Photosensitive resin and preparation method and application thereof

A photosensitive resin and resin technology, applied in the direction of additive processing, can solve the problems of complex processing technology and energy consumption, and achieve the effects of improved resolution, high elongation at break, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

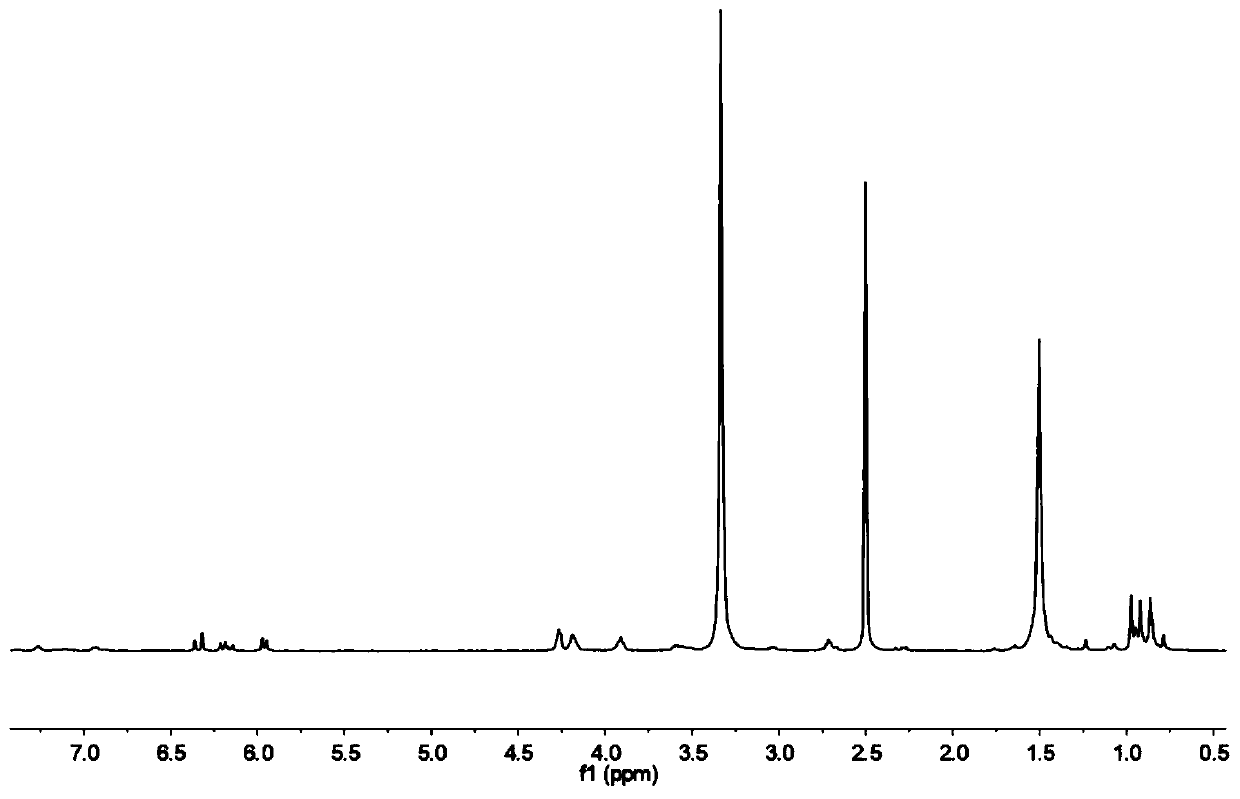

[0056] A kind of preparation of colorless and transparent polyurethane acrylate resin, concrete steps are as follows:

[0057] At room temperature, mix 150g of polytetrahydrofuran diol (molecular weight: 2000g / mol), 15g of hexamethylene diisocyanate and 10ml of tetrahydrofuran, add 0.03g of dibutyltin dilaurate, then raise the temperature to 70°C for 4 hours, and then take out a small amount of For the prepolymer, use the method specified in HG / T2409-1992 to measure the isocyanate group content, and then titrate 3.70g of hydroxypropyl acrylate into the system to react all the isocyanate groups according to the calculation results. After adding hydroxypropyl acrylate, continue to React at 70°C for 3 hours, and use infrared to test whether the -NCO in the prepolymer is completely reacted. If the characteristic peak of -NCO with a wave number of 2260 disappears, it means that the hexamethylene diisocyanate has been completely reacted. After the complete reaction of the isocyanate...

