Center component of electronic brake booster capable of being mechanically and fully decoupled

An electronic braking and booster technology, applied in the direction of brakes, vehicle components, brake transmission devices, etc., can solve problems such as poor sealing, mode failure, and inability to achieve full mechanical decoupling, achieving strong reliability and fast response speed. , to avoid the effect of poor sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

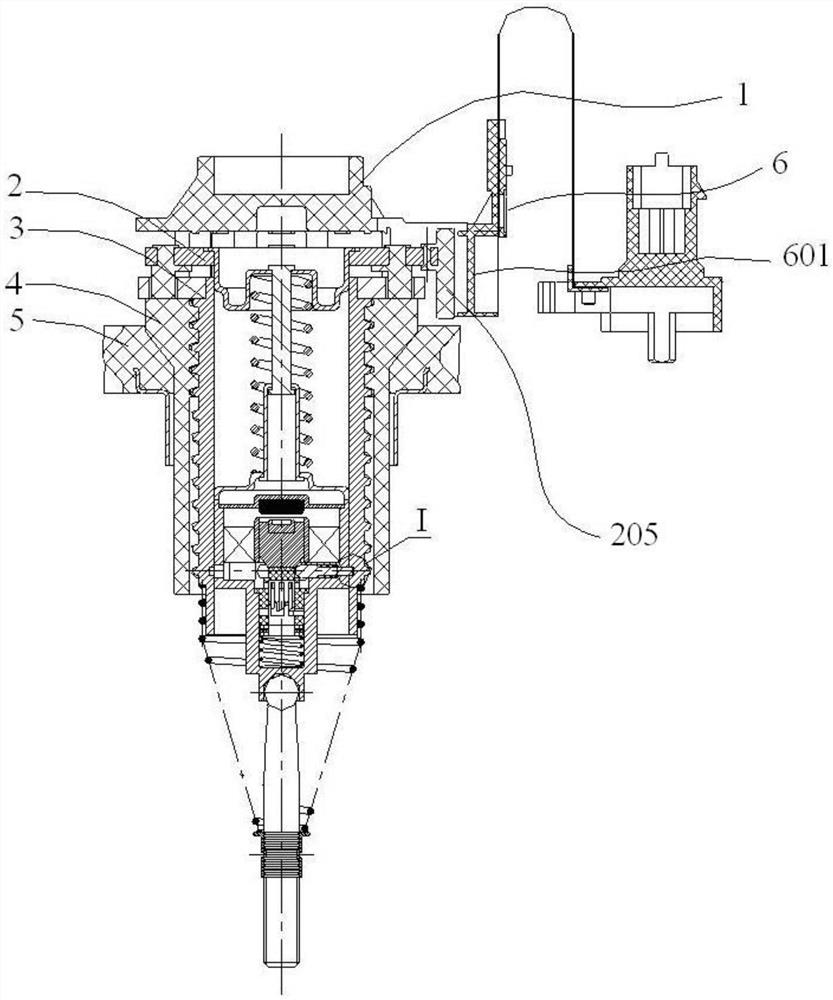

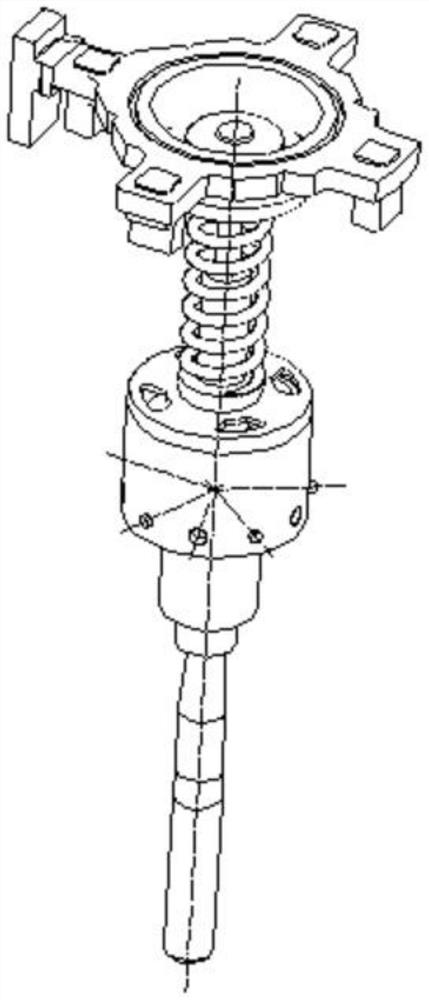

[0028] Such as figure 1 As shown, it includes a bracket 1, a valve body part 2, a screw assembly 3, a transmission nut 4, a gear 5 and a displacement sensor part 6, wherein the gear 5 is rotationally connected with the transmission nut 4, the transmission nut 4 is threaded with the screw assembly 3, and the valve body The component 2 and the screw assembly 3 are in clearance fit and sliding connection, the screw assembly 3 is fixedly connected with the support 1 through a buckle, the displacement sensor 601 in the displacement sensor component 6 is fixedly connected with the support 1, and the magnet 205 of the valve body component 2 is connected to the displacement sensor 601 The gap fits and slides relative to the axial direction, and the magnet 205 slides relative to the displacement sensor 601 to generate a relative displacement to generate a displacement signal for controlling the action of the motor.

[0029] The bracket 1 of the present invention is made of tough plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com