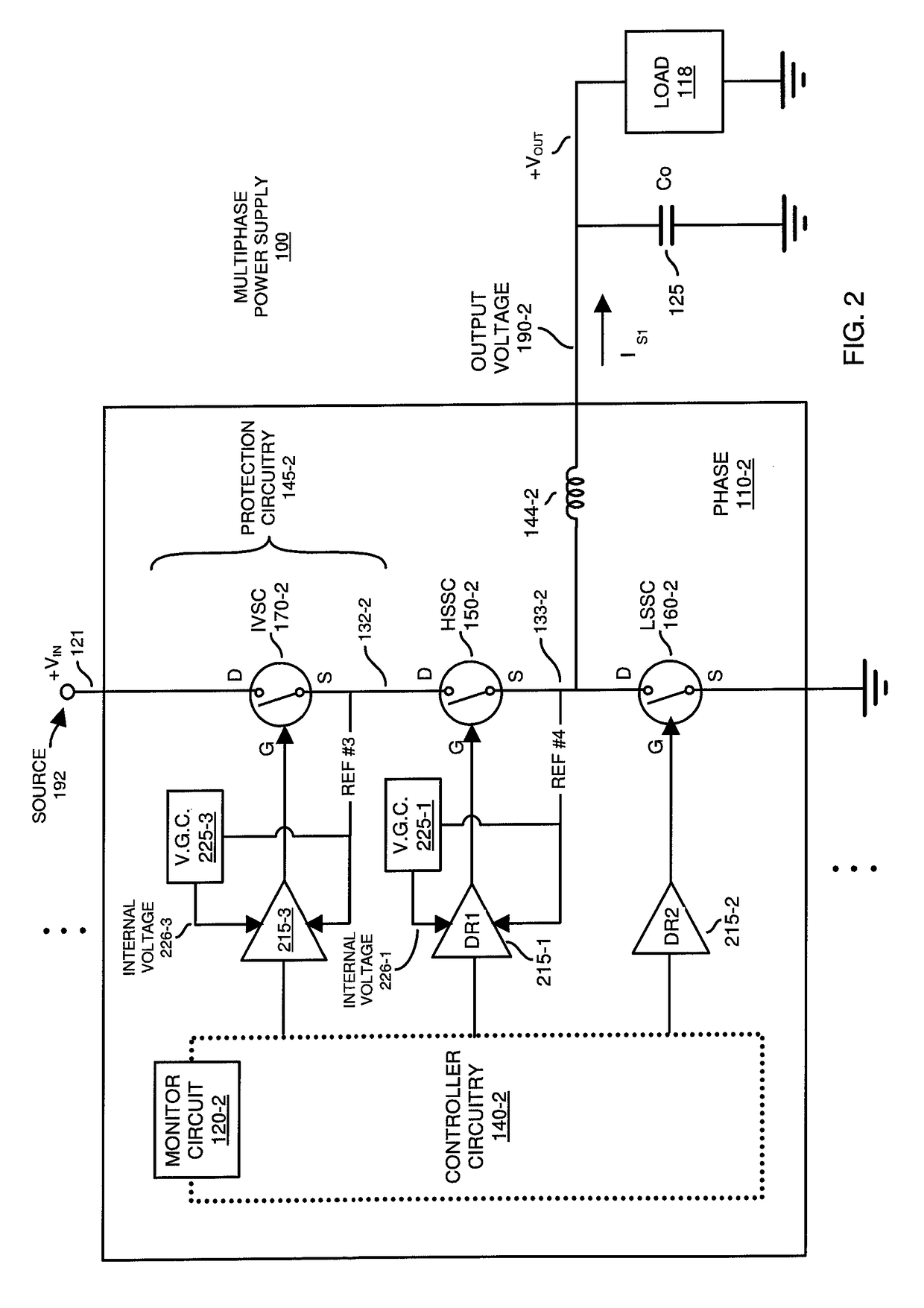

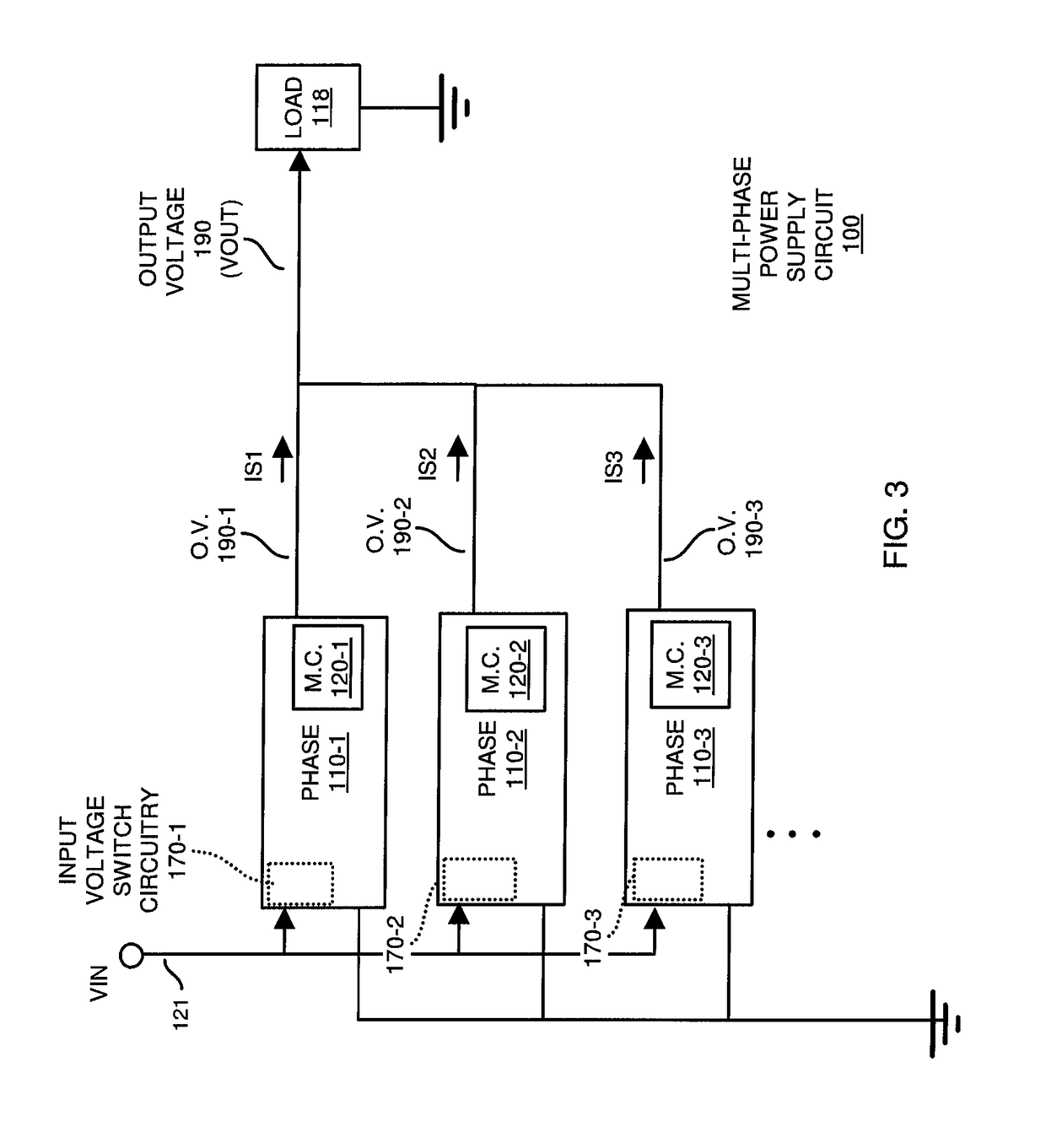

Multiphase power supply and failure mode protection

ActiveUS10153697B2Protection to failAvoid failure modeDc-dc conversionArrangements responsive to excess currentEngineeringVoltage source

A multi-phase power supply circuit includes multiple phases to convert an input voltage into a respective output voltage to power a load. A first phase of the multi-phase power supply includes a core power supply circuit including, for example, high side switch circuitry and low side switch circuitry. During normal operation, the core power supply circuit converts an input voltage into a respective output voltage to power a load. To provide failure mode protection with respect to the core power supply circuit and prevent a failure mode in which the first phase would otherwise produce a dangerous over-voltage condition, the first power supply phase includes an input voltage switch circuit disposed between an input voltage source and the core power supply circuit. The input voltage switch circuit provides a way of preventing the input voltage from being conveyed to the core power supply circuit during a failure mode.