Embodiment 2

[0068] A kind of preparation of colorless and transparent polyurethane acrylate resin, concrete steps are as follows:

[0069] At room temperature, mix 100g of polycaprolactone diol (molecular weight: 1000g / mol), 33.3g of isophorone diisocyanate and 5ml of tetrahydrofuran, add 0.02g of dibutyltin dilaurate, then raise the temperature to 80°C for 5 hours, and then Take out a small amount of prepolymer, use the method specified in HG / T2409-1992 to measure the content of isocyanate groups, titrate 13g of hydroxypropyl acrylate into the system according to the calculation results to react all the isocyanate groups, add hydroxypropyl acrylate and continue React at 80°C for 3 hours, and use infrared to test whether the -NCO in the prepolymer is completely reacted. If the characteristic peak of -NCO with a wave number of 2260 disappears, it means that the isophorone diisocyanate has completely reacted. After the diisocyanate has completely reacted, p-hydroxyanisole (0.04g) is added t...

Embodiment 3

[0074] A kind of preparation of colorless and transparent polyurethane acrylate resin, concrete steps are as follows:

[0075]At room temperature, mix 100g of polypropylene glycol (molecular weight: 2000g / mol), 11.31g of toluene diisocyanate and 8ml of tetrahydrofuran, add 0.01g of dibutyltin dilaurate, then raise the temperature to 60°C for 4 hours, and then take out a small amount of prepolymer. Use the method specified in HG / T2409-1992 to measure the content of isocyanate groups. According to the calculation results, titrate 3.9g of hydroxypropyl acrylate into the system to react all the isocyanate groups. After adding hydroxypropyl acrylate, continue to react at 80°C for 3h. Whether the -NCO in the prepolymer is tested by infrared is completely reacted, if the characteristic peak of -NCO at wave number 2260 disappears, it shows that the toluene diisocyanate has completely reacted, and after the completion of the toluene diisocyanate reaction, p-hydroxyanisole ( 0.03g) was ...

