Differential lock provided with proximity switch

A technology of proximity switch and head, which is applied in the field of differential lock, can solve the problems of large shape and damage, and achieve the effects of long service life, long operating life and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

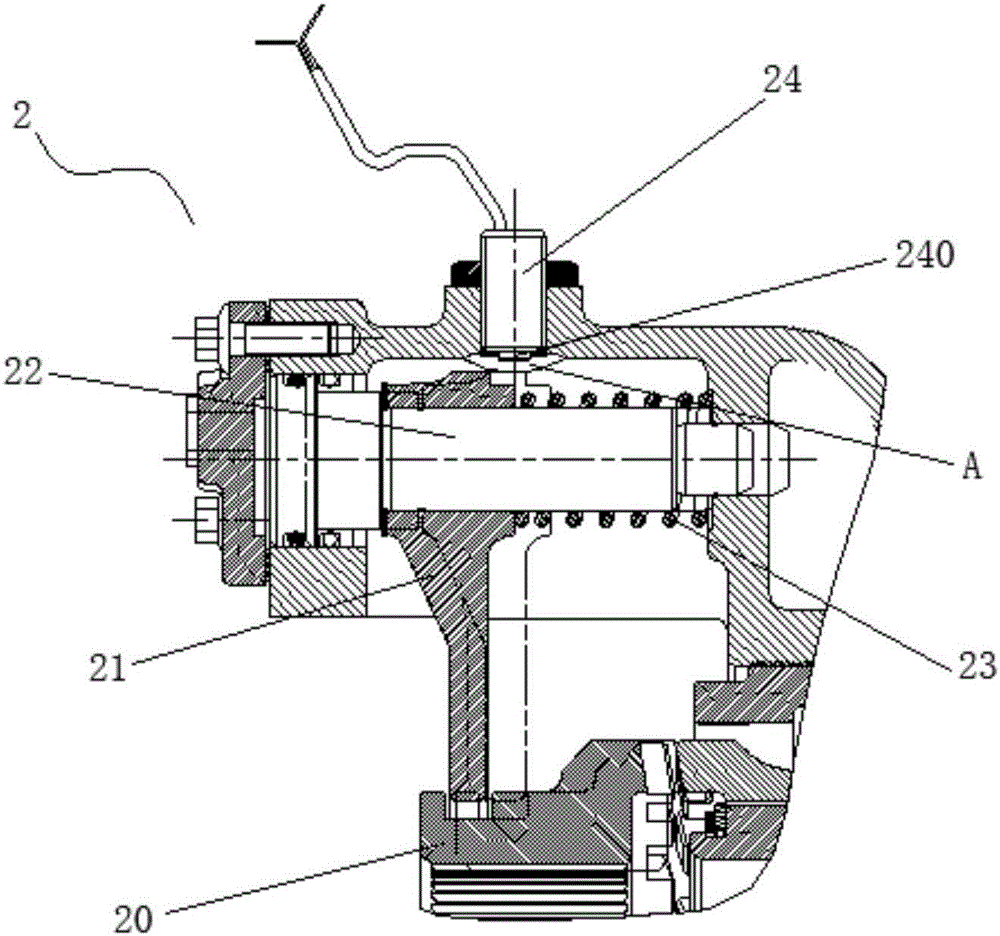

[0022] see image 3 , which is a structural schematic diagram of a differential lock with a proximity switch of the present invention. The differential lock 2 with a proximity switch provided by the present invention includes a sliding joint sleeve 20 , a shift fork 21 , a shift fork shaft 22 movable along its axial direction, a return spring 23 and a proximity switch 24 . image 3 The double dotted line in the middle indicates the position of the shift fork 21 when the differential lock 2 is in the state of locking the differential; the semicircular area indicated by A indicates the detection area of the proximity switch 24 .

[0023] The sliding joint sleeve 20 is provided with an annular groove, the head of the shift fork 21 is fixedly mounted on the shift fork shaft 22 , and its foot is snapped into the annular groove of the sliding joint sleeve 20 . The return spring 23 is sleeved on the shift fork shaft 22, one end thereof abuts against the head of the shift fork 21, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com