Owner:INFINEON TECH AUSTRIA AG

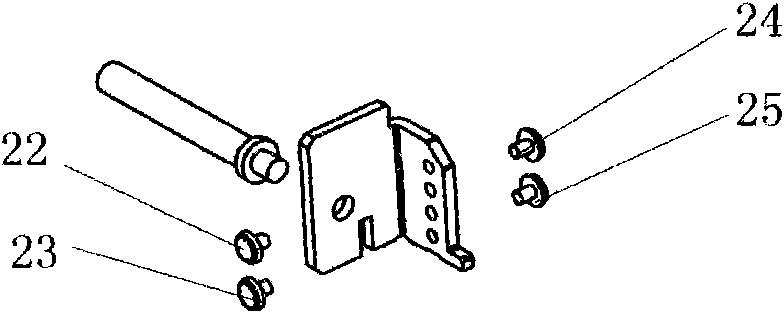

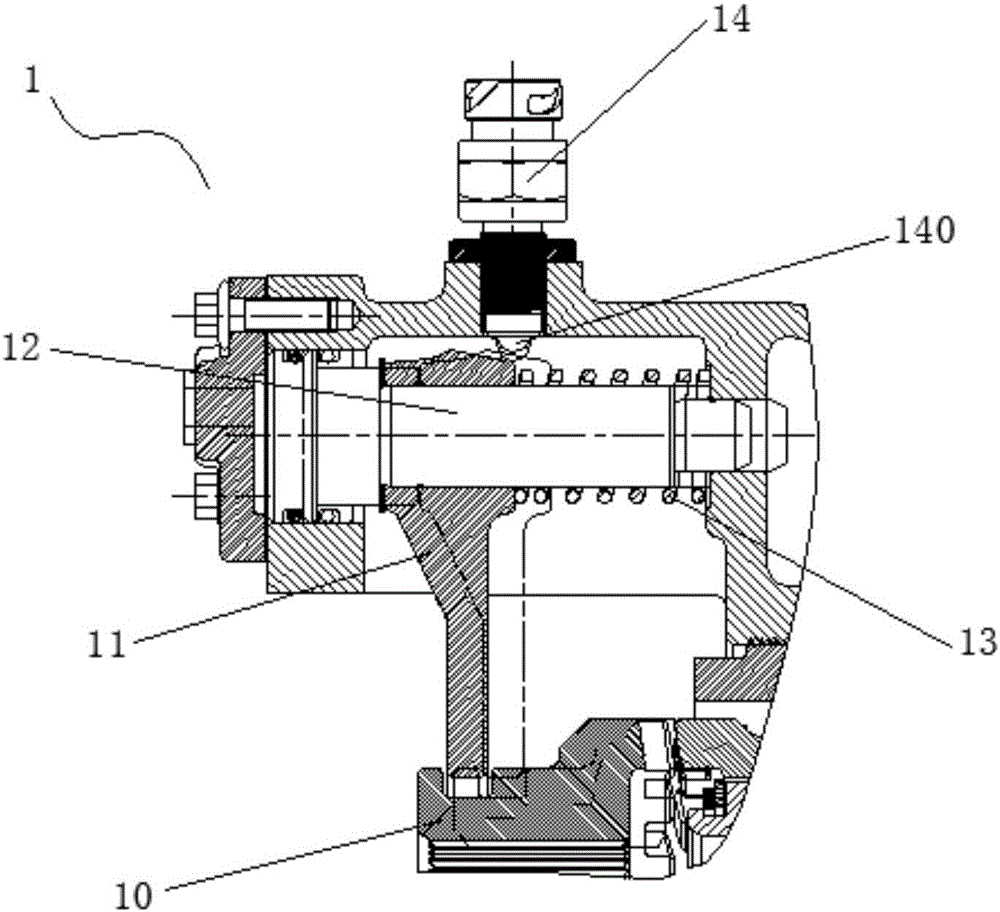

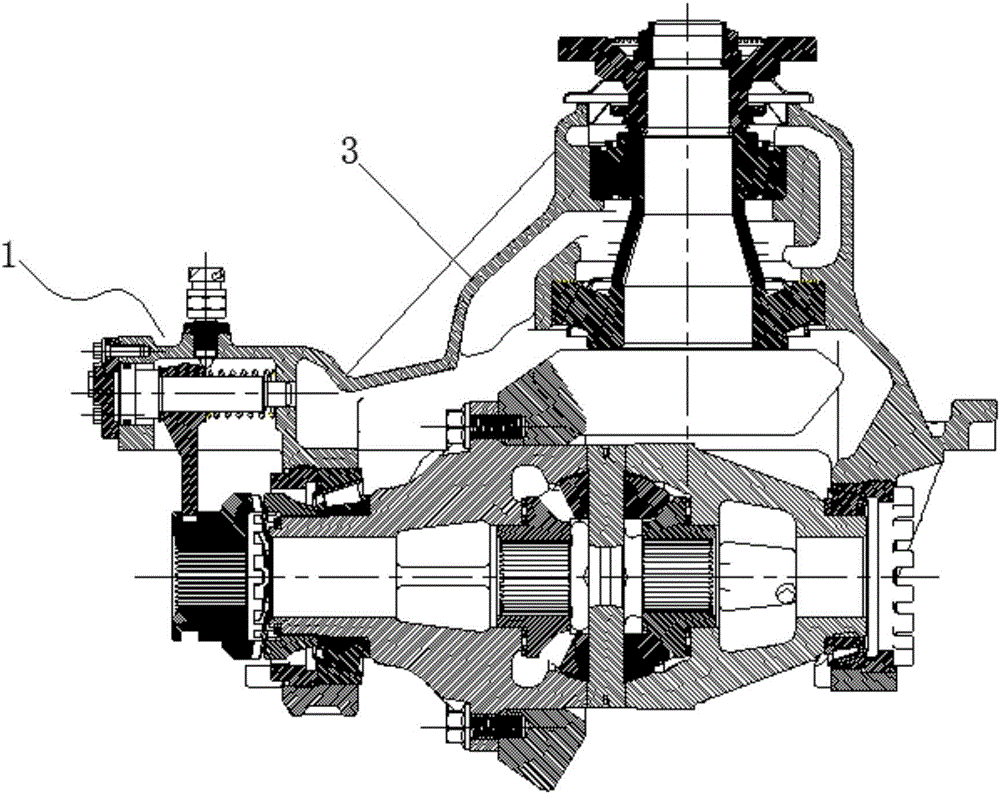

Differential lock provided with proximity switch

The invention discloses a differential lock provided with a proximity switch. The differential lock comprises a sliding combining sleeve, a shifting fork, a shifting fork shaft capable of moving in the axial direction, a reset spring and the proximity switch, wherein the proximity switch is arranged on one side of the head of the shifting fork; when the reset spring is not compressed, the head of the shifting fork is positioned out of a detection area of the proximity switch, and the proximity switch is disconnected; and when the reset spring is compressed, the head of the shifting fork enters the detection area of the proximity switch, and the proximity switch is connected. Compared with the prior art, the proximity switch is adopted to replace a traditional mechanical pressure switch to avoid direct collision and contact, so that the service life is longer; and in addition, the proximity switch is smaller, and the part, stretching out of a main reducer assembly, of the proximity switch after being assembled is also shorter, so that the proximity switch can be effectively prevented from being damaged due to collision during assembling, transporting, hoisting, packaging and finished vehicle operation.

Owner:GUANGDONG FUWA HEAVY IND

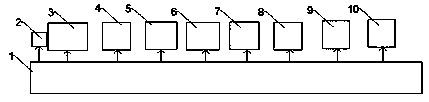

Full-automatic connection glass production line

InactiveCN110775595AIncrease productivityImprove yieldSortingConveyor partsPrinting pressConveyor belt

The invention discloses a full-automatic connection glass production line. The full-automatic connection glass production line includes a first conveyor belt, an ABB sheet lifting mechanical arm, a Bando cutting machine, an automatic appearance defect inspection system, a printing machine, a toughening furnace, a baler / sheet laminator, a sandwich line roller press, and an autoclave; the Bando cutting machine, the automatic appearance defect inspection system, the printing machine, the toughening furnace, the baler / sheet laminator, the sandwich line roller press, and the autoclave are sequentially connected with a conveyor belt in order to complete automatic production and inspection of glass; and the ABB sheet lifting mechanical arm is mounted at the feeding end of the Bando cutting machine and used for automatically lifting a glass sample to be cut onto the conveyor belt. On the one hand, the production efficiency is effectively improved, and manpower is reduced; on the other hand, through the designs and uses of the automatic appearance defect inspection system, an automatic trademark printing detection system, and an inspection station, the failure mode and risks which may occurin a production system are effectively avoided, and the yield rate is effectively improved while the occurrence of the risks is reduced.

