Ferroboron-containing alloy wear-resistant material and preparation method thereof

A technology of wear-resistant materials and base alloys, applied in the field of wear-resistant metal materials, can solve the problems of increased material cost and excessive addition of chromium, and achieve the effects of simple production process, excellent wear resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

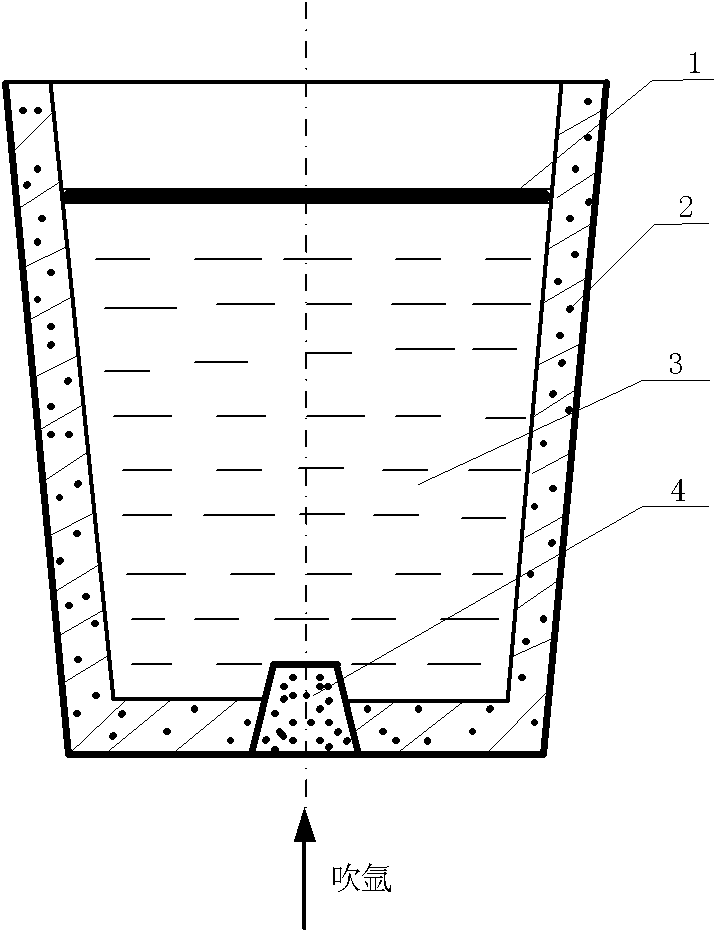

Image

Examples

Embodiment 1

[0027] Adopt 500 kilograms of intermediate frequency induction furnaces to smelt the material of the present invention, the concrete process steps are:

[0028] (1) 40% high manganese steel is returned to charge (mass percentage is as follows: 1.27% C, 12.65% Mn, 0.58% Si, 0.047% P, 0.020% S, balance Fe), 10% medium carbon ferrochromium (mass percentage As follows: 62.65% Cr, 1.57% C, 1.86% Si, 0.05% P, 0.02% S, balance Fe) and 42% Q235 steel scrap (mass percentages are as follows: 0.19% C, 0.53% Mn, 0.26% Si, 0.01 %S, 0.03%P, balance Fe) mixed heating and melting, when the temperature reaches 1483 ° C, add 0.4% nitrogen-containing ferromanganese (mass percentages are as follows: 75.04% Mn, 5.30% N, 0.27% C, 0.98% Si, 0.01% S, 0.08% P, balance Fe) and 1.5% silicon calcium barium alloy (46.36% Si, 14.07% Ca, 17.29% Ba, 3.40% Al, 0.47% C, 0.02% S, 0.04% P, balance Fe), then heated to 1525°C, and added 0.6% ferrotitanium (30.84% titanium content), 5% ferroboron (20.51% boron c...

Embodiment 2

[0032] Adopt 500 kilograms of intermediate frequency induction furnaces to smelt the material of the present invention, the concrete process steps are:

[0033] (1) 45% high manganese steel is returned to charge (mass percentage is as follows: 1.27% C, 12.65% Mn, 0.58% Si, 0.047% P, 0.020% S, balance Fe), 12% medium carbon ferrochrome (mass percentage As follows: 62.65% Cr, 1.57% C, 1.86% Si, 0.05% P, 0.02% S, balance Fe) and 37% Q235 steel scrap (mass percentages are as follows: 0.19% C, 0.53% Mn, 0.26% Si, 0.01 %S, 0.03%P, balance Fe) mixed heating and melting, when the temperature reaches 1498 ° C, add 0.6% nitrogen-containing ferromanganese (mass percentages are as follows: 75.04% Mn, 5.30% N, 0.27% C, 0.98% Si, 0.01% S, 0.08% P, balance Fe) and 1.2% silicon calcium barium alloy (46.36% Si, 14.07% Ca, 17.29% Ba, 3.40% Al, 0.47% C, 0.02% S, 0.04% P, balance Fe), then heated to 1549°C, and added 0.9% ferro-titanium (30.84% titanium content), 3% ferro-boron (20.51% boron con...

Embodiment 3

[0037] Adopt 500 kilograms of intermediate frequency induction furnaces to smelt the material of the present invention, the concrete process steps are:

[0038] (1) 42% high manganese steel is returned to charge (mass percentage is as follows: 1.27% C, 12.65% Mn, 0.58% Si, 0.047% P, 0.020% S, balance Fe), 11% medium carbon ferrochrome (mass percentage As follows: 62.65% Cr, 1.57% C, 1.86% Si, 0.05% P, 0.02% S, balance Fe) and 40% Q235 steel scrap (mass percentages are as follows: 0.19% C, 0.53% Mn, 0.26% Si, 0.01 %S, 0.03%P, balance Fe) mixed heating and melting, when the temperature reaches 1489 ° C, add 0.5% nitrogen-containing ferromanganese (mass percentages are as follows: 75.04% Mn, 5.30% N, 0.27% C, 0.98% Si, 0.01% S, 0.08% P, balance Fe) and 1.3% silicon calcium barium alloy (46.36% Si, 14.07% Ca, 17.29% Ba, 3.40% Al, 0.47% C, 0.02% S, 0.04% P, balance Fe), then heated to 1531°C, and added 0.8% ferro-titanium (30.84% titanium content), 4% ferro-boron (20.51% boron c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com