Preparation method of cotton fiber coal-base material, and application thereof as electrode material of supercapacitor

A cotton fiber and carbon-based material technology is applied in the field of preparation of cotton fiber and carbon-based materials, and can solve the problems of high cost and complicated preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

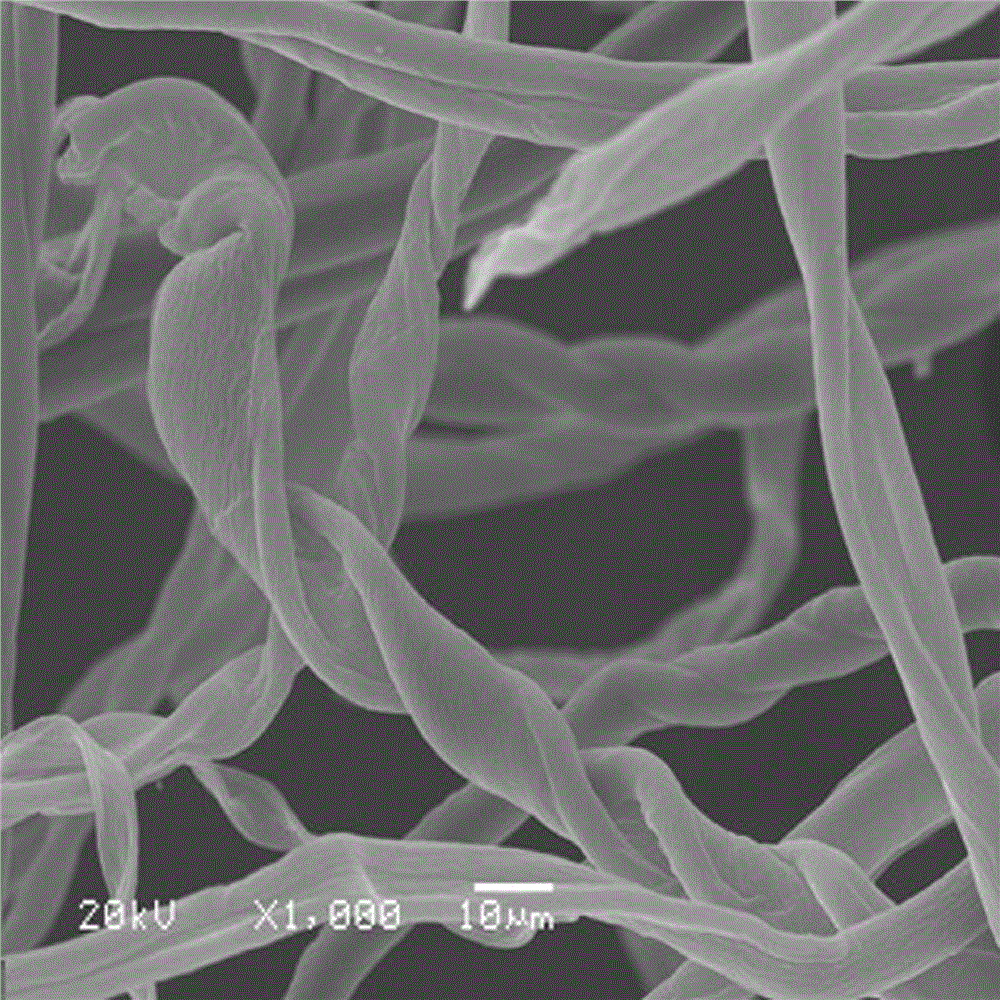

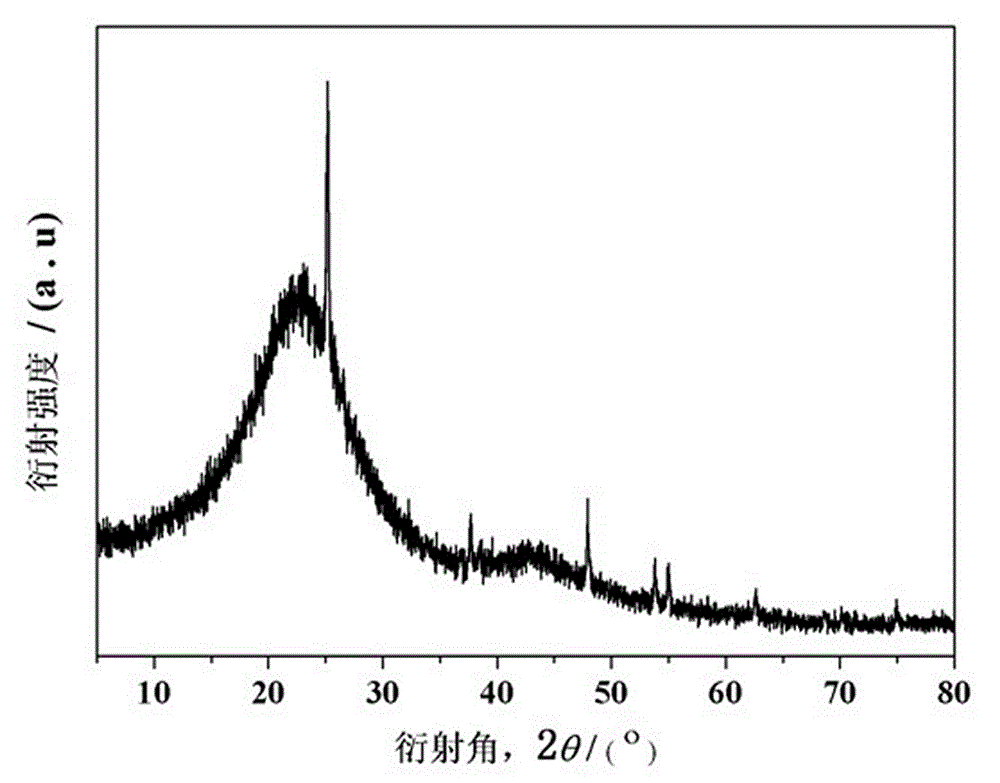

[0021] Weigh 1.0 g of cotton, wash it with deionized water and ethanol several times, and dry it in a vacuum oven at 60 °C; pre-carbonize the dried cotton at 300–350 °C for 3–5 h, and then dry it under N 2 Under protection, the activated cotton fiber was carbonized at 700 °C for 3 h; then the carbonized cotton was soaked in 50 ml 10 % KOH solution, soaked at 70 °C for 2 h, cooled to room temperature, filtered, and then soaked in 50 ml 1 M Soak in HCl for 12 h, finally wash with deionized water until neutral, and dry to obtain a cotton fiber carbon-based material.

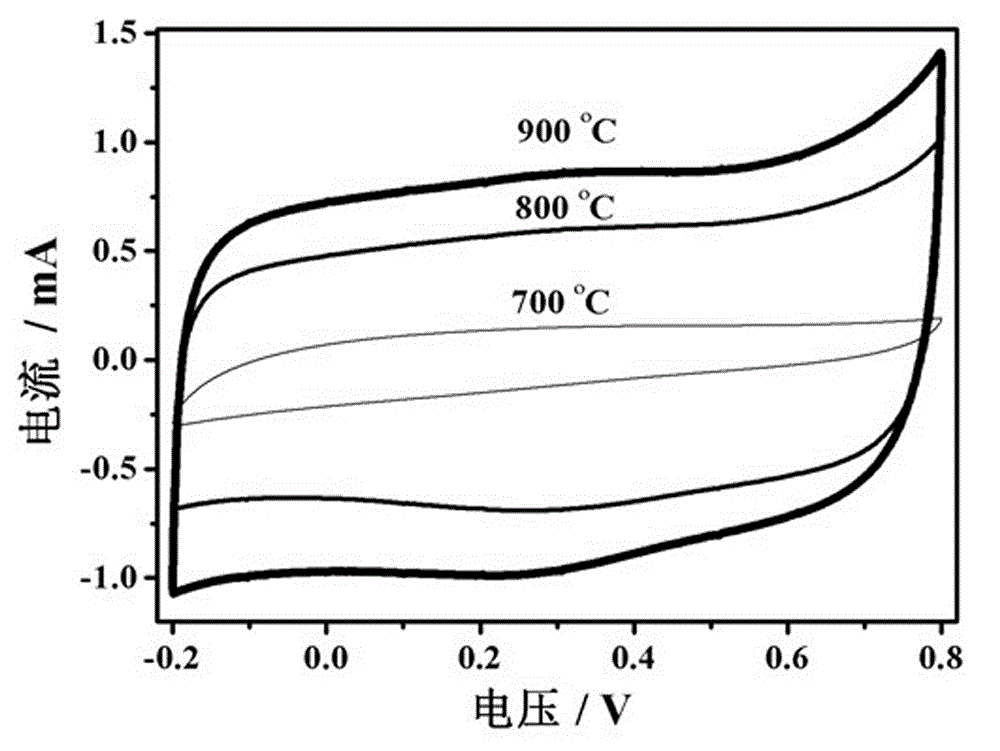

[0022] Cotton fiber carbon-based material at 1 mol / L H 2 SO 4 The specific capacitance in the electrolyte is 185 F g -1 .

Embodiment 2

[0024] Weigh 1.0 g of cotton, wash it with deionized water and ethanol three times, and dry it in a vacuum oven at 60 °C; pre-carbonize the dried cotton at 300–350 °C for 3–5 h, and then dry it under N 2 Under protection, the activated cotton fiber was carbonized at 800 °C for 6 h; then the carbonized cotton was soaked in 50 ml 30 % KOH solution, soaked at 50 °C for 4 h, cooled to room temperature, filtered, and then soaked in 50 ml 1 M Soak in HCl for 8 h, finally wash with deionized water until neutral, and dry to obtain cotton fiber carbon-based materials.

[0025] Cotton fiber carbon-based material at 1 mol / L H 2 SO 4 The specific capacitance in the electrolyte is 193 F g -1 .

Embodiment 3

[0027] Weigh 1.0 g of cotton, wash it with deionized water and ethanol several times, and dry it in a vacuum oven at 60 °C; pre-carbonize the dried cotton at 300–350 °C for 3–5 h, and then dry it under N 2 Under protection, the activated cotton fiber was carbonized at 900 °C for 3 h; then the carbonized cotton was soaked in 50 ml 20 % KOH solution, soaked at 80 °C for 2 h, cooled to room temperature, filtered, and then soaked in 50 ml 1 M Soak in HCl for 16 h, finally wash with deionized water until neutral, and dry to obtain a cotton fiber carbon-based material.

[0028] Cotton fiber carbon-based material at 1 mol / L H 2 SO 4 The specific capacitance in the electrolyte is 201 F g -1 .

[0029] In the above examples, the electrochemical performance evaluation system of cotton fiber carbon-based materials is completed in a conventional three-electrode system, and the CHI 660D electrochemical workstation of Shanghai Chenhua Co., Ltd. is used for testing; the cycle stability te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com