Owner:常熟耀皮汽车玻璃有限公司

Apparatus and method for a reusable functional failure test for a specific technical system

ActiveUS10948549B2Avoids inconsistency of failure effectFast executionDatabase updatingElectronic circuit testingFailure rateComputer engineering

A computer based method for a reusable functional failure test for a specific technical system, e.g., a traffic light system is provided. The method avoids inconsistencies in the functional failure test and reuses items of the respective data structures. Furthermore, the embodiment can identify components or electronic devices that do exceed assumed failure rates and that might be repaired or replaced to keep implementations of the specific technical in the desired failure rate limitations of the analysis, which can be done during the operation of the specific technical system.

Owner:SIEMENS AG

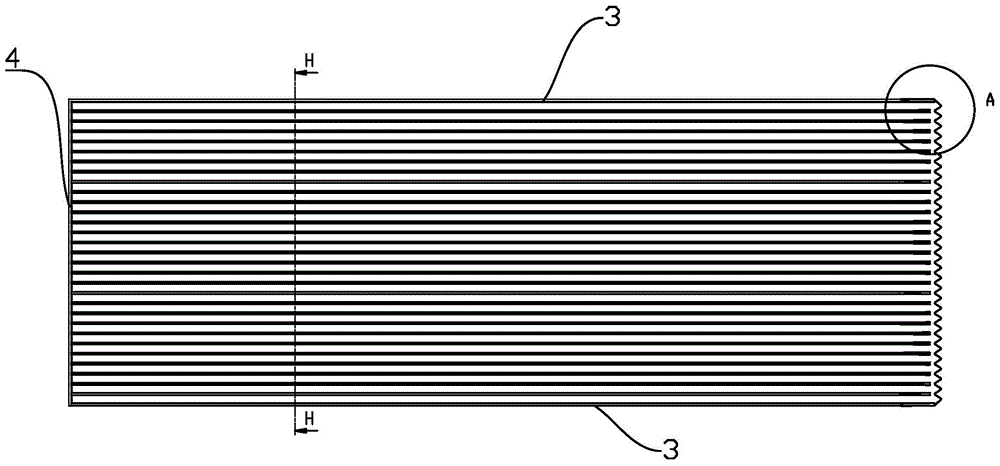

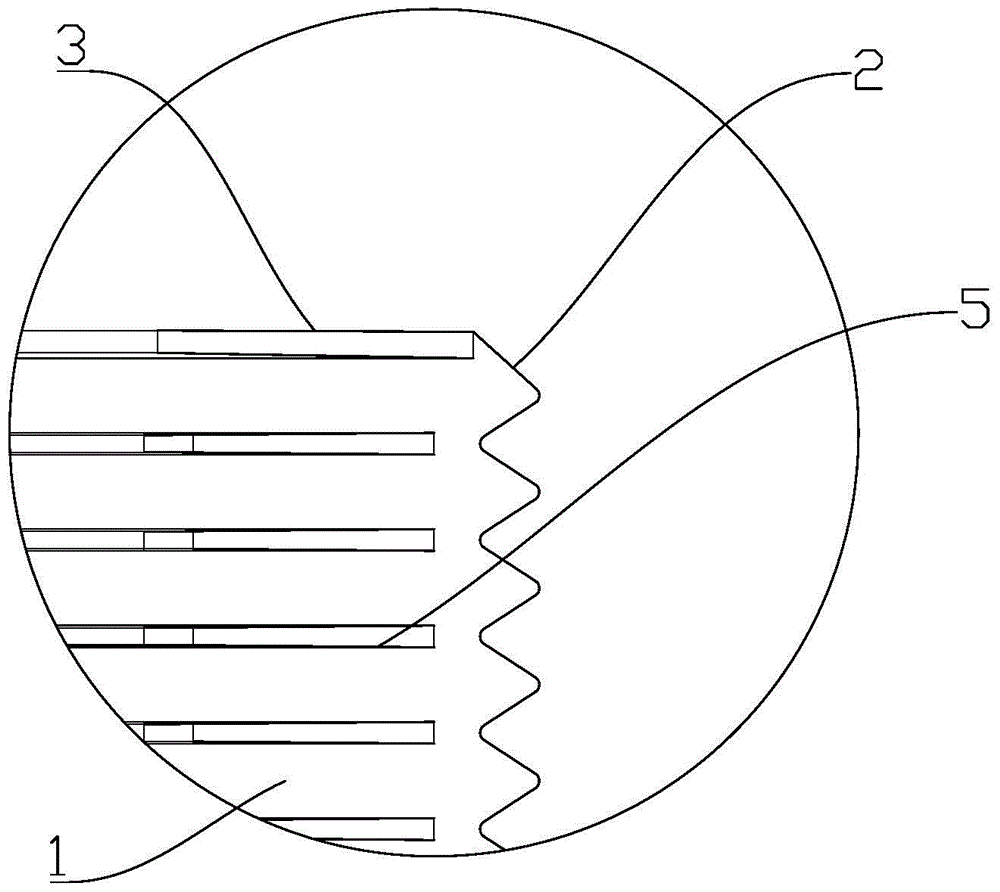

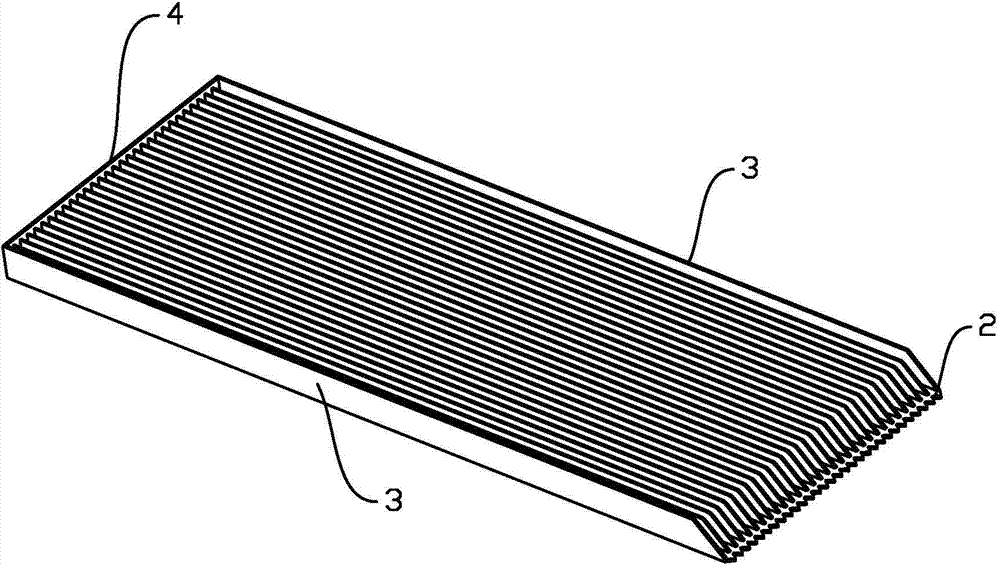

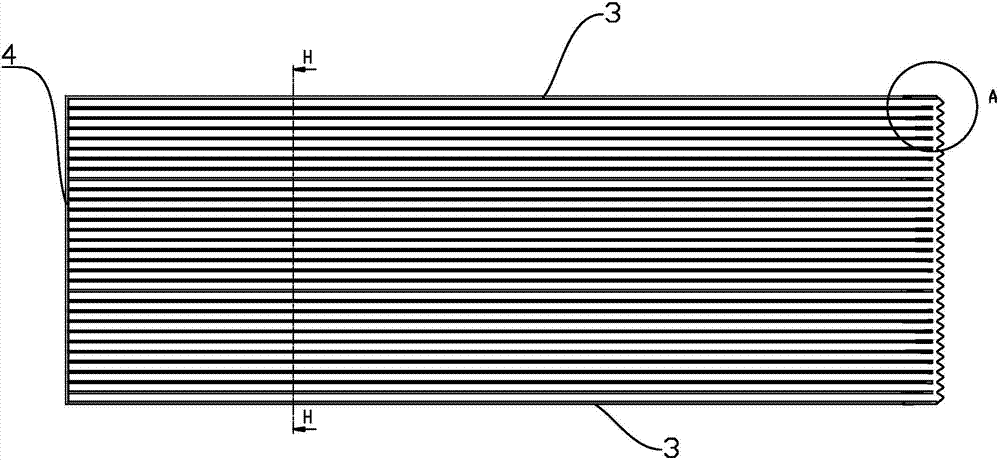

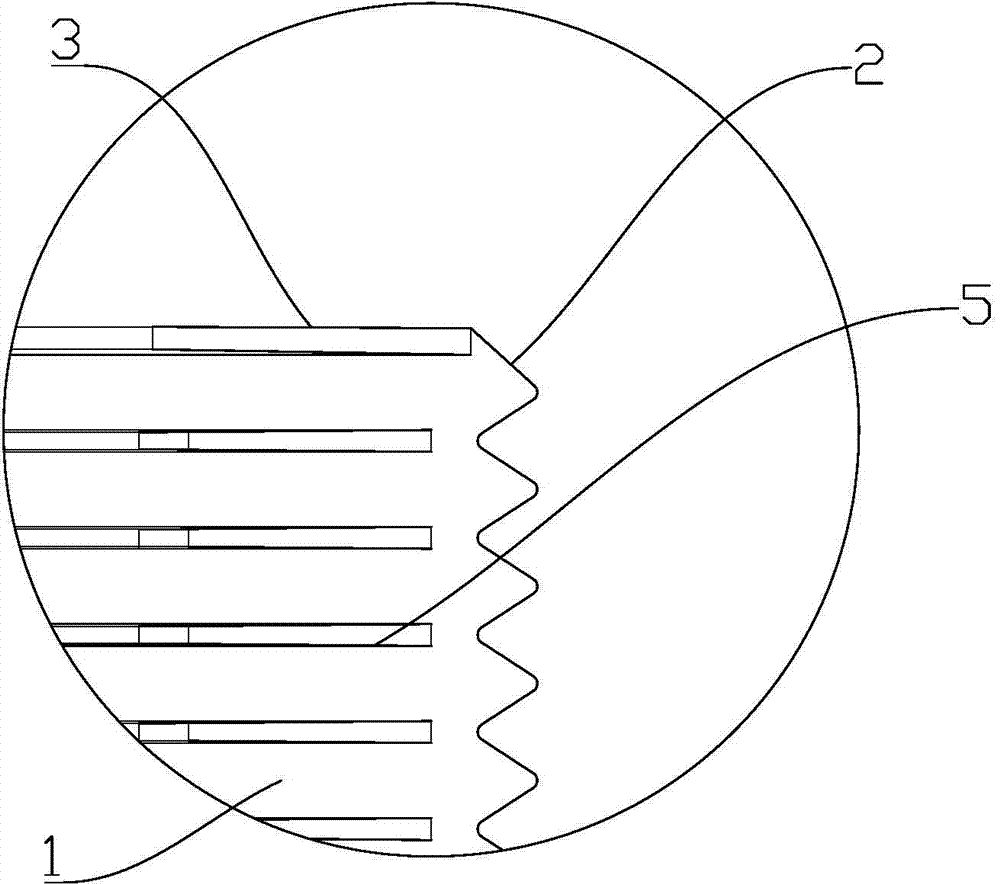

A cooling belt collection box

The invention provides a heat dissipation belt collecting box. The heat dissipation belt collecting box comprises a bottom plate and baffle plates, wherein uniform front teeth are formed in front of the bottom plat; the baffle plates comprise baffle plates arranged at left, right and rear sides of the heat dissipation belt collecting box, and inner baffle plates arranged at the inner sides of the left and right baffle plates; at least 13 groups of inner baffle plates are arranged on the bottom plate in parallel; the inner baffle plates, the left and the right baffle plates are parallel to one another and the interval between the inner baffle plates and the left baffle plates