One-way clutch compact in structure

A one-way clutch, compact technology, applied in one-way clutches, clutches, mechanical equipment, etc., can solve the problems of difficult transportation of one-way roller assemblies, complex structure of one-way clutches, and many parts, etc. The effect of size reduction and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

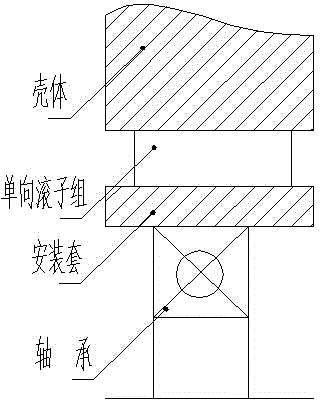

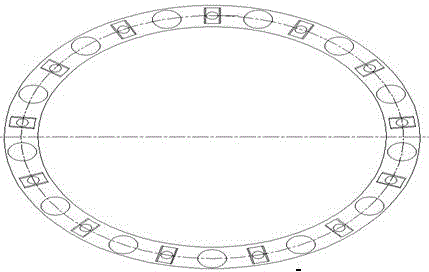

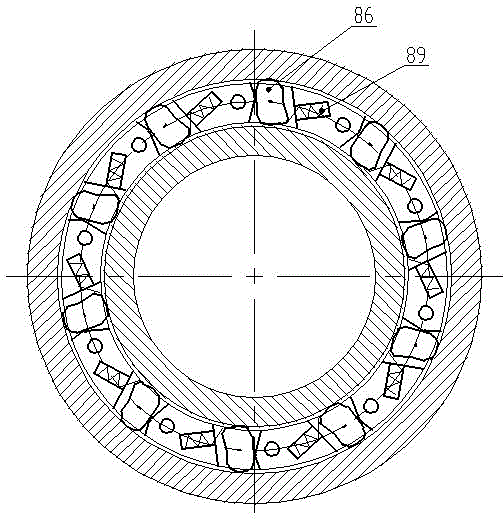

[0021] Such as image 3 , Figure 4 As shown, the present invention includes a rolling bearing. The rolling bearing includes an inner ring 02, an outer ring 01, a cage 46, and rolling elements 04. The rolling elements in the cage and the elliptical rollers 86 are distributed alternately. The elliptical rollers The two ends of the long axis contact the inner ring and the outer ring respectively, and an open groove is provided at the contact point with the inner ring, and a spring 89 connected with the elliptical roller is arranged in the open groove, when the elliptical roller moves toward When the spring moves, the one-way clutch rotates freely, and when the elliptical roller moves away from the spring, the inner and outer rings are locked to lock the one-way clutch. The cage is held in position by a cage cover 16 .

[0022] Since the obliquely arranged elliptical r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com