PUM

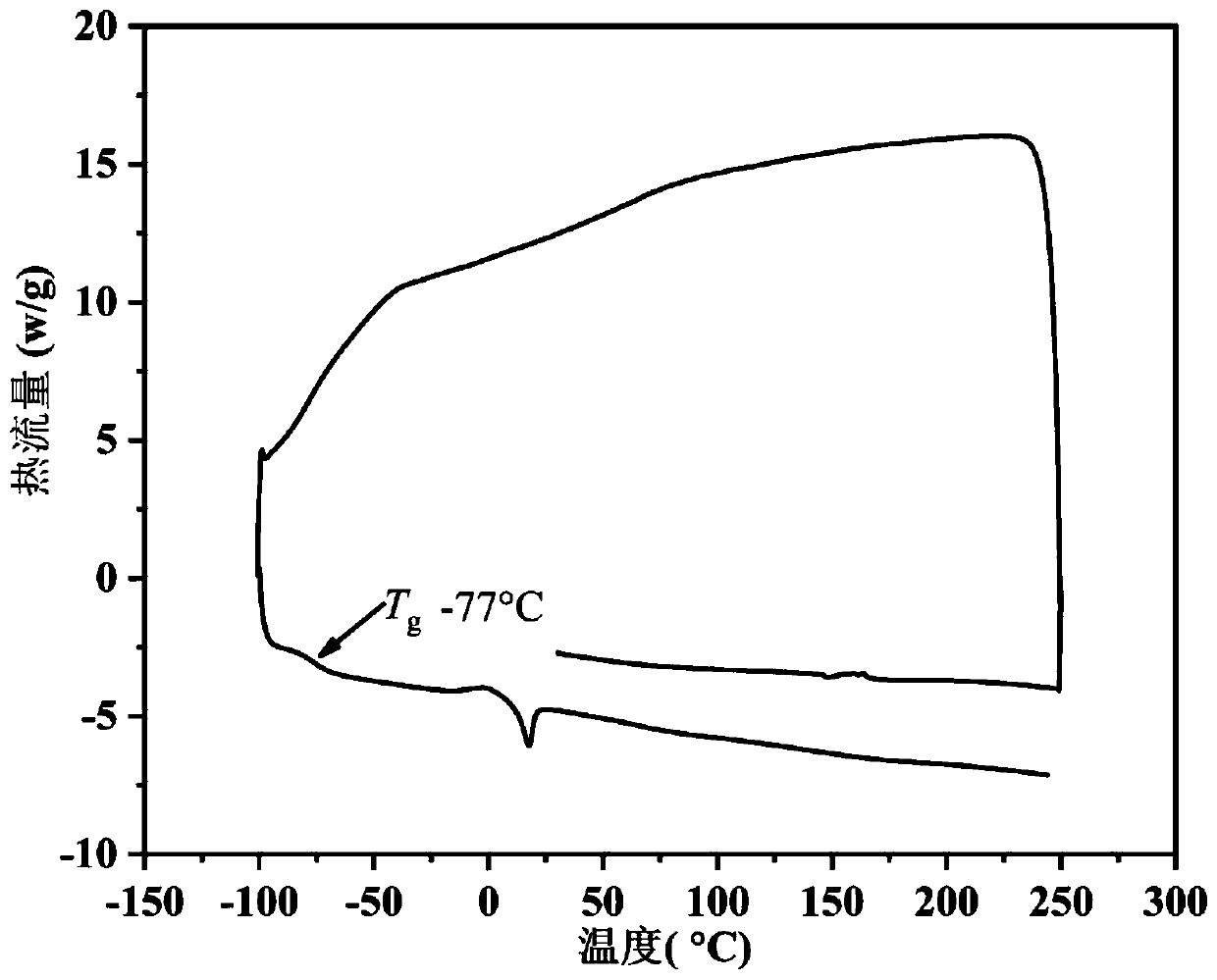

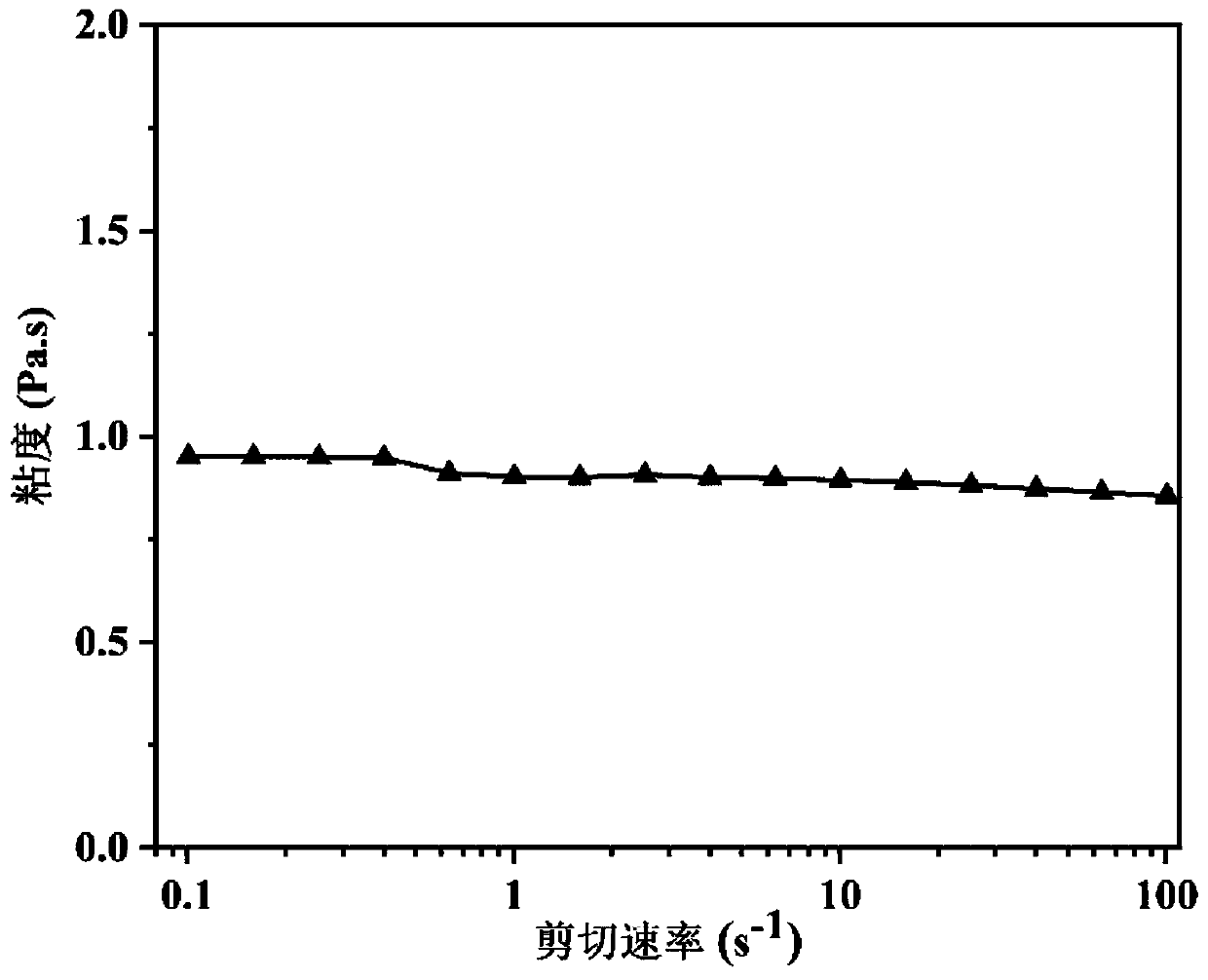

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com