and that between the inner baffle plates and the right baffle plates are same; the baffle plates are vertically arranged above the bottom plate; one end of each of the inner baffle plates, the left and right baffle plates is vertically connected to the rear baffle plate, the other ends of the inner baffle plates, the left and right baffle plates are in the shape of an inclined plane, an included angle of 25-40 degrees is formed by the inclined plane and the bottom plate; the intervals between the baffle plates and the front teeth are the same; the center lines of the two baffle plates are aligned with the center lines of tooth slots of the front teeth. The heat dissipation belt collecting box can be used for effectively avoiding a potential failure mode after manufacturing pf the heat dissipation belts, solving a storage problem after the heat dissipation belt production, and effectively improving the cloth belt production efficiency during the core assembly process.

Owner:CHONGQING TOKYO RADIATOR

Heat dissipation belt collecting box

ActiveCN104495025AAvoid failure modeSolve storage problemsInternal fittingsEngineeringStorage Problem

The invention provides a heat dissipation belt collecting box. The heat dissipation belt collecting box comprises a bottom plate and baffle plates, wherein uniform front teeth are formed in front of the bottom plat; the baffle plates comprise baffle plates arranged at left, right and rear sides of the heat dissipation belt collecting box, and inner baffle plates arranged at the inner sides of the left and right baffle plates; at least 13 groups of inner baffle plates are arranged on the bottom plate in parallel; the inner baffle plates, the left and the right baffle plates are parallel to one another and the interval