Method for quantitatively evaluating safety of boiler parts

A technology for safety evaluation and boiler parts, which is applied in the field of boilers and can solve the problems of inability to determine the quantitative evaluation results of the safety of boiler parts, and the lack of suitability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

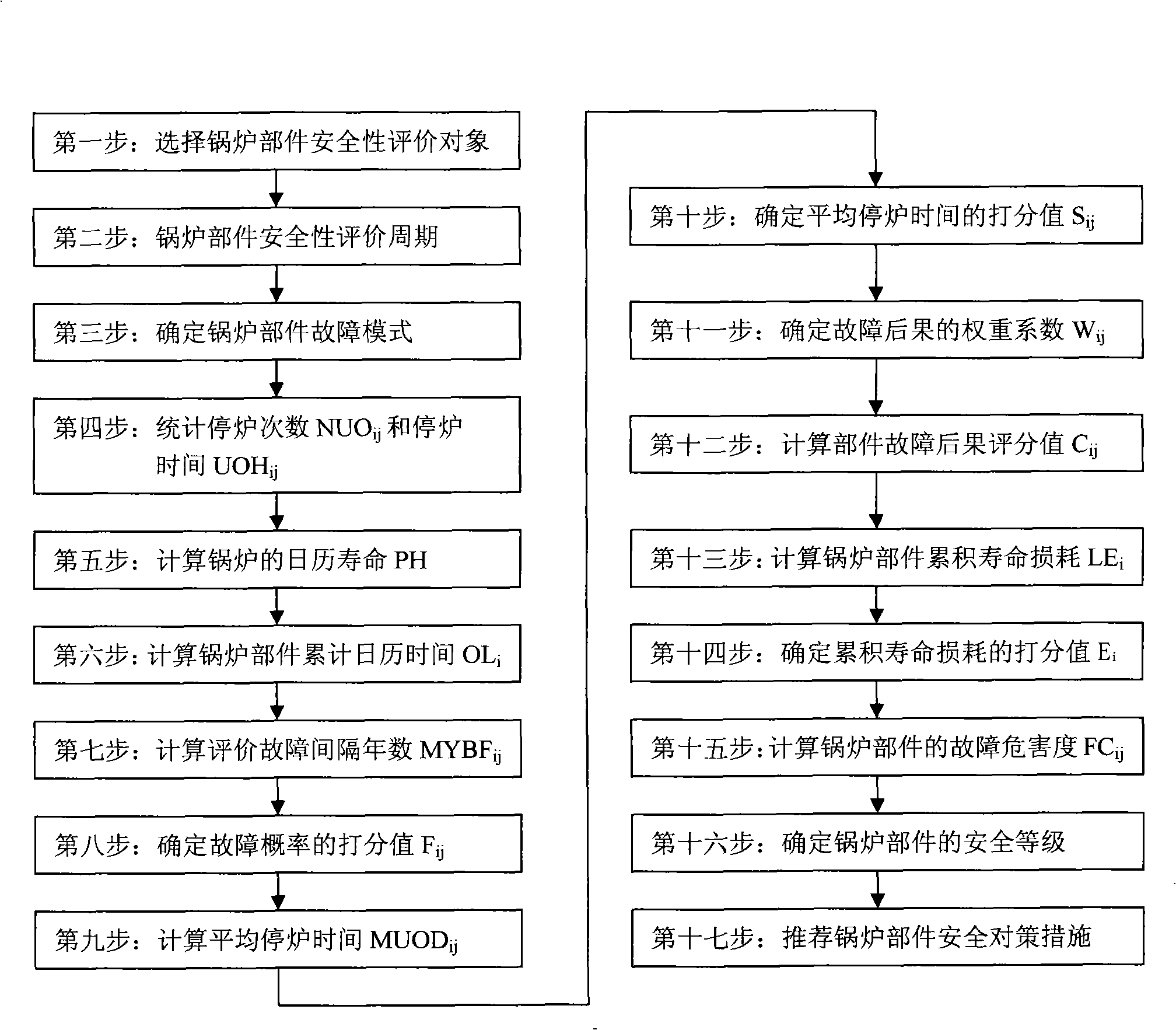

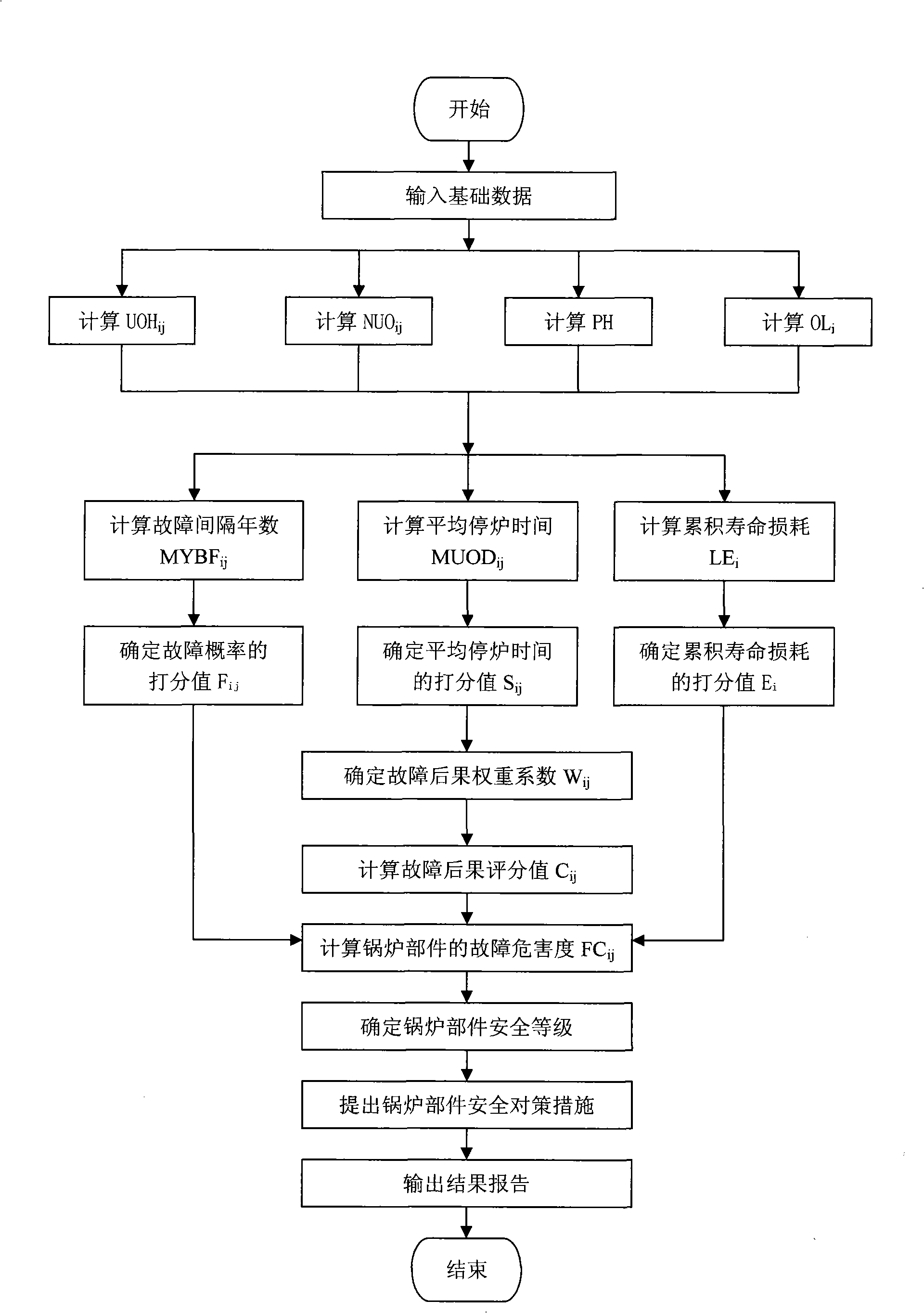

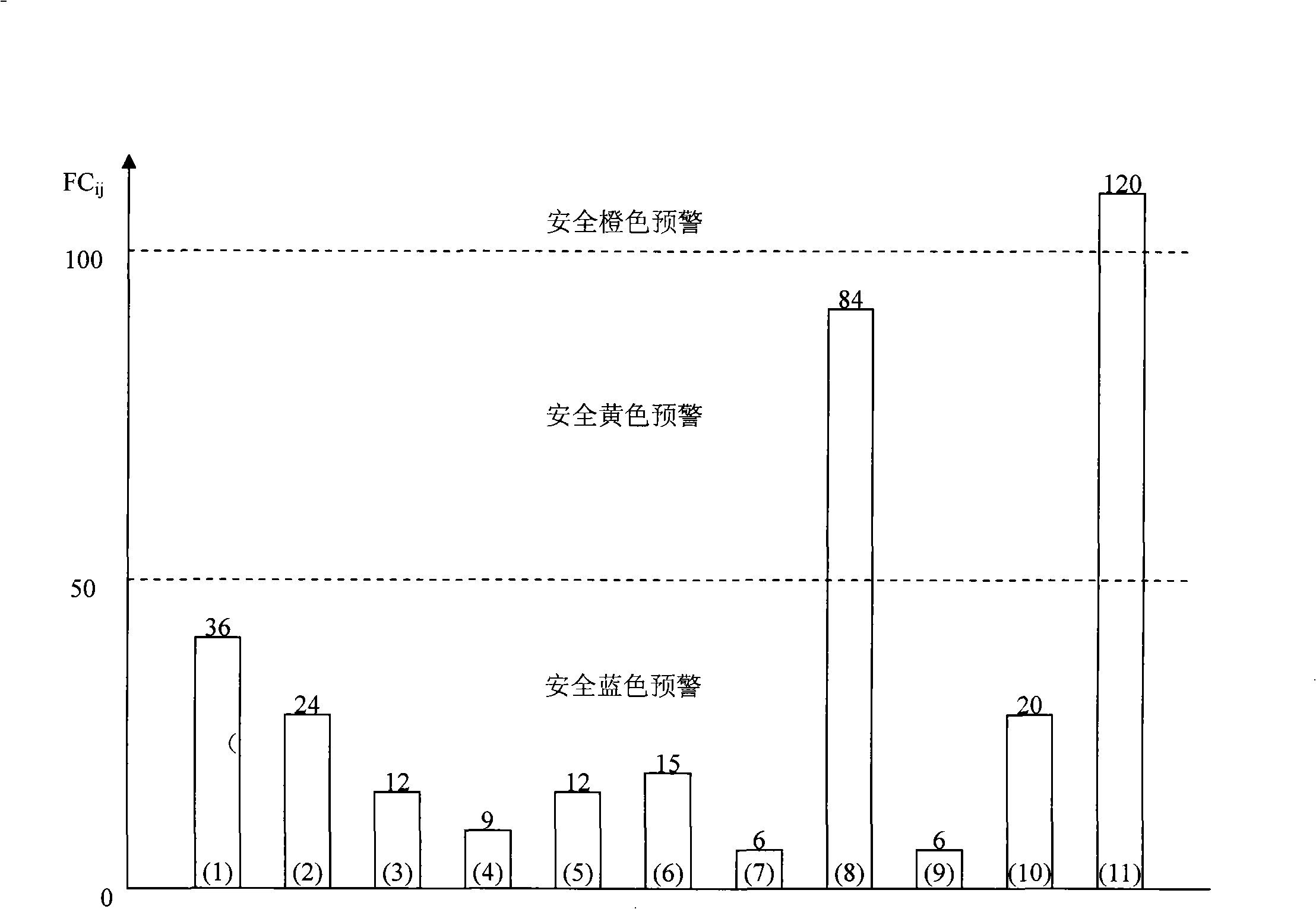

[0068] For the economizer tube of a certain type of 300MW utility boiler, adopt figure 1 The flow chart of the quantitative evaluation method for the safety of boiler components and the program written in C language are shown and installed in the computer of the production safety supervision department of the power station. figure 2 The computer software for the quantitative evaluation of the safety of the boiler components is shown, and the calculated results of the quantitative evaluation of the safety of the economizer tubes of this type of boiler are listed in image 3 .

[0069] Step 1: Select the economizer pipe of this type of boiler as the safety evaluation object;

[0070] The second step: in the 8th year when the boiler of this type is put into operation, conduct the second quantitative safety evaluation;

[0071] Step 3: Referring to the existing boiler reliability statistics method, the damage locations of the economizer pipes of this type of boiler are: pipes (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com