Preparation method of single component room temperature curing epoxy construction glue

A room temperature curing, one-component technology, used in epoxy resin adhesives, adhesives, non-polymer adhesive additives, etc., can solve problems such as waste, pollution of building materials, and decrease in bonding strength, and achieve reasonable formulation and process. Concise, source-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

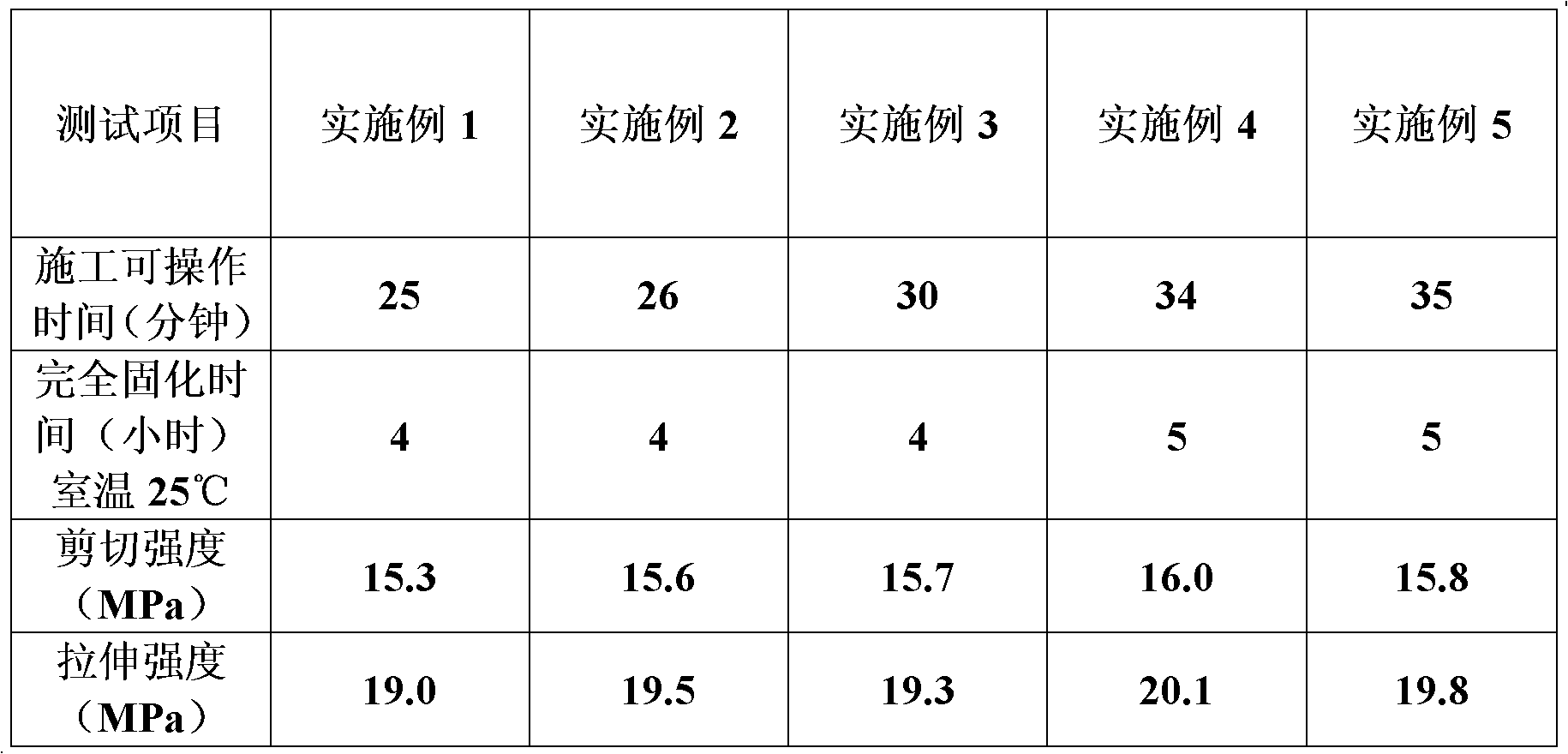

Examples

Embodiment 1

[0023] First, 80 parts by weight of bisphenol A type epoxy resin (epoxy value 0.52 equivalent / 100g, produced by Yueyang Petrochemical Plant in Hunan, China) and 6 parts by weight of ethylene glycol diglycidyl ether (produced by Jiangsu Sanmu Group Co., Ltd.) were added to the reaction In the container, stir evenly, then add 12 parts by weight of diethylenetriamine (produced by Changshu Qiangsheng Chemical Co., Ltd., Jiangsu Province), 0.5 parts by weight of tris-(dimethylaminomethyl)phenol, γ-aminopropyltriethoxysilane 3.0 parts by weight, 1.2 parts by weight of fumed silicon dioxide (produced by China Jiangxi Bluestar Chemical New Material Co., Ltd.), stirred for 20min, and finally vacuumized and degassed, and discharged in a can to obtain the single-component room temperature curing epoxy resin of the present invention. construction glue.

Embodiment 2

[0025] First bisphenol F type epoxy resin (epoxy value 0.48 equivalent / 100g, produced by China Hunan Yueyang Petrochemical Plant) 85 parts by weight and 1,4-butanediol diglycidyl ether (produced by Jiangsu Sanmu Group Co., Ltd.) 12 Add the parts by weight into the reactor, stir evenly, and then add 14 parts by weight of triethylenetetramine, 0.7 parts by weight of tris-(dimethylaminomethyl)phenol (produced by China Shanghai Runjie Chemical Reagent Co., Ltd.), γ-aminopropyl 3.6 parts by weight of triethoxysilane, 3.0 parts by weight of precipitated silica (produced by China Jiangxi Lanxing Chemical New Material Co., Ltd.), stirred for 25min, and finally vacuumized and degassed, and then packed in a can to obtain the compound of the present invention. Components Room temperature curing epoxy construction adhesive.

Embodiment 3

[0027] First, 90 parts by weight of polyglycidyl ether epoxy resin (epoxy value 0.46 equivalent / 100g, produced by Yueyang Petrochemical Plant in Hunan, China) and 15 parts by weight of tetraethyl orthosilicate (produced by Shanghai Sinopharm Chemical Reagent Co., Ltd., China) were added to the reaction In the container, stir evenly, then add 10 parts by weight of diethylenetriamine, 5 parts by weight of hexahydropyridine (produced by Qiangsheng Chemical Co., Ltd., Changshu, Jiangsu, China), 1.2 parts by weight of tris-(dimethylaminomethyl)phenol, γ- Aminopropyltriethoxysilane (produced by Chenguang Chemical Industry Research Institute) 4.2 parts by weight, fumed silica 2.0 parts by weight, nano-magnesia 2.0 parts by weight (Sinopharm Chemical Reagent Co., Ltd.), stirred for 25min, and finally vacuumed for degassing , out of canned. That is, the one-component room temperature curing epoxy construction adhesive of the present invention is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com