between the inner baffle plates and the left baffle plates and that between the inner baffle plates and the right baffle plates are same; the baffle plates are vertically arranged above the bottom plate; one end of each of the inner baffle plates, the left and right baffle plates is vertically connected to the rear baffle plate, the other ends of the inner baffle plates, the left and right baffle plates are in the shape of an inclined plane, an included angle of 25-40 degrees is formed by the inclined plane and the bottom plate; the intervals between the baffle plates and the front teeth are the same; the center lines of the two baffle plates are aligned with the center lines of tooth slots of the front teeth. The heat dissipation belt collecting box can be used for effectively avoiding a potential failure mode after manufacturing pf the heat dissipation belts, solving a storage problem after the heat dissipation belt production, and effectively improving the cloth belt production efficiency during the core assembly process.

Owner:CHONGQING TOKYO RADIATOR

Self-restraining abrasion prevention exhaust conduit

ActiveUS10669919B2Out energyAvoid failure modePipeline expansion-compensationSilencing apparatusDamperMechanics

A multiple component hot gas flowing conduit has an elongated, convoluted bellows, an interlock liner, frequency dampers and elastic spacers engaging the dampers and biasing the dampers into respective bellows convolution with no contact of bellows and liner for all operating states of the conduit. Assembly pretension of the interlock liner preferably flattens out the elastic spacers permitting assembly of the liner into the bellows and upon relaxation of the liner, the spacers extend radially outwardly to engage and bias the dampers into the bellows. The bellows is convoluted throughout, or may have convoluted ends with an integral smooth-wall tube therebetween. Components are isolated from abrasion against one another.

Owner:AMERICAN BOA

Center component of electronic brake booster capable of being mechanically and fully decoupled

PendingCN113997918ANovel structureRealize full mechanical decouplingBraking action transmissionFoot actuated initiationsGear wheelElectric machinery

The invention relates to a center component of an electronic brake booster capable of being mechanically and fully decoupled, and belongs to the field of vehicle braking. The gear is rotatably connected with the transmission nut, the transmission nut is in threaded connection with the screw assembly, the valve body component is in clearance fit and sliding connection with the screw assembly, the screw assembly is fixedly connected with the support through a buckle, a displacement sensor in the displacement sensor component is fixedly connected with the support, and a magnet of the valve body component is in clearance fit with the displacement sensor. The magnet and the displacement sensor slide relatively to generate relative displacement, and a displacement signal is generated and used for enabling the motor to act. The component has the advantages that the structure is novel, a failure mode caused by poor sealing can be avoided, a machine is used as a decoupling form, the reliability is higher, mechanical full decoupling can be realized, the booster brings greater endurance to a vehicle when the brake energy of the vehicle is recovered, and the booster is the development trend of a future service brake system.

Owner:JILIN DONGGUANG AOWEI AUTOMOBILE BRAKE SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com